Patents

Literature

34results about How to "Control positive and negative" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

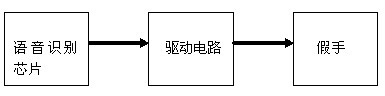

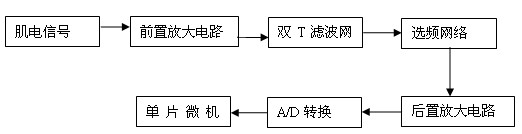

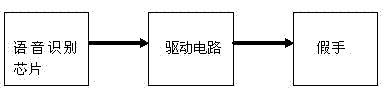

Electronic artificial hand with voice/myoelectricity mixed control

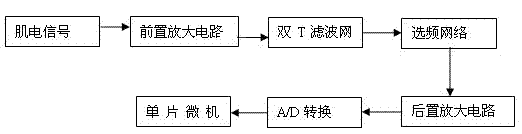

The invention relates to an electronic artificial hand with voice / myoelectricity mixed control, comprising a voice control system, a myoelectricity control system, a voice control and myoelectricity control switching system and a voice switching control joint system, wherein the voice control and myoelectricity control switching system consists of voice recognition chips; when the voice recognition chips receive a voice command 'myoelectricity', a control signal is outputted to drive the myoelectricity control system to work; when the voice recognition chips receive a voice command 'voice', the voice recognition chips are communicated with the voice control system to control the artificial hand; and when the voice recognition chips receive a voice command 'collaboration', the voice control command received by the voice recognition chips is processed to output a control signal to the myoelectricity control system so as to switch joints of the artificial hand, and the voice control system and the myoelectricity control system work simultaneously. The electronic artificial hand comprises the voice control system and the myoelectricity control system and can switch corresponding control according to actual use conditions.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +1

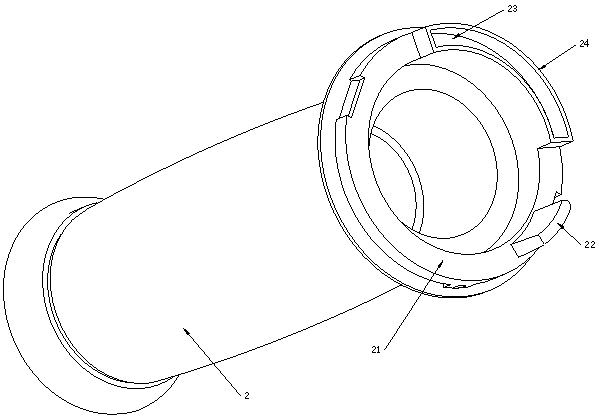

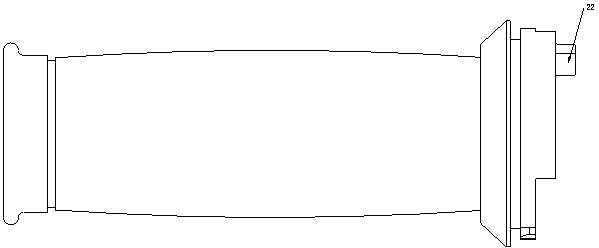

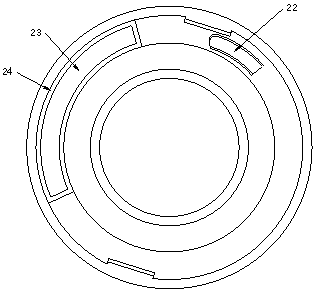

Forward and reverse speed adjustable handle for electric vehicle and power control device for electric vehicle

ActiveCN104015855ADescribe wellRealize forward and reverse controlCycle control systemsEngineeringElectric vehicle

The technology provides a forward and reverse speed adjustable handle for an electric vehicle. The forward and reverse speed adjustable handle can be turned in both forward and reverse directions to control the forward or reverse turning of an electric vehicle. The forward and reverse speed adjustable handle has the advantages of simple structure, no back-up switch, convenience in operation and high reliability, and the cost is equivalent to that of an ordinary speed regulating handle. The forward and reverse speed adjustable handle comprises a fixed part consisting of a handle stem and a handle seat, and a turning handle, wherein a left turning spring and a right turning spring are arranged between the fixed part and the turning handle; the left turning spring enables the turning handle to counterclockwise turn relative to the handle stem, and the right turning spring enables the turning handle to clockwise turn relative to the handle stem; the turning handle is in a reset position under the combined action of the left turning spring and the right turning spring. When an external force is applied to the turning handle, the turning handle can clockwise or counterclockwise turn from the reset position; a Hall sensor and an arc-shaped permanent magnet are respectively arranged on the turning handle and the fixed part oppositely but without contact; when the turning handle is turned, the Hall sensor moves relative to the arc-shaped permanent magnet, senses different positions of the arc-shaped permanent magnet and outputs relevant different signals.

Owner:NANJING SANYE GOLDEN EAGLE MOTORCYCLE

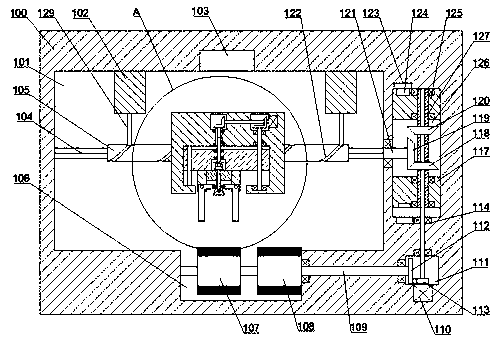

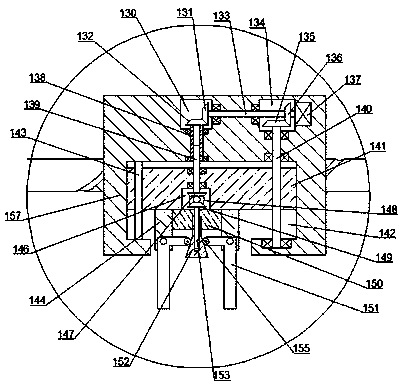

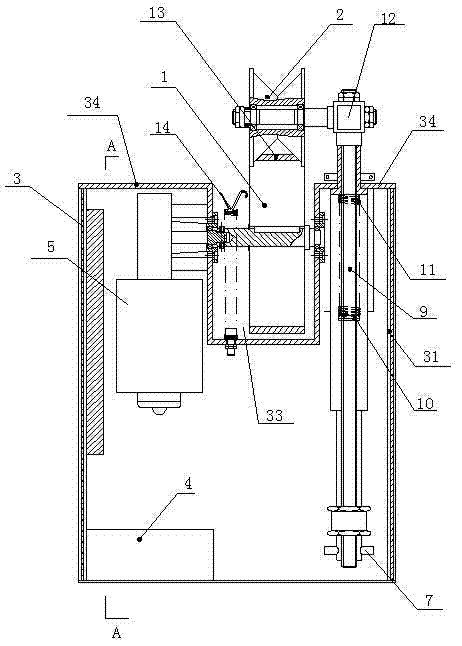

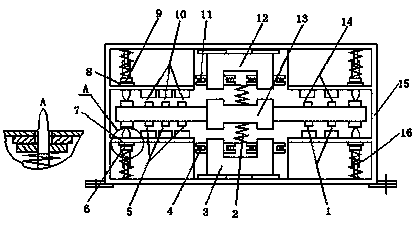

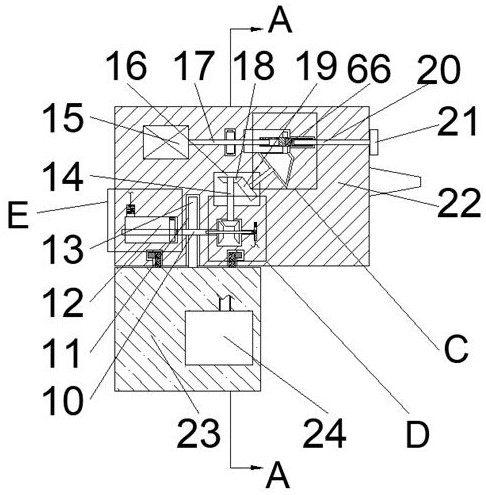

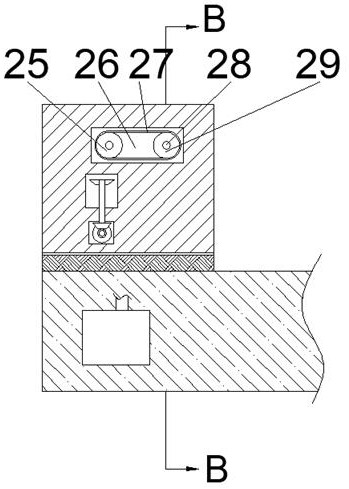

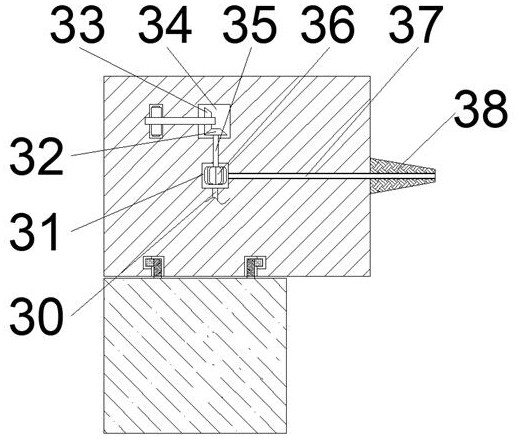

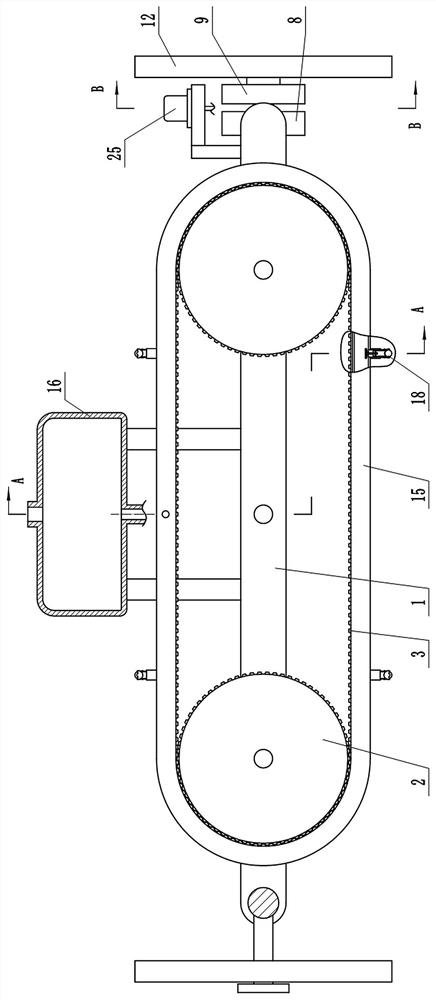

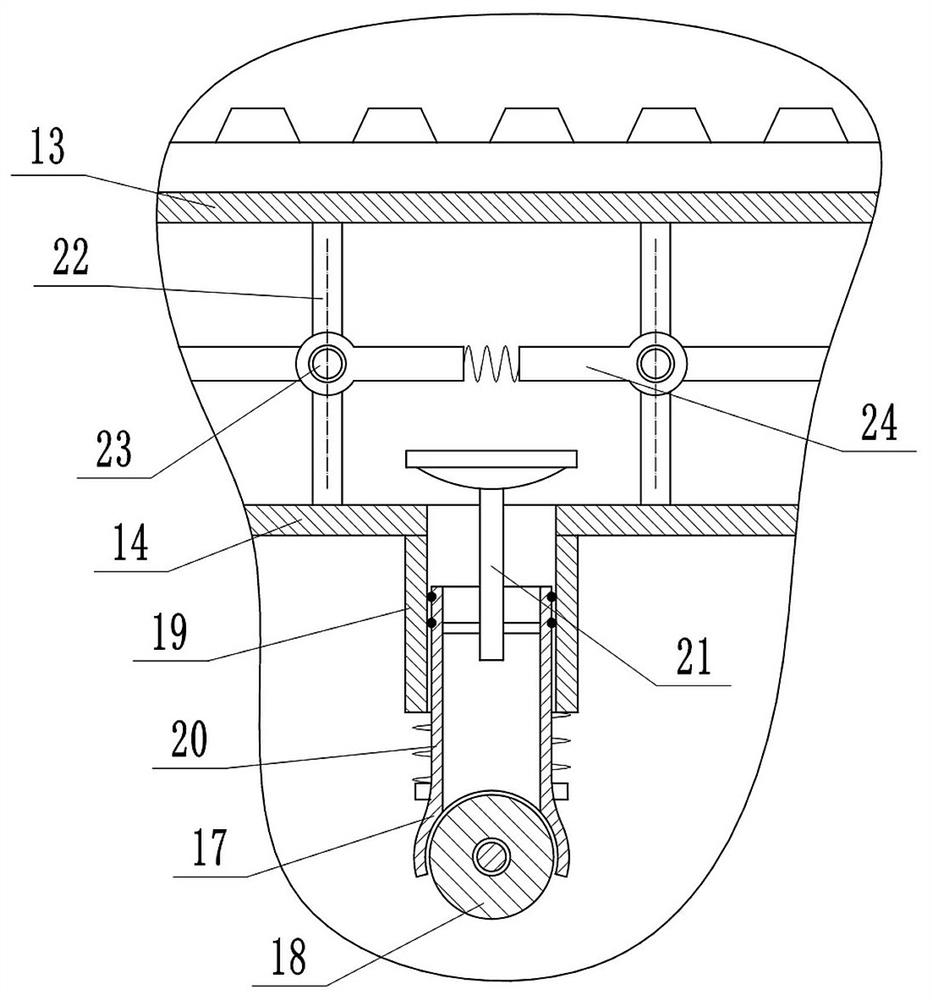

Magnetic force testing equipment for earphone

InactiveCN109168121AControl positive and negativeAchieve clampingElectrical apparatusMagnetic testingPower switching

The invention provides magnetic force testing equipment for an earphone. The testing equipment includes a main body. A working chamber is arranged in the main body. A fixture mechanism is arranged inthe working chamber. A conveyor belt cavity is arranged on the bottom wall of the working cavity. A conveyor belt mechanism is arranged in the conveyor belt cavity. A transmission chamber is arrangedin the main body on the right side of the conveyor belt mechanism. A power mechanism is arranged in the transmission chamber. A switch chamber located on that right side of the working chamber is arranged in the host body at the top of the transmission chamber. A power switching mechanism is arranged in the switching cavity. The device can realize the clamping of the earphone head through the clamping mechanism, and at the same time, the earphone head can be sent into the detecting mechanism for magnetic testing by turning 180 degrees, and the qualified and unqualified earphone heads can be separated by the conveyor belt mechanism, so that the conveyor belt mechanism can realize the feeding of the earphone head, the automation degree is high, and the production efficiency is improved.

