Sintering device of battery positive electrode material for new energy automobile production

A technology for new energy vehicles and positive electrodes of batteries, which is applied in electrode manufacturing, electrode heat treatment, furnace materials, etc., can solve the problem that the heating temperature cannot meet the sintering temperature of new positive electrode materials, and achieve good sintering quality, wide application range, and improved sintering efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

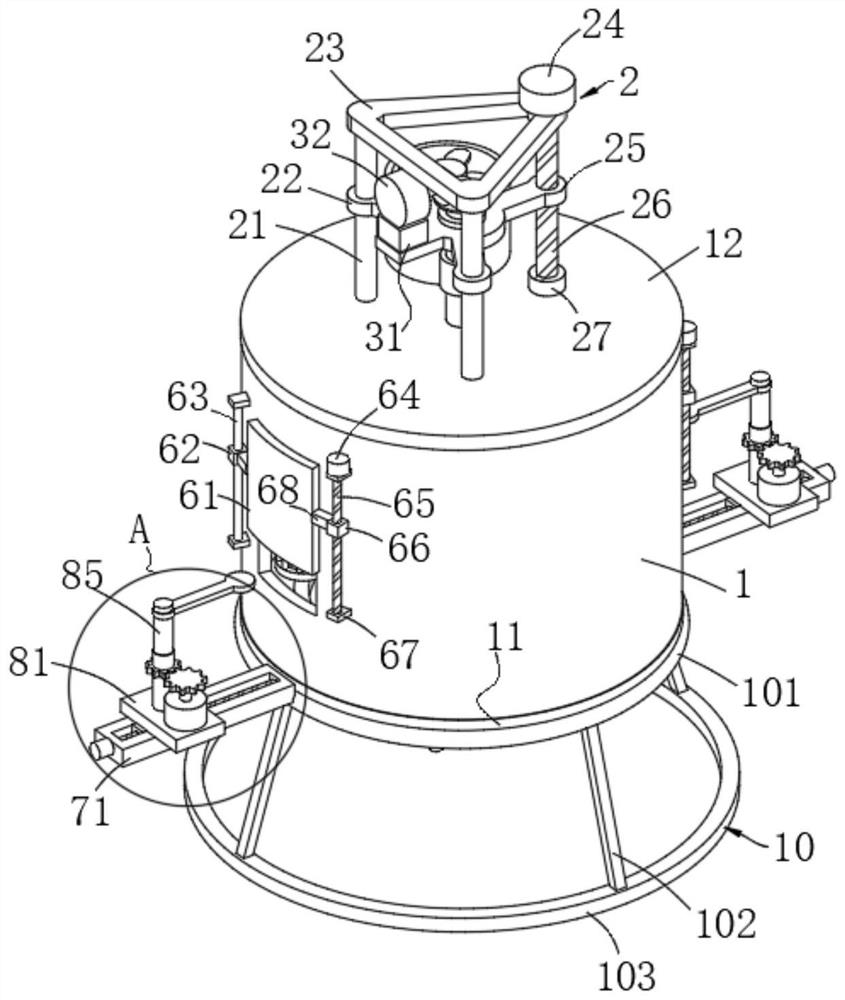

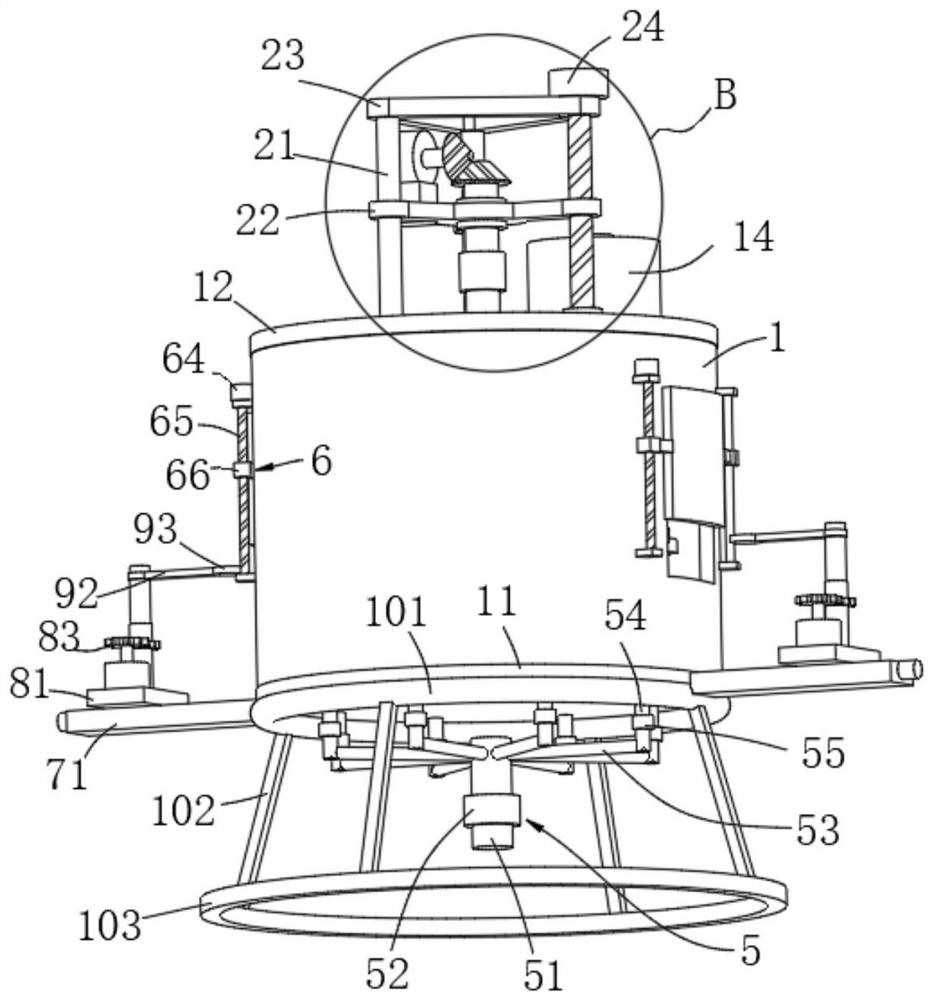

[0040] Example 1, please refer to figure 1 and Figure 3-5 , this embodiment provides a technical solution: a sintering device for battery positive electrode materials used in the production of new energy vehicles, including a sintering furnace body 1, the bottom of the sintering furnace body 1 is connected to the furnace body base 11, and the bottom of the furnace body base 11 is supported by Frame 10 supports;

[0041] The support frame 10 includes a support ring 101, a support rod 102 and a ground support ring 103. The bottom of the furnace base 11 is provided with a support ring 101, and the bottom of the support ring 101 is connected by three support rods 102 provided at an inclined equidistant distance. The ground ring 103, the support frame 10 supports the body of furnace base 11 to facilitate the installation of parts at the bottom of the body of furnace base 11;

