An intelligent concrete management and control method and system

A concrete pipe and concrete technology, applied in data processing applications, instruments, calculations, etc., can solve problems such as untimely feedback, out-of-synchronization of information, difficulty in adapting to modern building needs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

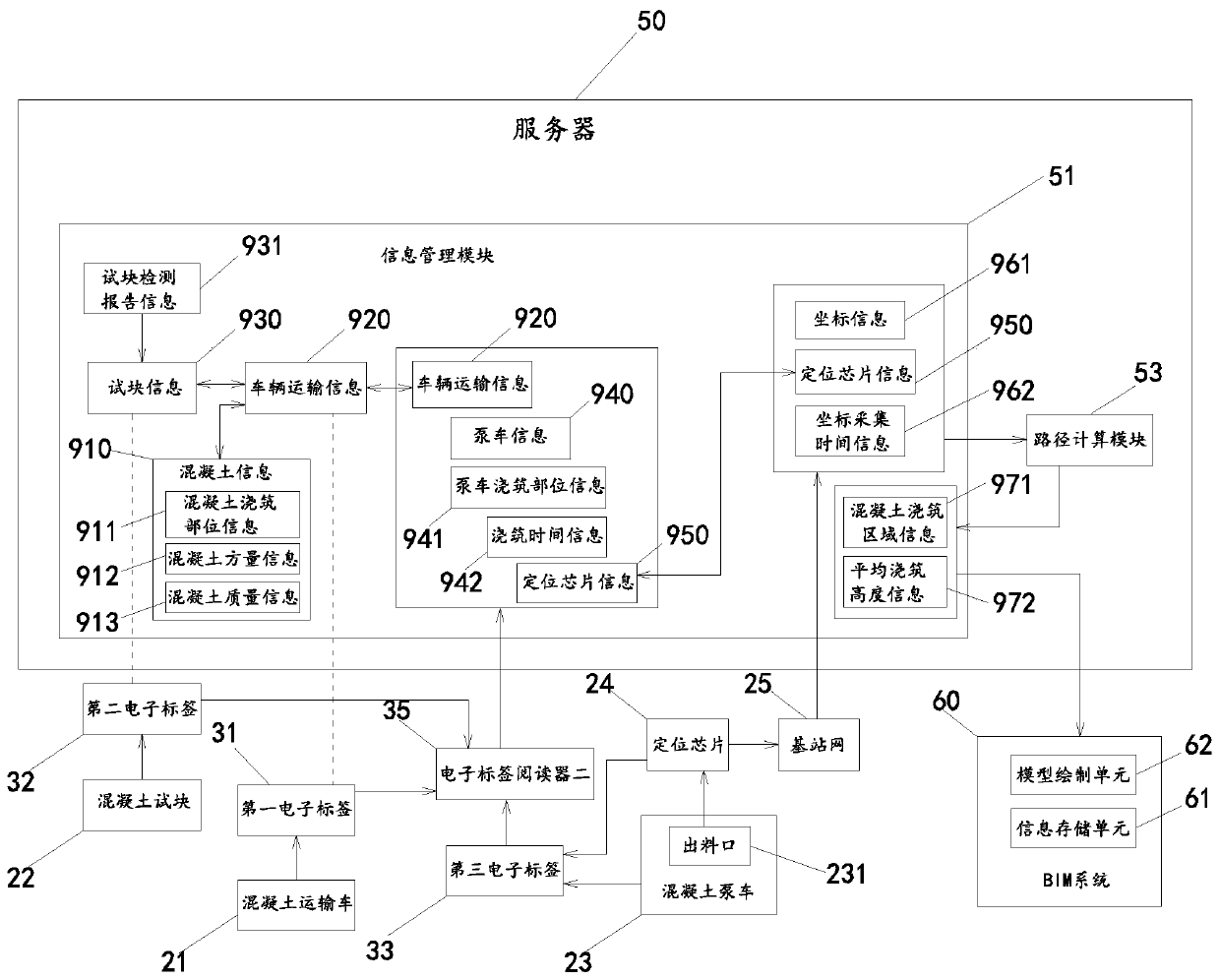

[0060] This embodiment provides an intelligent concrete control method, which is combined with Figure 1 to Figure 6 Give further introduction to the method. The method includes the following steps:

