A cascade leaching process of germanium-rich zinc oxide fumes

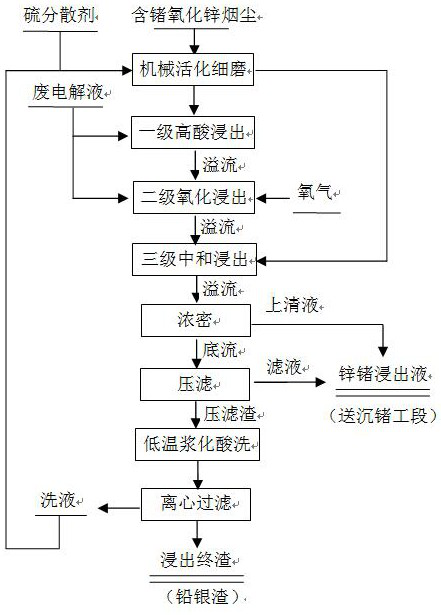

A technology of zinc oxide and soot, which is applied to germanium and the process of synchronously controlling the valence state of iron in the solution, in the field of efficient zinc leaching by zinc oxide soot, can solve the problems of difficult control of ferric iron concentration and high equipment requirements, and reduce the amount of leaching slag, The effect of high leaching rate and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The main components of germanium-rich zinc oxide dust provided by a certain factory are as follows: Zn: 45.33wt%, Fe: 3.22wt%, S: 2.05wt%, Pb13.89wt%, Ge: 1972g / t, zinc hydrometallurgy The main components of the electrolytic waste solution are as follows: H 2 SO 4 : 155g / L, Zn: 46g / L;

[0030] ① Mix 1.67kg of germanium-rich zinc oxide dust with 3g of sodium lignosulfonate, add 3L of water, and perform mechanical activation through a wet ball mill to obtain a finely ground pulp with a dust particle size of less than 0.074mm;

[0031] ②According to the ratio of adding 11L of wet zinc electrolysis waste liquid to 1 kg of finely ground pulp on a dry basis, mix the finely ground pulp with the wet zinc electrolysis waste liquid, control the terminal acidity to 100g / L, and conduct a first-level high Acid leaching, after 1.5 hours of reaction, the high-acid leaching pulp overflows to the 1# oxidation leaching tank;

[0032]③According to the mixing ratio of 0.80kg of finely g...

Embodiment 2

[0037] The main components of germanium-rich zinc oxide dust provided by a certain factory are as follows: Zn: 47.26wt%, Fe: 5.03wt%, S: 7.98wt%, Pb12.57wt%, Ge: 506g / t, zinc hydrometallurgy The main components of the electrolytic waste solution are as follows: H 2 SO 4 : 185g / L, Zn: 53g / L;

[0038] ① Mix 1.7 kg of germanium-rich zinc oxide dust with 5 g of calcium lignosulfonate, add 4 L of the lotion in step ⑤ of Example 1 to adjust the pulp, and perform mechanical activation through a wet ball mill to obtain a finely ground pulp with a dust particle size of less than 0.074 mm;

[0039] ②According to the ratio of adding 9L of wet zinc electrolysis waste liquid to 1 kg of finely ground pulp on a dry basis, mix the finely ground pulp with wet zinc electrolysis waste liquid, control the terminal acidity to 90g / L, and conduct a first-level high Acid leaching, after 1 hour of reaction, the high-acid leaching pulp overflows to the 1# oxidation leaching tank;

[0040] ③According...

Embodiment 3

[0045] The main components of germanium-rich zinc oxide dust provided by a certain factory are as follows: Zn: 47.17wt%, Fe: 4.03 wt%, S: 6.45 wt%, Pb11.96 wt%, Ge: 721g / t, zinc hydrometallurgy The main components of the electrolytic waste solution are as follows: H 2 SO 4 : 165g / L, Zn: 49g / L;

[0046] ①Mix 1.6kg of germanium-rich zinc oxide fumes with 1.6g of sodium lignosulfonate, add 3.4L of the lotion in step ⑤ of Example 2 to adjust slurry, and perform mechanical activation through a wet ball mill to obtain finely ground dust with a particle size of less than 0.074mm pulp;

[0047] ②According to the ratio of adding 10L of wet zinc electrolysis waste liquid to 1 kg of finely ground pulp on a dry basis, mix the finely ground pulp with the wet zinc electrolysis waste liquid, control the final acidity to 80g / L, and the reaction temperature to 85°C for a first-level high Acid leaching, after 2 hours of reaction, the high-acid leaching pulp overflows to the 1# oxidation leac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com