Owner:廖瑶丽

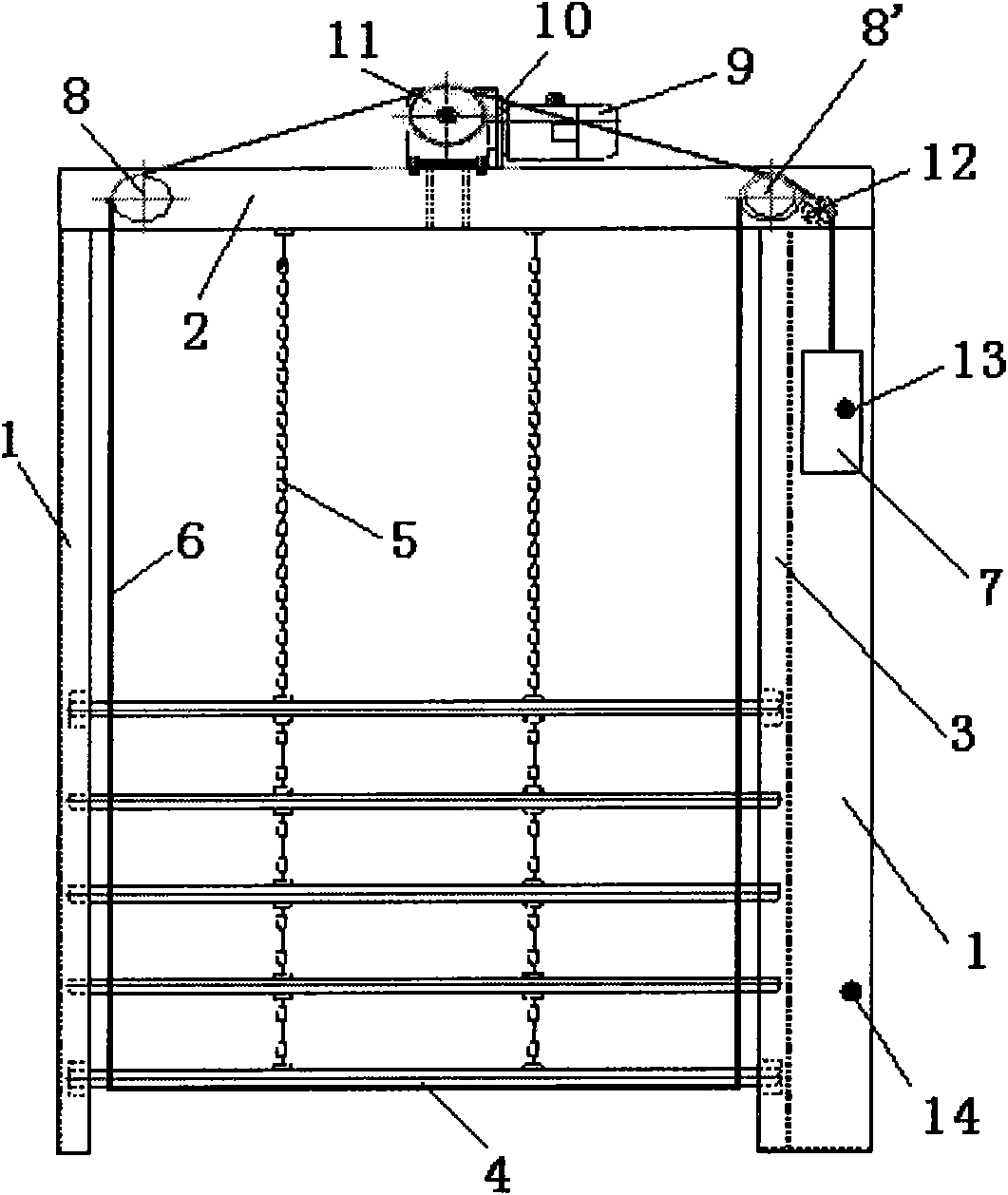

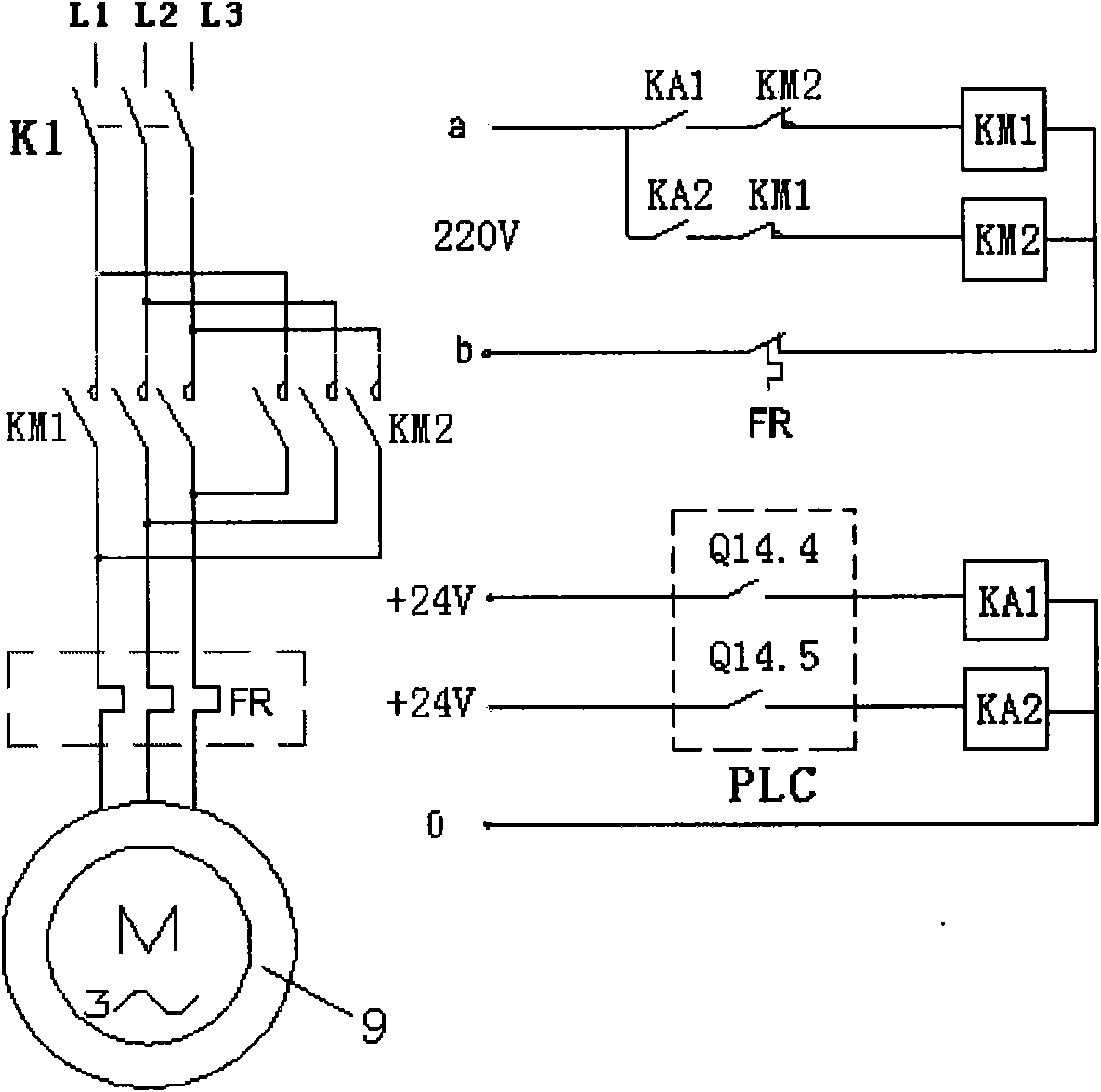

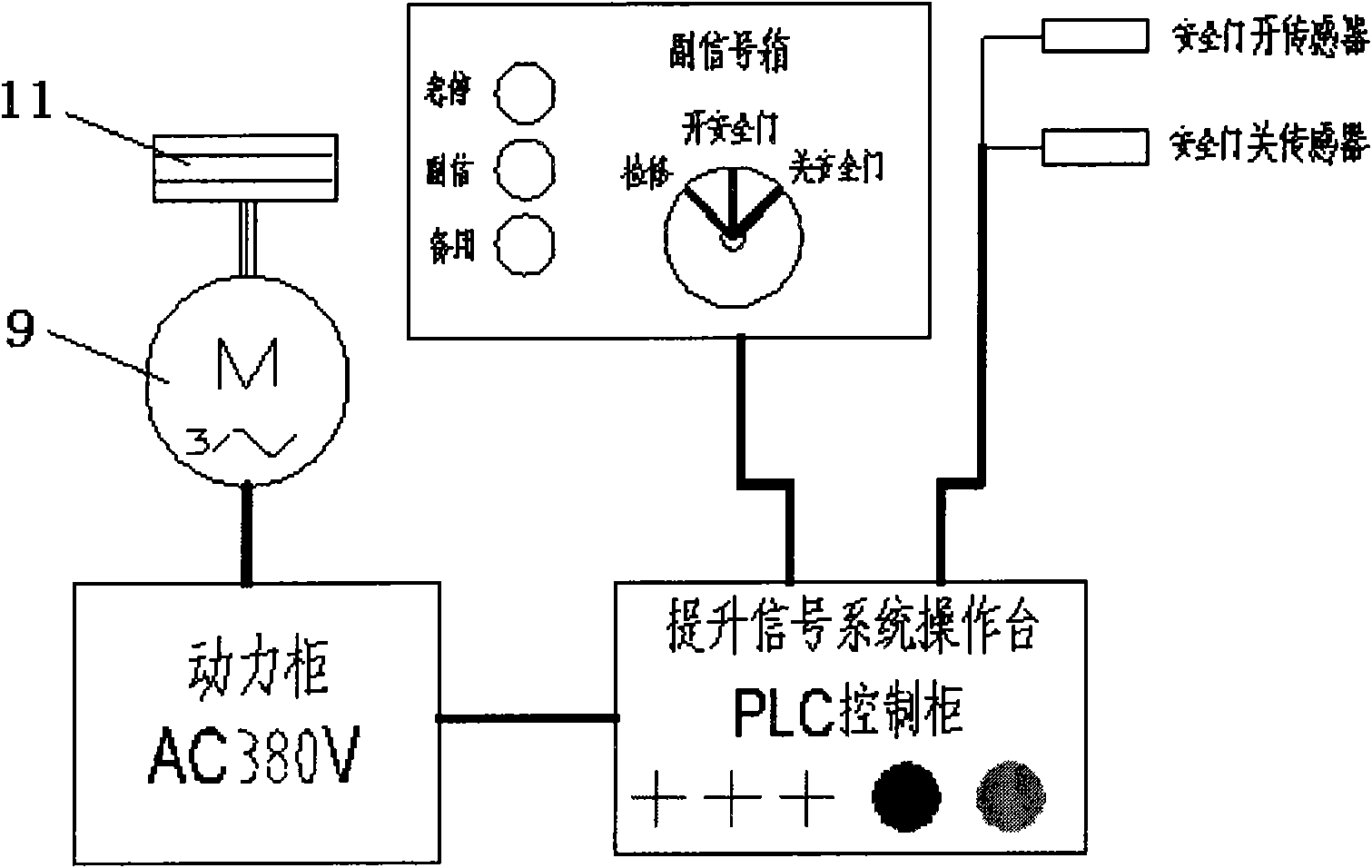

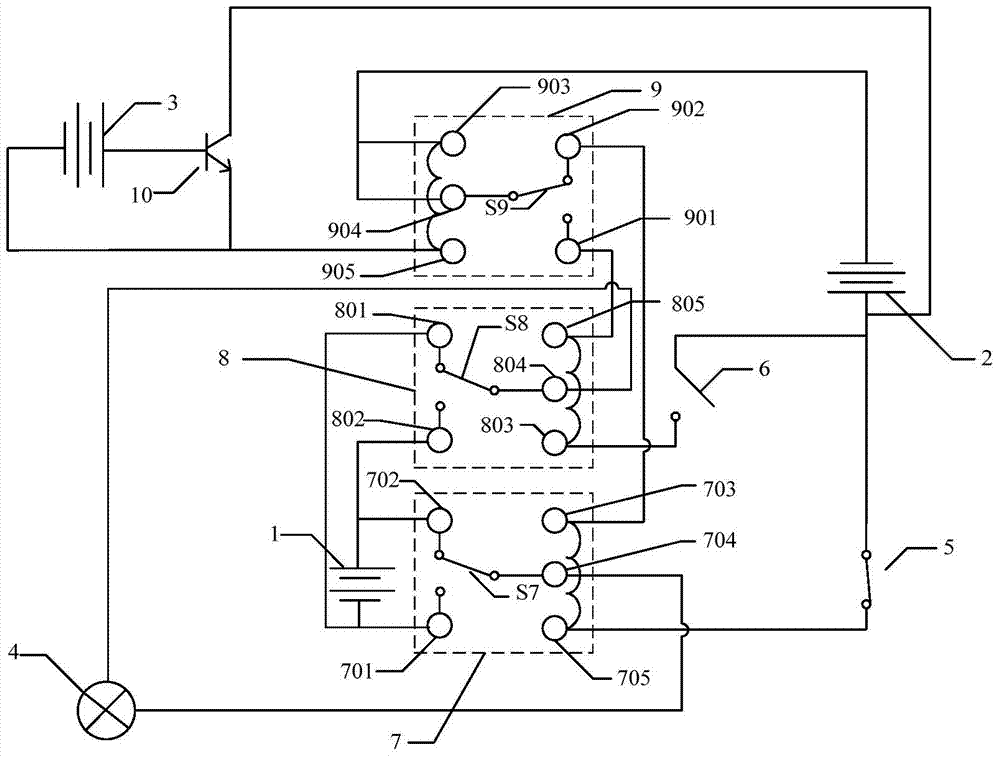

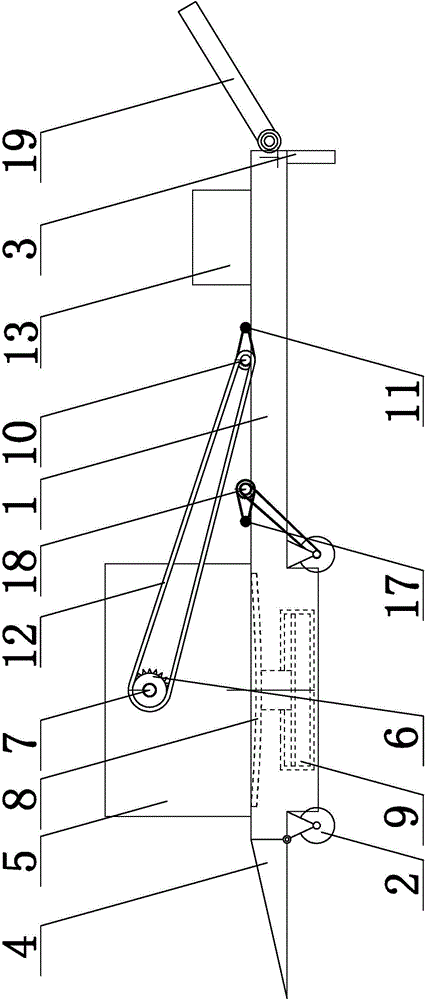

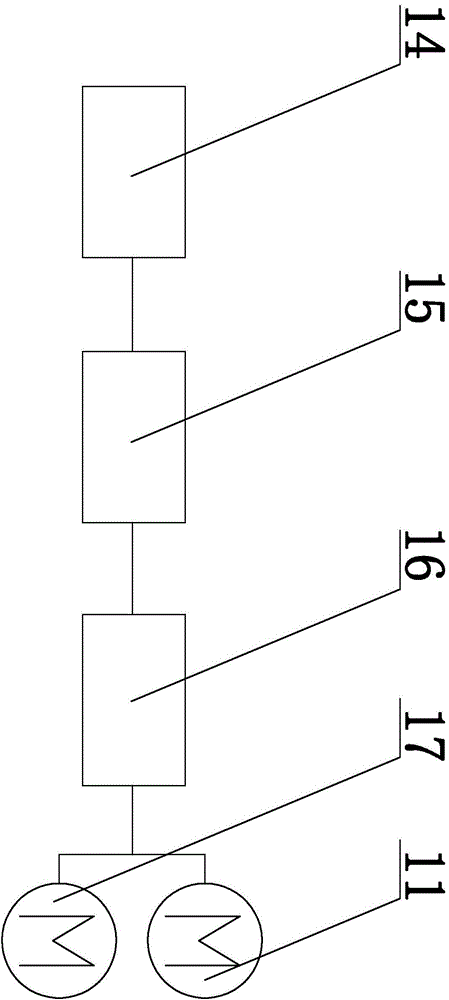

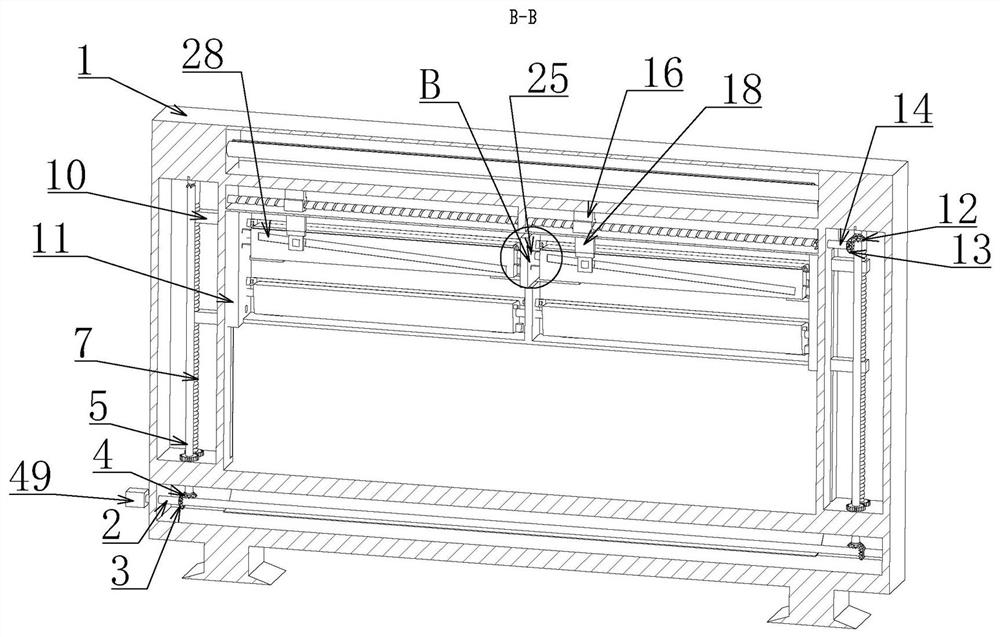

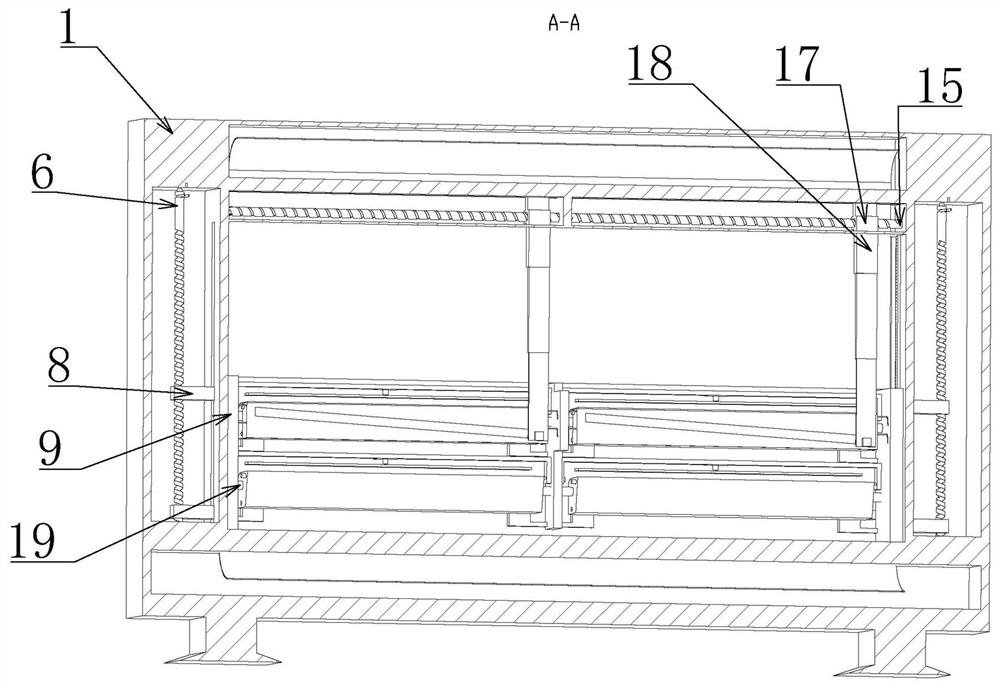

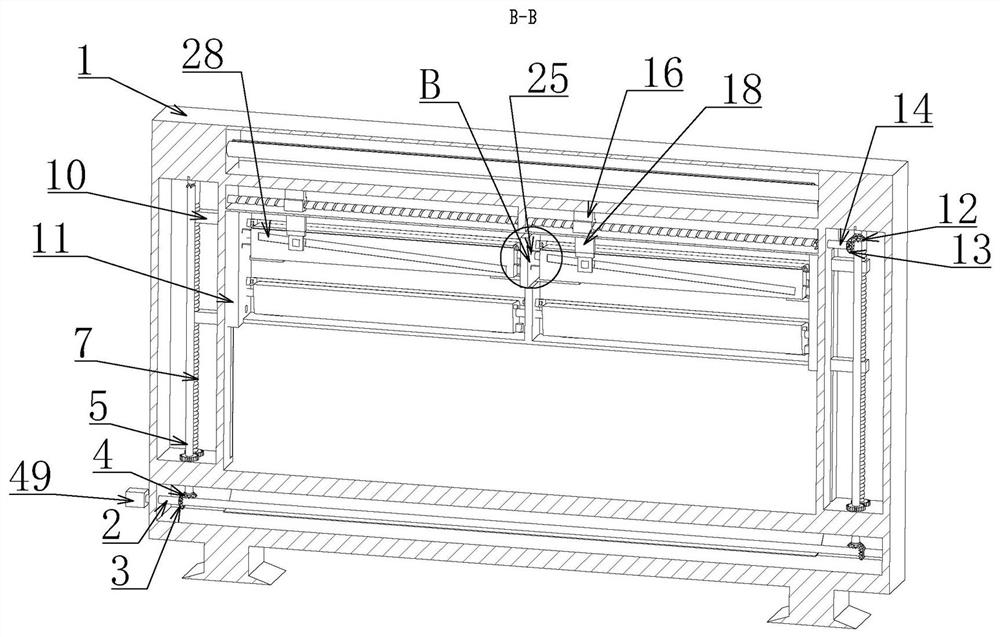

Programmable logic controller (PLC)-controlled electric safety door

ActiveCN101927937AEasy to operateSmooth switch operationMine liftsProgrammable logic controllerControl circuit

The invention relates to a programmable logic controller (PLC)-controlled electric safety door. The PLC-controlled electric safety door comprises a door frame, a door body, an electromotor (9) and a pulling rope driving wheel (11), wherein the electromotor (9) is arranged on an upper beam (2); the pulling rope driving wheel is wound with a pulling rope (6); one end of the pulling rope (6) rounds a second guide wheel (8') arranged on one side of the upper beam (2) and is connected to a counterweight block (7), while the other end rounds a first guide wheel (8) arranged on the other side, passes through one side of the door body downwards, extends to the bottom of the door body, extends to the other side of the door body along the bottom of the door body, then passes through the door body upwards, rounds the second guide wheel (8') and is fixed to the counterweight block (7); and the positive and negative rotations of the electromotor (9) are controlled by a control circuit of a programmable controller. The electric safety door is driven by the PLC-controlled electromotor, so that the electric safety door has the advantages of stable and precise switch operation, reliable working, low failure rate and effectively ensured safety of hoisting operation of coal mine vertical shafts.

Owner:CHINA SHENHUA ENERGY CO LTD +2

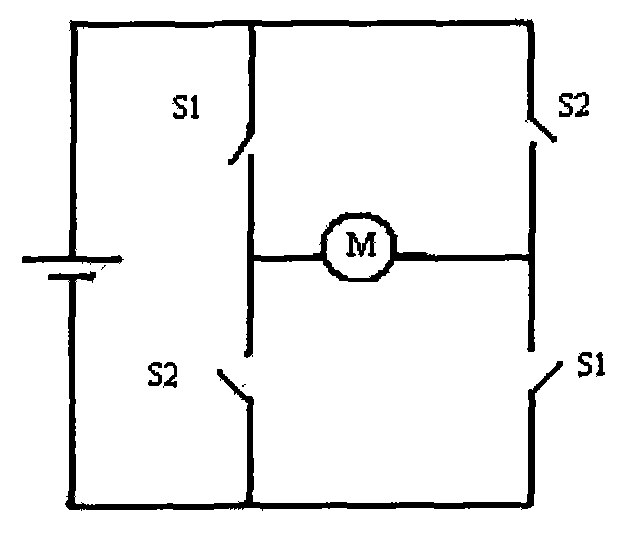

Relay system

ActiveCN103699024AControl positive and negativeSave energyProgramme control in sequence/logic controllersEngineeringVoltage

The invention discloses a relay system, which comprises a first five-pin relay, a second five-pin relay, a motor, a first switch, a second switch and a ridge rack, wherein a normally open terminal of the first five-pin relay is electrically connected with a normally open terminal of the second five-pin relay, a normally closed terminal of the first five-pin relay is electrically connected with a normally closed terminal of the second five-pin relay, a wiring terminal of the motor is electrically connected with a common terminal of the first five-pin relay, the other wiring terminal of the motor is electrically connected with the common terminal of the second five-pin relay, the ridge rack is provided with a plurality of ridge teeth, a first wiring terminal of the first switch is electrically connected with a second voltage applying terminal of the first five-pin relay, a first wiring terminal of the second switch is electrically connected with a first voltage applying terminal of the second five-pin relay, and the motor is used for driving the ridge rack to move so as to open and close the first switch and the second switch.

