Sintering method of high-grade vanadium-titanium-iron ore concentrates

A vanadium ilmenite concentrate and sintering method technology, applied in the field of smelting, can solve the problems of sintered ore yield, utilization coefficient, poor drum index, low content of silicate binder phase, etc. The effect of improving the sintering process and increasing the sintering rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for sintering high-grade vanadium-titanium iron ore concentrate, comprising:

[0030] 1) Sieving coke powder to obtain coke powder with particle size ≤ 2mm and coke powder with particle size ≤ 6mm;

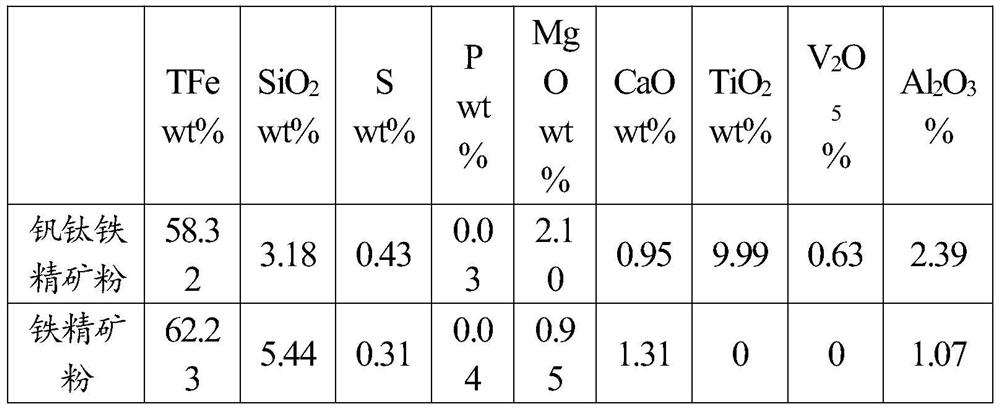

[0031] Mix the sintering raw materials evenly, the sintering raw materials include 50-60 parts by weight of high-grade vanadium-titanium iron concentrate powder, 5-8 parts of iron concentrate powder, 10-20 parts of flux, and 3-5 parts of fuel A;

[0032] 2) Potassium permanganate solution is sprayed on the sintered raw material, and water is added to infiltrate the sintered raw material, and then pelletized to obtain pellet B;

[0033] 3) The material layer B is obtained by distributing the pellets B; the material layer C is obtained by using the cloth fuel C on the material layer B; the thickness of the material layer B is 650mm-700mm, and the thickness of the material layer C is 20mm-50mm;

[0034] 4) ignition and sintering in a nitrogen environment to obtain va...

Embodiment 2

[0046] A kind of sintering method of high-grade vanadium-titanium iron concentrate

[0047] The difference between this embodiment and embodiment 1 is only:

[0048] In step 1), the sintering raw materials are uniformly mixed, and the sintering raw materials include 50 parts by weight of high-grade vanadium-titanium iron concentrate powder, 8 parts of iron concentrate powder, 20 parts of flux, and 3 parts of fuel A.

[0049] In this embodiment, the sintering utilization coefficient is 1.358t / (m2·h), the yield is 76.62%, and the drum index is 75.6%.

Embodiment 3

[0051] A kind of sintering method of high-grade vanadium-titanium iron concentrate

[0052] The difference between this embodiment and embodiment 1 is only:

[0053] In step 1),

[0054] Mix the sintering raw materials evenly, and the sintering raw materials include 60 parts by weight of high-grade vanadium-titanium-iron concentrate powder, 5 parts of iron concentrate powder, 10 parts of flux, and 3 parts of fuel A.

[0055] In this embodiment, the sintering utilization coefficient is 1.357t / (m2·h), the yield is 76.51%, and the drum index is 75.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com