Non-well underground coal gasification ignition device

An ignition device, a technology of coal gasification, which is applied in coal gasification, underground mining, construction, etc., can solve problems such as difficulty in ignition, and achieve the effects of high coal seam combustion efficiency, improved success rate, and high ignition success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be further described below in conjunction with the drawings.

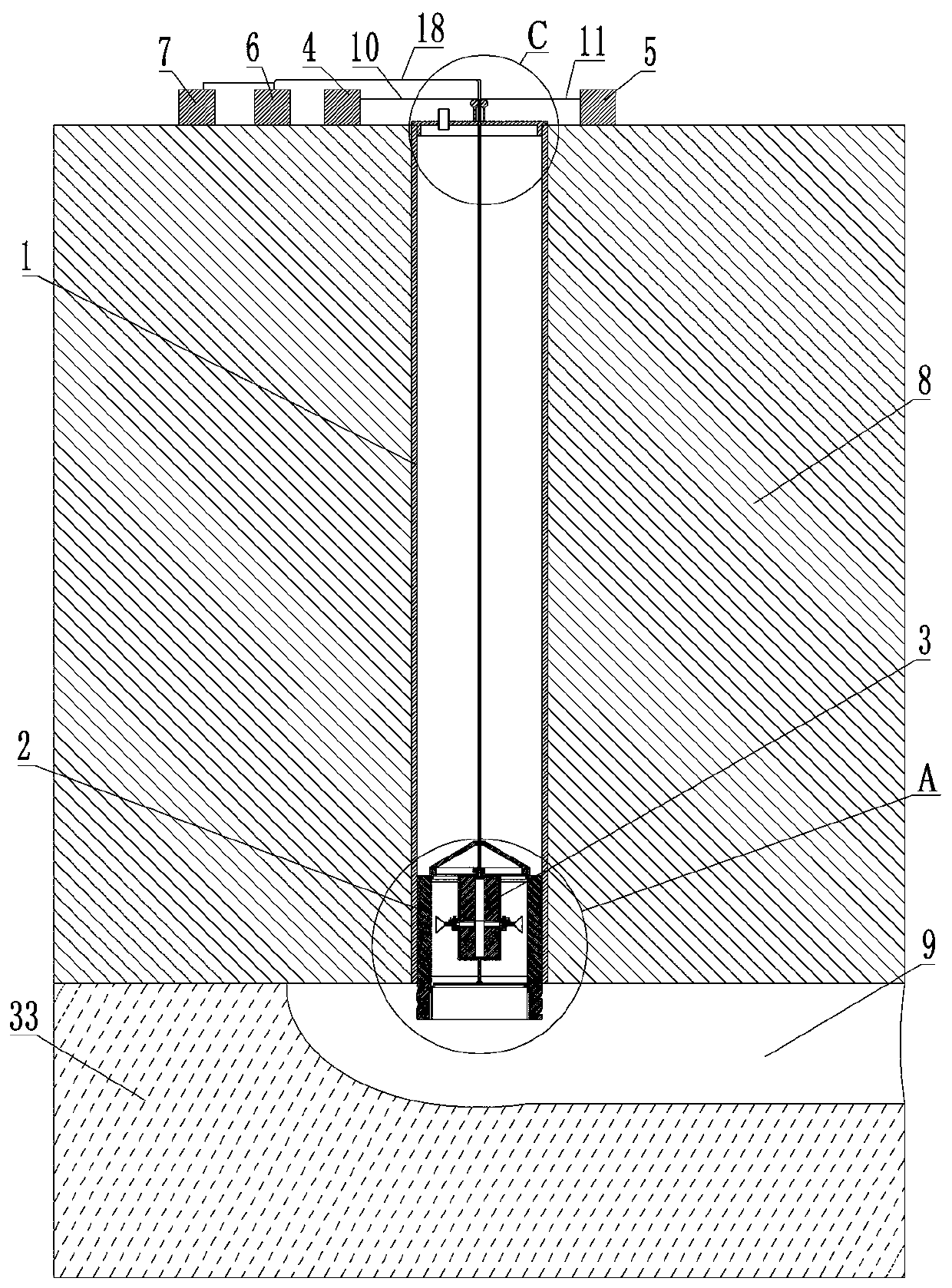