Owner:SHANGHAI JINGDUN TECH ECONOMIC INFORMATION

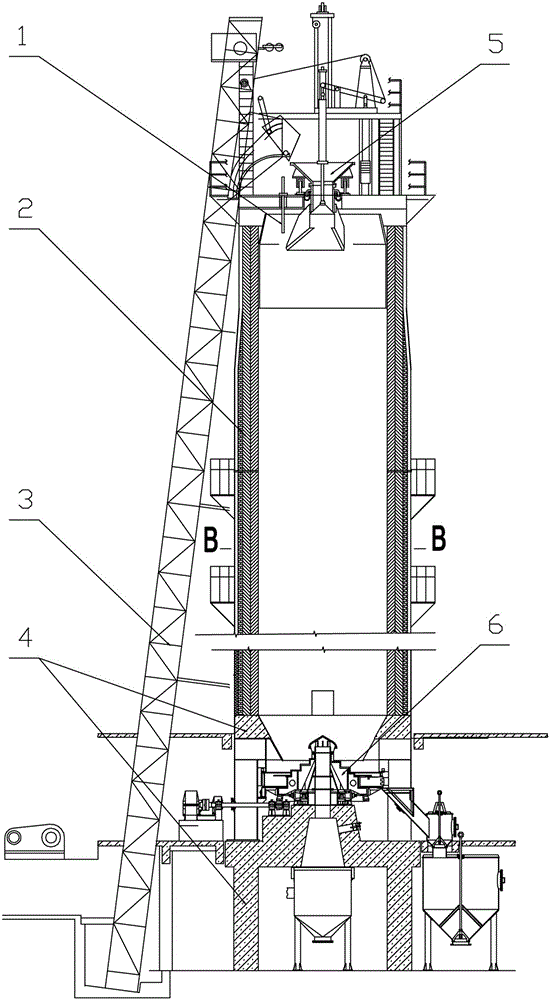

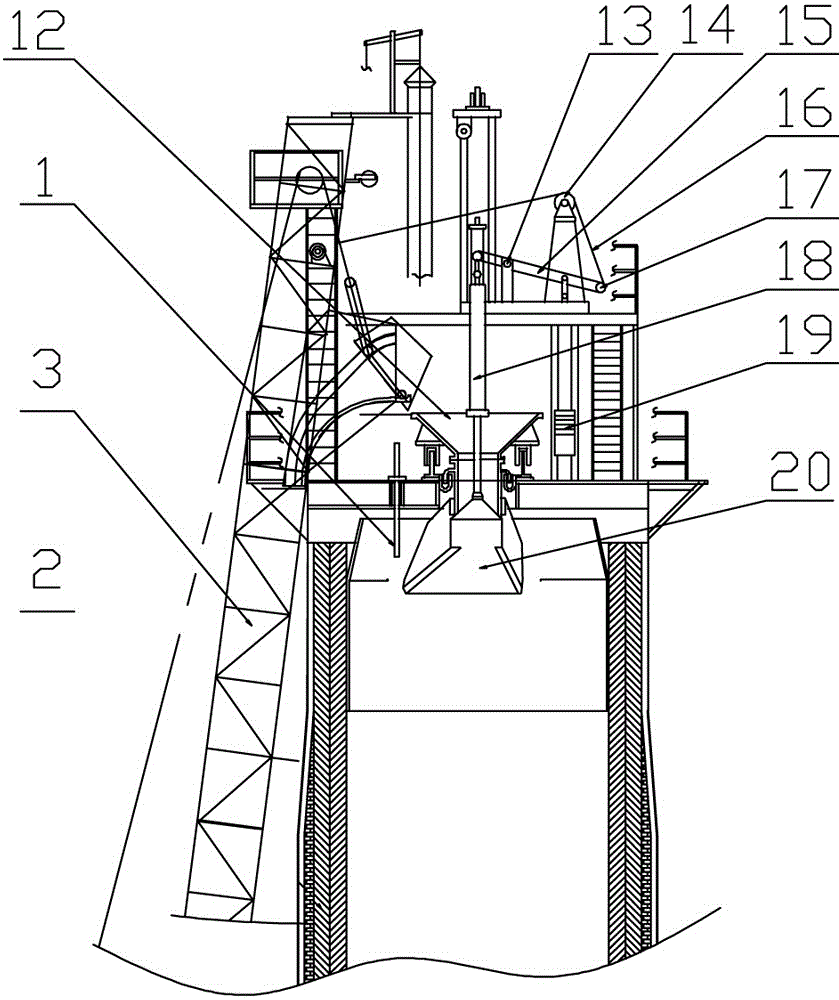

Energy-saving environment-friendly lime shaft kiln

The invention relates to an energy-saving environment-friendly lime shaft kiln with a kiln body. A feeding device is arranged on the outer side of the kiln body, a distributing device is positioned at the top of the kiln body, and a heat-resistant concrete supporting table is poured on the lower portion of the kiln body. A discharging device is arranged at the bottom of the kiln body and located at the middle of the heat-resistant concrete supporting table. The discharging device comprises a spiral cone ash-discharging tower, and a cap is installed at the top of the spiral cone ash-discharging tower, a kiln air inlet channel is arranged at the center of the spiral cone ash-discharging tower, and an external structure of the spiral cone ash-discharging tower is a spiral step structure. A round of secondary supporting plate is arranged on a bottommost layer spiral step of the spiral step structure in a butt joint mode and comprises an upper layer small supporting plate and a lower layer large supporting plate. A surrounding plate is arranged on the periphery of the large supporting plate, a baffle is slantly arranged between the lower layer large supporting plate and the upper layer small supporting plate, an ash receiving tank is arranged on the lower portion of the large supporting plate in a butt joint mode, a material receiving pipe is arranged on the lower portion of a discharging port of the ash receiving tank, and two bin type discharging devices are positioned at the lower end of the material receiving pipe. The energy-saving environment-friendly lime shaft kiln is environmentally friendly, saves energy and is low in underfiring rate, the working conditions in the kiln are stable, and the yield is high.

Owner:HUANGSHI LANTIAN ENVIRONMENTAL PROTECTION ENERGY SAVING EQUIP

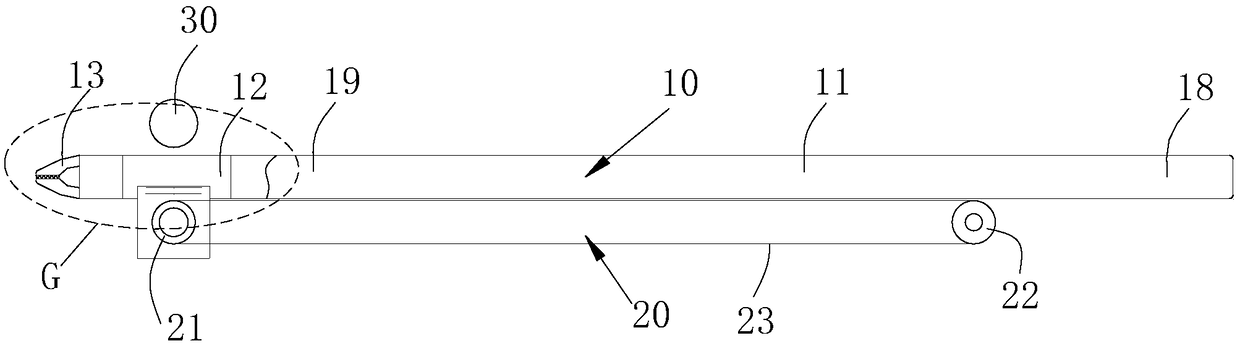

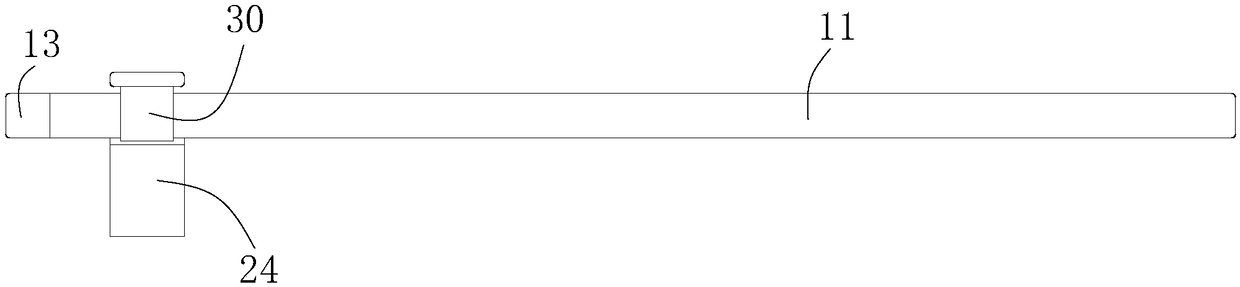

Weft yarn clamping mechanism

The invention discloses a weft yarn clamping mechanism. The mechanism comprises a belt conveyer, a clamping rod and a pressing block, wherein the belt conveyer is fixedly mounted on a bracket of a weft guiding mechanism; an annular belt capable of cyclically rotating is arranged on the belt conveyor, the clamping rod is arranged on the belt of the belt conveyor, and the pressing block is rotatablymounted on the bracket and presses the clamping rod on the belt; the clamping rod comprises a straight rod-shaped rapier, the two ends of the rapier are adopted as a clamping end and a tail end respectively, and an inner cavity is formed in the clamping end of the rapier and provided with an opening in the end face of the clamping end; an air cylinder is mounted in the inner cavity, a clamping head is mounted at the opening of the inner cavity. The clamping head comprises two clamping jaws which are oppositely arranged, and when a piston rod moves, the clamping jaws can be driven to rotate, so that engaging ends of the two clamping jaws are abutted together. The mechanism can be connected with an automatic control system, and the production efficiency is effectively improved.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

