An inclined water simulation experimental device and experimental method for the purification process of aluminum melt

A simulated experimental device, inclined technology, applied in the direction of measuring device, fluid dynamics test, material analysis through optical means, etc., can solve the problems that affect reliability, fail to reach the similar level, and cannot realize gas, etc., to achieve The structure of the device is reasonable, the experimental method is simple, and the effect is reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

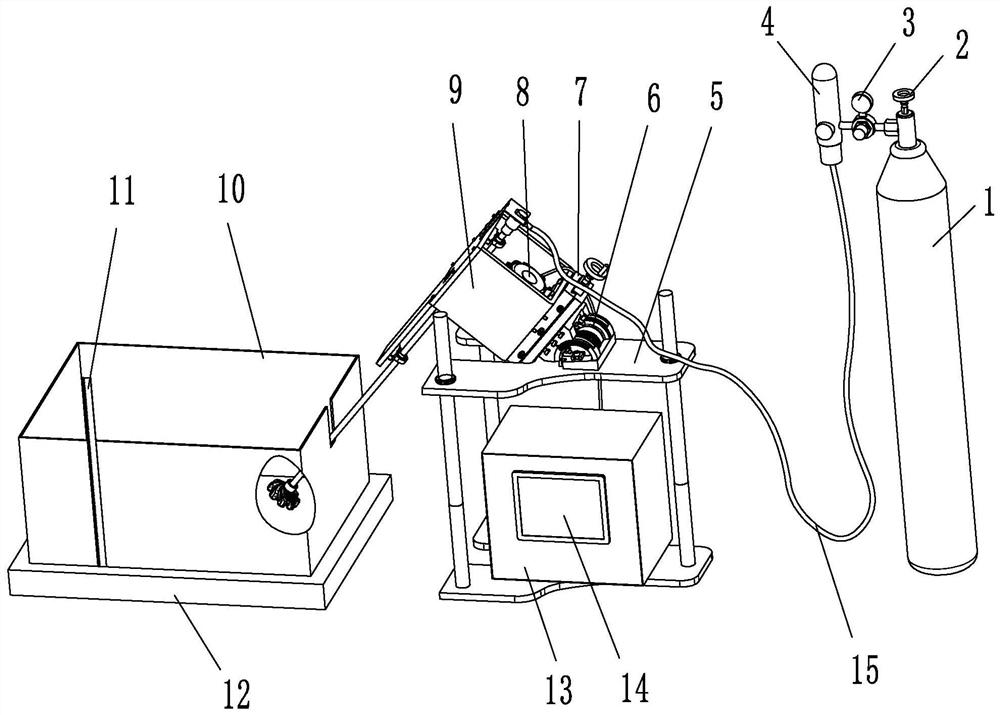

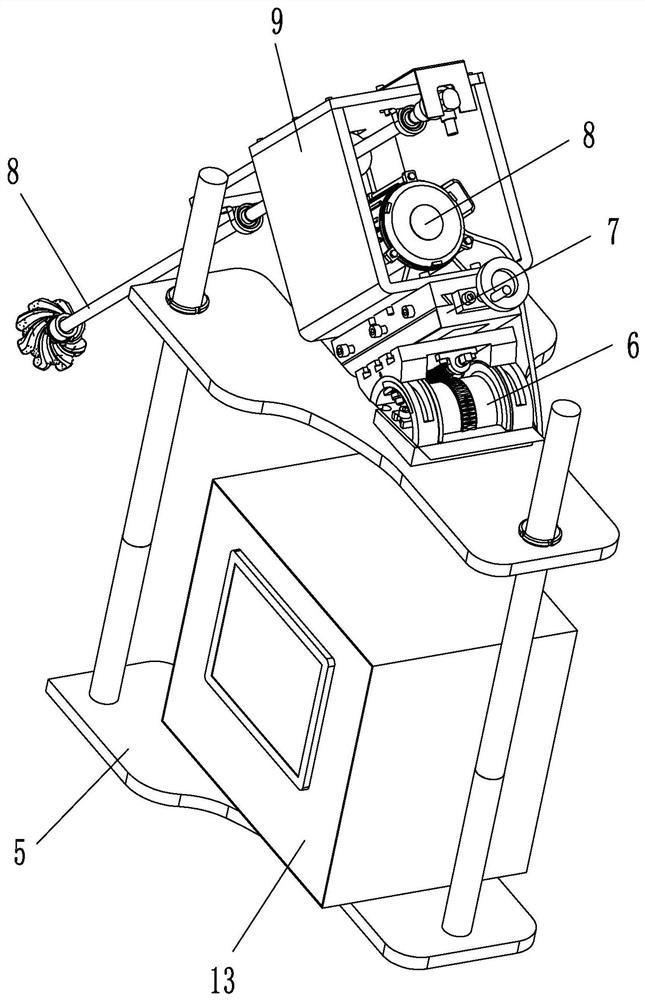

[0063] Example 1: A tilting water simulation experiment device for the purification process of aluminum melt, such as Figure 1-Figure 11 As shown, it includes an air source device 1, a frame 5, a motor bracket 9, a sliding table assembly 7, a transmission assembly 8, an inclined table assembly 6, a frequency converter 16, a control cabinet 13, a transparent container 10 and a device for controlling the transmission assembly. PLC microcontroller17.