[0042] The top of the sintering furnace body 1 is connected to the furnace body top cover 12, and the t...

Embodiment 2

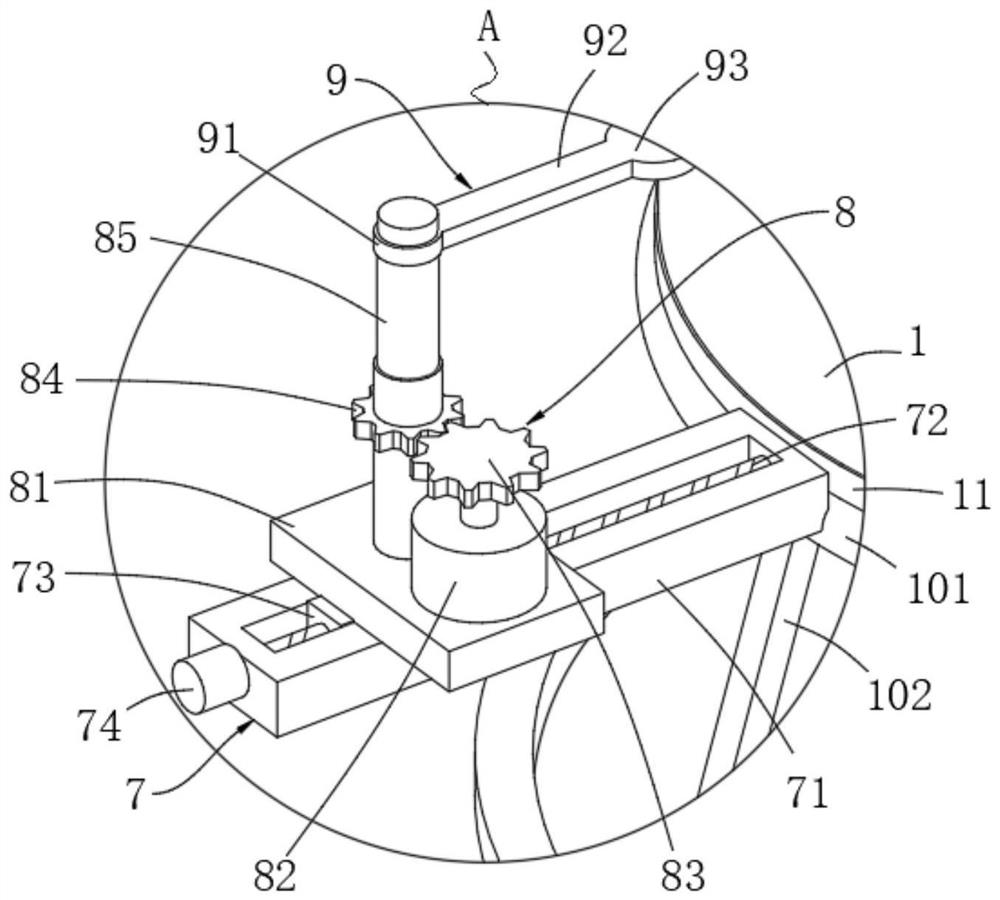

[0059] Example 2, please refer to Figure 1-2 and Figure 6 , this embodiment provides a technical solution: a sintering device for battery positive electrode materials used in the production of new energy vehicles. 8 and the sintering material holding unit 9, the distance adjustment unit 7, the orientation adjustment unit 8 and the sintering material holding unit 9 are provided with two and correspond to two pick-and-place slots, and the distance adjustment unit 7 includes a mounting groove body 71, Adjust the threaded rod 72, the movable block 73 and the adjustment motor 74. One end of the installation tank body 71 is fixedly connected to the side of the body of furnace base 11. The adjustment threaded rod 72 is rotatably connected in the installation tank body 71, and is also slidably connected in the installation tank body 71. Movable block 73, the screw hole on the side of movable block 73 is threadedly connected with adjustment threaded rod 72, and the end of adjustment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com