Integrated forward and reverse rotation alternating-current contactor

An AC contactor, integrated technology, applied in the direction of non-polar relays, etc., can solve the problems of dazzling connection wires, laborious brains, etc., to save costs, reduce the number of uses, and facilitate maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

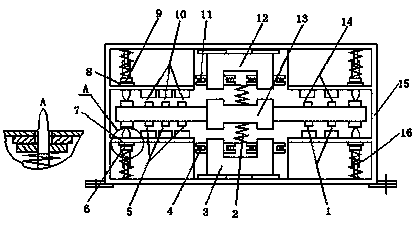

[0008] As shown in the figure: when the forward rotation start button is pressed, the forward rotation coil 4 is energized and the forward rotation static iron core 3 generates electromagnetic suction to attract the armature 13. The forward rotation main contact 5 is closed, and the forward rotation auxiliary normally open contact 1 is closed. The forward rotation auxiliary normally closed moving contact 6 overcomes the resistance of the contact spring 16 and is disconnected from the forward rotation auxiliary normally closed static contact 7, and the motor is energized to rotate forward. Press the reverse start button, the reverse coil 11 is energized and the reverse static iron core 12 generates electromagnetic suction to attract the upper armature 13, the reverse main contact 10 is closed, the reverse auxiliary normally open contact 14 is closed, and the reverse auxiliary normally closed The moving contact 9 overcomes the resistance of the contact spring 16 and is disconnect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com