Control method and control mechanism for throttle motor of excavator

A technology of throttle motor and control method, which is applied in the directions of engine control, machine/engine, earth mover/shovel, etc., and can solve problems such as the forward and reverse switching process of the throttle motor and the complexity of the control method, and achieve a small duty cycle , Guarantee the effect of response speed and control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

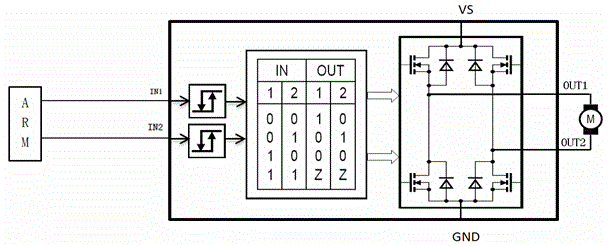

[0030] As shown in the figure, the control method of a kind of excavator throttle motor of the present invention, described control method is:

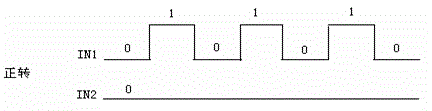

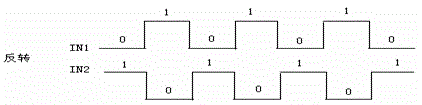

[0031] 1) Control the forward and reverse direction and speed of the throttle DC motor: ARM controller controls the forward and reverse direction and speed of the throttle DC motor by detecting the position of the throttle control knob and generating two complementary PWM signals and steering control signals inside it;

[0032] When it is necessary to control the reverse rotation of the throttle DC motor with position feedback, set the pin GPIOD0 connected to the ARM controller to be low level, and the triode in the triode circuit connected to this pin is not conducting, which has no effect on the signal of IN2, IN1 , IN2 is 01 or 10; when you want to control the forward rotation of the throttle DC motor with position feedbac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com