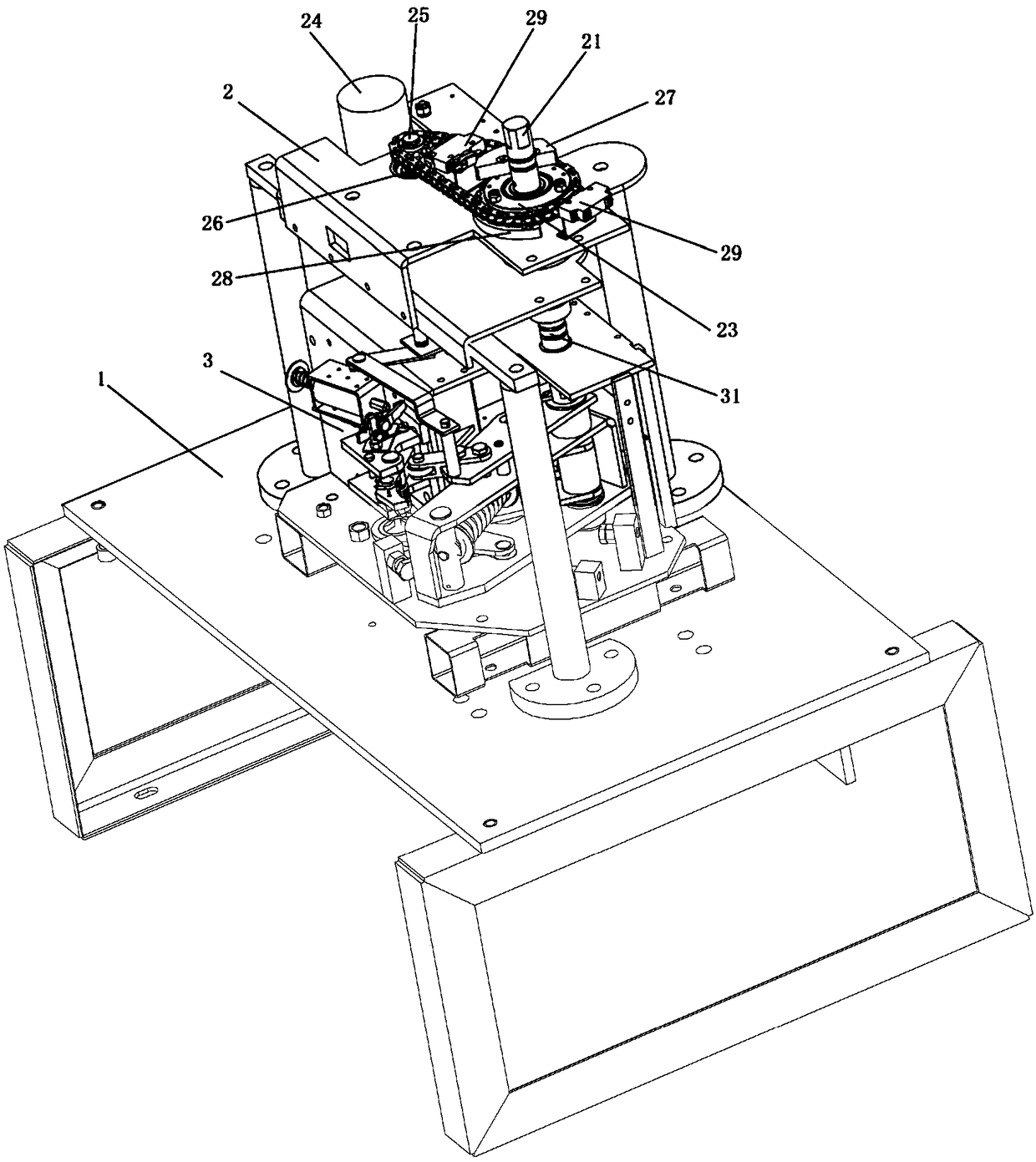

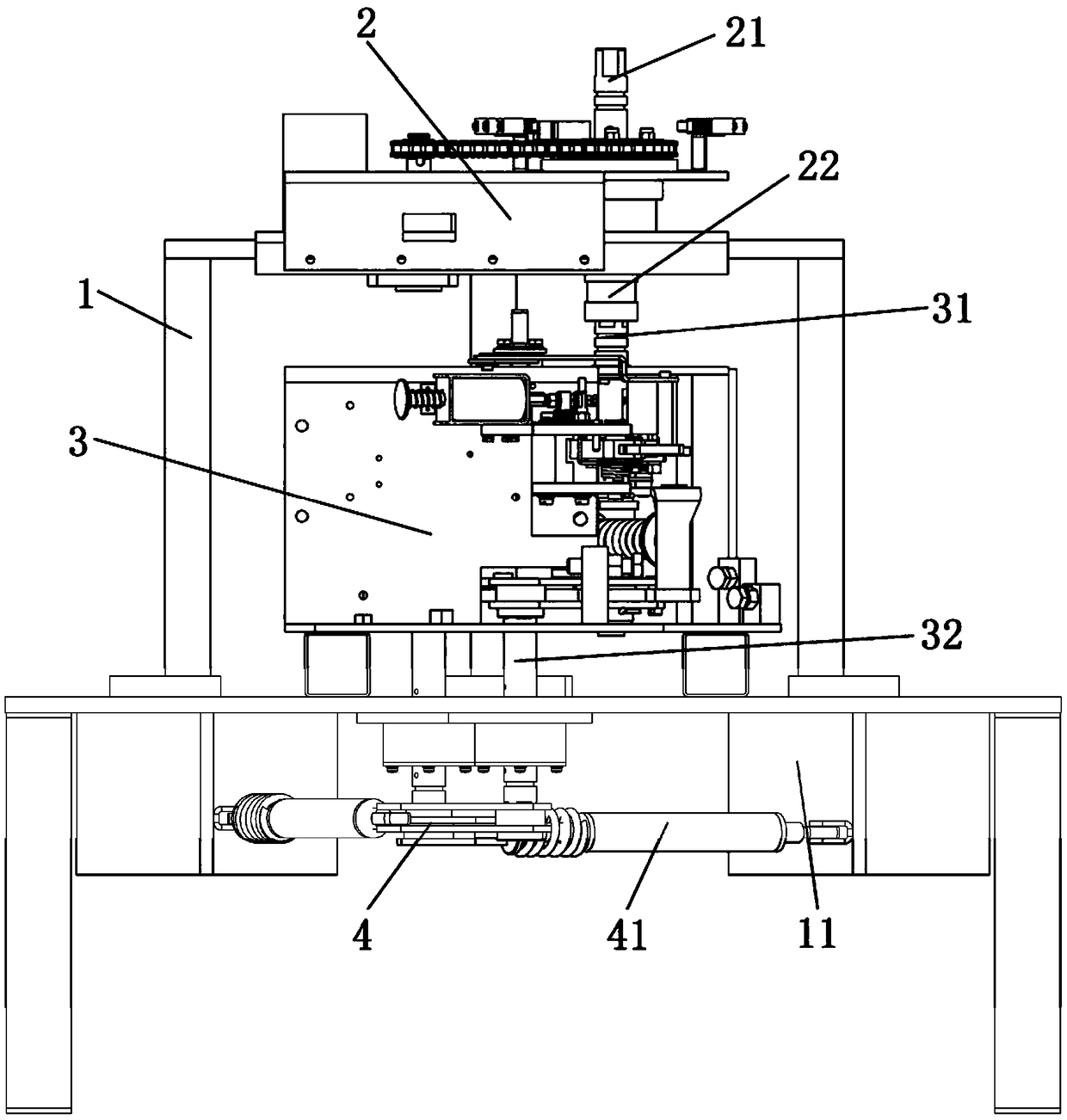

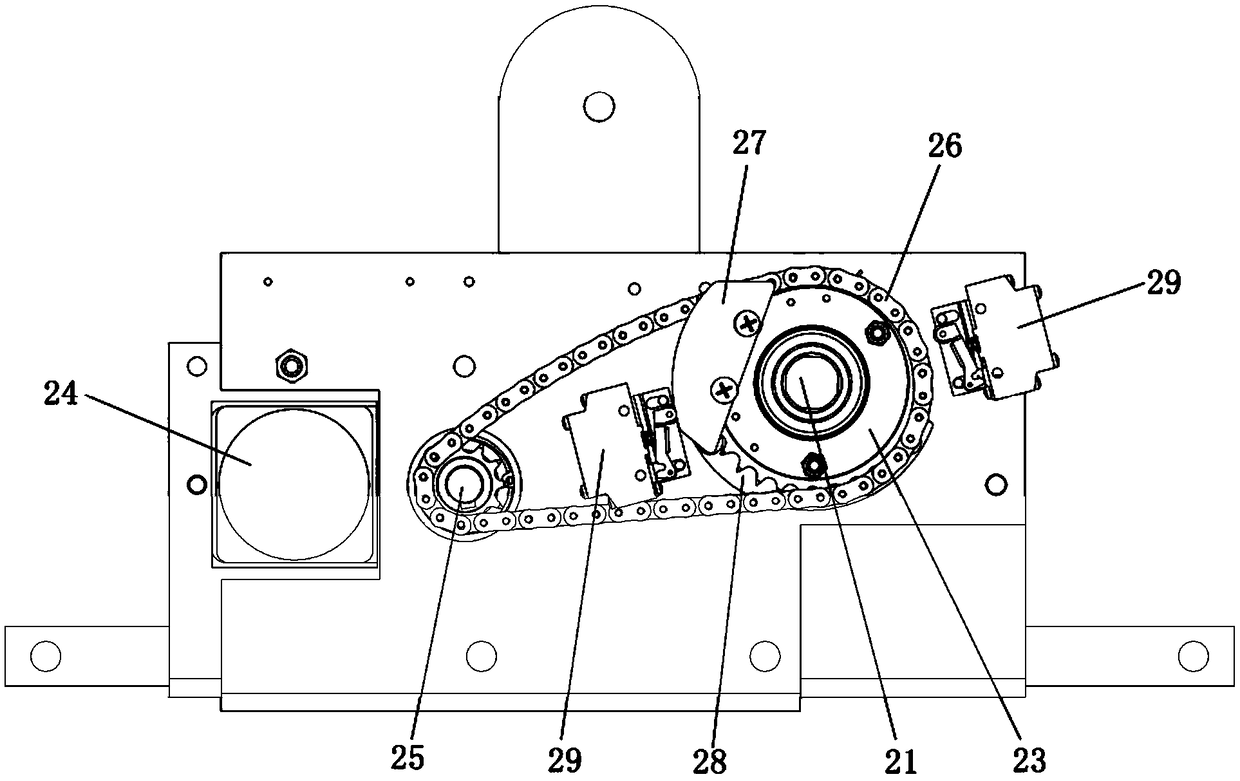

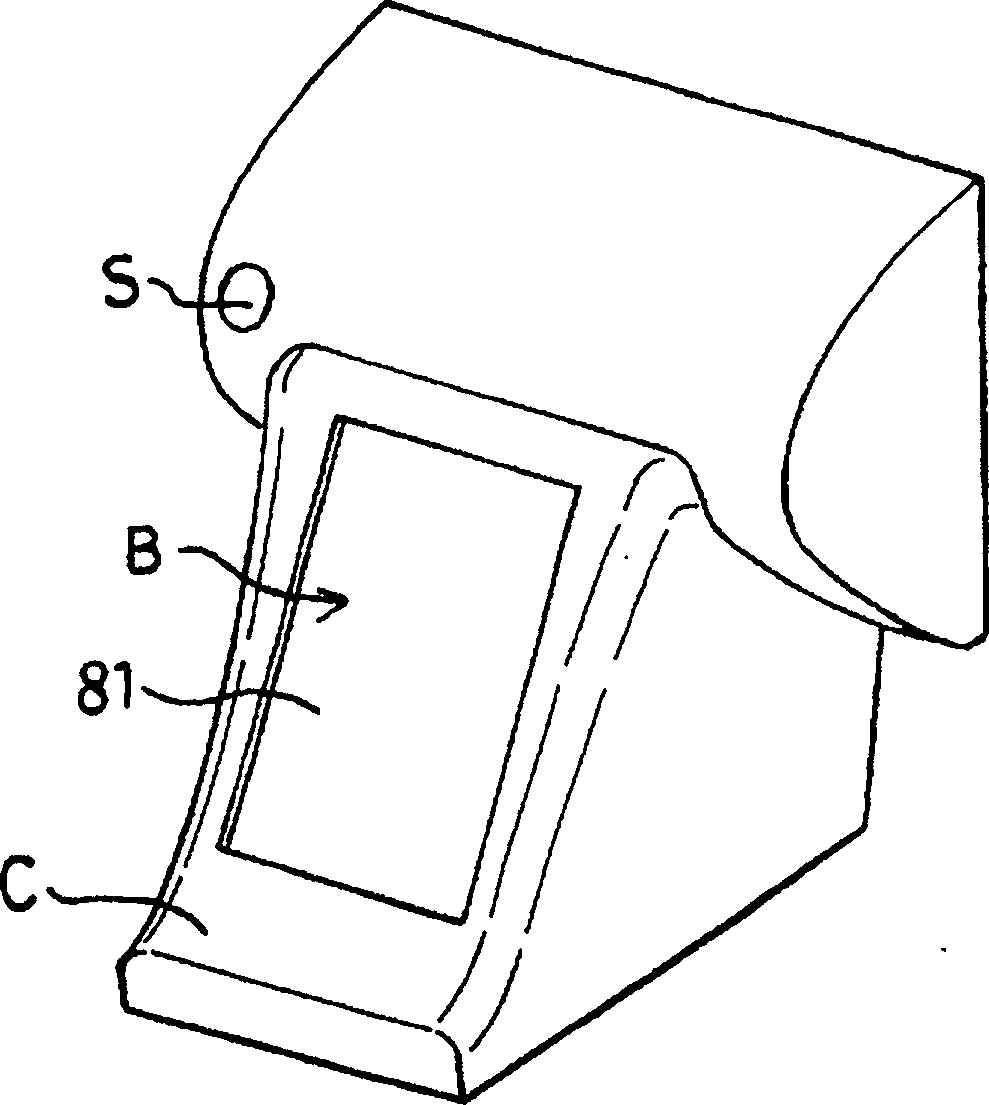

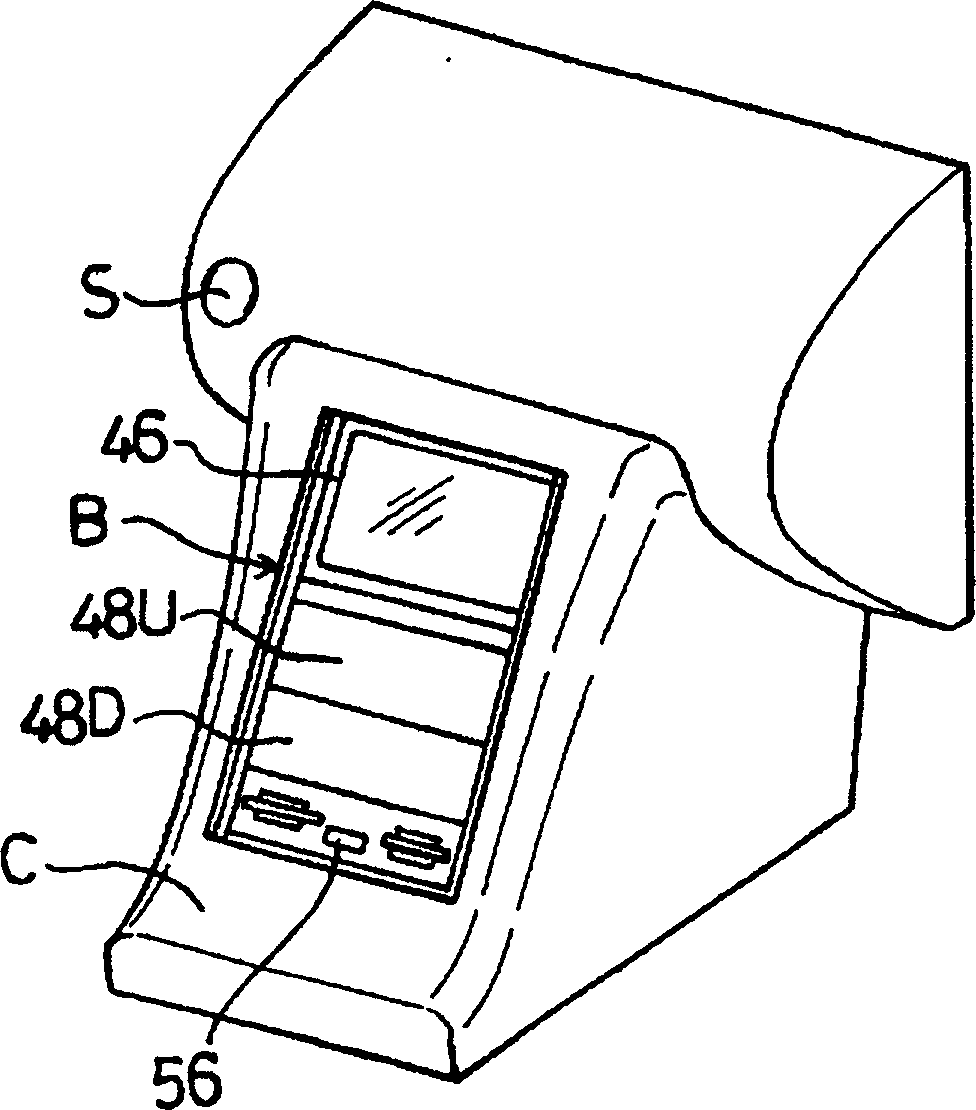

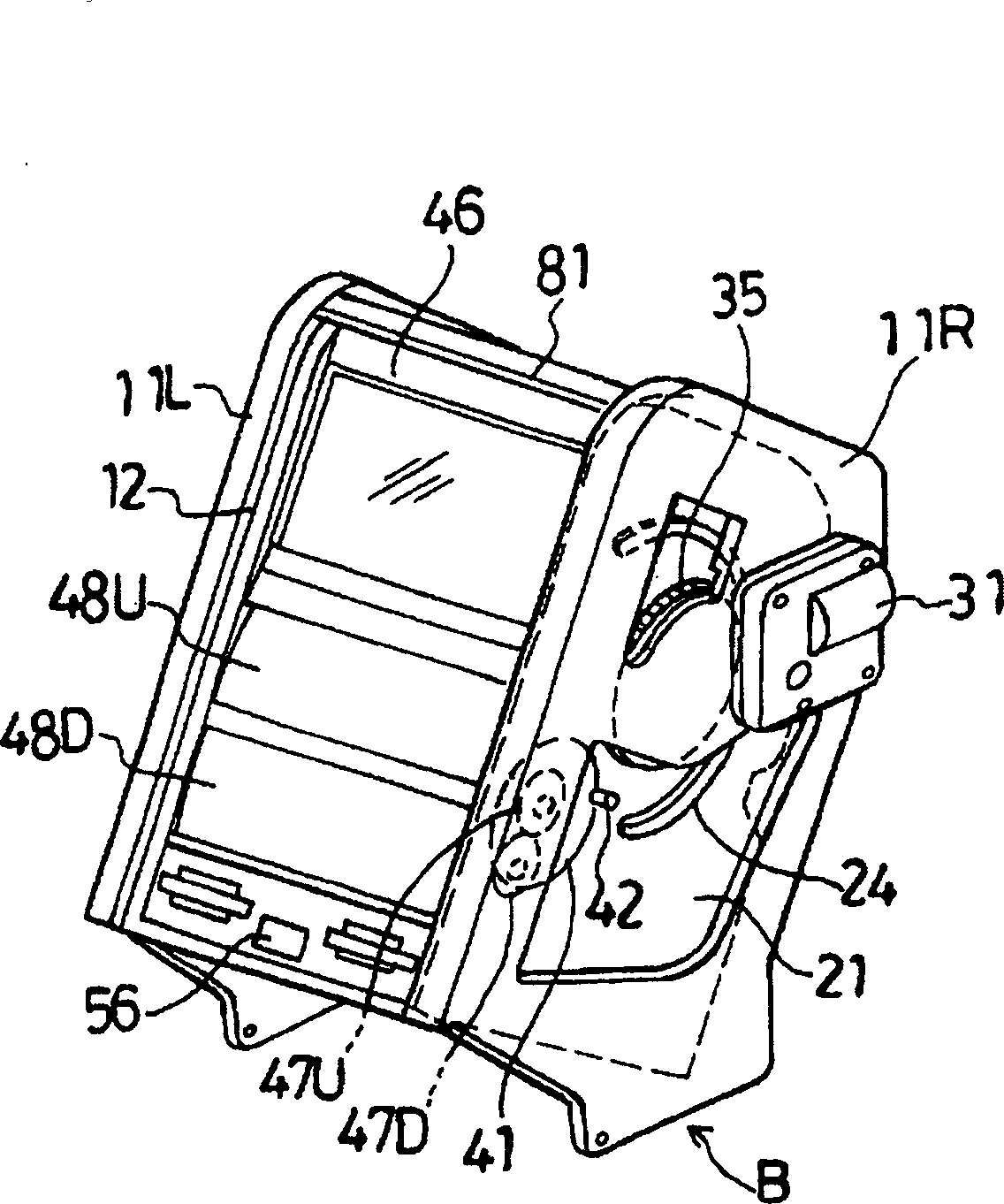

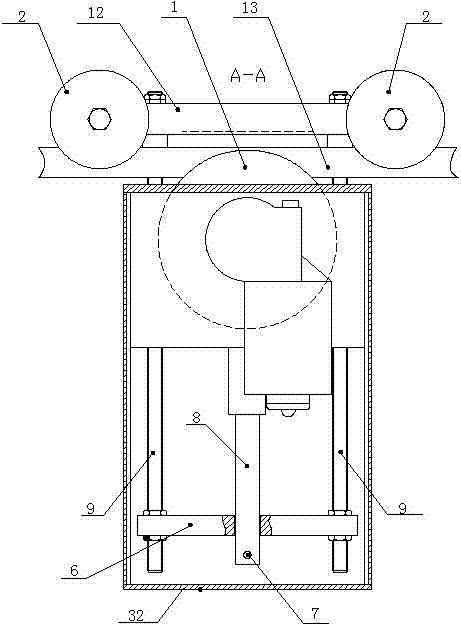

Circuit breaker operating mechanism test fixture

PendingCN109283463ATested and reliableTest stableMachine part testingCircuit interrupters testingEngineeringCam

The invention provides a circuit breaker operating mechanism test fixture. With the circuit breaker operating mechanism test fixture adopted, an operating mechanism can be quickly tested. The circuitbreaker operating mechanism test fixture comprises a base for supporting an operating mechanism to be detected; the base is provided with a rotation testing mechanism for driving the input shaft of the operating mechanism to be detected to act to realize a closing action; the rotation testing mechanism comprises a rotating shaft that is in transmission connection with the input shaft; the rotationtesting mechanism further comprises a driving wheel disposed coaxially with the rotating shaft; the rotating shaft is fixedly provided with a cam; the driving wheel is provided with detents in a manner that the detents can swing, wherein the detents are located beside the cam; clamping openings into which the detents can be clamped into are formed in the cam; during the swing stroke of each detent, the detent has a clamping position in which the detent can be clamped into the corresponding clamping opening, and a retreat position in where the detent can retreat from the corresponding clampingopening; the driving wheel pushes the cam by the detents so as to push the rotating shaft to rotate; and a limiting slider which is matched with the detents to make the detents retreat from the clamping openings of the cam during the rotation stroke of the driving wheel is arranged in the rotation testing mechanism.

Owner:HENAN HUASHENGLONGYUAN ELECTRICAL CO LTD

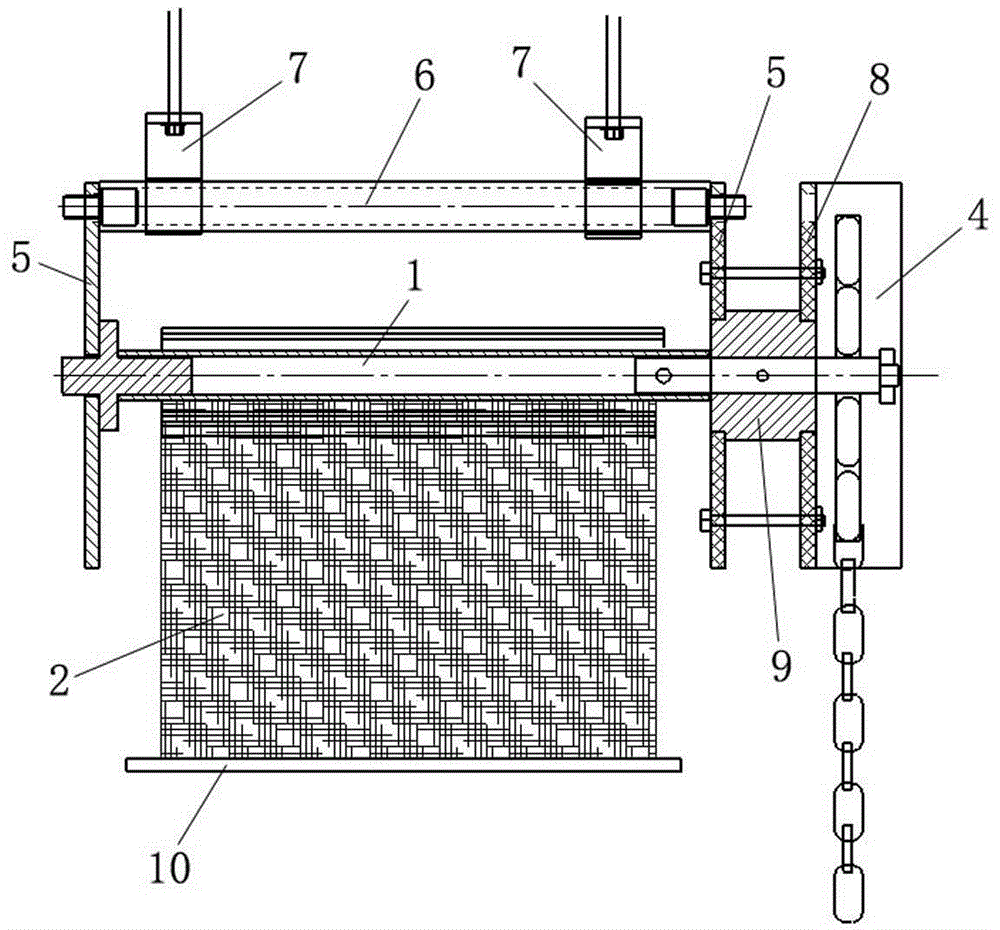

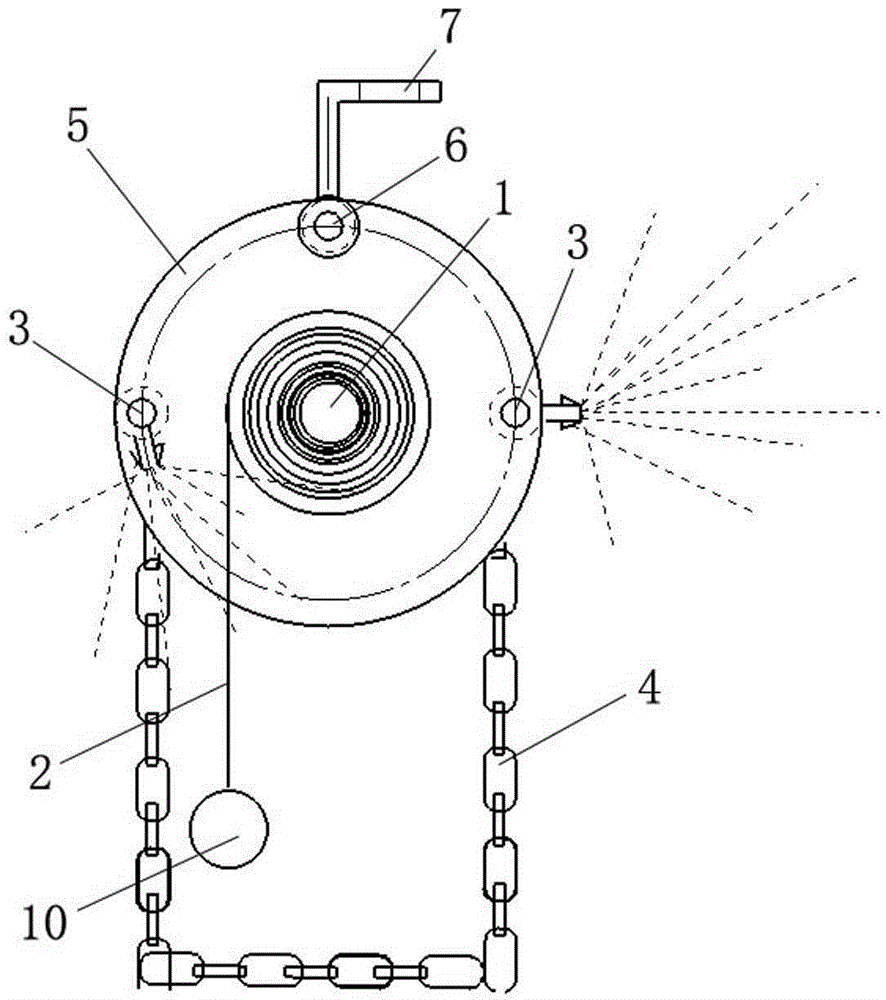

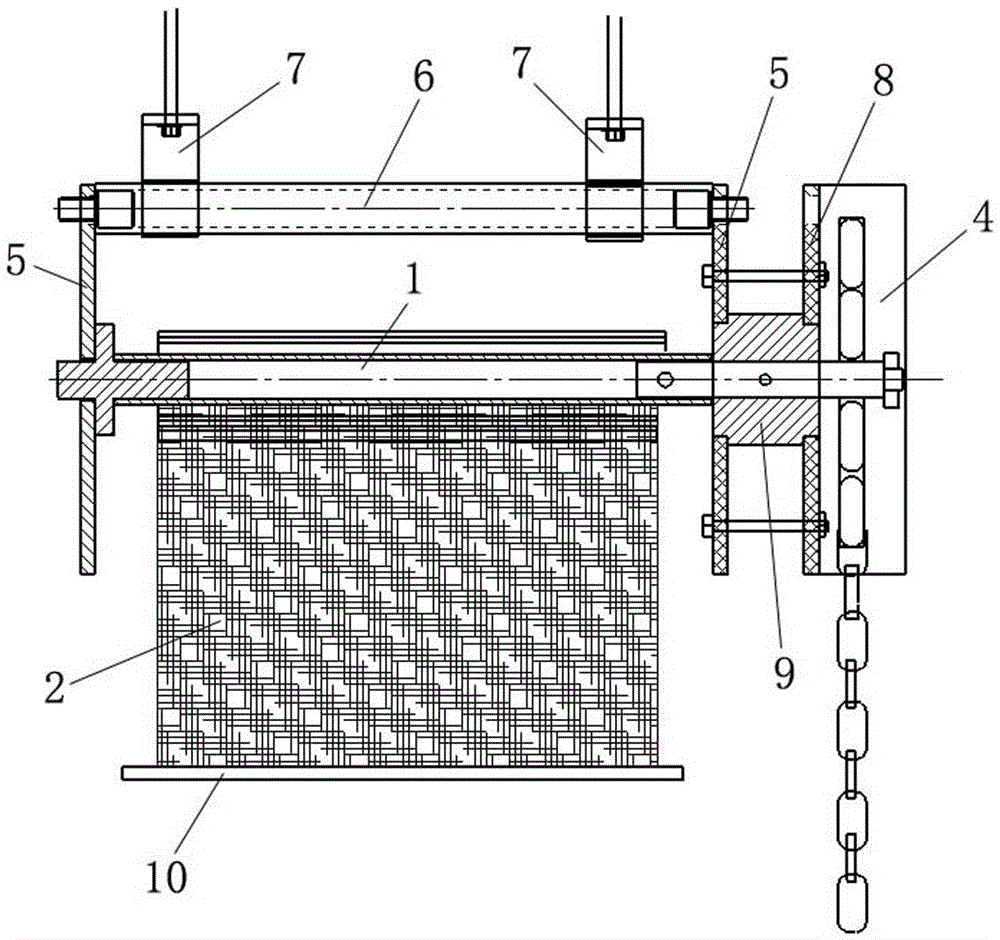

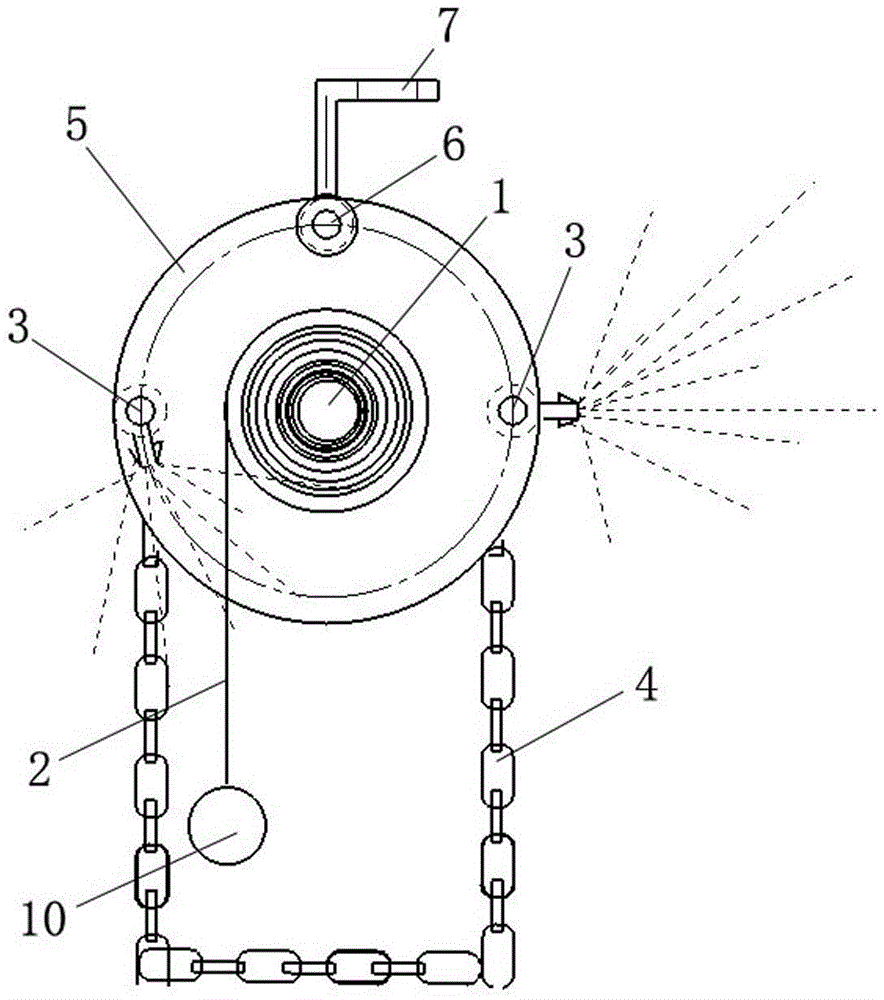

Roller shutter type dust collecting net device

The invention relates to a roller shutter type dust collecting net device. The roller shutter type dust collecting net device comprises a frame body, a rotary shaft, a nylon net, a spraying pipe and a chain block, wherein the rotary shaft is installed between two supporting plates on the frame body, the nylon net is connected to the rotary shaft, the spraying pipe is fixed between the two supporting plates on the frame body, a water inlet connector and a spraying head are arranged on the spraying pipe, an installation plate is fixed to the outer side of the frame body, the chain block is installed on the outer side of the installation plate, and a rotary shaft of the chain block is connected with one end of the rotary shaft. In addition, the nylon net is coated with a dedusting agent. The roller shutter type dust collecting net device is reasonable in design, simple in structure, safe, reliable, easy and convenient to maintain, high in mechanical efficiency, small in hand chain pulling force, low in self weight, convenient to install and durable. Due to the arrangement of the spraying pipe, the nylon net and the dedusting agent, dust can be well prevented from exceeding the standard, a safe production environment is created for workers, and the labor intensity of workers is relieved.