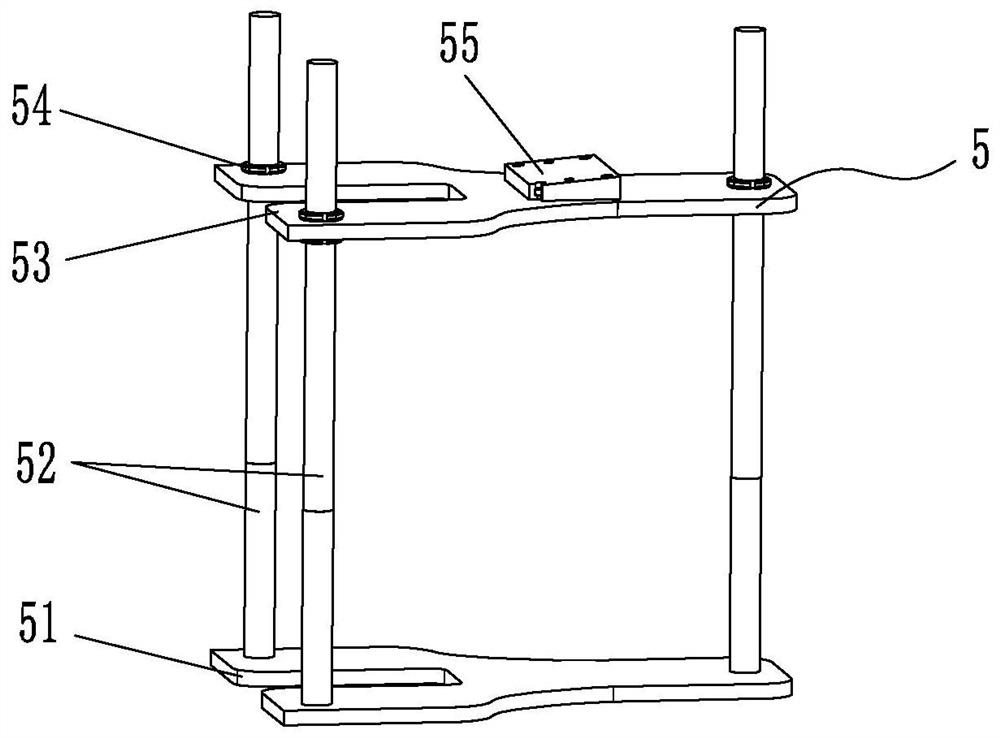

[0064] The frame 5 includes a base plate 51, a moving plate 53 and a pillar 52, the moving plate is installed above the base plate through a round nut 54, and a backing plate 55 for installing the tilting table assembly is also provided on the moving plate, the pad The upper end surface of the plate is inclined, and the backing plate is fixed on the moving plate by screws.

[0065] The motor bracket 9 includes a U-shaped frame 91 , a clamping plate 92 and a cover plate 93 , the cover plate is mounted on the U-shaped frame, and th...

Embodiment 2

[0076] Example 2: An inclined water simulation experiment device for the purification process of aluminum melt, the basic structure of which is the same as that of Example 1, the difference is: according to the actual size of the impeller in the aluminum alloy refining process of 400mm, according to the ratio of 1:3.5 , using a high-precision plastic filament fused deposition 3D printer to form a porous impeller, the diameter of the porous impeller is 110mm, and there are 168 radial injection holes of 0.5mm in the radial direction. Choose high-transparency acrylic material, and prepare a 940mm×830mm×500mm square barrel according to the ratio of 1:3.5 (the size of the melting furnace liner is 3300mm×2500mm×2000mm, and the height of the aluminum alloy melt is 900mm).

Embodiment 3

[0077] Example 3: A tilting water simulation experiment device for the purification process of aluminum melt, the basic structure of which is the same as that of Example 1, the difference is that according to the actual size of the impeller in the aluminum alloy refining process of 400mm, according to the ratio of 1:4.5 , A high-precision plastic filament fused deposition 3D printer is used to form a porous impeller. The diameter of the porous impeller is 90mm, and there are 120 radial injection holes of 0.5mm in the radial direction. Choose high-transparency acrylic material, and prepare a square barrel of 730mm×560mm×350mm according to the ratio of 1:4.5 (the size of the melting furnace liner is 3300mm×2500mm×2000mm, and the height of the aluminum alloy melt is 900mm).

[0078] Design concept and working principle of the present invention are:

[0079] 1. In order to increase the overall stability of the mechanism operation and reduce the vibration caused by elastic deformat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com