Positive and reverse rotation control circuit of electric motor

A technology for controlling circuits and motors, which is applied in the direction of motor starters, circuits, motor generators/starters, etc., and can solve the problem of increased cost of control circuits, increased number of relay circuits, and control circuit costs of electric door lock systems Increase and other problems, to achieve the effect of low cost and prevent damage to wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

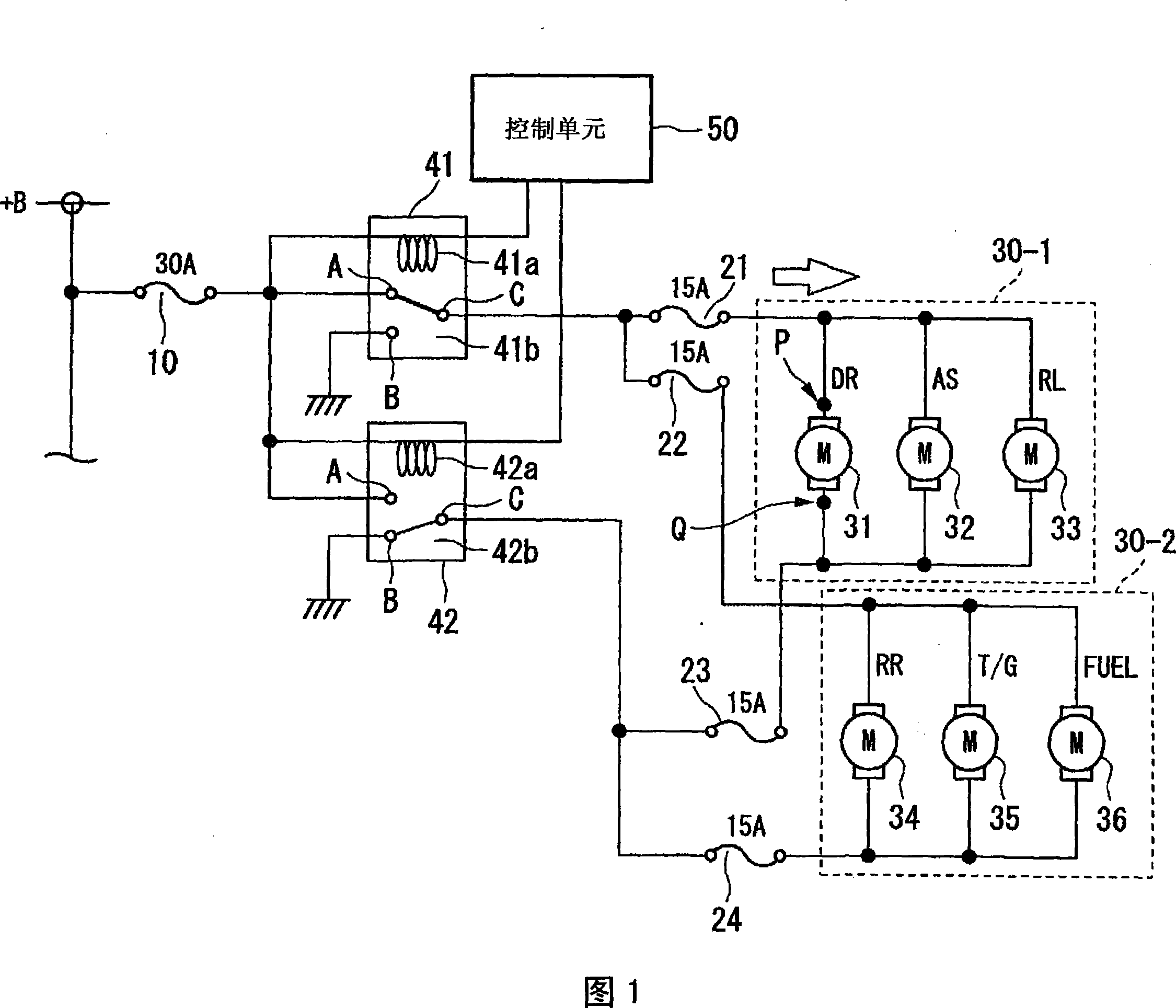

