Concrete preparation system and preparation method thereof

A technology for preparing system and concrete, which is applied in manufacturing tools, ceramic molding workshops, supply devices, etc., can solve the problems of high labor consumption, difficulty in meeting the needs of use, inconvenience in use, etc., and achieve the effect of increasing the scope of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

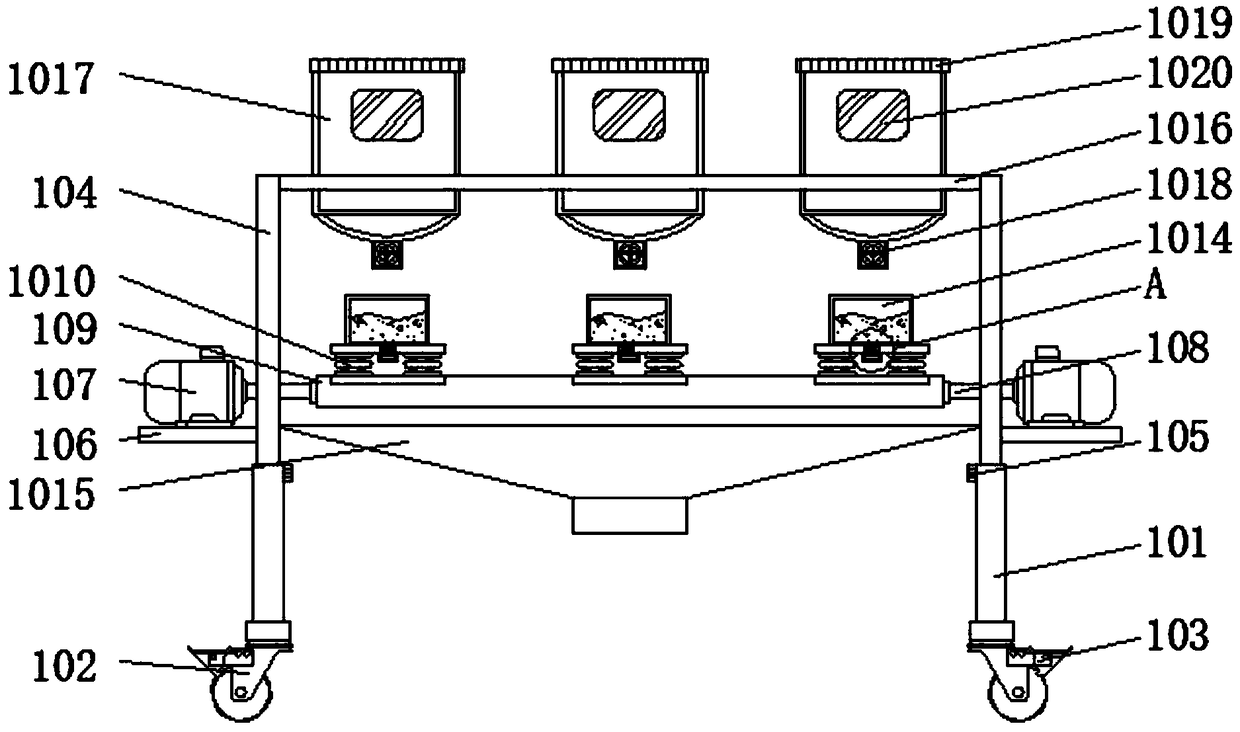

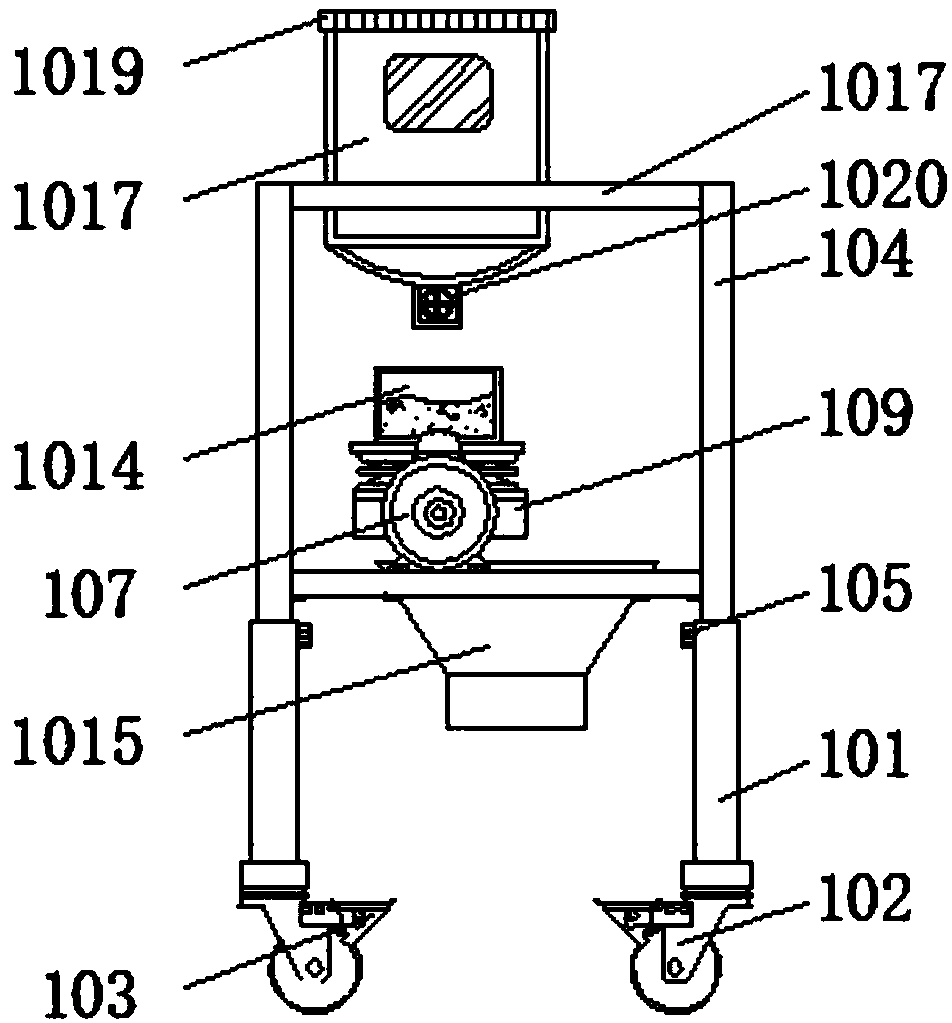

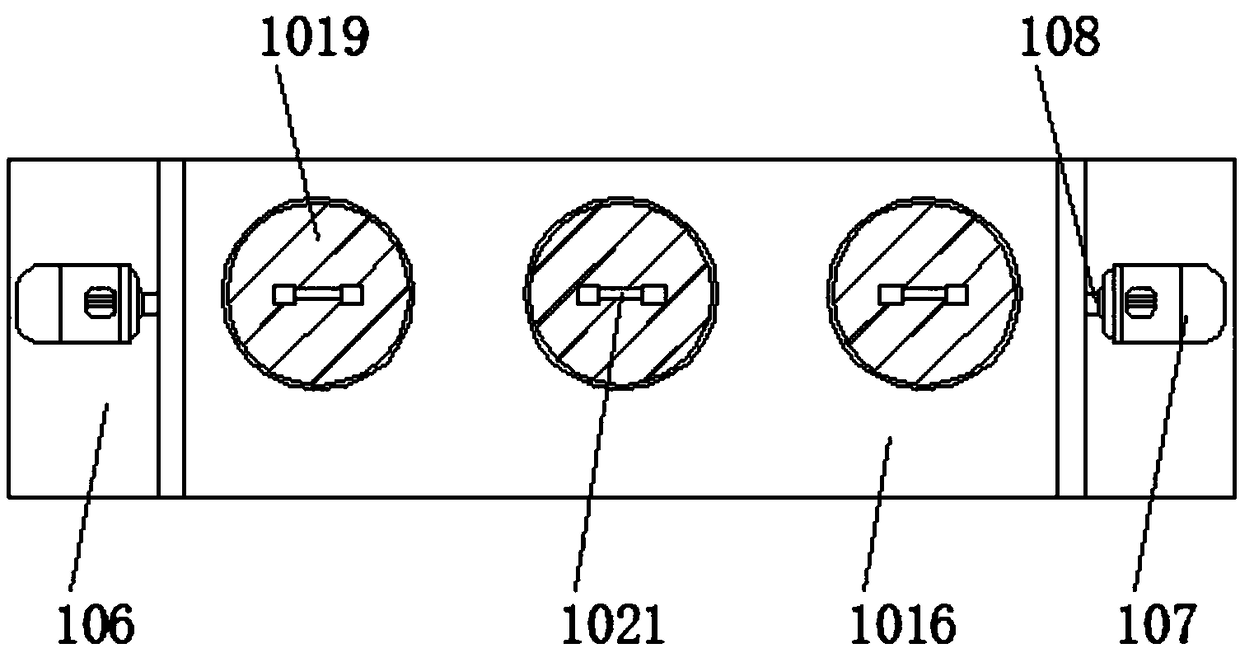

[0061] Such as Figure 16 As shown, the concrete preparation system of the present embodiment includes a raw material weighing device 1, a raw material mixing device 2, a pouring molding device 3, a curing device 4, a demoulding device 5 and a mold cleaning device 6;

[0062] First, the material is weighed by the raw material weighing device 1, and then the weighed raw material is put into the raw material mixing device 2, and after being fully mixed, it is discharged into the pouring mold device 3 to form it, and then Use the curing device 4 to maintain it. After curing, use the demoulding device 5 to separate the mold from the concrete block, and finally place the mold in the mold cleaning device 6 for cleaning. The whole process is highly automated, can save manpower, and is easy to use.

[0063] Such as Figure 1 to Figure 4 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com