Patents

Literature

45 results about "Finger extension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Clamp Device to Plicate the Stomach

Owner:PHILLIPS EDWARD H

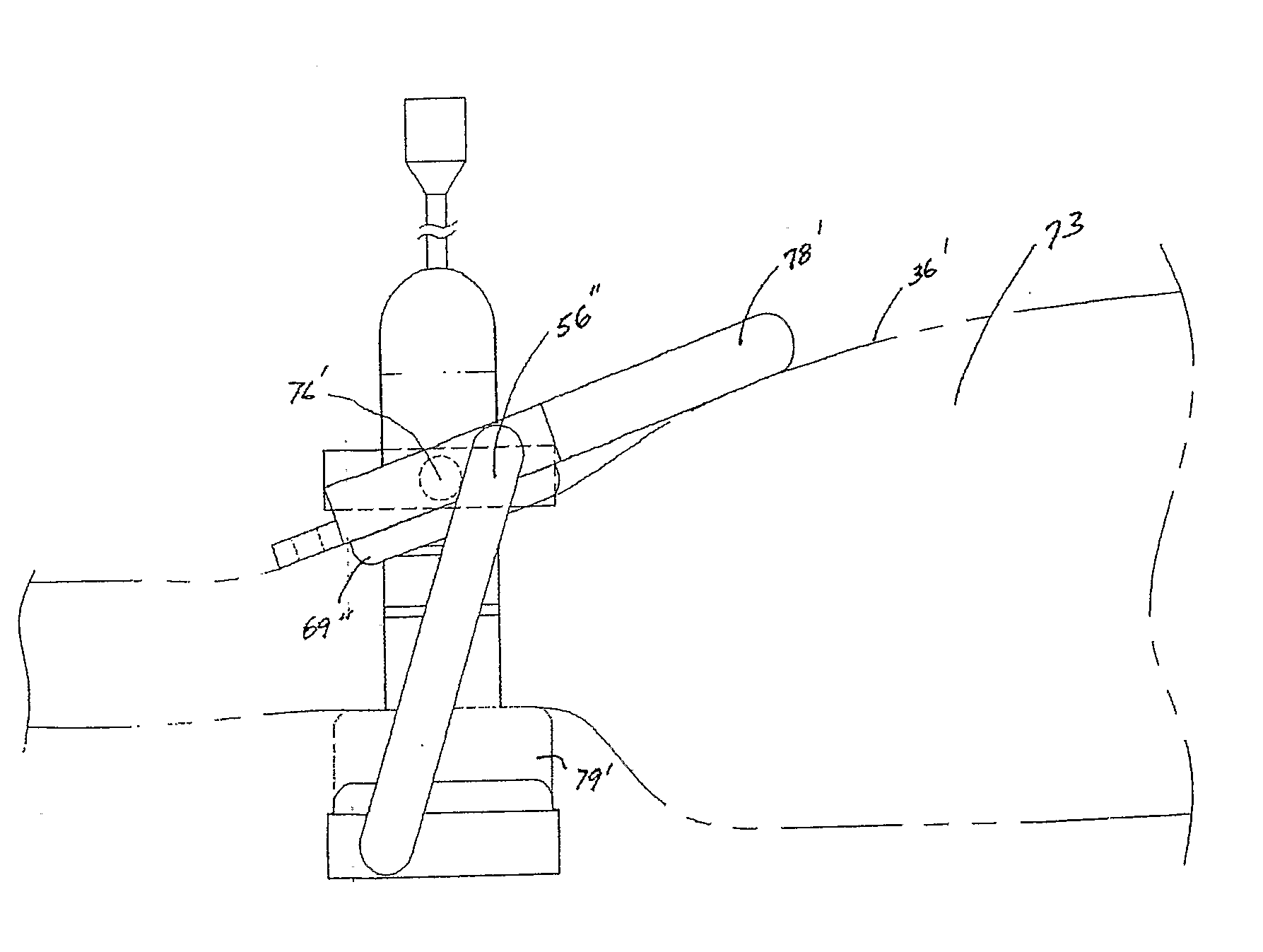

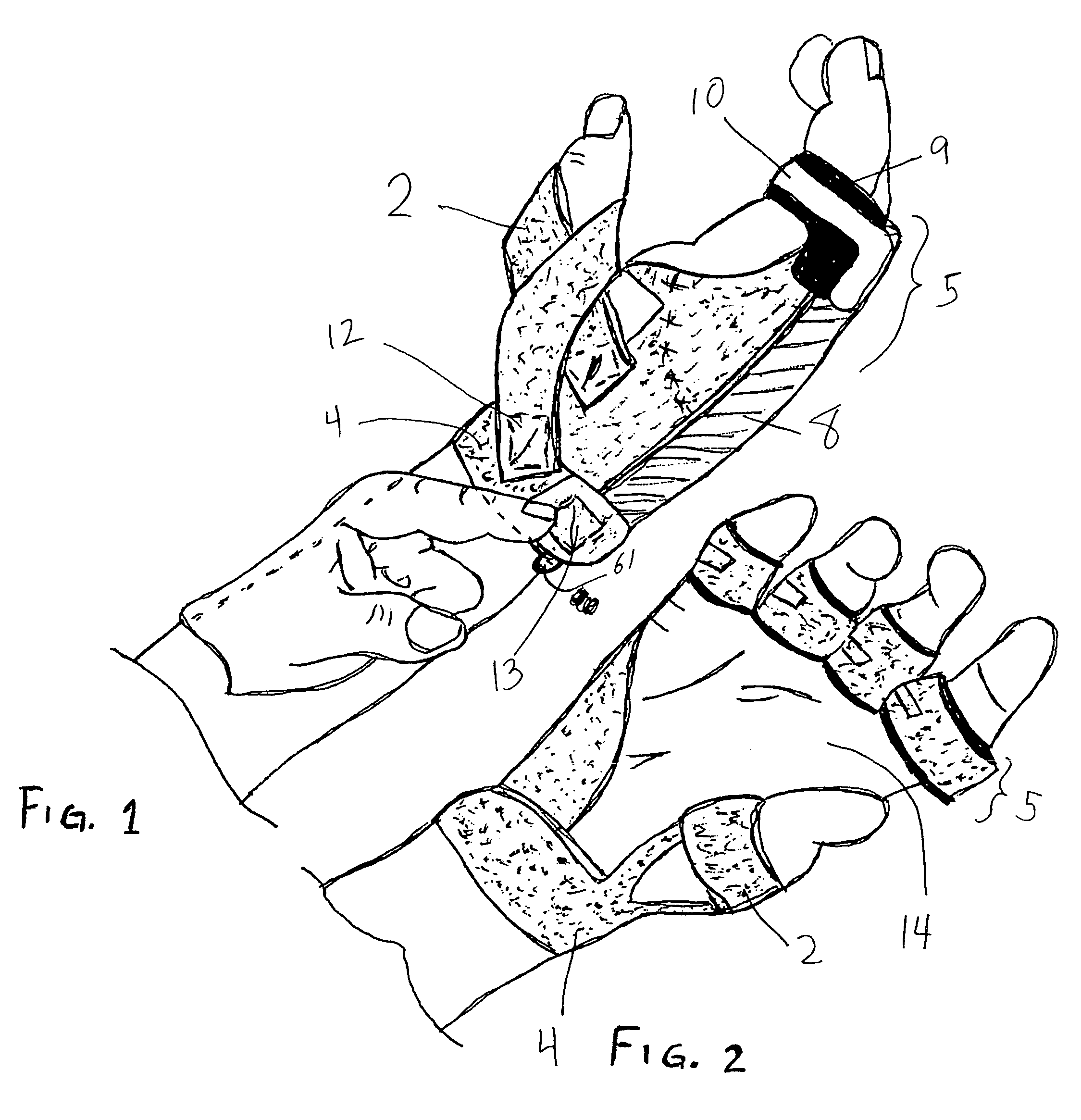

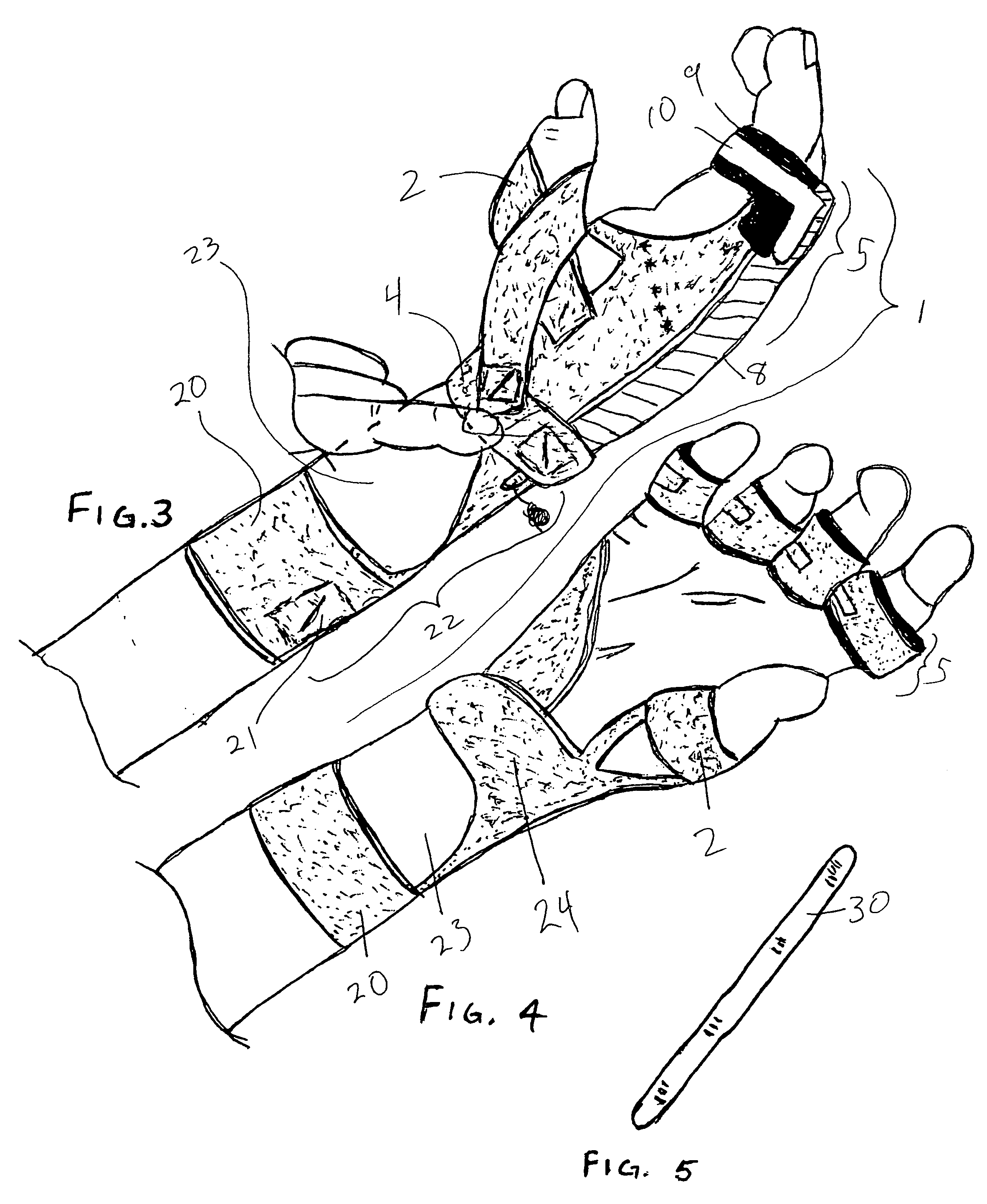