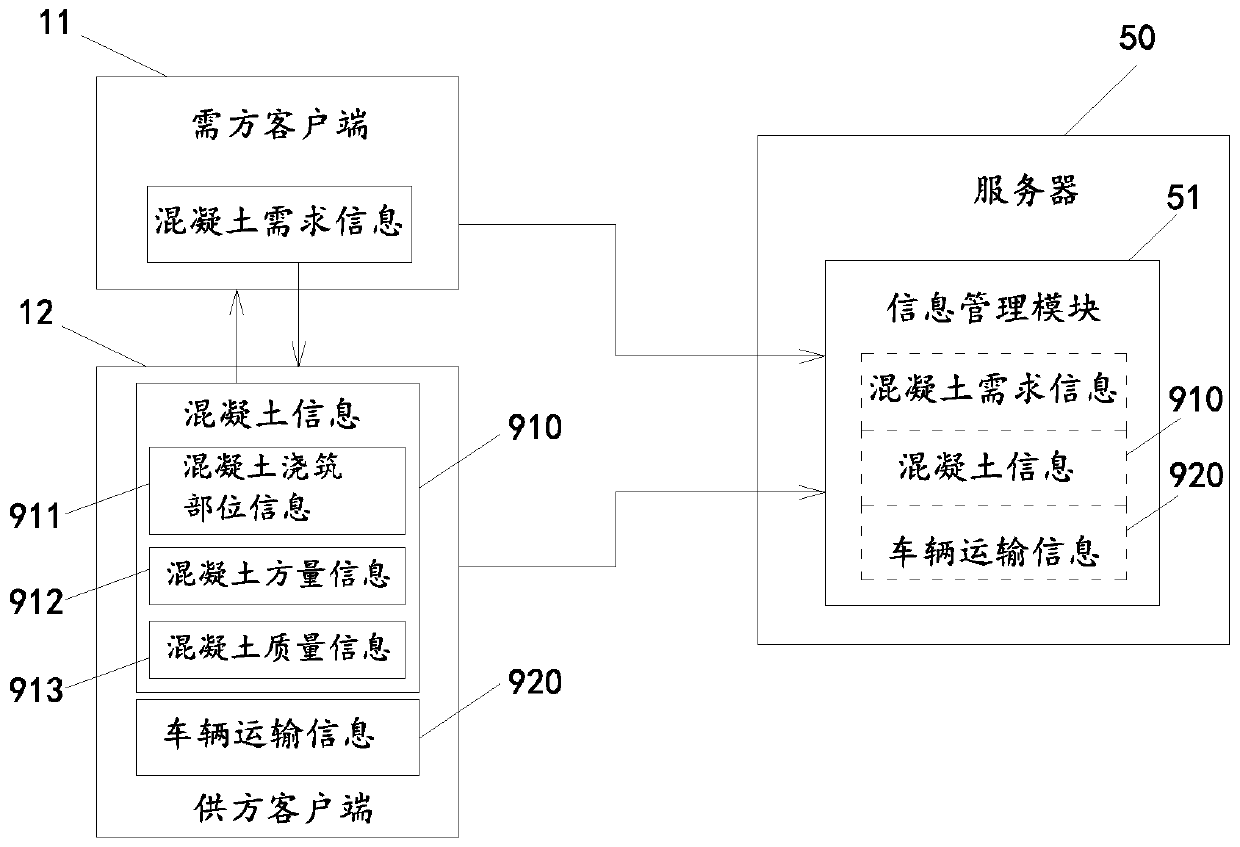

[0061] Step 1: See figure 1 As shown, the concrete demander sends concrete demand information to the supplier client 12 through the demander client 11, and sends it to the server 50 simultaneously; the concrete supplier prepares concrete according to the concrete demand information, and after the concrete is loaded, the concrete The vehicle transportation information 920 is written in the first electronic tag 31 carried by the transportation vehicle 21; the concrete information 910 and the vehicle transportation information 920 are associated and transmitted to the server 50. The information management module 51 in the server 50 stores concrete demand information, concrete information 910, and vehicle transportation information 910.

[0062] Among them, concrete demand information in...

