Light reflecting film and photovoltaic battery assembly

A light-reflecting film and light-reflecting technology, applied in photovoltaic power generation, electrical components, circuits, etc., can solve the problems of not considering the angle between light and reflecting surface, and not being fully utilized, so as to improve laying accuracy and utilization rate , Improve the effect of reflection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

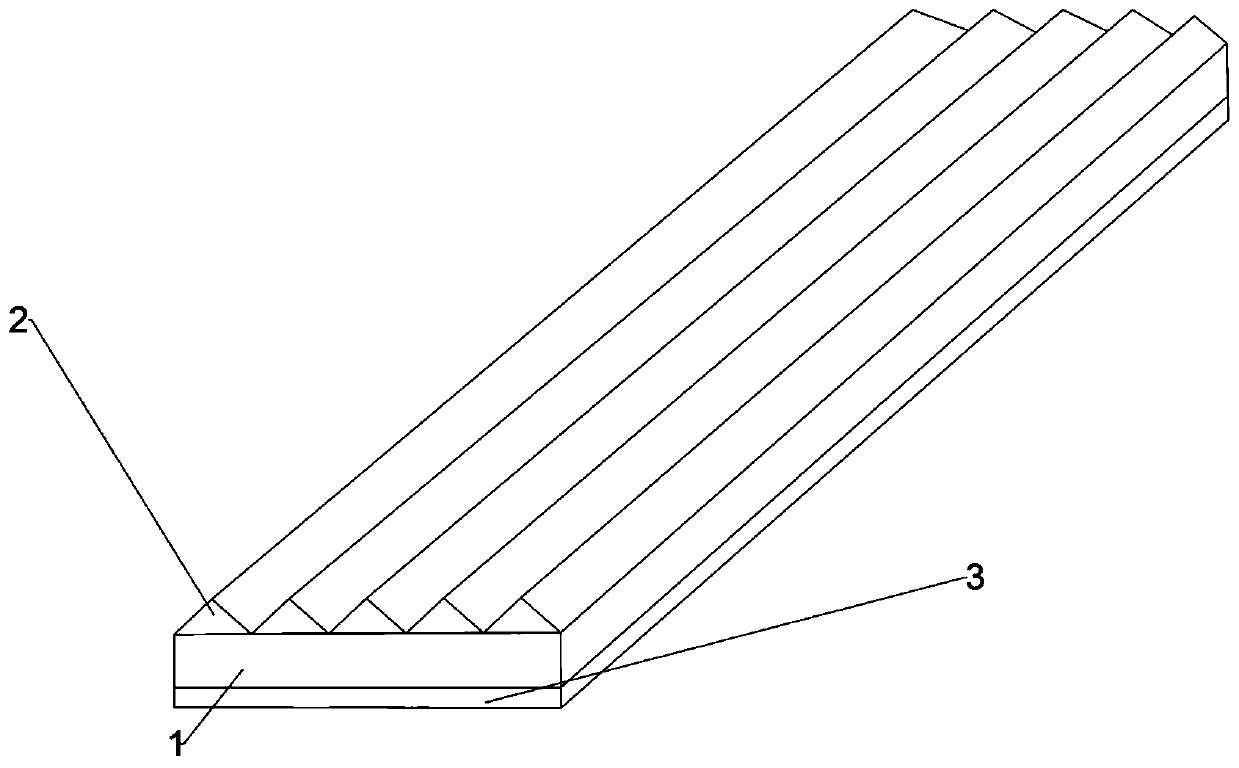

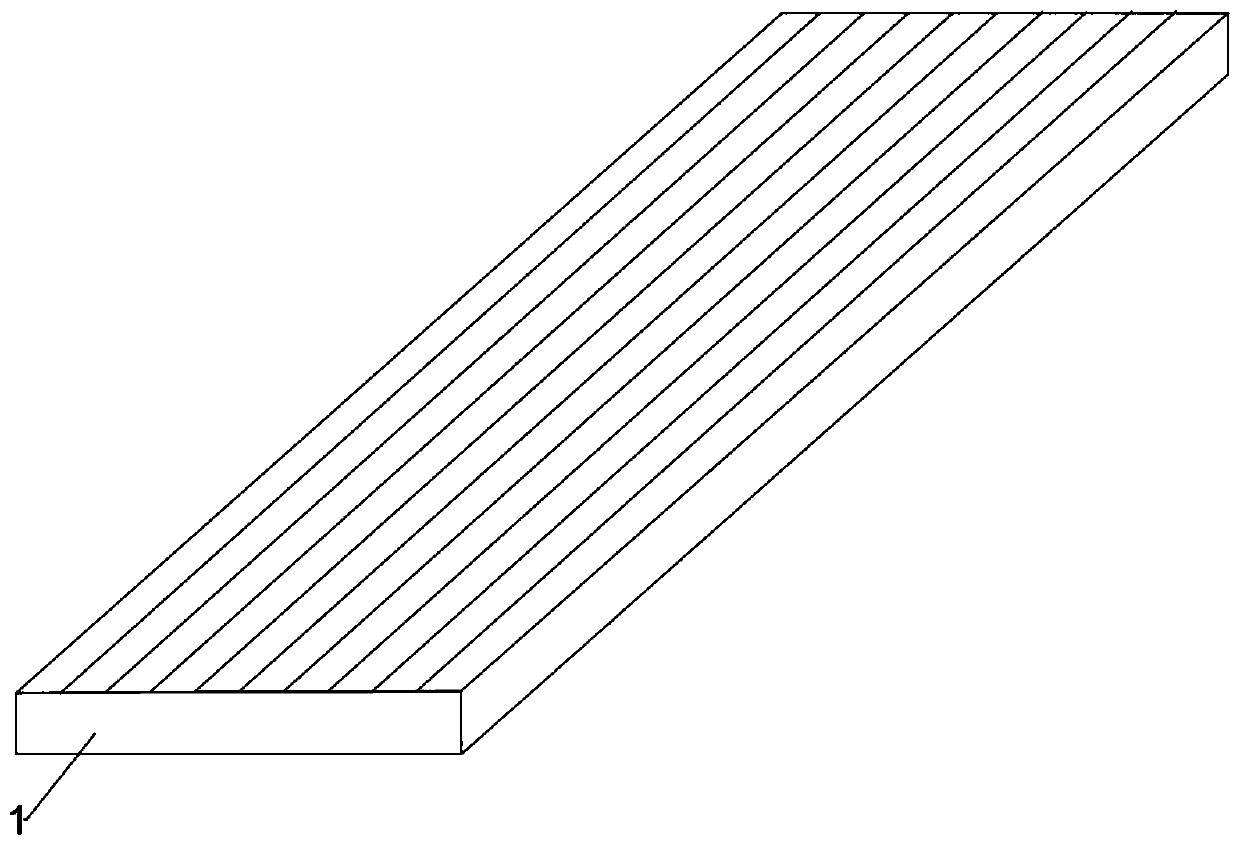

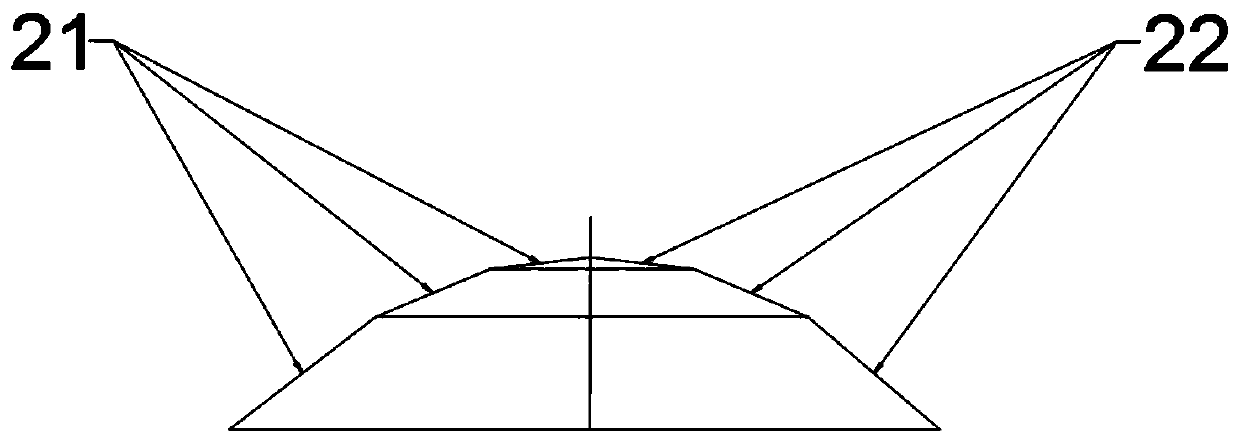

[0035] The invention provides a light reflective film and a photovoltaic cell assembly, the working principle of which is to control the angle of reflected light by setting the angle of the reflective surface, so that the light reflected to the surface of the photovoltaic cell is controlled within a smaller angle, maximizing Make the light shine directly on the surface of the photovoltaic cell, so as to achieve the maximum vertical reflection of the incident light irradiated on the gap between the ribbon and the battery string to the surface of the battery, and improve the utilization rate of light energy irradiated on the surface of the ribbon and the gap between the battery string.

[0036] The present invention will be described in further detail below in conjunction with ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com