Owner:TONGMEI DATANG TASHAN COAL MINE CO LTD

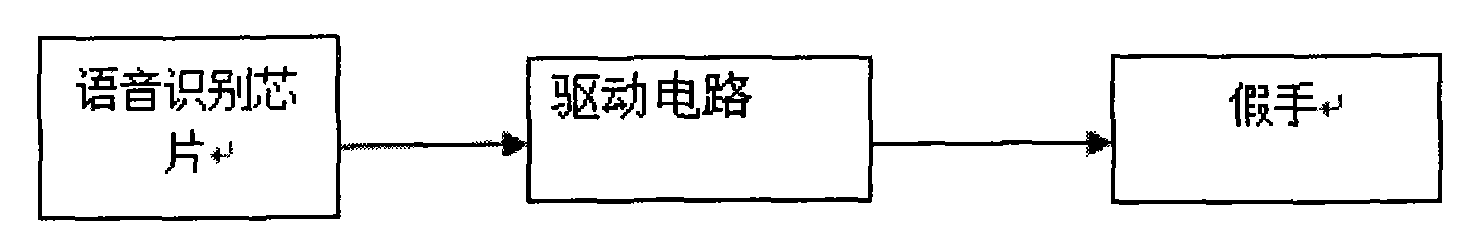

Electronic artificial hand based on sound control

InactiveCN101584616AAchieve outputRealize functionSpeech recognitionProsthesisThree degrees of freedomElectric machinery

The invention relates to an electronic artificial hand based on sound control, which includes an artificial hand speech recognition module, a signal amplification output chip and a signal relay control circuit. And the speech recognition module is composed of a speech recognition chip which can only recognize the user's own speech signal; and the speech recognition chip input end receives at least 7 kinds of speech instructions, one speech instruction is used for specialized training of urgency stop controls of any actions of artificial hand, other six instruction are outputted for the artificial hand electric relay control circuit, two to six instruction output signal are respectively used for controlling one to three freedom degrees of artificial hand, thereby finishing six actions of finger extension, finger bending, wrist internal rotation, wrist outward rotation, wrist extension and wrist bending. The invention can realize speech study function and recognition function, and realize outputs of two to more than six control instructions. The electric relay is used for controlling positive and negative rotation of electric motor, thereby realizing opening and closing functions of artificial hand controlled by two signals.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

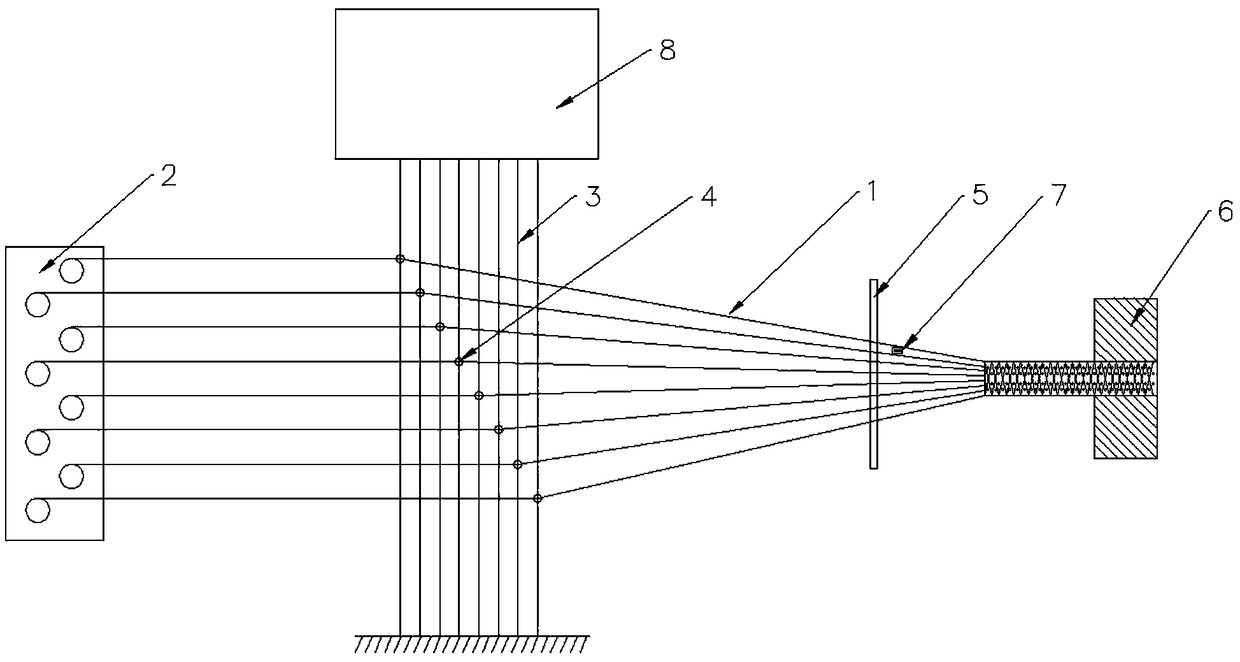

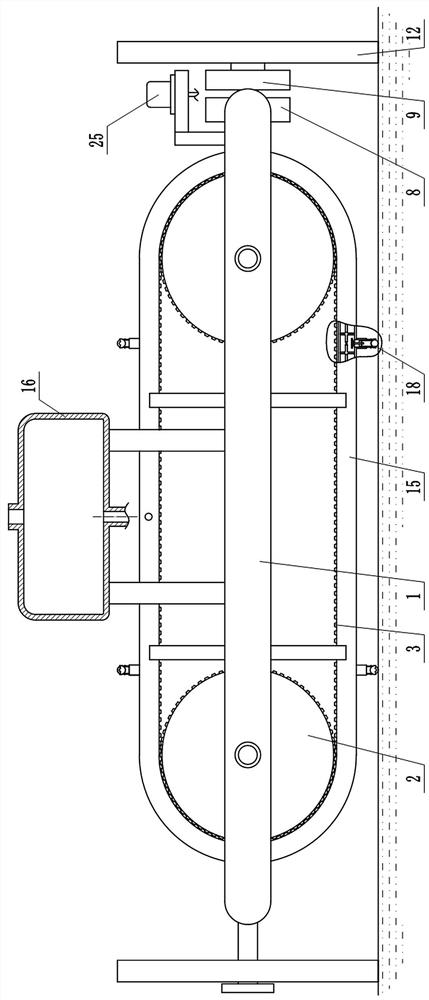

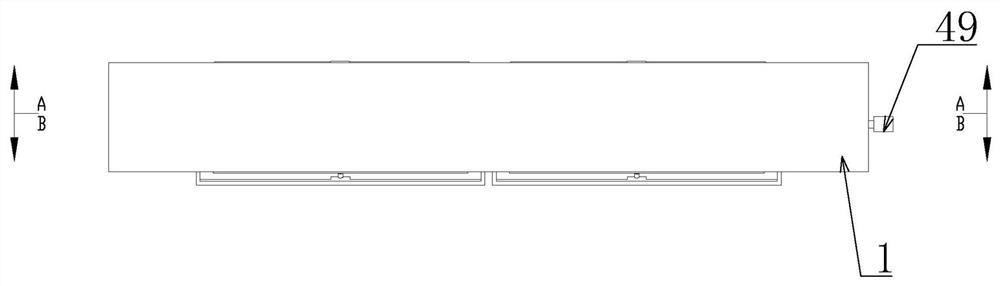

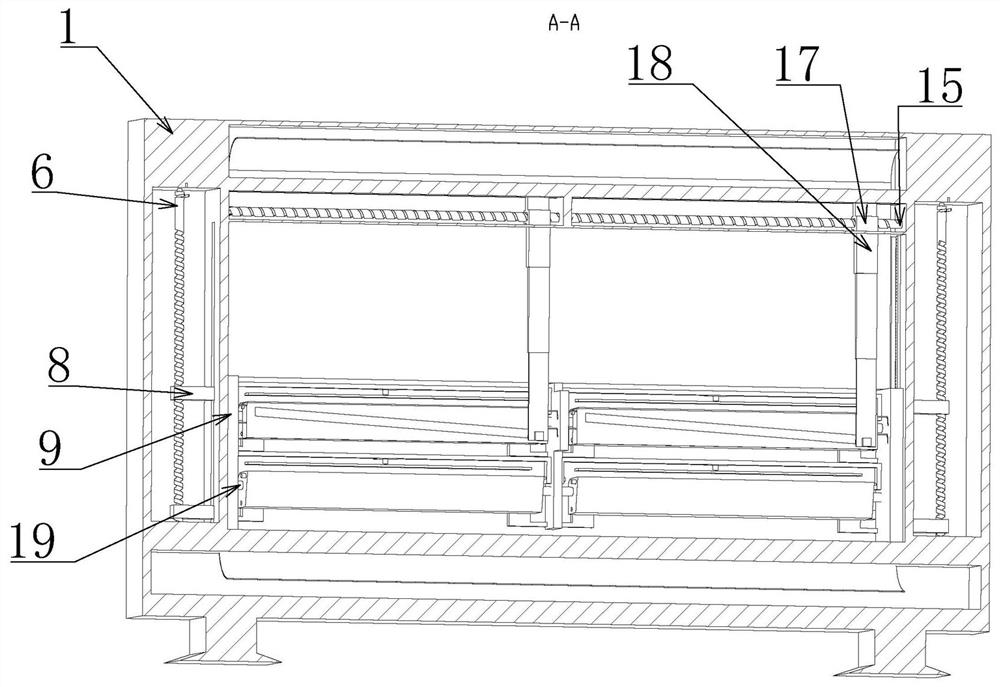

Paying-off robot and application thereof on erecting optical cables on 110kV circuit

ActiveCN103048759ASimple structureEasy to manufactureOptical fibre/cable installationPower gridEngineering

The invention relates to erecting and laying equipment for optical cables and wire cables, in particular to a paying-off robot and an application thereof on erecting the optical cables on a 110kV line. The paying-off robot realizes unwinding by pulling the optical cables needing to be erected along the old line wires, and since the line wires are erected in advance, the influence of trees and crossing brook on a line corridor and the like is eliminated, and the paying-off robot can be widely applied in construction of guide rope unwinding across large brook and river and has the beneficial effects that the construction intensity of paying-off staffs is greatly reduced and the construction safety is increased. The paying-off robot has the advantages that the structure is simple, the manufacture is easy, and the operation is also more convenient compared with the construction method in the prior art, so that the construction cost is very low, the construction efficiency is very high, the construction time is greatly shortened, simultaneously the power-failure time of the circuit is also reduced, a power consumption user on the circuit is convenient, and the reliability of operation of a power grid is improved.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +2

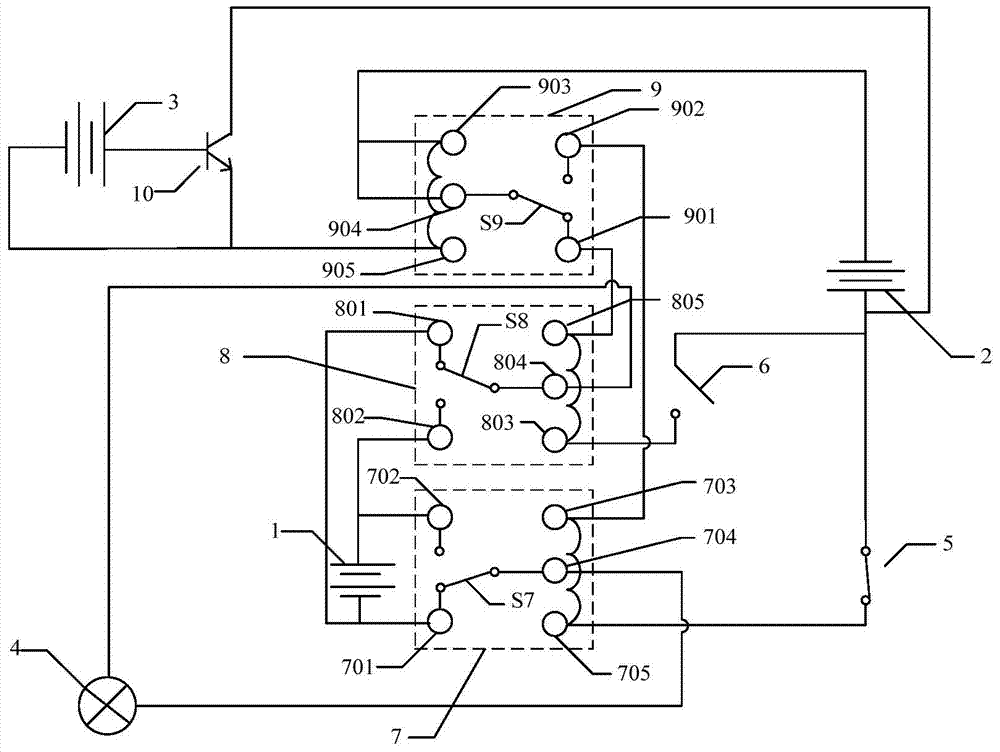

Integrated forward and reverse rotation alternating-current contactor

InactiveCN104143480AReduce usageControl positive and negativeNon-polarised relaysElectricityEngineering

The invention provides an integrated forward and reverse rotation alternating-current contactor. The integrated forward and reverse rotation alternating-current contactor is characterized in that when a forward rotation starting button is pressed down, a forward rotation coil is powered on, electromagnetic attraction force is generated by a forward rotation static iron core, an armature is attracted down, a main forward rotation contact is closed, an auxiliary forward rotation normally-open contact is closed, and resistance of a contact spring is overcome by an auxiliary forward rotation normally-closed moving contact so that the auxiliary forward rotation normally-closed moving contact can be disconnected from an auxiliary forward rotation normally-closed fixed contact and a motor can be powered on to perform forward rotation; a reverse rotation starting button is pressed down, a reverse rotation coil is powered on, electromagnetic attraction force is generated by a reverse rotation static iron core, the armature is attracted up, a main reverse rotation contact is closed, an auxiliary reverse rotation normally-open contact is closed, and resistance of the contact spring is overcome by an auxiliary reverse rotation normally-closed moving contact so that the auxiliary reverse rotation normally-closed moving contact can be disconnected from an auxiliary reverse rotation normally-closed fixed contact and the motor can be powered on to perform reverse rotation. A stop button is pressed down, the armature returns, the motor is powered off to stop rotating, and the phenomenon that the contacts are burnt by arc light caused when the contacts make contact is avoided through an arc extinguishing chamber. Due to the arrangement, the number of the contactors in use is reduced, the motor is controlled to perform forward and reverse rotation, cost is saved, and maintenance is facilitated.

Owner:SHANDONG VOCATIONAL COLLEGE OF SCI & TECH

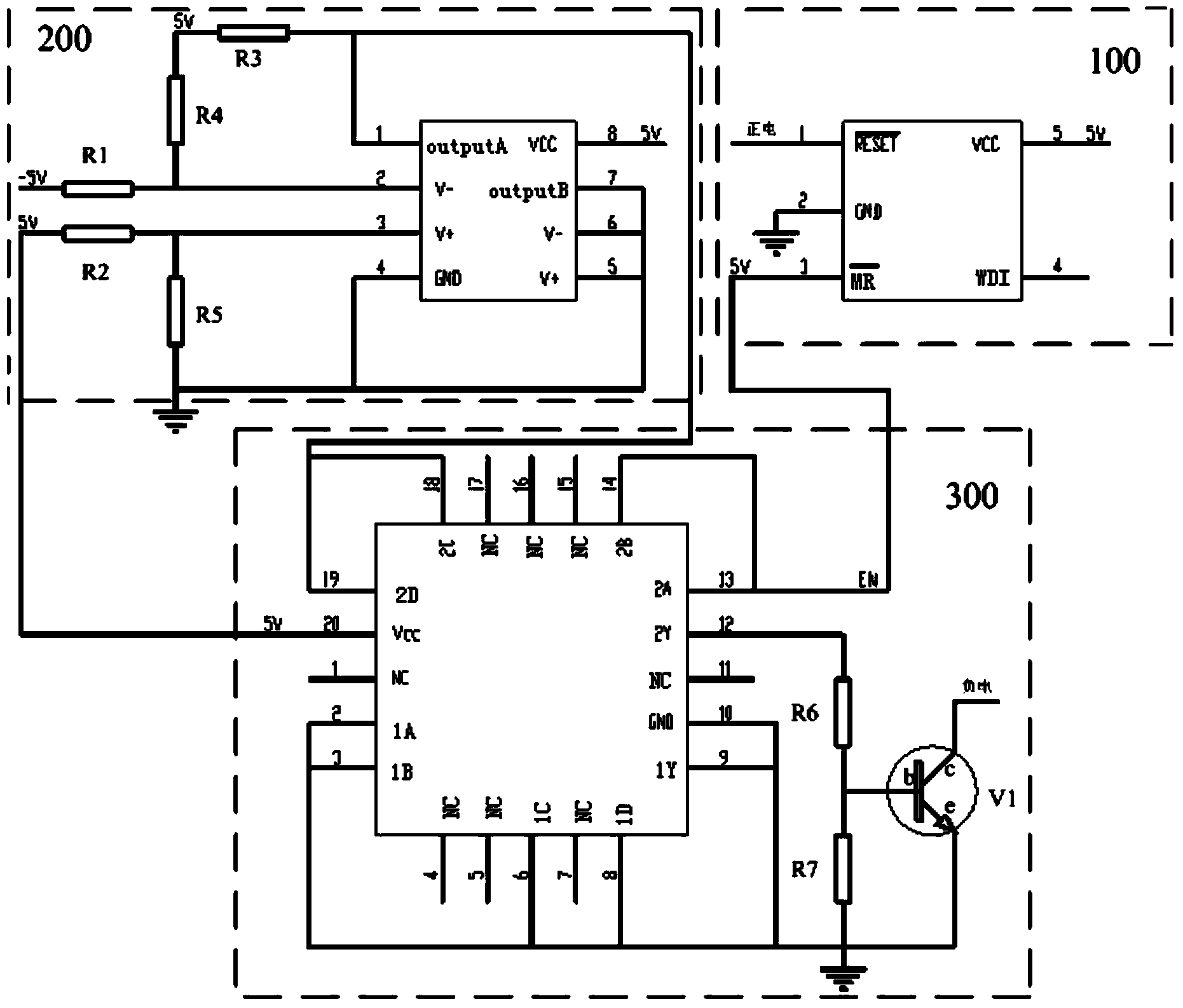

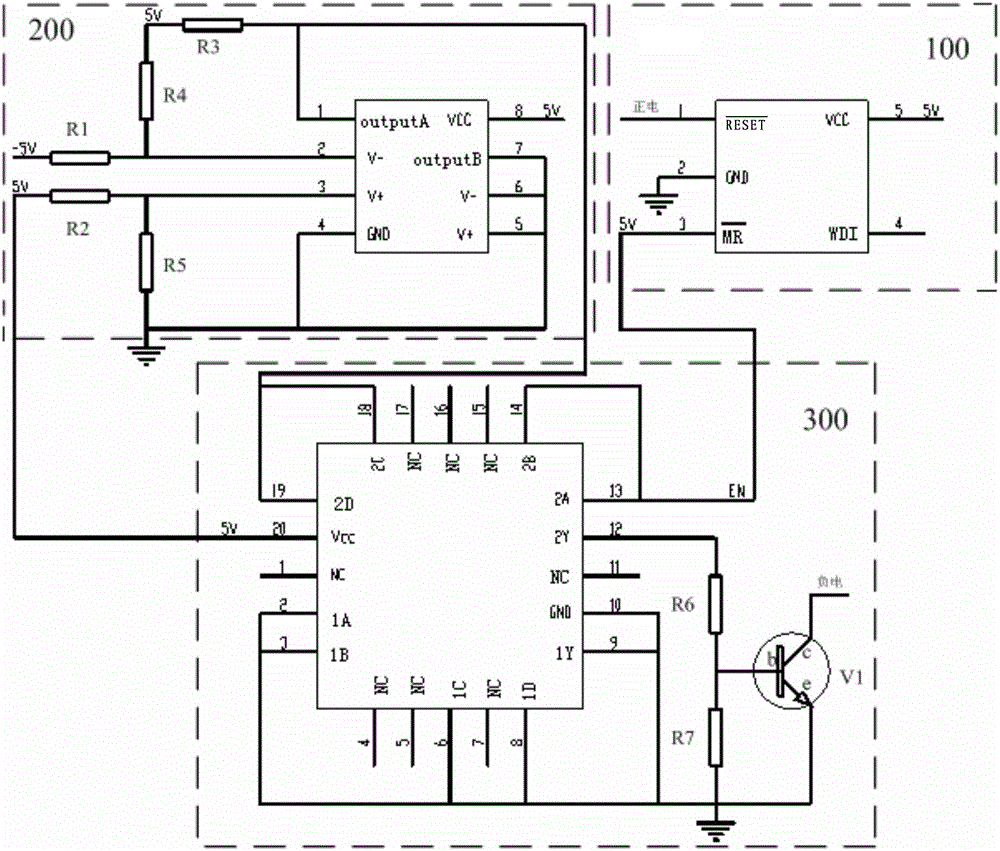

Circuit for achieving power supply sequential control

ActiveCN103955148AReduce failure rateEasy to controlProgramme control in sequence/logic controllersElectricityTime delays

The invention provides a circuit for achieving power supply sequential control, and belongs to the field of power supply sequential control. The circuit for achieving power supply sequential control is composed of a time delay circuit, a comparison circuit and a negative electricity control circuit. The simple circuits are additionally arranged by ingeniously utilizing multiple integrated chips, the negative electricity time delay power supply sequential control function is achieved, the logic protection function is achieved due to the fact that a hysteresis comparator is additionally arranged, and meanwhile antijamming capacity is enhanced, so that double guarantees of the circuit for achieving power supply sequential control on the time sequence and logic are achieved.

