Current and surface pressure adjustable cable buffer layer ablation fault simulation device and method

A fault simulation device and surface pressure technology, which are applied in the measurement of current/voltage, the measurement of the property force of piezoresistive materials, and the measurement of current only, to achieve the effects of convenient operation, strong operability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

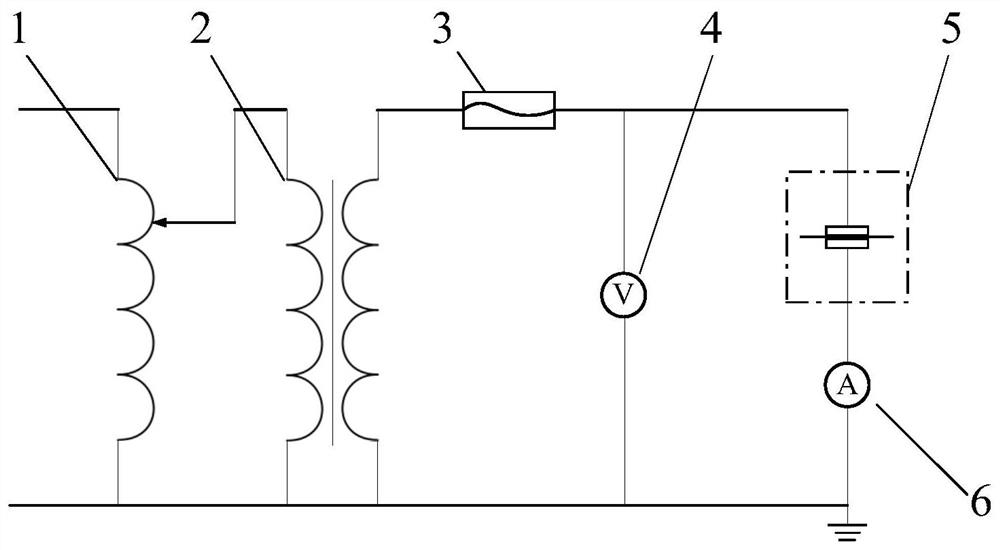

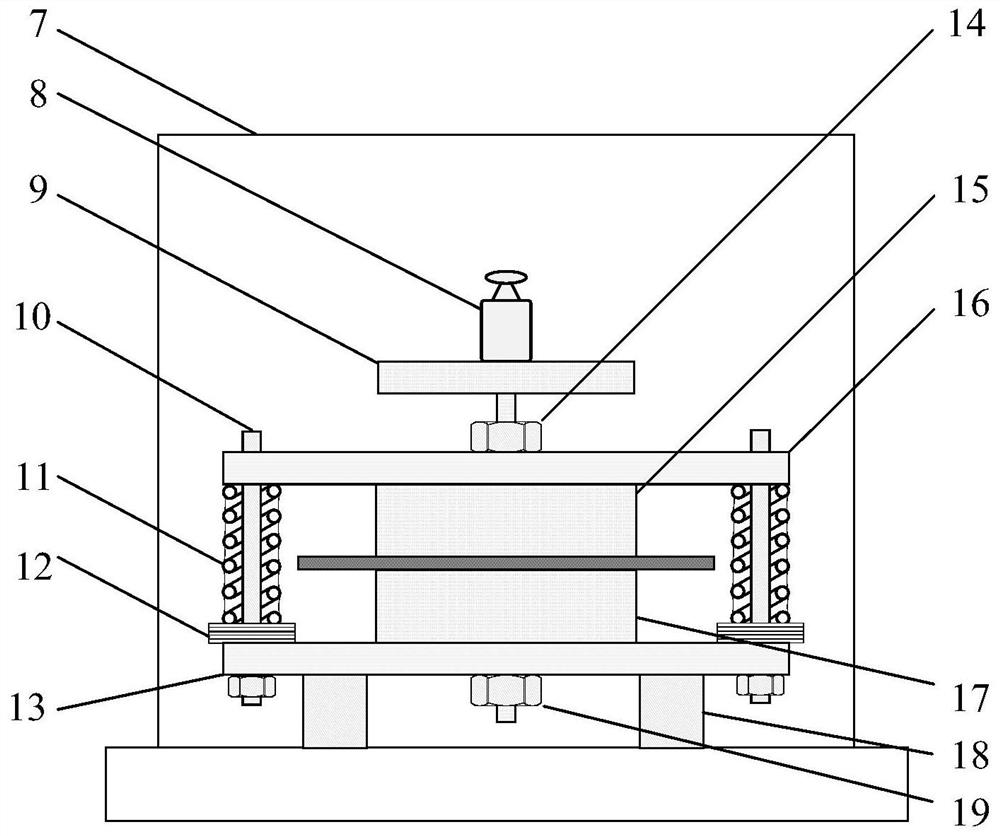

[0034] In this embodiment, the high-voltage cable buffer layer ablation fault simulation device with adjustable current and surface pressure is as follows: figure 1 As shown, it includes a power frequency voltage loop unit for providing a voltage applied to the buffer layer and a buffer layer ablation experiment unit connected to the power frequency voltage loop unit.

[0035] Such as figure 1 As shown, the power frequency circuit loop unit includes a voltage regulator 1 , a power frequency test transformer 2 , a fuse 3 , a voltmeter 4 and an ammeter 6 . The voltage regulator 1 should have a continuous voltage regulation function, and the manual control voltage regulation rate should not be greater than 2V / s. The input and output ends of the voltage regulator 1 are respectively connected to the 220V mains and the input of the power frequency test transformer 2. The maximum output voltage of the power frequency test transformer 2 should be less than 10kV, and the capacity shou...

Embodiment 2

[0043] In this example, a 110kV high-voltage cable non-woven fabric-sodium polyacrylate-fluffy cotton structure water-blocking buffer layer was taken and cut to a diameter of 100mm as a buffer layer sample.

[0044] In this embodiment, a high-voltage cable buffer layer ablation fault simulation method with adjustable current and surface pressure is provided. Using the high-voltage cable buffer layer ablation fault simulation device with adjustable current and surface pressure provided in Example 1, the Set the current amplitude and surface pressure to conduct the ablation experiment of the buffer layer of the high-voltage cable. The specific steps are as follows:

[0045] (1) Drying of the buffer layer ablation experimental unit: take off the sealing cover 7 of the buffer layer ablation experimental unit, use non-woven cloth to wipe each part of the buffer layer ablation experimental unit, and then carry out vacuum drying to each part, The drying temperature is 80°C-100°C, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com