Weighting test instrument device and manufacturing method thereof

A tester and weighing technology, which is applied in the direction of measuring devices, weighing equipment and instruments for materials with special properties/forms, can solve a lot of labor, time-consuming and labor-intensive problems, and achieve accurate sorting and batch feeding. The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

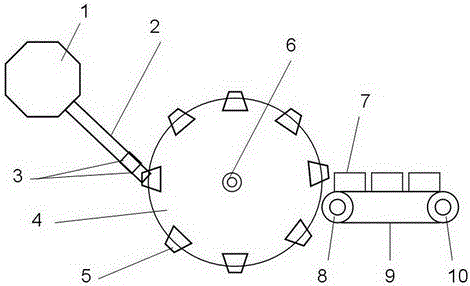

[0029] In Embodiment 1, a weighing tester device and its manufacturing method are provided, please refer to figure 1 , the present invention provides a weighing tester device and a manufacturing method thereof. The weighing tester device includes: a feeding device, a weighing and sorting device, a feeding device and a control device; the feeding device includes a vibrating feeding tray 1 , feeding chute 2 and feeding valve 3; the weighing and sorting device includes a rotary table 4 and eight overturning balances 5; the unloading device includes seven groups of receiving frames 7 and seven conveying devices; the manufacturing method is as follows: first A ladder-shaped frame is provided, and the vibration feeding tray 1 is installed at the high-order place of the ladder-shaped frame; secondly, the feeding slideway 2 is welded and fixed on the ladder-shaped frame, so that the feeding slideway 2 is relatively The high end is docked with the vibrating feeding tray 1, and the lowe...

Embodiment 2

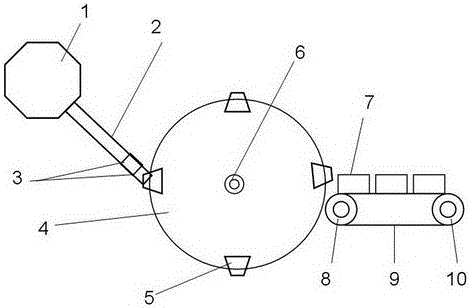

[0040] In Embodiment 2, a weighing tester device and its manufacturing method are provided, please refer to figure 2 , the invention provides one, weighing tester device comprises: feeding device, weighing and sorting device, unloading device and control device; 3; the weighing and sorting device includes a rotary table 4 and four flipping balances 5; the unloading device includes three groups of receiving frames 7 and three transfer devices; the manufacturing method is as follows: first a ladder-shaped frame is arranged, The high-order place of the frame is equipped with the vibrating feeding tray 1; secondly, the feeding slideway 2 is welded and fixed on the stepped frame, so that the higher end of the feeding slideway 2 is docked with the vibrating feeding tray 1, The lower end is docked with the rotary table 4; again, the rotary table 4 is rotated through the rotating shaft 6 and placed on the lower step of the ladder frame; specifically: a feeding slideway 2 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com