Owner:BEIJING RES INST OF TELEMETRY +1

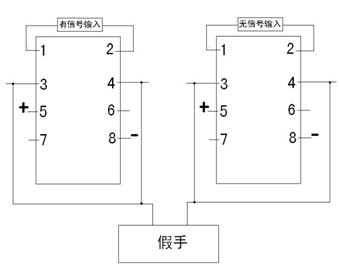

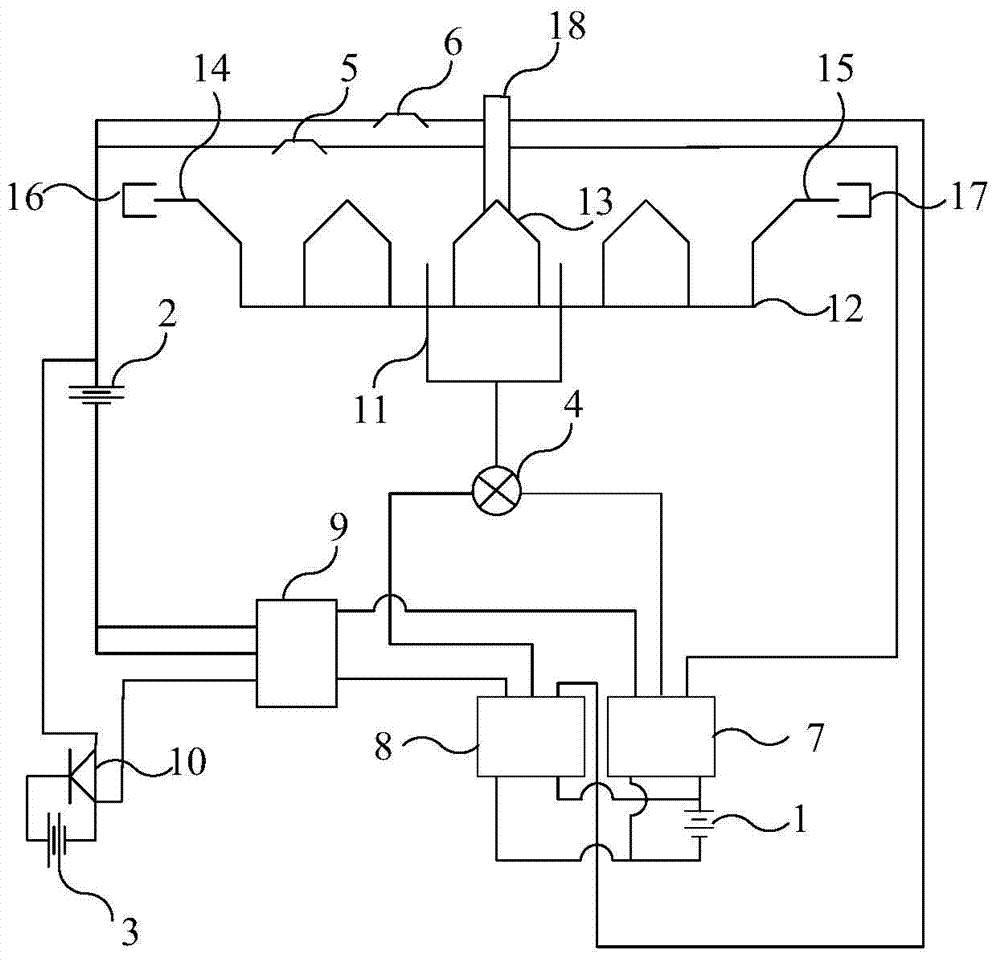

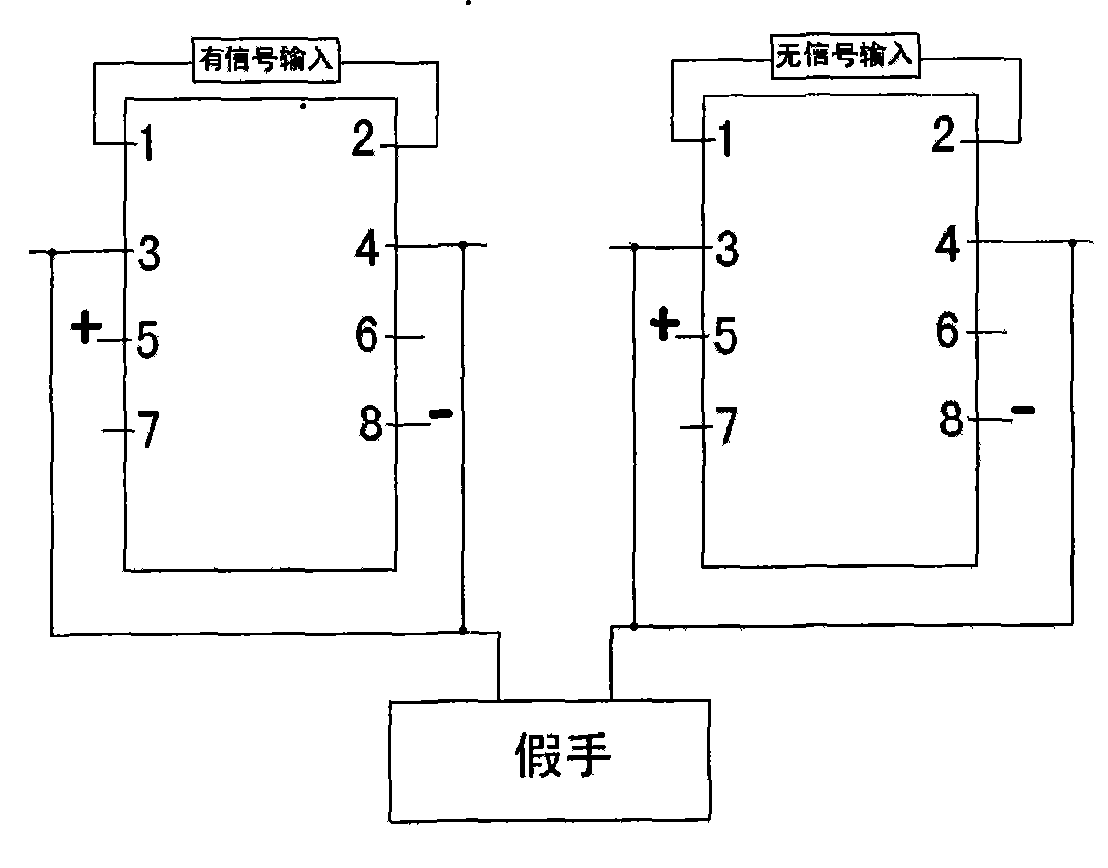

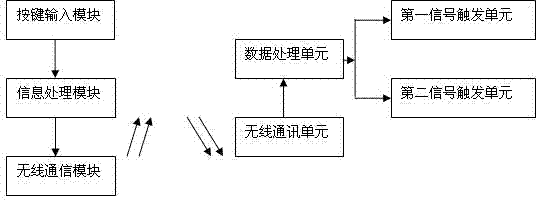

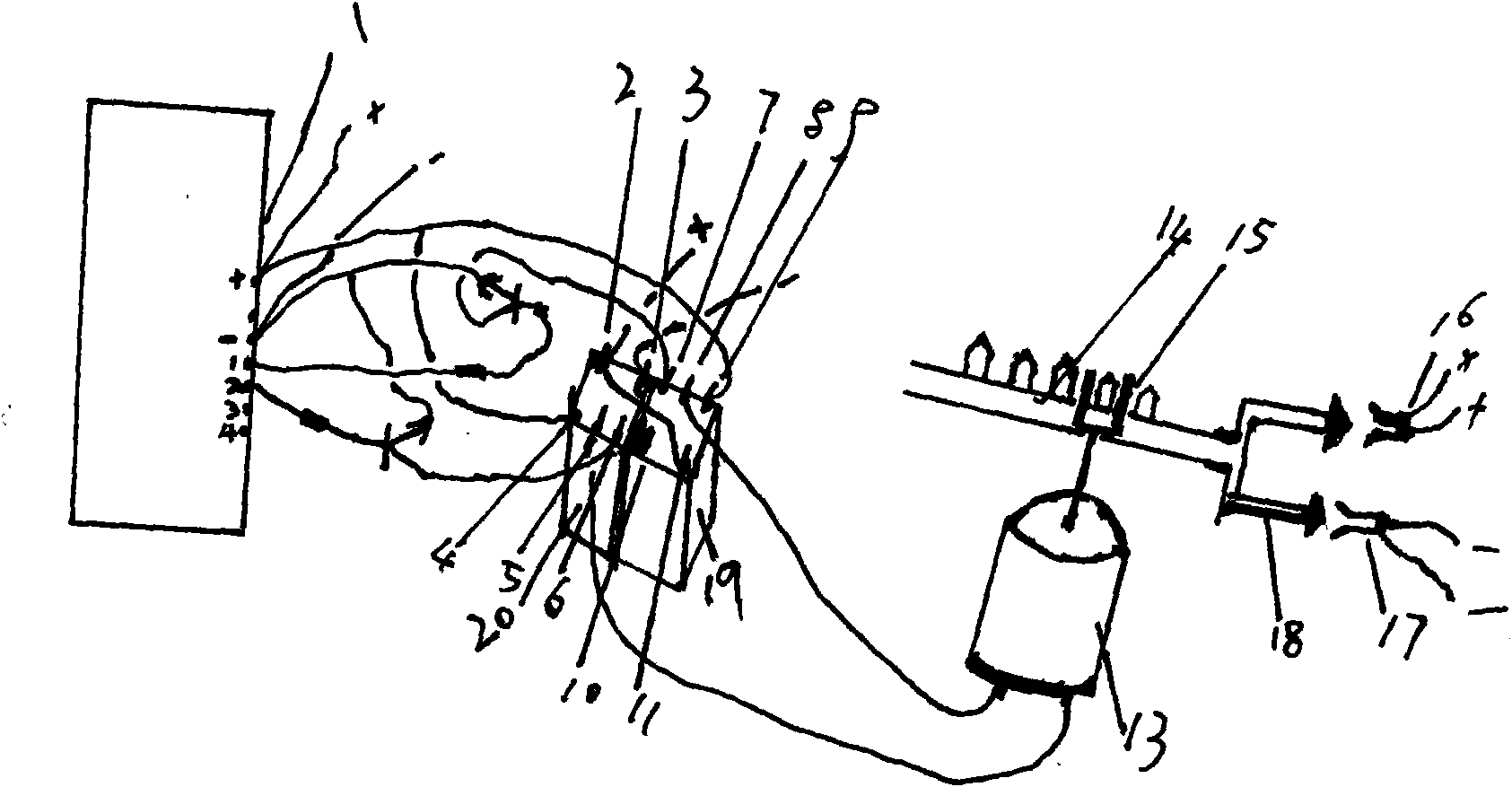

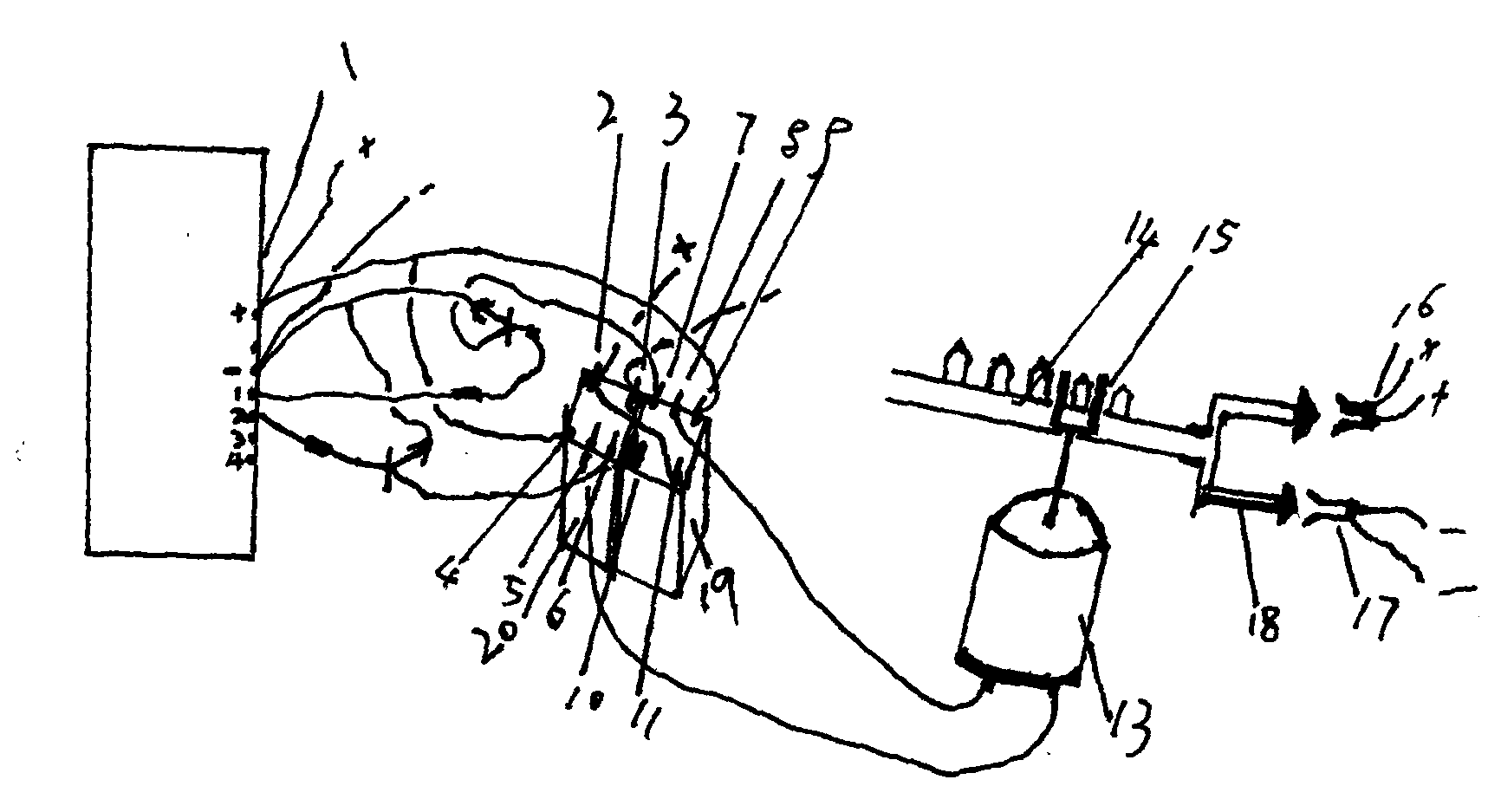

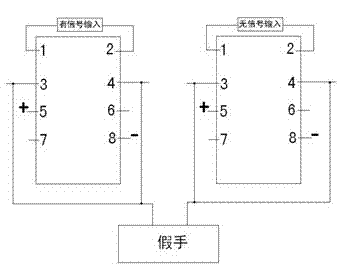

Method for integrating relays and remote control knife switch

The invention discloses the integration of relays and a remote control knife switch, which belong to electronic and machinery industries. A digital module or a voltage higher than 3V directly controls high voltage, intermediate links are reduced and the remote control knife switch is formed to make electricity utilization safe and convenient. The integration of the relays and the remote control knife switch solve the problem that a motor relay cannot be connected with the digital module or a microcomputer. A remote control absorption module (1) is connected with the two relays (19 and 20). Pins (2 and 1) of the two relays are connected with the anode of a power supply, the pins (3 and 10) of the two relays are connected with the cathode of the power supply, and the pins (5 and 8) of the two relays are connected with two electrodes of a motor (13) respectively. A sleeve fork (15) on a rotating shaft of the motor is downwards sleeved with a tooth of a rack (14). The tips of the sleeve fork on the rack (14) are provided with conducting strips, and correspond to leaf spring groups respectively. The leaf spring groups (16 and 17) are connected with a positive wire and a negative wire respectively. A signal voltage or voltage higher than 3V directly controls high-voltage heavy current; and the integration of the relays and the remote control knife switch are applied in various fields of industry, national defense, machinery, aviation, electronics, remote control and remote sensing and the like.

Owner:江苏麦浪建设科技有限公司

Electric cable take-up and pay-off barrow

Owner:STATE GRID CORP OF CHINA +1

Paint spraying device for controlling paint spraying thickness by changing moving speed

InactiveCN112058530AControl rotation speedControl movement speedLiquid spraying apparatusDrive wheelReciprocating motion

The invention relates to the related field of paint spraying machines, and discloses a paint spraying device for controlling the paint spraying thickness by changing the moving speed, which comprisesa moving body. A driving wheel cavity is formed in the moving body, a speed regulating cavity located on the right side of the driving wheel cavity is formed in the moving body, and a threaded body moving cavity is arranged on the right end wall of the speed regulating cavity in a communicating manner. A bevel gear cavity is arranged on the lower end wall of the speed regulating cavity in a communicating manner, a transmission gear cavity located on the lower side of the speed regulating cavity is formed in the moving body, the relative positions of a speed regulating gear and the bevel gear are controlled by rotating a lead screw, the rotating speed of a friction wheel is controlled, the moving speed of a spray head is controlled, and therefore the paint spraying thickness is controlled.Different requirements of different workpieces for the paint spraying thickness are met, the normal quality is greatly improved, meanwhile, sliding of a sliding block is controlled through thread fit,forward and reverse rotation of a friction wheel fixing shaft is controlled accordingly, reciprocating motion of the spray head is achieved, and the automation degree of equipment is improved.

Owner:三门蓝纪科技有限公司

An interior decoration wiring harness outlining device

ActiveCN112746722BControl speedControl positive and negativeDecorative surface effectsPretreated surfacesGear wheelEngineering

The present invention provides a wiring harness outline device for interior decoration, which effectively solves the problem in the prior art that when decorating walls and floors, the distance between the drawn oblique lines is not uniform, which affects the viewing effect in the later stage; it solves the problem The technical solution is to include a frame, a pulley is arranged on the frame, a synchronous belt is arranged between two pulleys on the pulley, and a rolling brush is arranged on the synchronous belt; a planetary gear mechanism is arranged on the rear side of the frame, and a second gear mechanism is arranged on the left side of the sun gear. A bevel gear, a second bevel gear is arranged on the pulley on the right side, a cylinder is arranged at the right end of the ring gear, a first friction wheel is arranged at the right end of the cylinder, a second friction wheel is arranged on the right side of the first friction wheel, the first friction plate and the second friction wheel There is a small friction wheel between the two friction discs, and a wheel is connected to the right end of the second friction wheel; the invention has an ingenious structure, which can outline the standard oblique lines or grid lines required by users according to certain rules, and can follow the pre-designed route Outline, in the process of outlining, ensure that the distance between lines is evenly distributed, easy to operate, and strong in adaptability.

Owner:YELLOW RIVER CONSERVANCY TECHN INST

library adjustable bookshelf

ActiveCN112056795BControl positive and negativeAvoid harmBook cabinetsBook-troughsInformation resourceEngineering

The present invention provides library adjustable bookshelves, including automatic tilt devices, book anti -slip device, and automatic clamping device. The upper bookshelf is slipped to the lower layer through the positive and reverse of the motor.The development of this country has a vital role. Among them, the main ways to read, and in order to facilitate the public reading, each country will set up a library in different institutions or units, because the library is collecting, organizing, collecting, collectionLibrary information for people's reading and reference institutions appeared in libraries as early as 3000 BC. The library has functions such as preserving human cultural heritage, development information resources, and participating in social education.The only device of the library book is bookshelves. There are many defects in the existing library bookshelves. The invention of the library of the present invention can effectively solve the defects of the existing library bookshelf.

