All-aluminum BSF (back surface field) back electrode slurry and preparation method and application thereof

An all-aluminum back field and back electrode technology, which is applied in the field of solar cells, can solve problems such as unusable, poor sintering, and low tensile force, and achieve the effects of reducing influence, improving electrical conductivity, and increasing tensile force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

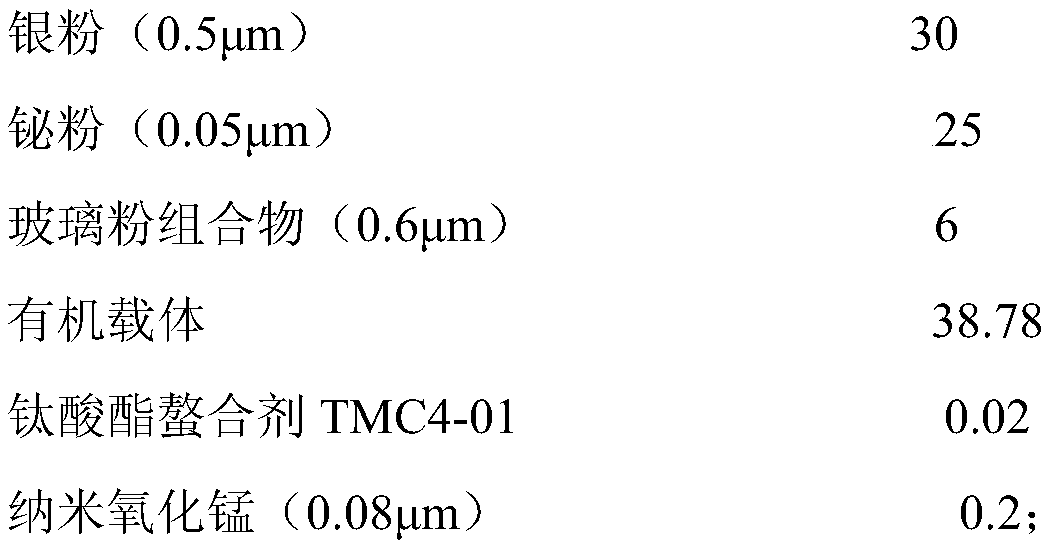

[0046] A back electrode silver paste for an all-aluminum back field, consisting of the following components (%):

[0047]

[0048] Wherein, the glass powder composition is prepared: the raw materials are mixed (50% of lead oxide, 12% of boron oxide, 3% of silicon oxide, 2% of aluminum oxide, 10% of zinc oxide, 13% of barium oxide, 8% of titanium oxide, 2% of chromium oxide %), followed by melting, quenching, grinding, and water washing processes to obtain a glass powder composition;

[0049] Preparation of organic vehicle: solvent (butyl carbitol acetate 40%, terpineol 35%), cellulose resin (ethyl cellulose 10%), additives (4% Span 85, 3% benzyl alcohol , 8% polyamide wax) mixed to obtain an organic vehicle.

[0050] Mix the above raw materials, stir evenly, transfer to a three-roll machine to grind for 1-3 hours, the fineness is ≤10μm, the viscosity is controlled at 30Pa·S-100Pa·S, and the back electrode silver paste of the all-aluminum back field is obtained.

Embodiment 2

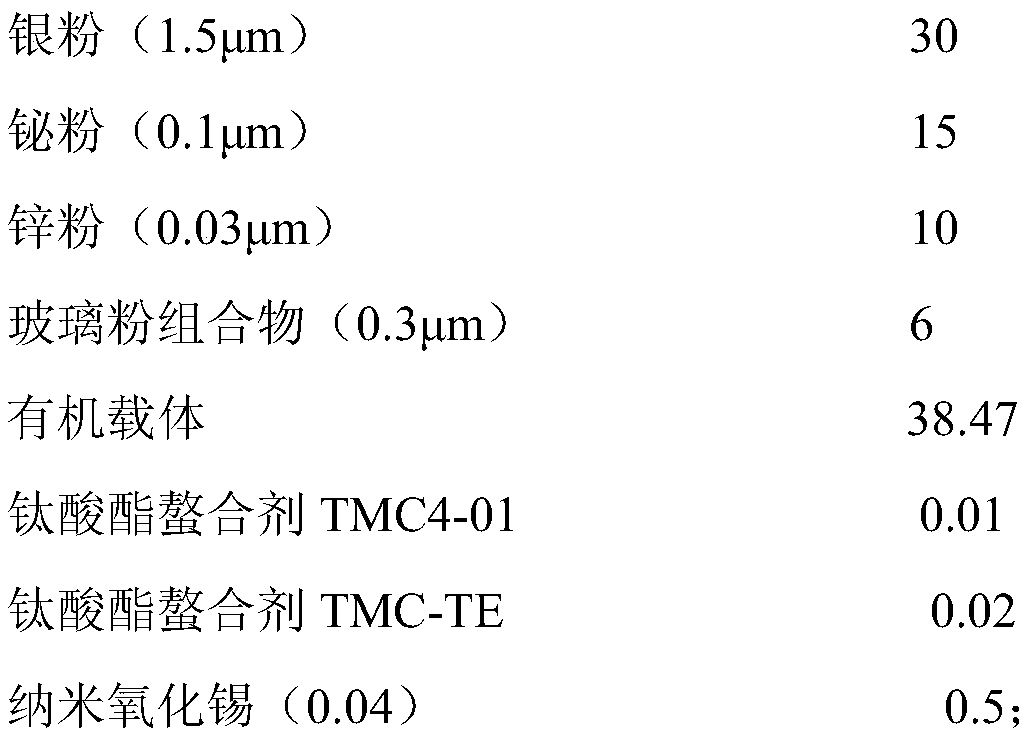

[0052] A back electrode silver paste for an all-aluminum back field, consisting of the following components (%):

[0053]

[0054] Wherein, the glass powder composition and the organic carrier are the same as in Example 1.

[0055] Mix the above raw materials, stir evenly, transfer to a three-roll machine to grind for 1-3 hours, the fineness is ≤10μm, the viscosity is controlled at 30Pa·S-100Pa·S, and the back electrode silver paste of the all-aluminum back field is obtained.

Embodiment 3

[0057] A back electrode silver paste for an all-aluminum back field, consisting of the following components:

[0058]

[0059] Wherein, the glass powder composition and the organic carrier are the same as in Example 1.

[0060] Mix the above raw materials, stir evenly, transfer to a three-roll machine to grind for 1-3 hours, the fineness is ≤10μm, the viscosity is controlled at 30Pa·S-100Pa·S, and the back electrode silver paste of the all-aluminum back field is obtained.

[0061] This embodiment also provides a PERC solar cell, which can be prepared by the following steps:

[0062] PERC solar cell silicon wafers are obtained by texturing, diffusion, back polishing, etching and impurity removal glass, deposition of passivation layer on the back, and deposition of anti-reflection layer on the front;

[0063] On the back light side of the above-mentioned silicon wafer, use screen printing to print non-graphic full back field aluminum paste, print back silver after drying, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com