A Commutation Method of Brushless DC Motor Based on Digital Hall Sensor

A brush DC motor and Hall sensor technology, which is applied in the field of commutation of brushless DC motors based on digital Hall sensors, can solve problems such as commutation disorder, and achieve the effect of improving real-time performance and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

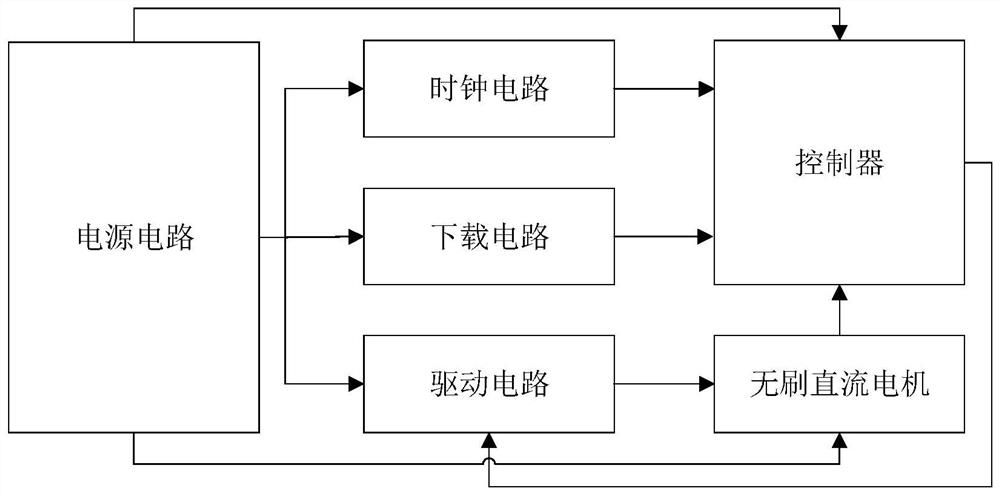

[0032] The experimental platform of the brushless DC motor commutation method based on the digital Hall sensor of the present invention includes a high-speed turntable, an elastic body and a torque motor. The projectile is equipped with a brushless DC motor, and the high-speed turntable drives the projectile to rotate counterclockwise. The arm of the torque motor is fixed with the rotor of the brushless DC motor, and the torque motor drives the rotor of the brushless DC motor to rotate clockwise. . After the high-speed turntable and the torque motor rotate at 5 Hz clockwise and 5 Hz counterclockwise respectively, the brushless DC motor is started, and the rotor of the brushless DC motor can be reduced to a certain speed according to the commutation method of the present invention. Realize the starting and control of the brushless DC motor in this special state.

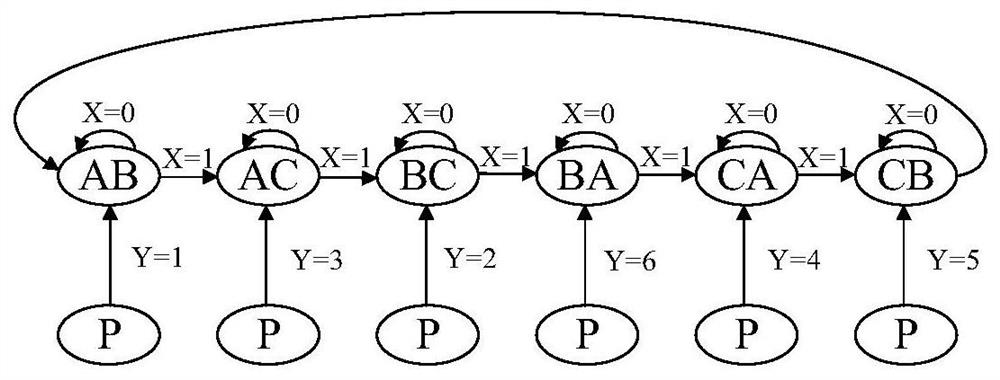

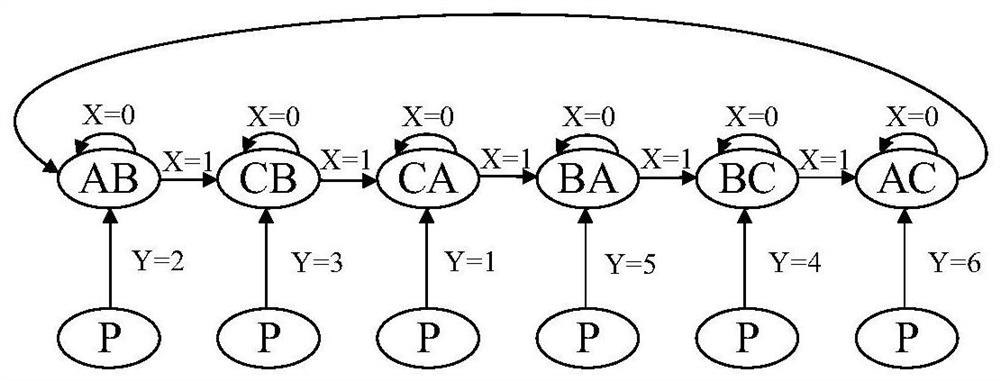

[0033] The brushless DC motor includes three parts: a motor body, a commutation circuit and three position sensors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com