Owner:马玲

Adjustable bookshelf for library

ActiveCN112056795AControl positive and negativeAvoid harmBook cabinetsBook-troughsInformation resourceEngineering

The invention provides an adjustable bookshelf for a library. The bookshelf comprises an automatic tilting device, a book anti-sliding device and an automatic clamping device. The upper layer of bookshelf slides to the lower layer through forward and reverse rotation of a motor, so that book borrowers and book managers can use the bookshelf conveniently; education plays a crucial role in development of each country; reading ways are main ways; in order to facilitate public reading, libraries are set up in different institutions or units by each country as the libraries are institutions for collecting, sorting and storing book materials for reading and reference of people; the libraries appear 3,000 years before christ; the library has the functions of saving human cultural heritage, developing information resources, participating in social education and the like; unique book collection equipment of the library is the bookshelf; an existing library bookshelf has many defects; and the adjustable bookshelf for the library effectively overcomes the defects of the existing library bookshelf.

Owner:马玲

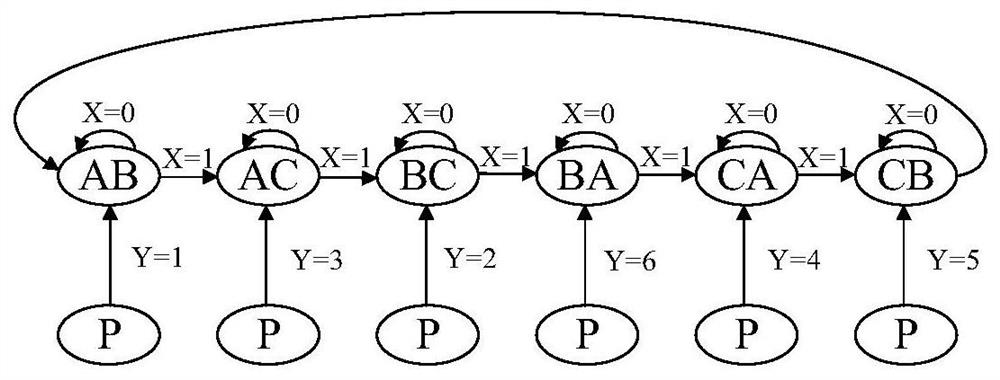

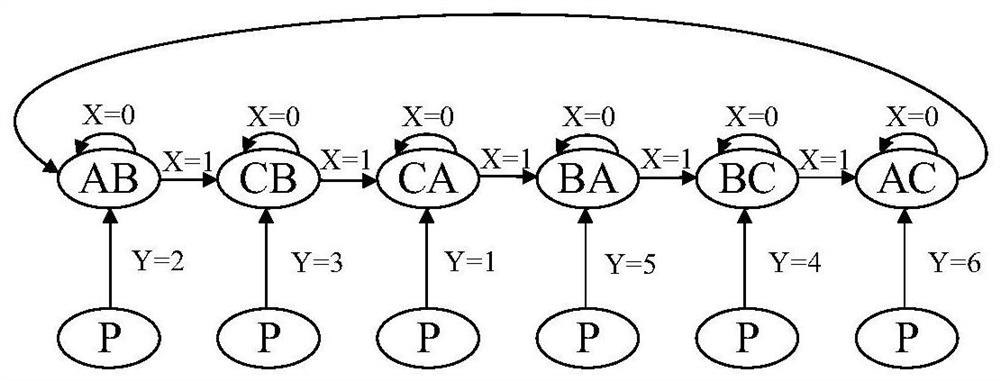

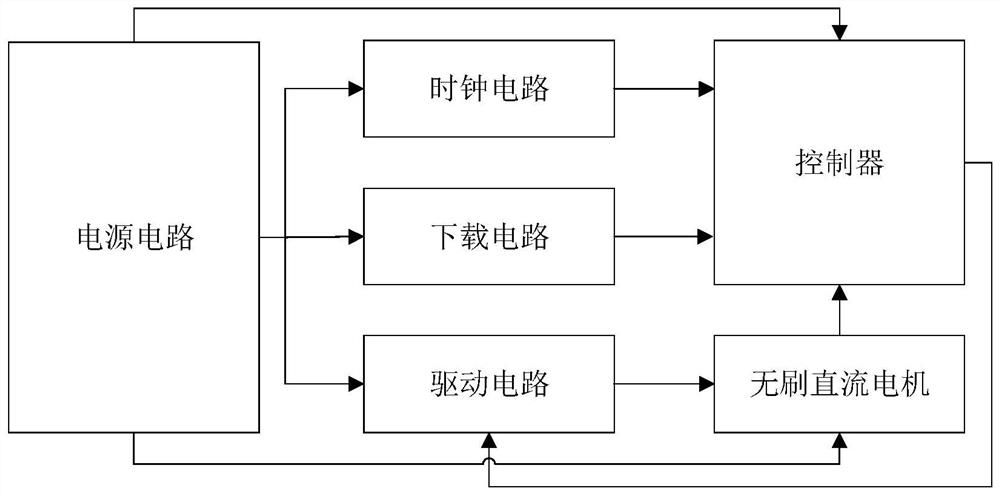

A Commutation Method of Brushless DC Motor Based on Digital Hall Sensor

ActiveCN109981000BImprove real-time controlControl positive and negativeElectric motor controlElectronic commutatorsElectric machineControl engineering

The invention discloses a brushless DC motor commutation method based on a digital Hall sensor. First, the speed difference between the rotor and the stator of the brushless DC motor reaches 10 Hz, and then the timer in the controller is used to capture the three-phase Hall control method. Word, then test the three-phase Hall control word, start the motor, and then enter the loop, when the controller detects the jump edge of the three-phase Hall, it will commutate the motor according to the set model, and finally realize the speed control of the motor . The invention can start the motor when the stator is rotating, make the motor commutate in the correct phase sequence, and control the speed of the motor. The invention has wide applicability and can be applied to brushless DC motors working in special environments.

Owner:NANJING UNIV OF SCI & TECH

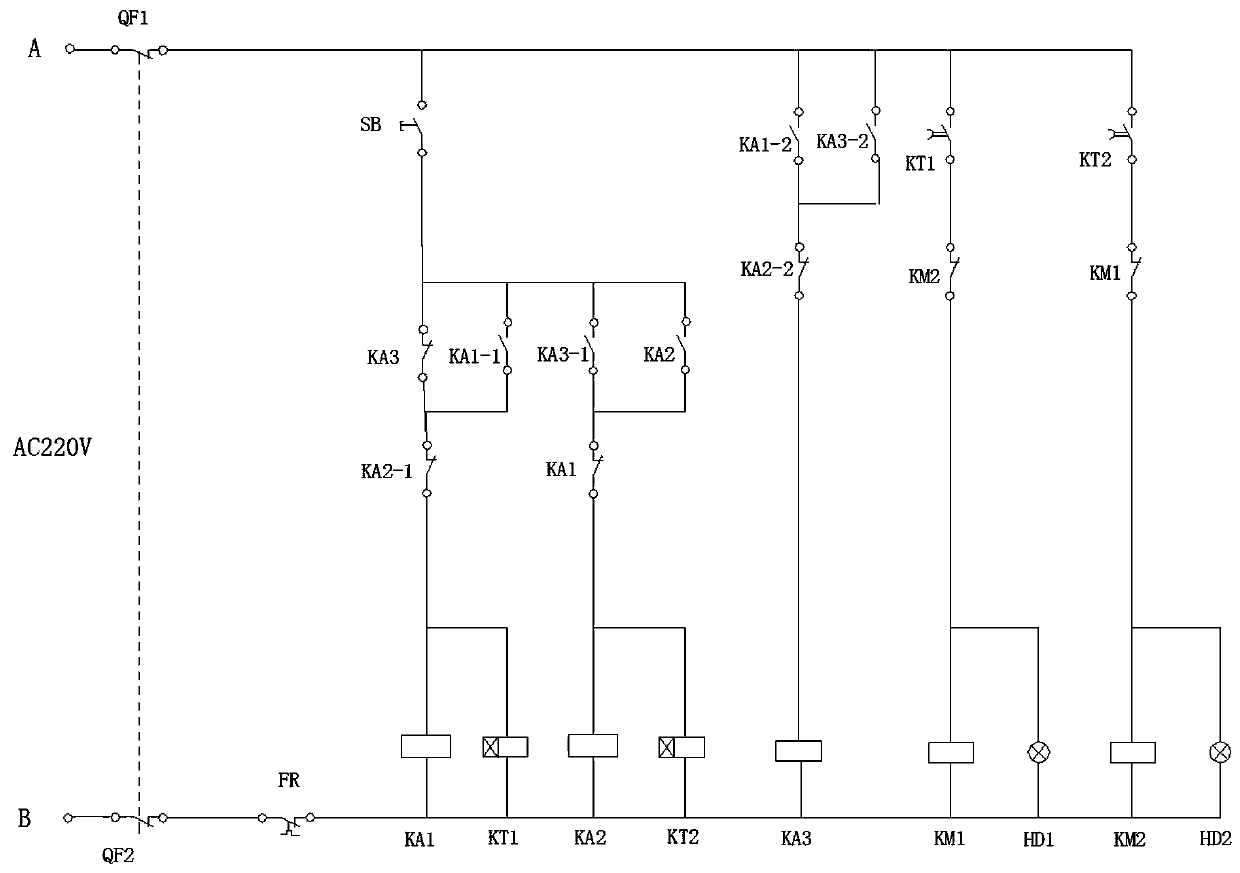

Single-button forward and reverse rotation automatic stop control circuit

PendingCN111585472AGuaranteed uptimeSimple and fast operationStarter detailsDynamo-electric converter controlControl engineeringAlternating current

The invention discloses a single-button forward and reverse rotation automatic stop control circuit. The circuit comprises a secondary line power supply port A and a power supply port B which are externally connected with a 220V alternating current power supply, a forward contactor KM1, a reverse contactor KM2, a forward intermediate relay KA1, a reverse intermediate relay KA2, a reversing intermediate relay KA3, a thermal relay FR, a forward time relay KT1, a reverse time relay KT2, bipolar circuit breakers QF1 and QF2, a button SB, a forward indicator lamp HD1 and a reverse indicator lamp HD2. The circuit is simple, easy and convenient to operate and reliable in operation, multiple protection is achieved, mechanical accidents and short-circuit accidents of a power supply cannot be causedby mistakenly pressing a positive and negative rotation button, and therefore normal operation of equipment is guaranteed.

Owner:ANHUI HUAMAO TEXTILE

A circuit for realizing power sequence control

ActiveCN103955148BReduce failure rateEasy to controlProgramme control in sequence/logic controllersElectricityTime delays

The invention provides a circuit for achieving power supply sequential control, and belongs to the field of power supply sequential control. The circuit for achieving power supply sequential control is composed of a time delay circuit, a comparison circuit and a negative electricity control circuit. The simple circuits are additionally arranged by ingeniously utilizing multiple integrated chips, the negative electricity time delay power supply sequential control function is achieved, the logic protection function is achieved due to the fact that a hysteresis comparator is additionally arranged, and meanwhile antijamming capacity is enhanced, so that double guarantees of the circuit for achieving power supply sequential control on the time sequence and logic are achieved.

Owner:BEIJING RES INST OF TELEMETRY +1

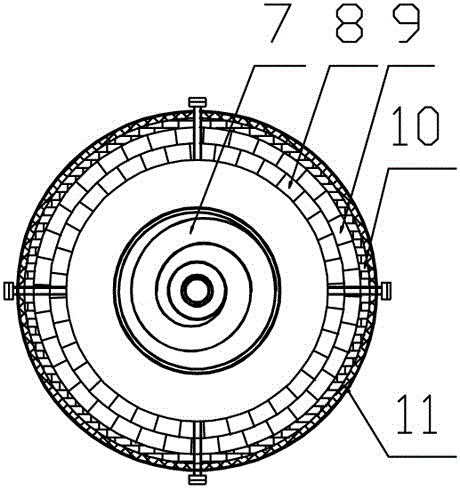

Electromagnetic clutch peristaltic pump

ActiveCN113931826AControl positive and negativeEasy to replacePositive displacement pump componentsFlexible member pumpsPeristaltic pumpElectromagnetic clutch

The invention particularly discloses an electromagnetic clutch peristaltic pump which comprises a mounting frame, a transmission device, a power device, a mounting plate and a plurality of peristaltic pump heads. The mounting plate is arranged on the inner side of the mounting frame, the mounting plate is in threaded connection with the mounting frame, the transmission device and the power device are both mounted on the mounting plate in a threaded manner, the peristaltic pump heads are detachably connected with the transmission device, and each peristaltic pump head is independently controlled by the transmission device. One or more peristaltic pump heads can be independently controlled, forward and reverse rotation, timing and quantitative control of the peristaltic pump heads can be achieved, each peristaltic pump head can be independently detached, and a water pipe is convenient to replace.

