Electric cable take-up and pay-off barrow

An electric and wire car technology, which is applied in the field of cable take-up and pay-off cars, can solve problems such as inconvenient construction, troublesome take-up and take-up and take-up, waste of manpower, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

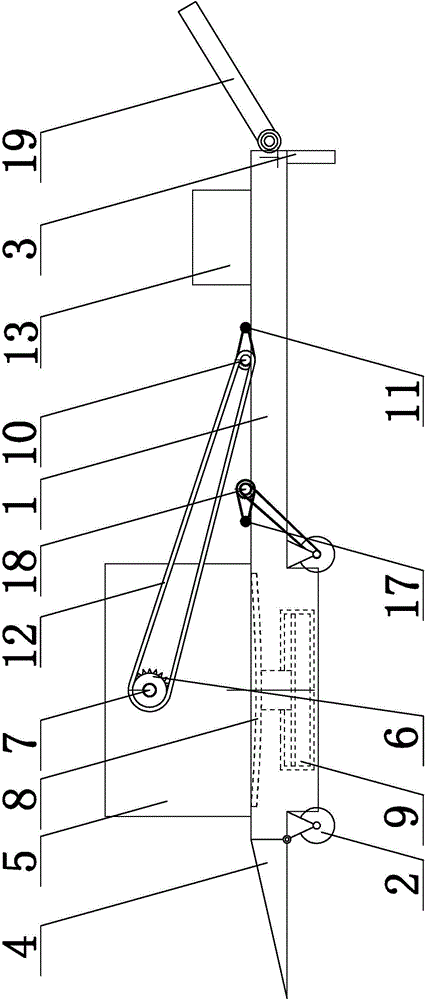

[0020] Embodiment 1: as figure 1 As shown, the electric cable take-up and pay-off car of the present invention comprises a car body 1, four wheels 2 are provided at the bottom of the car body 1, two supports 3 are provided on one side of the car body 1, and two supports 3 are provided on the other side of the car body 1. There is a pedal 4, and the pedal 4 is in a hinged relationship with the car body 1. The car body 1 is provided with two opposite baffles 5 adjacent to the pedal 4, and the corresponding positions on the two baffles 5 are installed with transmission parts 6 through bearings. , the transmission part 6 is provided with a through hole, is provided with a rotating shaft 7, and the two ends of the rotating shaft 7 pass through the through holes of the two transmission parts 6, and the car body 1 is provided with a groove relative to the position between the two baffle plates 5, and in the groove A curved plate 8 is provided, the highest point of the curved plate 8 ...

Embodiment 2

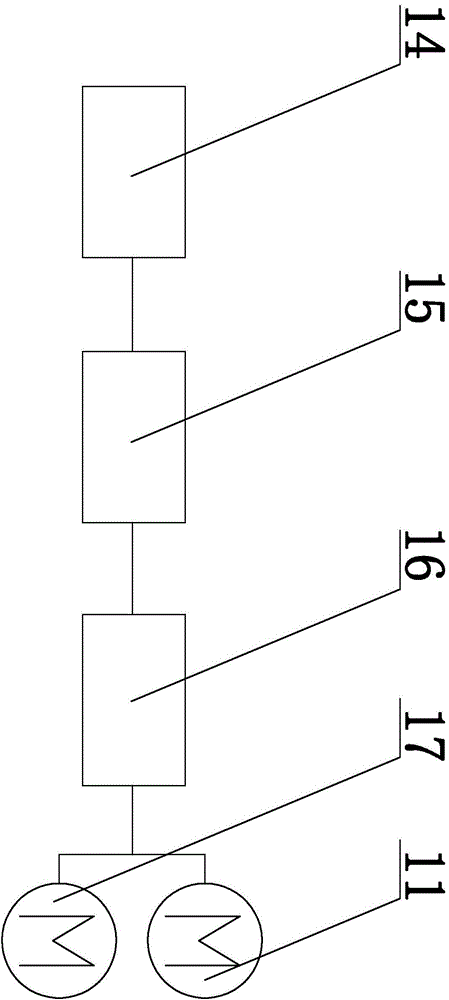

[0021] Embodiment 2: on the basis of the structure described in embodiment 1, as figure 2 As shown, the power supply 13 includes a battery 14, a voltage-stabilizing inverter 15 and a frequency converter 16, the battery 14 is connected to the frequency converter 16 through the voltage-stabilizing inverter 15, and the output terminal of the frequency converter 16 is connected to the power supply end of the motor 11, and the motor 11 The power supply terminal is connected to the output terminal of the frequency converter 16 through the phase commutation device.

Embodiment 3

[0022] Embodiment 3: on the structural basis described in embodiment 2, be provided with motor B17, be provided with gear on the rotor of motor B17, be provided with transmission shaft B18, gear cooperate with transmission shaft B18 by chain, set on the rotating shaft of wheel 2 There are gears, the power transmission shaft B18 cooperates with the gears on the wheel shaft through the chain, and the middle position on the side where the support 3 is installed on the car body 1 is hinged with a pull rod 19 .

[0023] Operation steps and working principle:

[0024] When using the electric cable take-up and pay-off car, first step on the pedal 4 so that one side thereof is in contact with the ground, and the operator can roll the cable drum so that it rushes onto the pedal 4 and falls into the In the arc-shaped plate 8, it is guaranteed that it will not roll randomly. The cable drum is lifted by the jack 9. When the center of the drum is concentric with the center of the through h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com