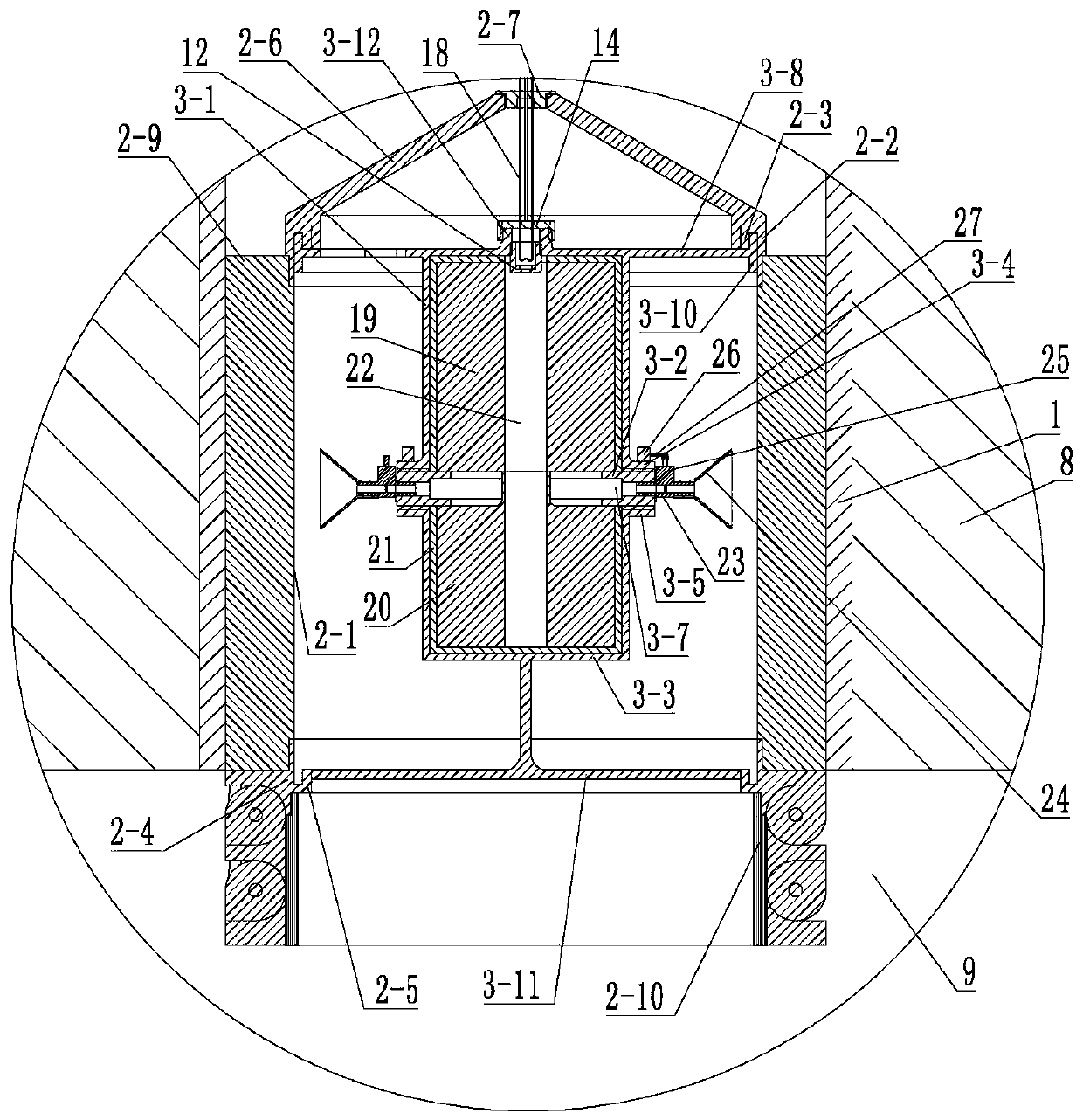

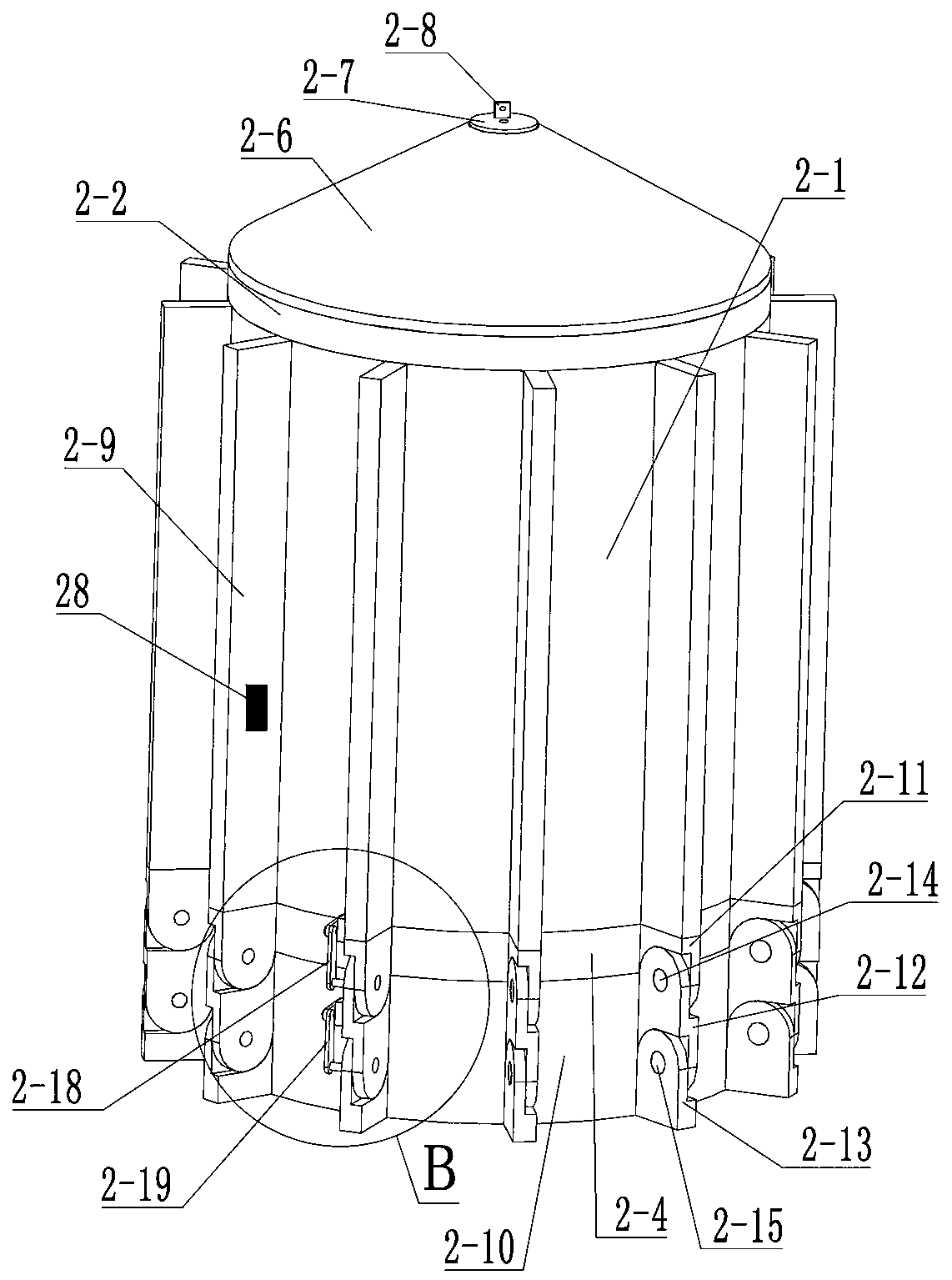

[0025] Such as Figure 1-7 As shown, the non-well underground coal gasification ignition device includes a gas pipeline 1, a bleed tube 2, a combustion tube 3, a first winch 4, a second winch 5, a power supply 6 and a controller 7. The gas pipeline 1 is fixedly supported in The vertical drilling is set in the intake borehole in the formation 8. The outer wall of the gas pipeline 1 is in tight contact with the inner wall of the intake borehole. The bottom of the gas pipeline 1 is connected with the coal seam roadway 9, and the bottom of the air duct 2 is open. The bleed cylinder 2 moves up and down and slides in the gas pipeline 1, the combustion cylinder 3 moves up and down in the bleed cylinder 2. The first winch 4, the second winch 5, the power supply 6 and the controller 7 are all set on the ground. The first winch A first wire rope 10 is wound on 4, the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com