Owner:GUANGZHOU MAIGUANG ELECTRONIC TECHNOLOGY CO LTD

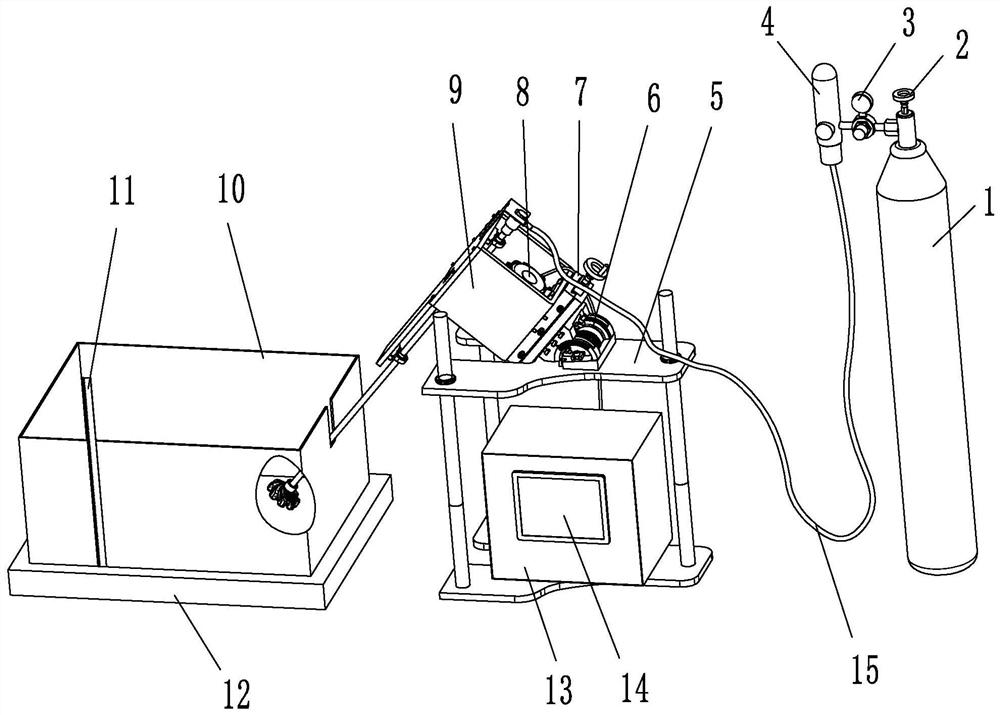

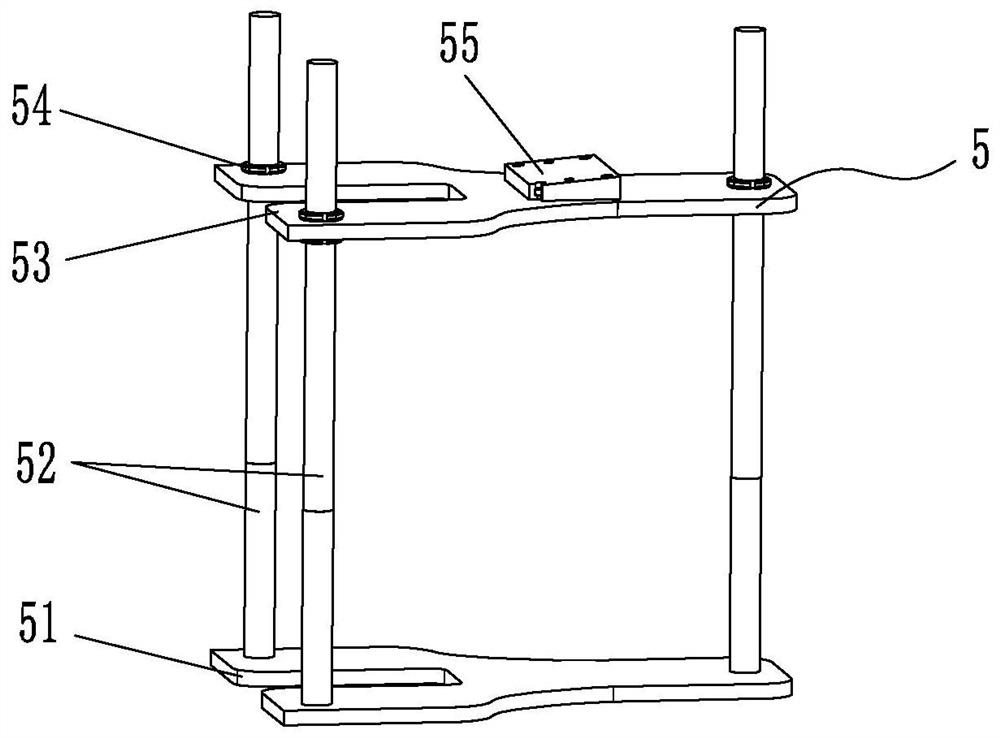

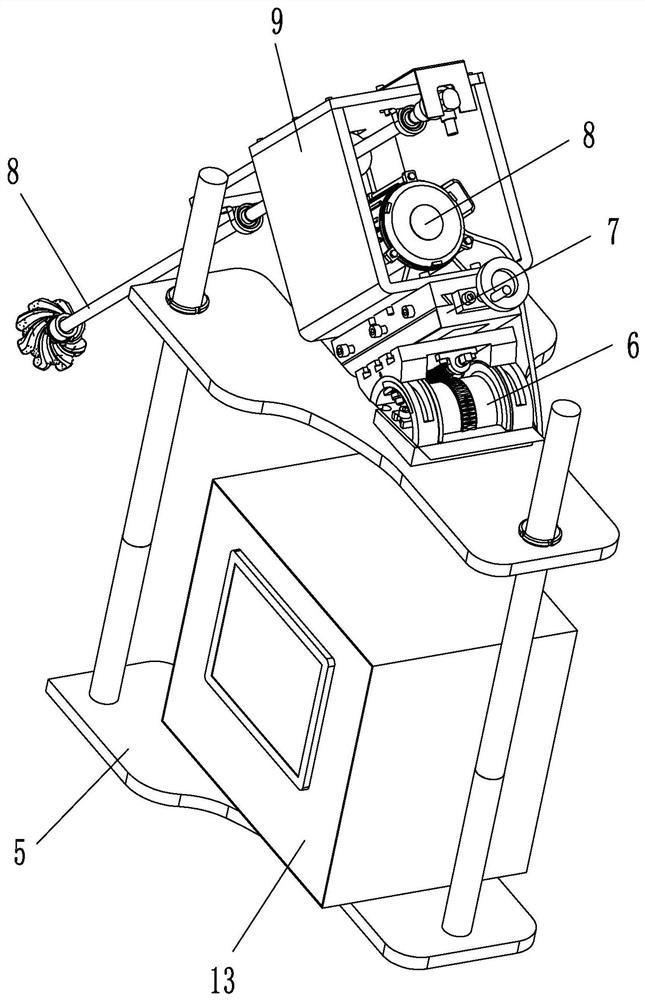

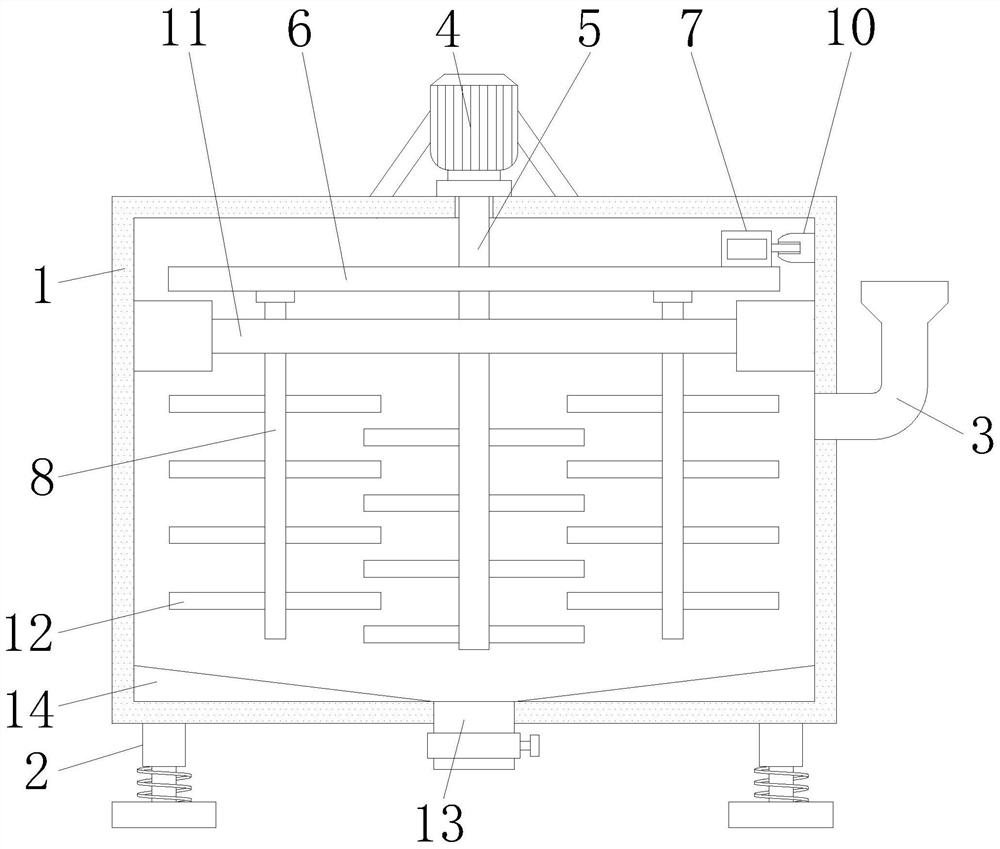

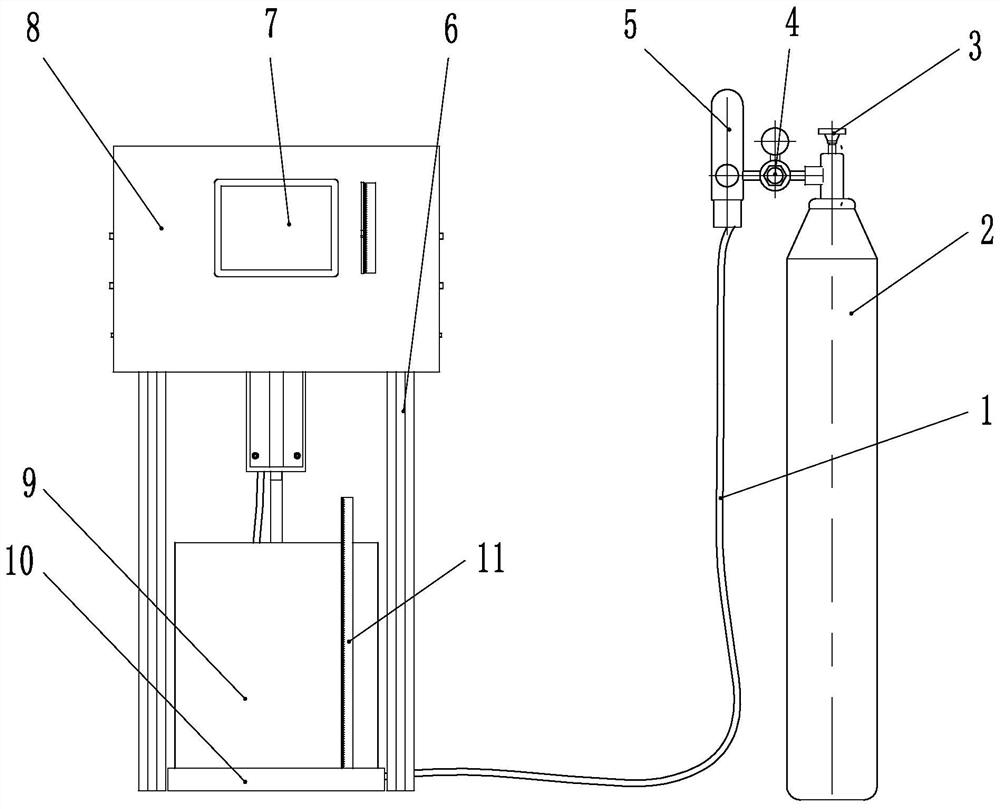

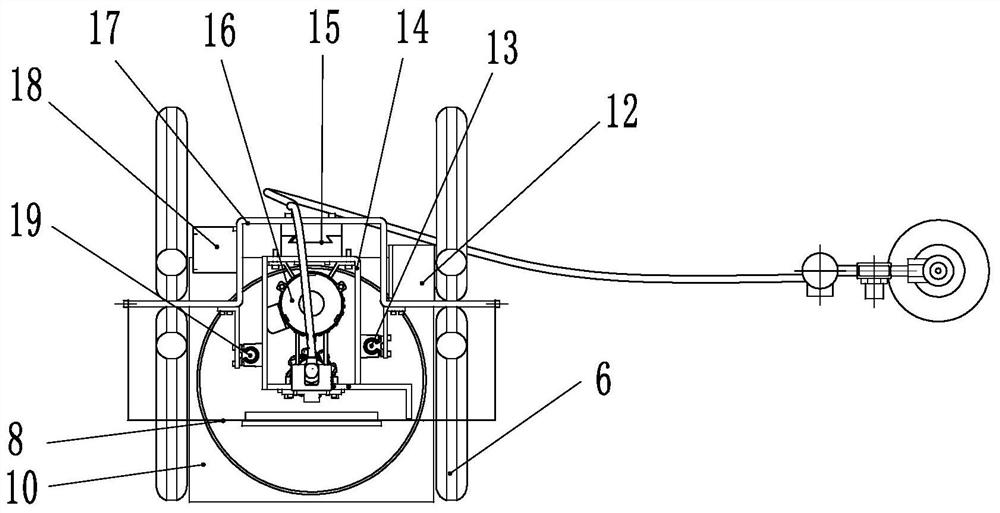

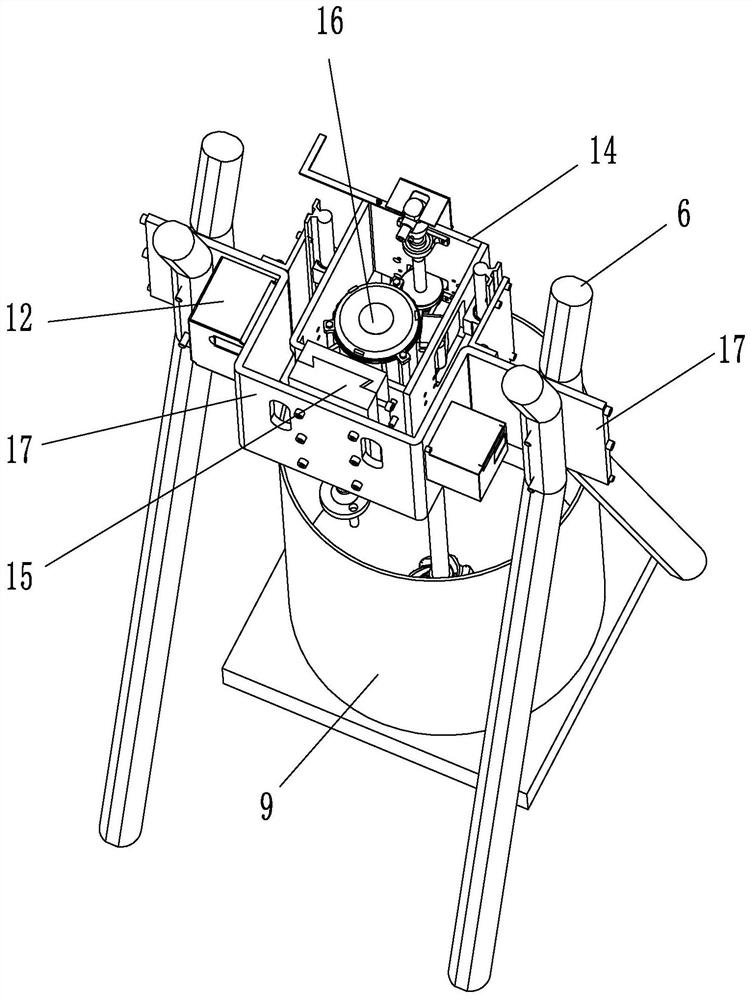

An inclined water simulation experimental device and experimental method for the purification process of aluminum melt

ActiveCN113049222BAccurate angle adjustmentAccurate adjustment positionHydrodynamic testingMaterial analysis by optical meansFrequency changerThermodynamics

The present invention relates to an inclined water simulation experiment device and an experiment method thereof in the process of purifying aluminum melt. Body, transparent container and PLC single-chip microcomputer used to control the transmission components. This method uses clarified water as the medium to simulate the aluminum alloy melt, and selects a transparent acrylic square bucket as the container for the water medium. The evolution process of the furnace realizes the simulation of the purification process in the furnace or on-line, and achieves a completely similar degree through the adjustment of the inclination angle. Through the simulation experiment carried out by the method of the present invention, it is possible to visually observe and record the flow field velocity distribution, bubble distribution and size in the transparent container, and finally realize the gas-liquid two-phase analysis of the opaque aluminum alloy melt under specific process conditions (for example: the shaft is inclined) Accurate prediction of the flow field.

Owner:柳州一阳科技股份有限公司

A kind of mixing equipment for eraser production

ActiveCN109747061BGuaranteed to move back and forth in reverseIncrease the range of dispersionNon-rotating vibration suppressionSound producing devicesElectric machineGear wheel

The invention relates to the technical field of eraser production equipment, and discloses a stirring device for eraser production, which includes an equipment box, four noise reduction mechanisms are arranged at the bottom of the equipment box, and the right side of the equipment box is A feed pipe is provided, a motor is fixedly installed in the middle of the top of the equipment box, the output shaft of the motor is fixedly connected to a rotating rod, and the bottom end of the rotating rod penetrates and extends to the inside of the equipment box, the The outer circular surface of the rotating rod is fixedly connected with a fixed plate, and the edge of the top of the fixed plate is provided with a knocking mechanism, and the bottom of the fixed plate is connected with two symmetrical rotating shafts through bearings, and the outer circle of the rotating shaft A round gear is socketed on the surface, and a single-pole double-throw switch is fixedly installed on the inner wall on the right side of the equipment box. The invention solves the problems that the stirring direction of the existing stirring equipment is one-way, the material dispersion range is small during stirring, the stirring is uneven, the stirring time is long, and the working efficiency is low.

Owner:安徽省潜山市创先实业有限公司

Nano insulation coating material dispenser

InactiveCN105148788AAvoid damageControl positive and negativeMixer accessoriesThrust bearingEngineering

The invention discloses a nano insulation coating material dispenser and relates to the machinery filed. The nano insulation coating material dispenser comprises a base, a horizontal rack, guide pillars, guide sleeves, a lifting mechanism and stirring mechanisms, wherein the guide sleeves are symmetrically distributed on the rack, the guide pillars are fixed at the top of the rack and matched with the guide sleeves, a thread through hole is formed in the center of the rack, the center of the top of the base is rotationally connected with a screw rod through a thrust bearing, the top of the screw rod is connected with the thread through hole, a horizontal rectangular through hole is formed in the base, the bottom of the screw rod is connected with a servo motor which is mounted in the rectangular through hole, and the stirring mechanisms are symmetrically distributed at two ends of the rack. According to the nano insulation coating material dispenser, the screw rod drives the rack so that the rack can lift, the operation process is stable, the movement precision and the safety are high, the two stirring mechanisms are adopted, the stirring efficiency is improved, the stirring mechanisms adopt two kinds of stirring shafts, no-dead-angle stirring is realized, the stirring effect is good, the structure is simple, the manufacturing cost is low, and the service life is long.

Owner:泰州市鑫润天冶金保温材料有限公司

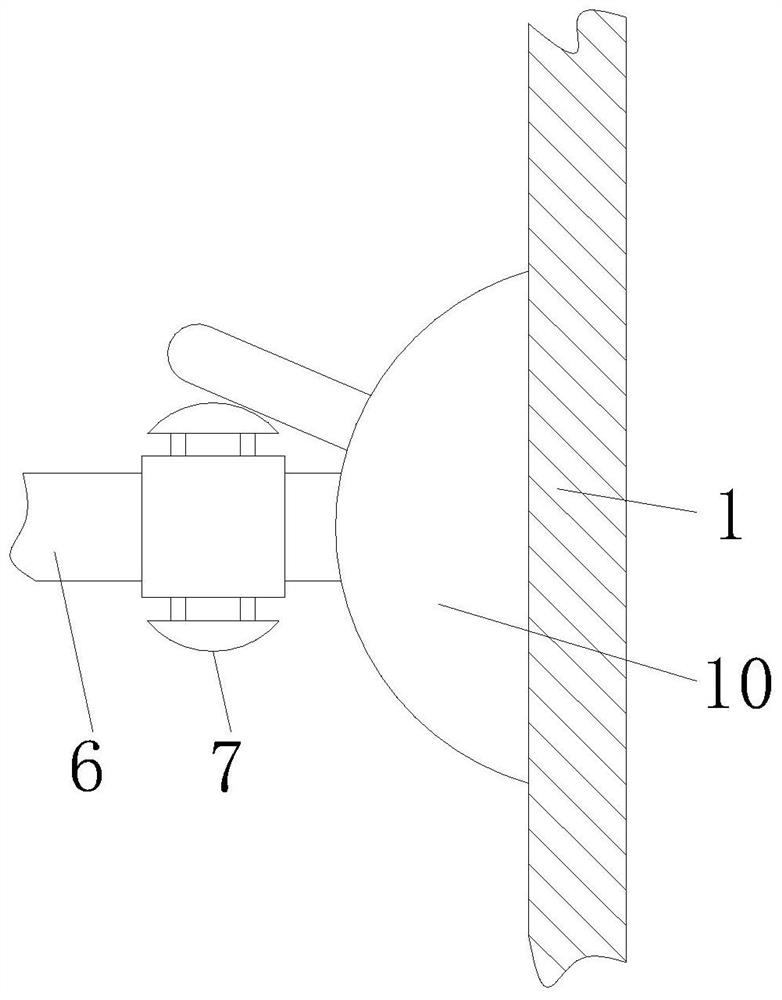

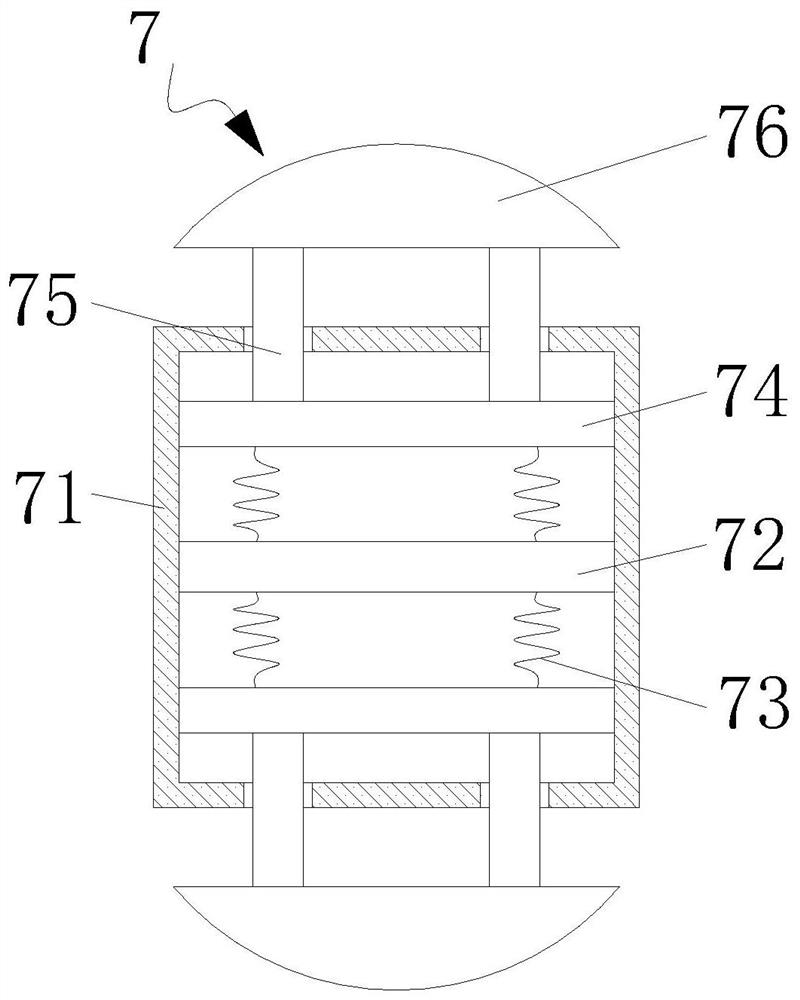

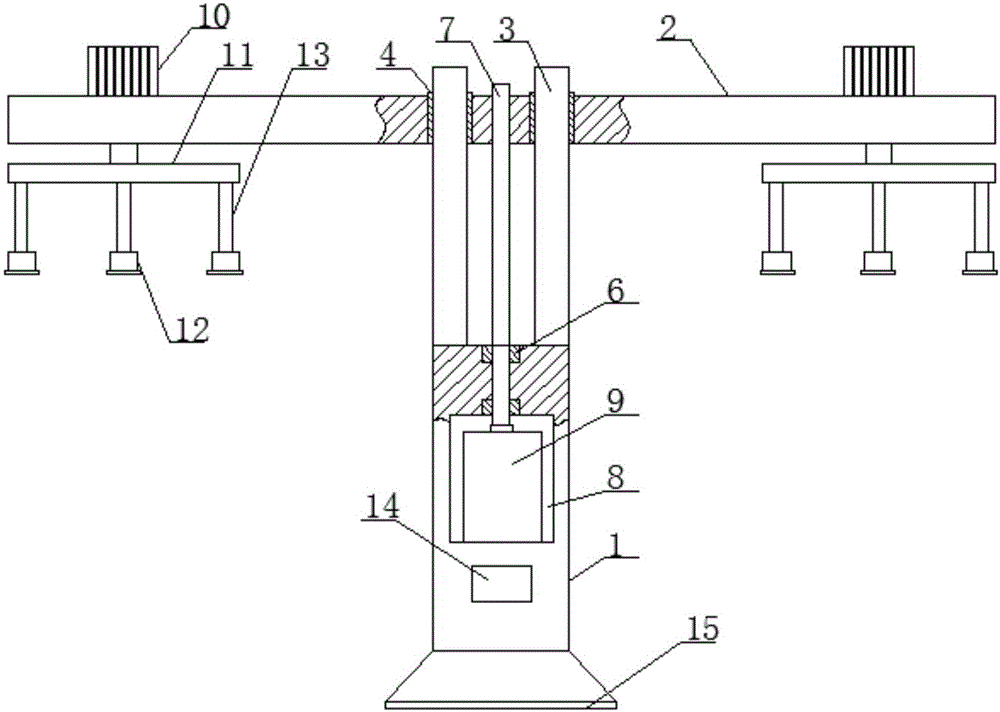

A vertical water simulation experimental device and experimental method for the purification process of aluminum melt

ActiveCN113049221BControl positive and negativeStepless speed adjustmentHydrodynamic testingMaterial analysis by optical meansFrequency changerThermodynamics

The invention relates to a vertical water simulation experimental device and an experimental method for the purification process of aluminum melts. The device includes an air source device, a bracket, a seat plate assembly, a sliding table assembly, a transmission assembly, a beam assembly, a PLC single-chip microcomputer, and a frequency converter , a panel and a transparent container, the device can steplessly adjust the speed of the rotating shaft, satisfying the research on the influence of different directions, different speeds, and running time on the generation of bubbles and the law of motion. This method adopts the aforementioned vertical water simulation experiment device, uses clarified water as the medium to replace the opaque aluminum alloy melt, selects a transparent acrylic cylinder as the container for the water medium, and observes the evolution process of the gas introduced in the water to realize the Similar simulation of the purification process of aluminum alloy melt outside the furnace. This method can visually observe and record the flow field velocity distribution, bubble distribution and size in the transparent container, and finally realize the accurate prediction of the gas-liquid two-phase flow field of the opaque aluminum alloy melt.

Owner:柳州一阳科技股份有限公司

Electronic artificial hand with voice/myoelectricity mixed control

The invention relates to an electronic artificial hand with voice / myoelectricity mixed control, comprising a voice control system, a myoelectricity control system, a voice control and myoelectricity control switching system and a voice switching control joint system, wherein the voice control and myoelectricity control switching system consists of voice recognition chips; when the voice recognition chips receive a voice command 'myoelectricity', a control signal is outputted to drive the myoelectricity control system to work; when the voice recognition chips receive a voice command 'voice', the voice recognition chips are communicated with the voice control system to control the artificial hand; and when the voice recognition chips receive a voice command 'collaboration', the voice control command received by the voice recognition chips is processed to output a control signal to the myoelectricity control system so as to switch joints of the artificial hand, and the voice control system and the myoelectricity control system work simultaneously. The electronic artificial hand comprises the voice control system and the myoelectricity control system and can switch corresponding control according to actual use conditions.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +1

Roller shutter dust catcher

InactiveCN104453976BControl positive and negativeAchieve liftingDust removalFire preventionPull forcePulp and paper industry

The invention relates to a roller shutter type dust collecting net device. The roller shutter type dust collecting net device comprises a frame body, a rotary shaft, a nylon net, a spraying pipe and a chain block, wherein the rotary shaft is installed between two supporting plates on the frame body, the nylon net is connected to the rotary shaft, the spraying pipe is fixed between the two supporting plates on the frame body, a water inlet connector and a spraying head are arranged on the spraying pipe, an installation plate is fixed to the outer side of the frame body, the chain block is installed on the outer side of the installation plate, and a rotary shaft of the chain block is connected with one end of the rotary shaft. In addition, the nylon net is coated with a dedusting agent. The roller shutter type dust collecting net device is reasonable in design, simple in structure, safe, reliable, easy and convenient to maintain, high in mechanical efficiency, small in hand chain pulling force, low in self weight, convenient to install and durable. Due to the arrangement of the spraying pipe, the nylon net and the dedusting agent, dust can be well prevented from exceeding the standard, a safe production environment is created for workers, and the labor intensity of workers is relieved.

Owner:TONGMEI DATANG TASHAN COAL MINE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com