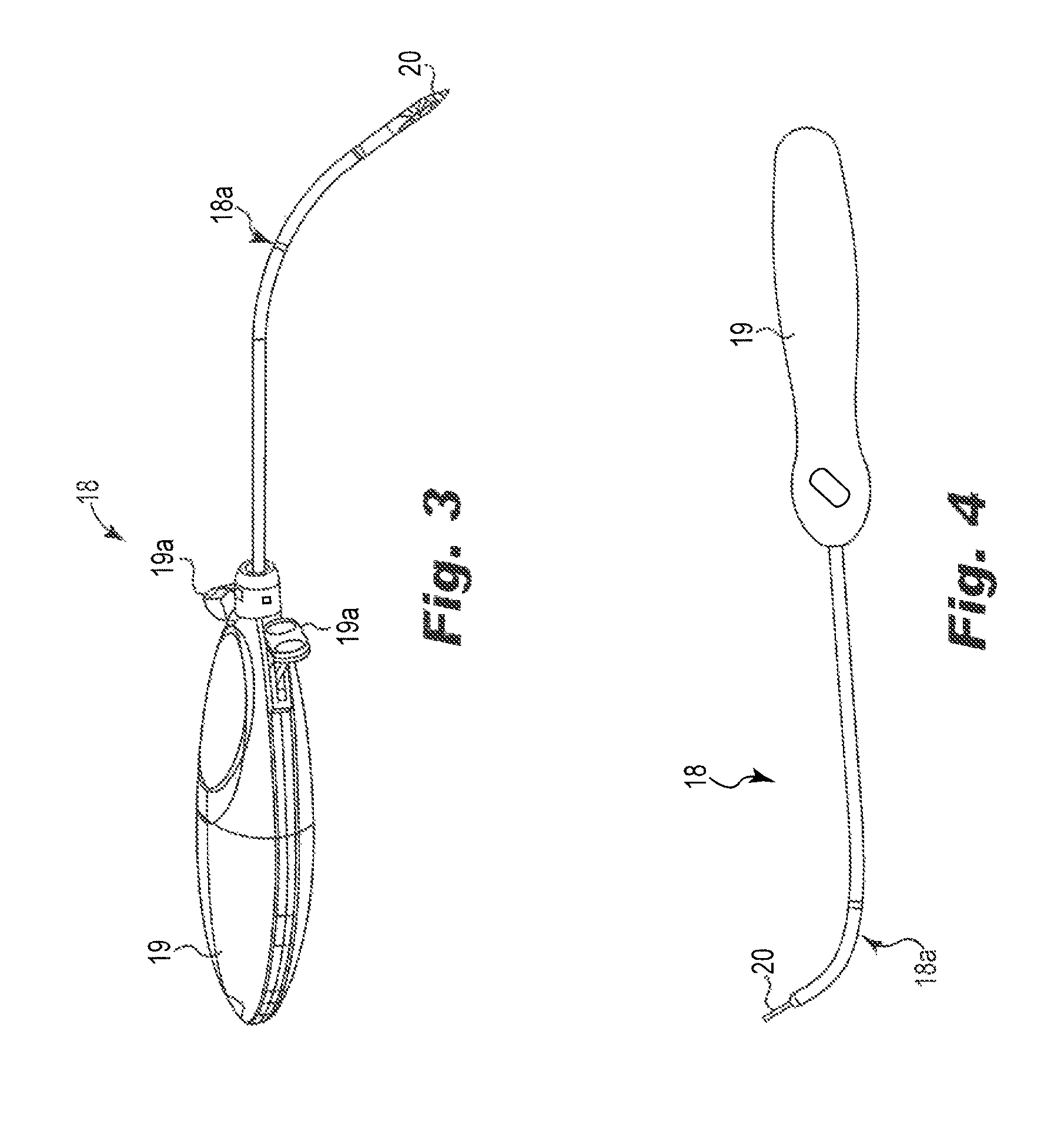

Low-profile, radial nerve splint with interchangeable resilient digit extensor elements and supination adjustment means

