Flue gas waste heat recovery element and device capable of breaking through low temperature dew point

A flue gas waste heat and heat exchange element technology, applied in the direction of tubular elements, heat exchange equipment, heat exchanger types, etc., can solve the problems of unfavorable non-metallic material compounding, inability to coat anti-corrosion, thickening of tube sheet materials, etc. Achieve the effect of saving manpower, saving air supply and heating equipment, and reducing process resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

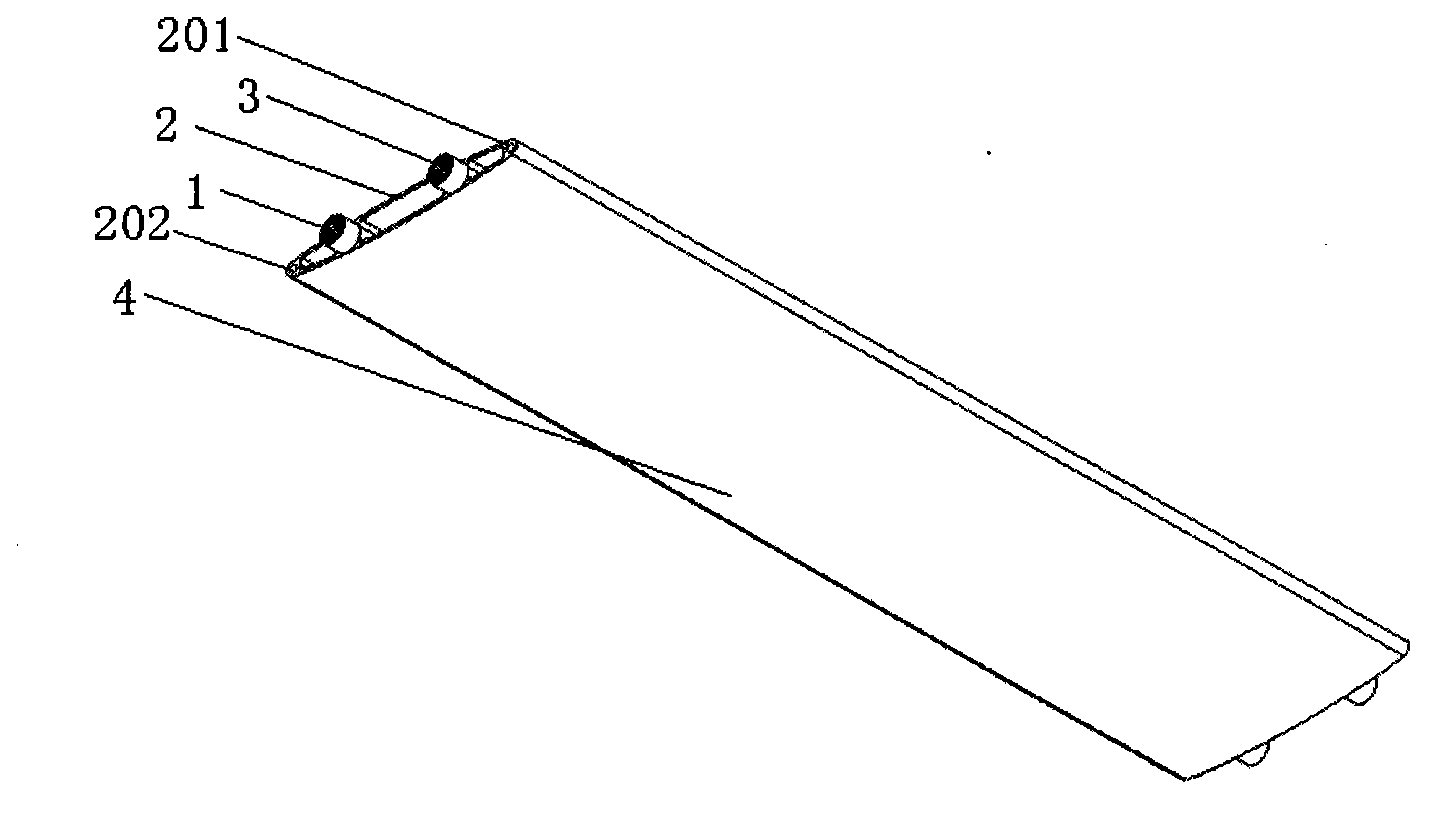

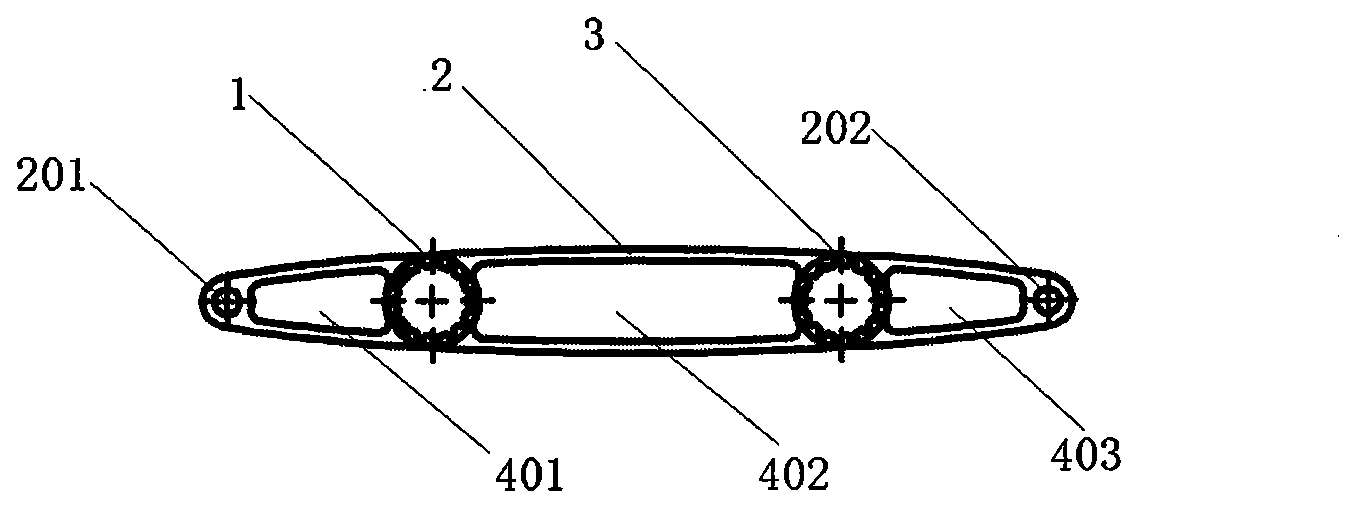

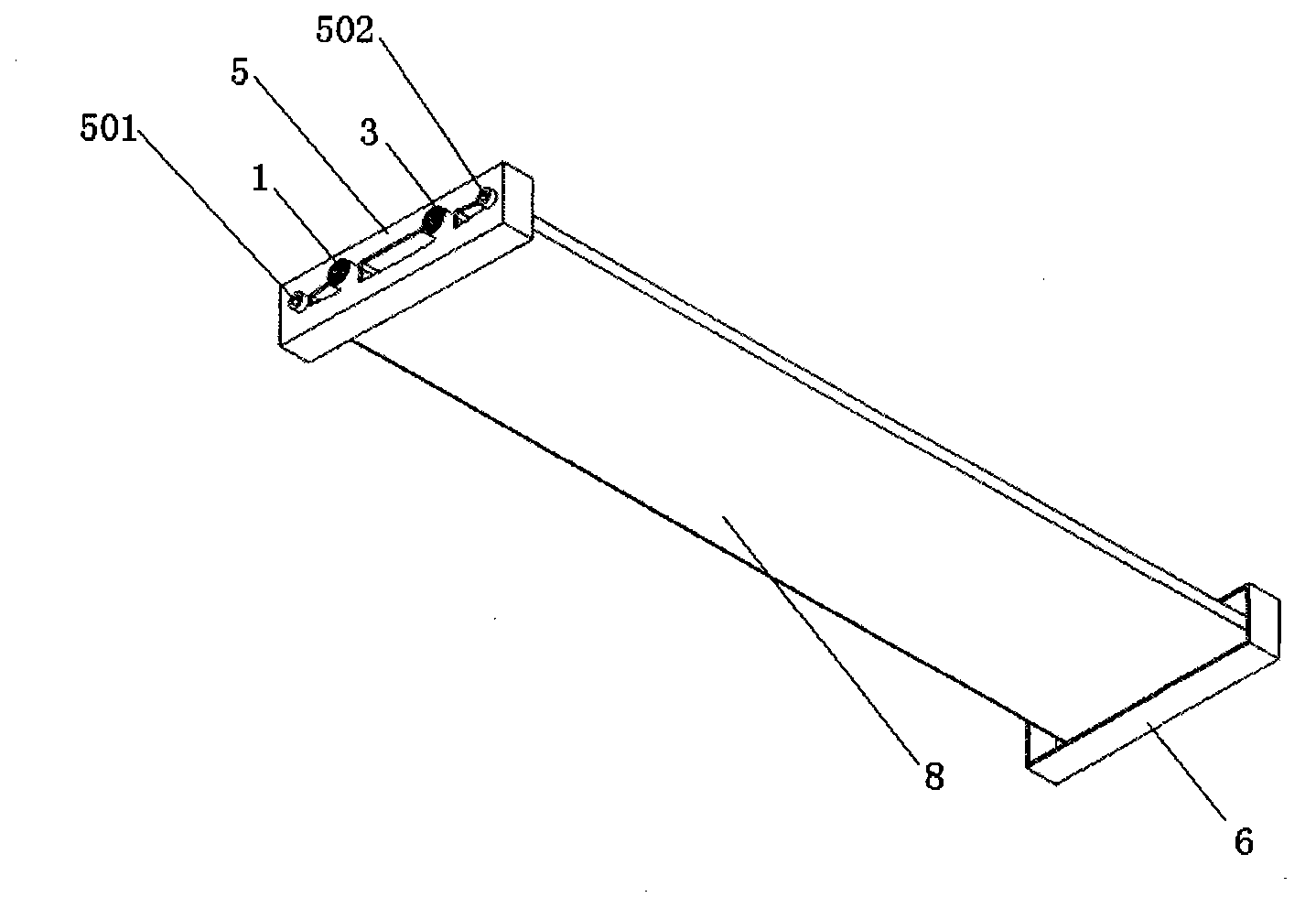

[0026] Such as figure 1 , figure 2 As shown, a flue gas waste heat recovery element and device that breaks through the low-temperature dew point uses the existing aluminum material processing technology to make a flat elliptical tubular fin 2 with two screw fixing holes 201, 202 and two fluid tubes 1 , 3 one-time molding to obtain the original heat exchange element 4, then do the surface enamel treatment on the heat exchange element original 4, compound the enamel material with corrosion resistance, wear resistance and high temperature resistance, and then make the surface enamel treatment on it. The outer surface of the heat element element 4 is covered with a polymer heat shrinkable tube with unsaturated shrinkage, that is, the heat exchange element 8 is made. In order to increase the inner surface area of the fluid pipe wall, the inner walls of the fluid pipes 1 and 3 are toothed. The space between the flat elliptical fin 2 and the two fluid tubes 1, 3 constitutes thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com