A cable buffer layer ablation fault simulation device and method with adjustable current and surface pressure

A fault simulation device and surface pressure technology, applied in the direction of measuring current/voltage, measuring the property force of piezoelectric resistance materials, measuring devices, etc., to achieve the effect of convenient operation, strong operability, and intuitive and convenient experiment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

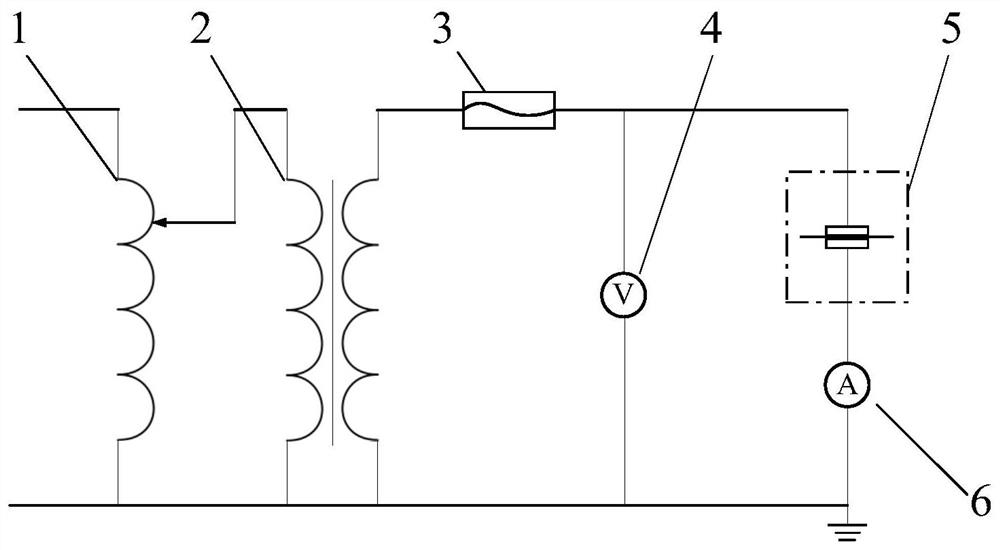

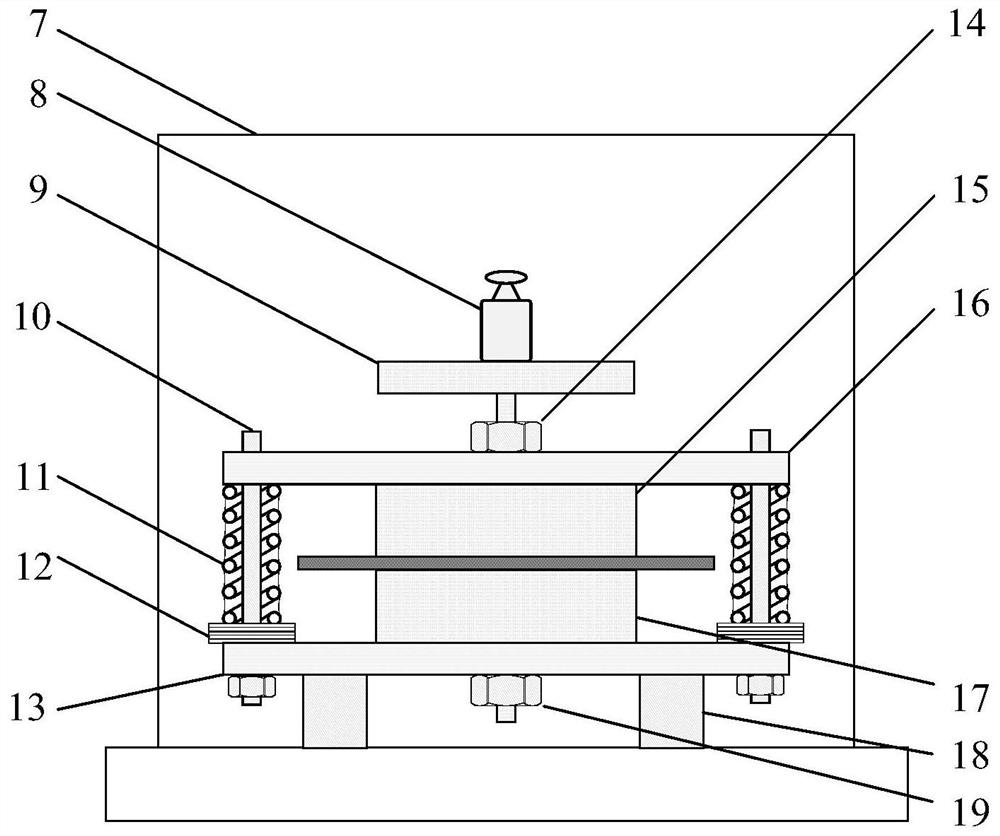

[0034] In this embodiment, the high-voltage cable buffer layer ablation fault simulation device with adjustable current and surface pressure is as follows: figure 1 As shown, it includes a power frequency voltage loop unit for supplying a voltage applied to the buffer layer and a buffer layer ablation experiment unit connected to the power frequency voltage loop unit.

[0035] like figure 1 As shown, the power frequency voltage loop unit includes a voltage regulator 1 , a power frequency test transformer 2 , a fuse 3 , a voltmeter 4 and an ammeter 6 . The voltage regulator 1 should have the function of continuous voltage regulation, and the manually controlled voltage regulation rate should not be greater than 2V / s. The maximum output voltage of the power frequency test transformer 2 should be less than 10kV, and the capacity should not be less than 10kVA. The output end of the power frequency test transformer 2 is connected to the buffer layer ablation test unit through the ...

Embodiment 2

[0043] In this example, a 110kV high-voltage cable non-woven fabric-sodium polyacrylate-fluffy cotton structure water-blocking buffer layer was taken and cut to a diameter of 100 mm as a buffer layer sample.

[0044] In this embodiment, a method for simulating ablation faults of a high-voltage cable buffer layer with adjustable current and surface pressure is provided. Using the high-voltage cable buffer layer ablation fault simulation device with adjustable current and surface pressure provided by The high-voltage cable buffer layer ablation experiment is carried out under the set current amplitude and surface pressure. The specific steps are as follows:

[0045] (1) Drying of the buffer layer ablation experimental unit: Take off the sealing cover 7 of the buffer layer ablation experimental unit, use a non-woven fabric to wipe each part of the buffer layer ablation experimental unit, and then vacuum dry each part, The drying temperature is 80℃~100℃, the drying vacuum degree i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com