Test bed for simulating reliability of power servo knife rest of numerical control machine tool under real working condition

A servo tool holder and CNC machine tool technology, which is applied in the testing of mechanical parts, machine/structural parts testing, instruments, etc., can solve the problem that the power servo tool holder needs to be replaced with the backing plate of the power servo tool holder, the angle of the loading mechanism and the XYZ three-dimensional Inconvenient to adjust, unable to apply cutting fluid and other problems, to achieve the effect of accurate adjustment angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

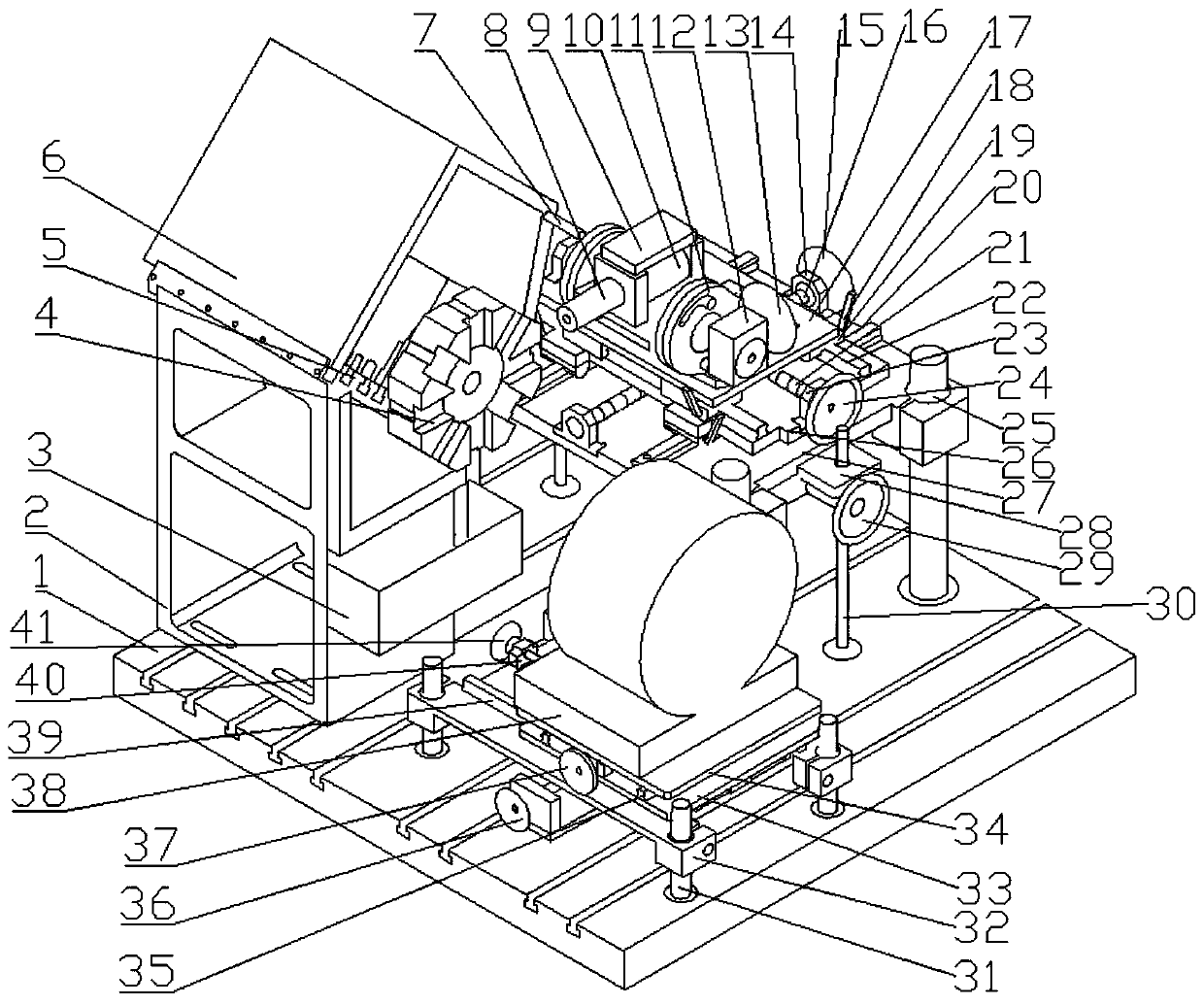

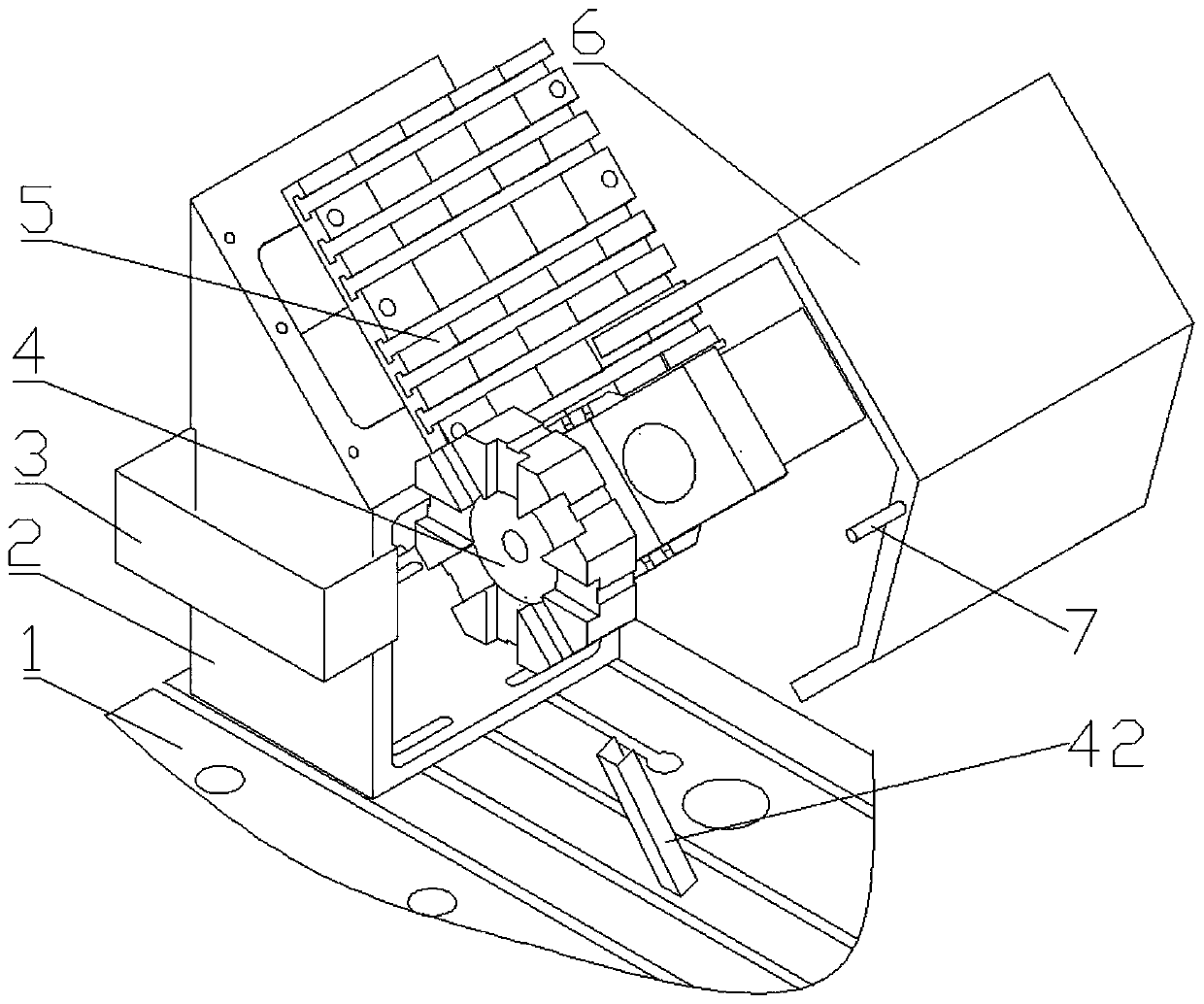

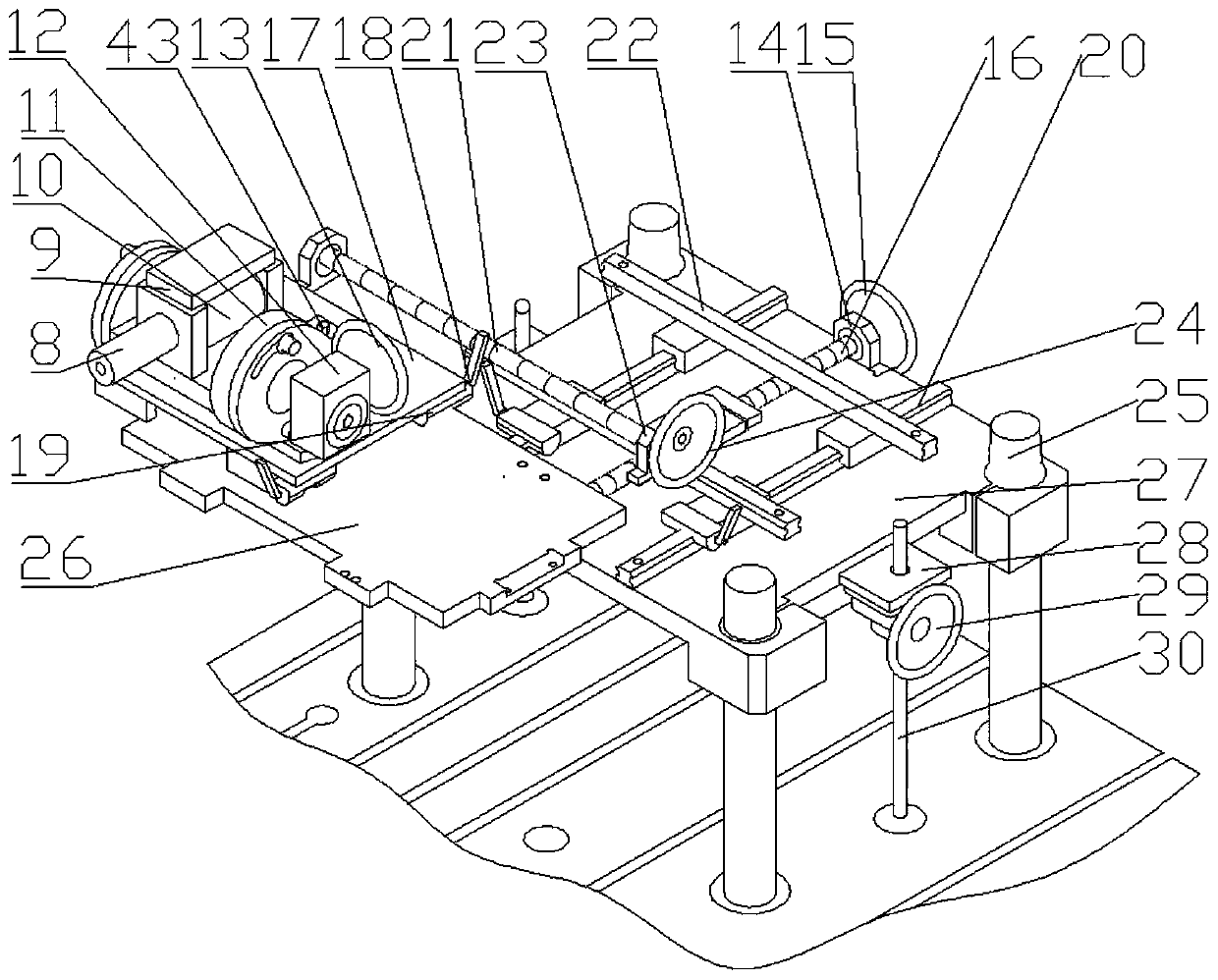

[0030] The present invention is described in detail below in conjunction with accompanying drawing:

[0031] refer to figure 1 According to the present invention, the test bench for the reliability of CNC machine tool power servo tool holder under simulated real working conditions is composed of a power servo tool holder support part, a cutting force loading part, a torque loading part, and a cutting fluid spray protection and cutting fluid recovery device.

[0032] 1. Power servo tool post support part

[0033] refer to figure 1 , figure 2 , The power servo tool holder supporting part includes a power servo tool holder support base 2 , a power servo tool holder backing plate 5 and a power servo tool holder 4 .

[0034] The base 2 of the power servo knife rest is an empty box structure, which is welded by seven flat steel plates. In order to save the weight of the box, the middle part of the plate is removed, and a reinforcing plate is set in the middle. The top surface an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com