Optical fiber weighing system

A weighing system and optical fiber technology, applied in the field of micro-bending optical fiber weighing sensing system, to achieve the effect of low cost, remote alarm and monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

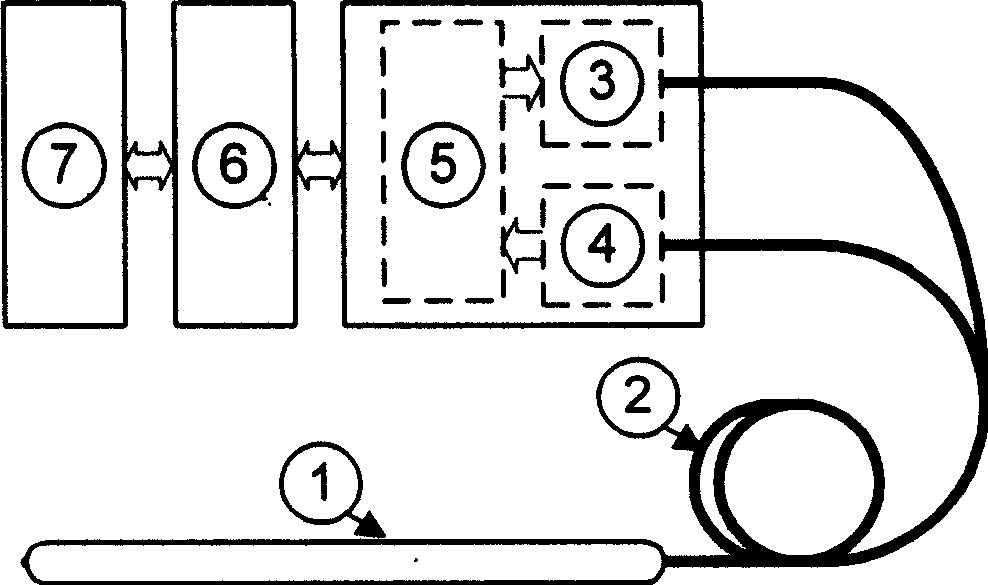

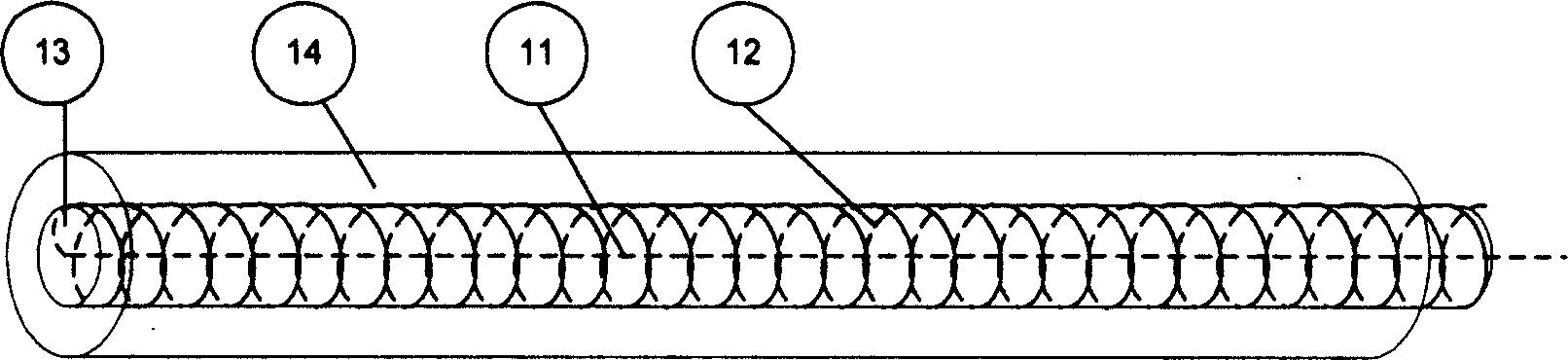

[0010] The microbending fiber optic load cell 1 is connected to the light emitter 3 and the light receiver 4 through the optical fiber 2 that conducts the light signal. The signal is converted into an electrical signal, and the optical transmitter 3 and the optical receiver 4 are respectively connected to an optical transceiver driving circuit 5, and the optical transceiver driving circuit 5 is connected to a high-speed analog converter 6, and the high-speed analog converter 6 is connected to the digital signal The data processing system 7 for data processing and compensation is connected; wherein the microbending optical fiber load cell 1 is packaged on the axis of a resin rod 13 for a part 11 of the optical fiber, and the other part 12 of the optical fiber is wound on the surface of the resin rod 13 and wrapped with another resin rod. Barrel 14 is protected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com