Embodiment 2

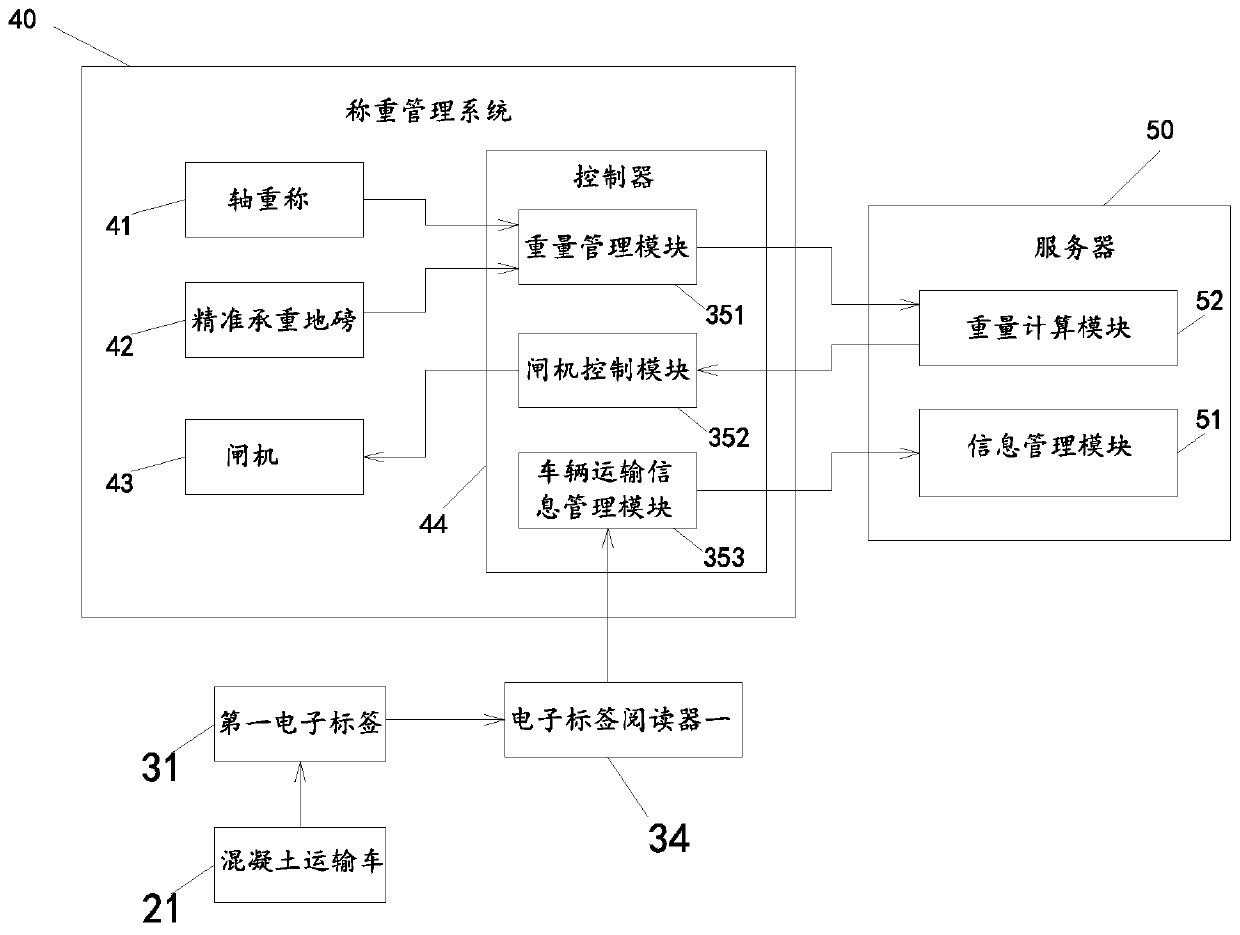

[0107] This embodiment provides an intelligent concrete management and control system. Refer to Image 6 Shown and combined with Figure 1 to Image 6 , To further describe the smart concrete control system. The system includes a buyer client 11, a supplier client 12, a server 50, a first electronic label 31, a second electronic label 32, a third electronic label 33, an electronic label reader 34, and an electronic label reader two 35 , Weighing management system 40 and positioning device;

[0108] The demand-side client 11 is used to send material demand information to the material supplier client 12 and synchronously sent to the server 50; the supplier client 12 is used to send vehicle transportation information 920 to the material demand-side client 11, The concrete information 910 is simultaneously sent to the server 50. Among them, concrete demand information includes concrete demand quality information, demand-side quantity information, and concrete pouring location informa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com