Owner:PHELAN CAROLYN HOYNE +2

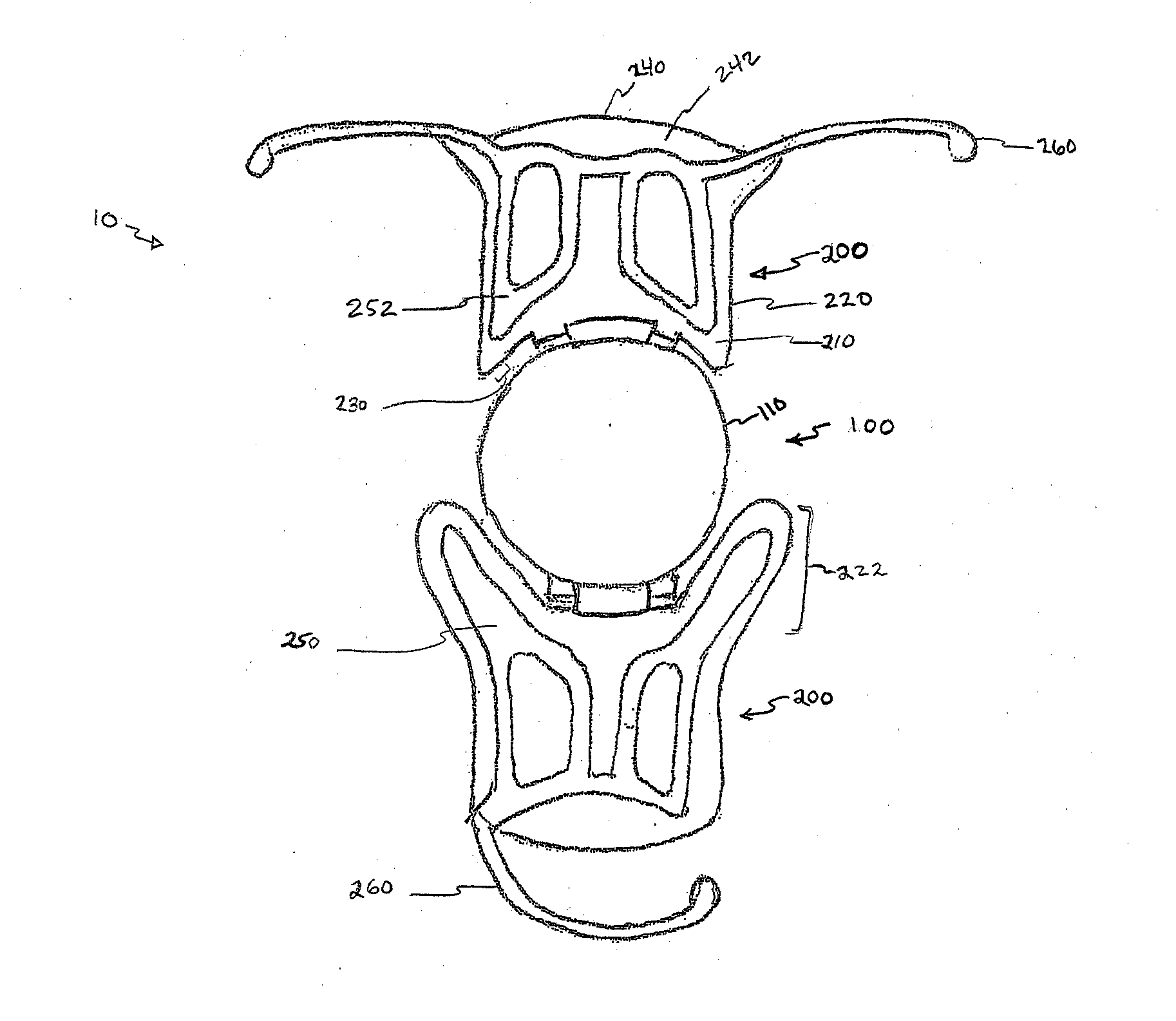

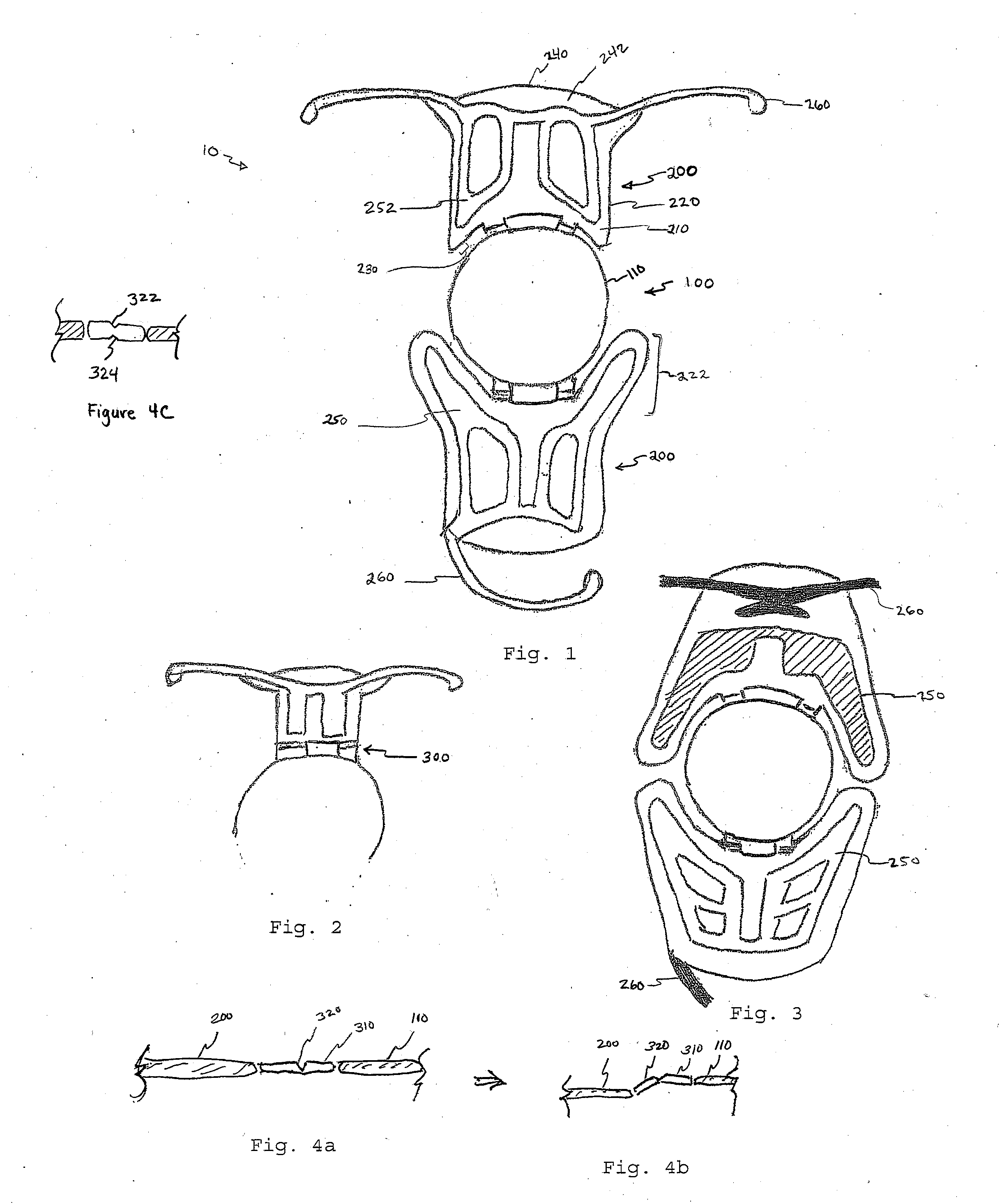

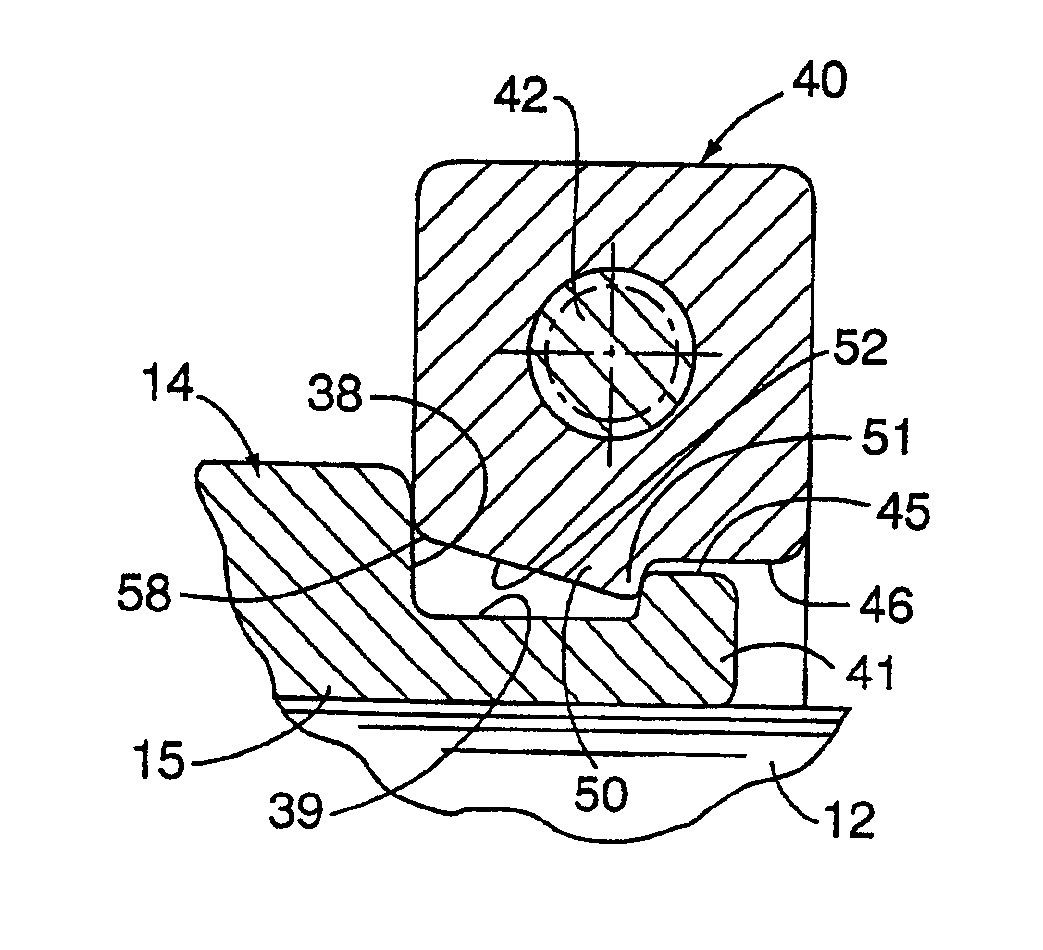

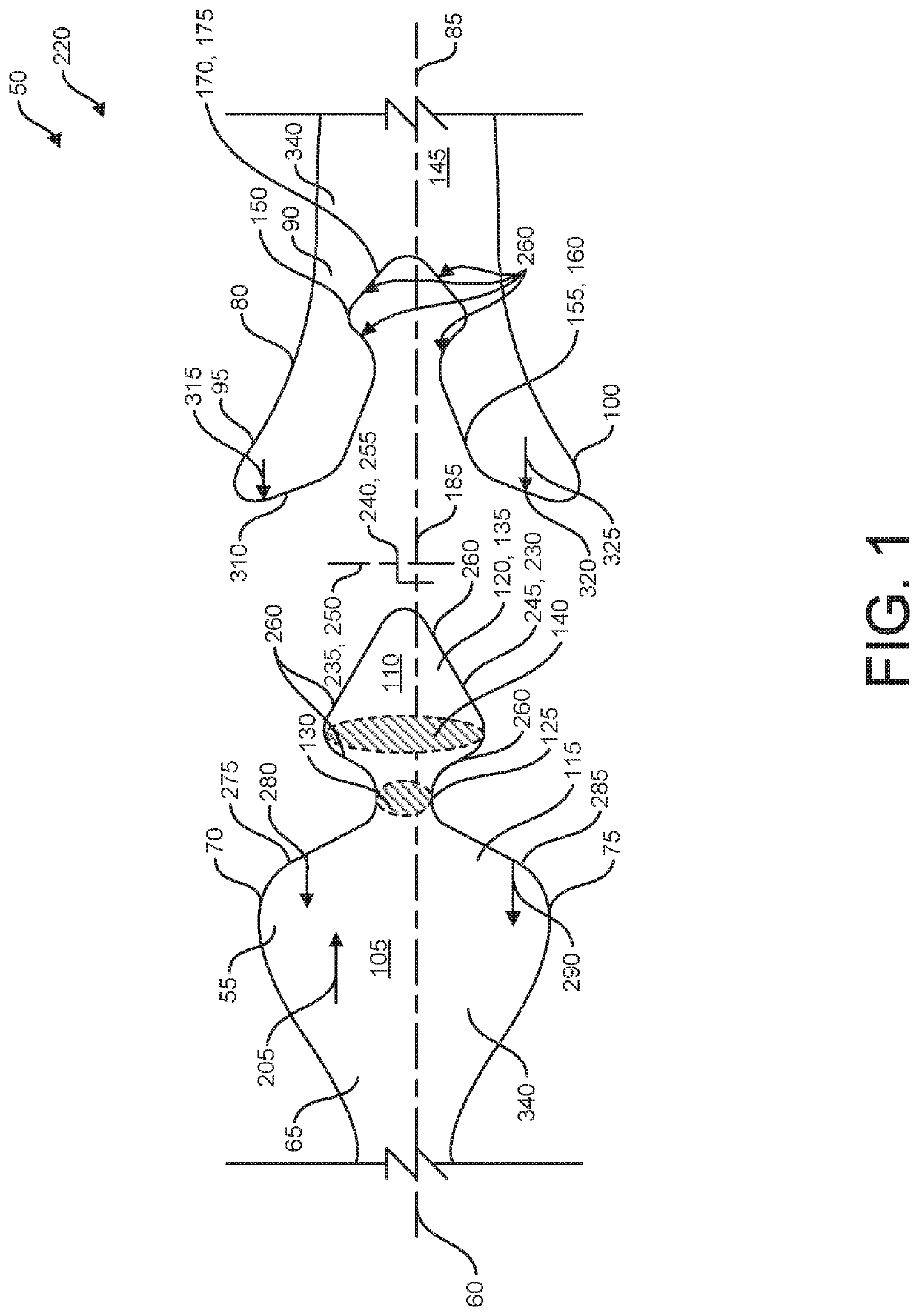

Accommodating Intraocular Lens

ActiveUS20110313519A1Reduce widthProcess stabilityIntraocular lensIntraocular lensMuscle contraction

An intraocular lens for insertion into a capsular bag of an eye comprises: an optic; and at least one plate haptic coupled to the optic by one or more flexible connecting members. The plate haptic with flexible finger extensions is designed to engage the periphery of the capsular bag. An increase in radial pressure upon constriction of the ciliary muscle causes the rigid posteriorly vaulted plate haptics to move centrally to further increase the vitreous cavity pressure with constriction of the ciliary muscle: the optic with its thin stretchable hinge across the connecting member is then displaced anteriorly along the axis of the eye. The haptic includes a longitudinally rigid frame to restrict deformation of the haptic in a longitudinal direction while permitting deformation in a transverse direction. Furthermore, the flexible connecting members include one or more hinged straps that extend radially and / or longitudinally from the optic. The optic can move forwards and backwards, relative to both the distal and proximal ends of the plate haptics, in response to ciliary muscle contraction and relaxation with an increase and decrease of vitreous cavity pressure. Finger-like projection extends from the plate haptic to engage the capsular bag to center and fixate the accommodating lens within the capsular bag.