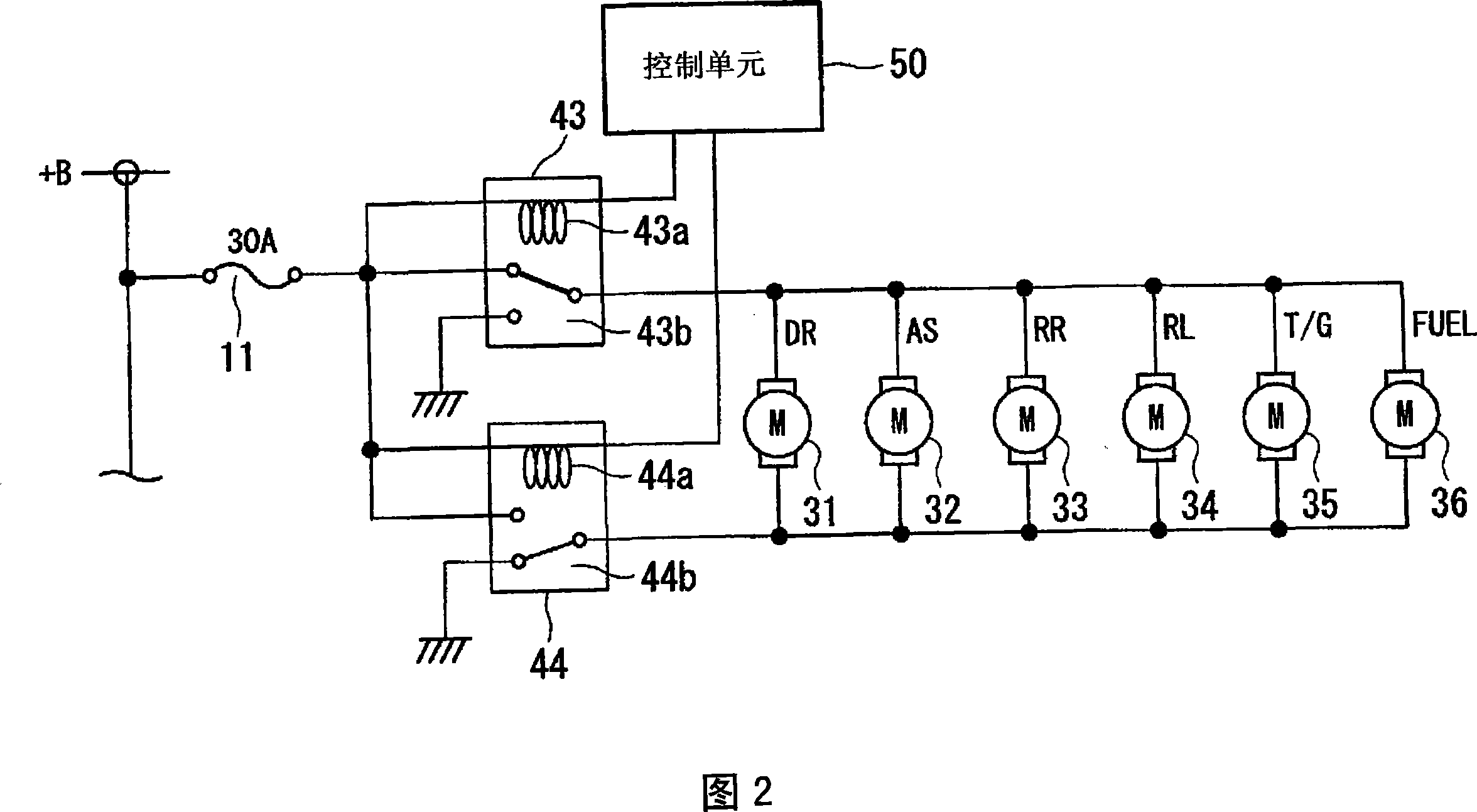

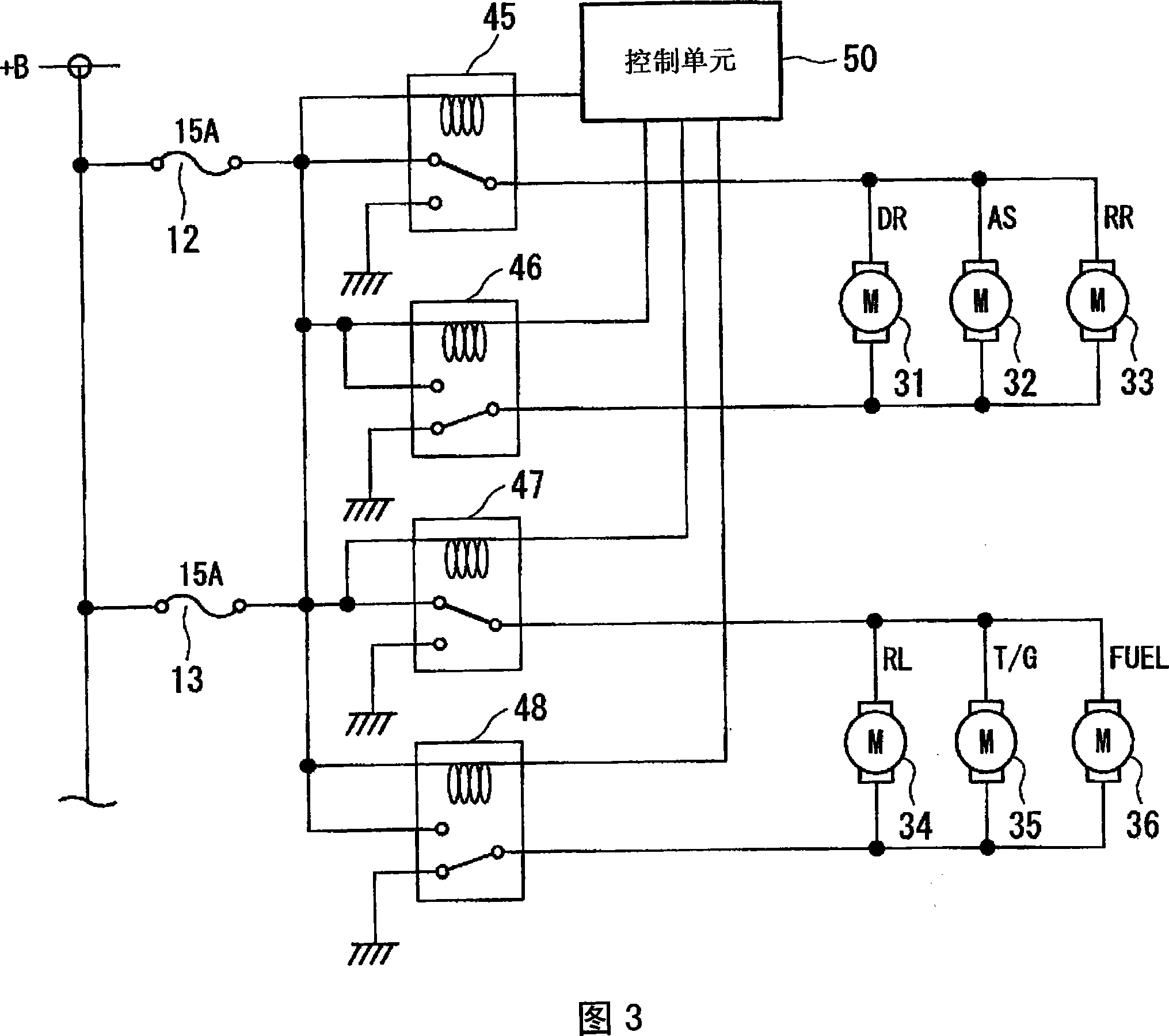

[0022] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0023] FIG. 1 shows the configuration of a motor forward and reverse rotation control circuit 1 according to an embodiment of the present invention. The motor is used here to unlock or lock the opening and closing body of the door for getting on and off the car, and the control circuit 1 of FIG. Lock / unlock.

[0024] The control circuit 1 includes a total of six motors 31 to 36 for opening and closing the opening and closing bodies. The motors 31 to 36 for opening and closing the above-mentioned opening and closing bodies are respectively connected to the opening and closing of the driver's door DR, the passenger's door AS, the rear left door RL, the rear right door RR, the tailgate TG, and the fuel inlet cover FUEL. The bodies are arranged correspondingly, and the corresponding opening and closing bodies are locked and unlocked through the forward / reverse r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com