Owner:CUMMING JAMES STUART

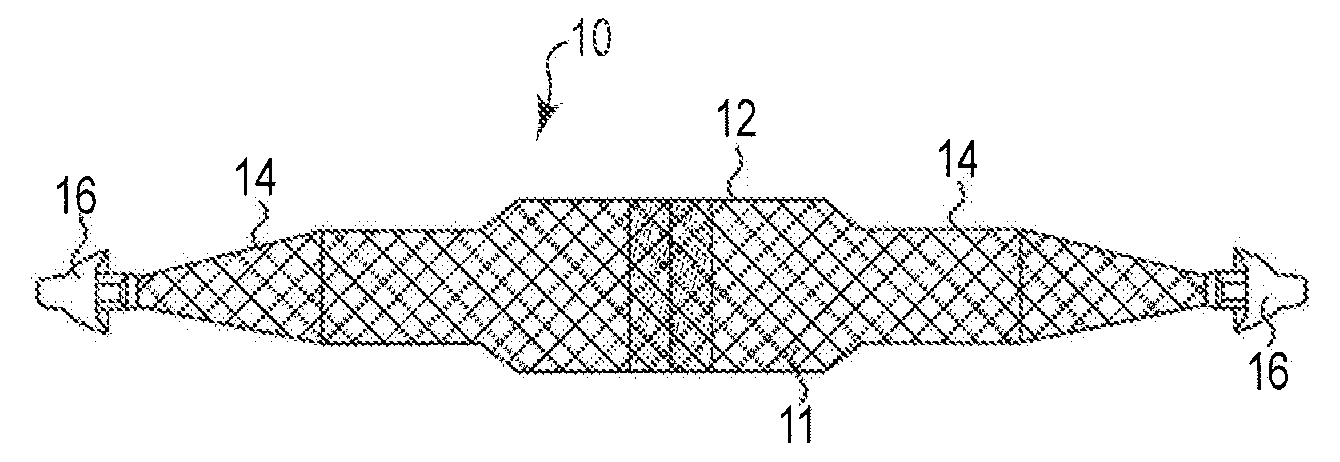

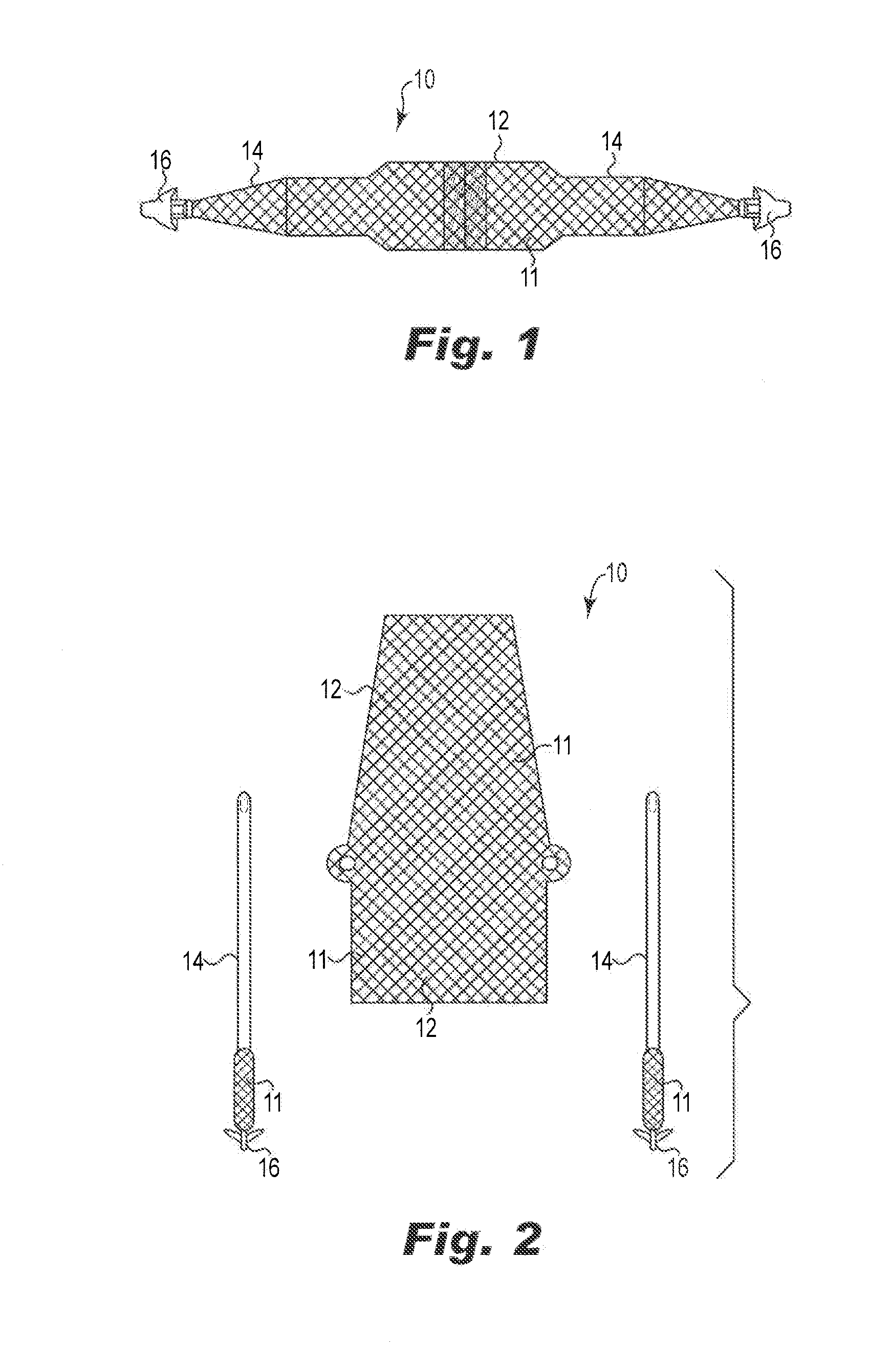

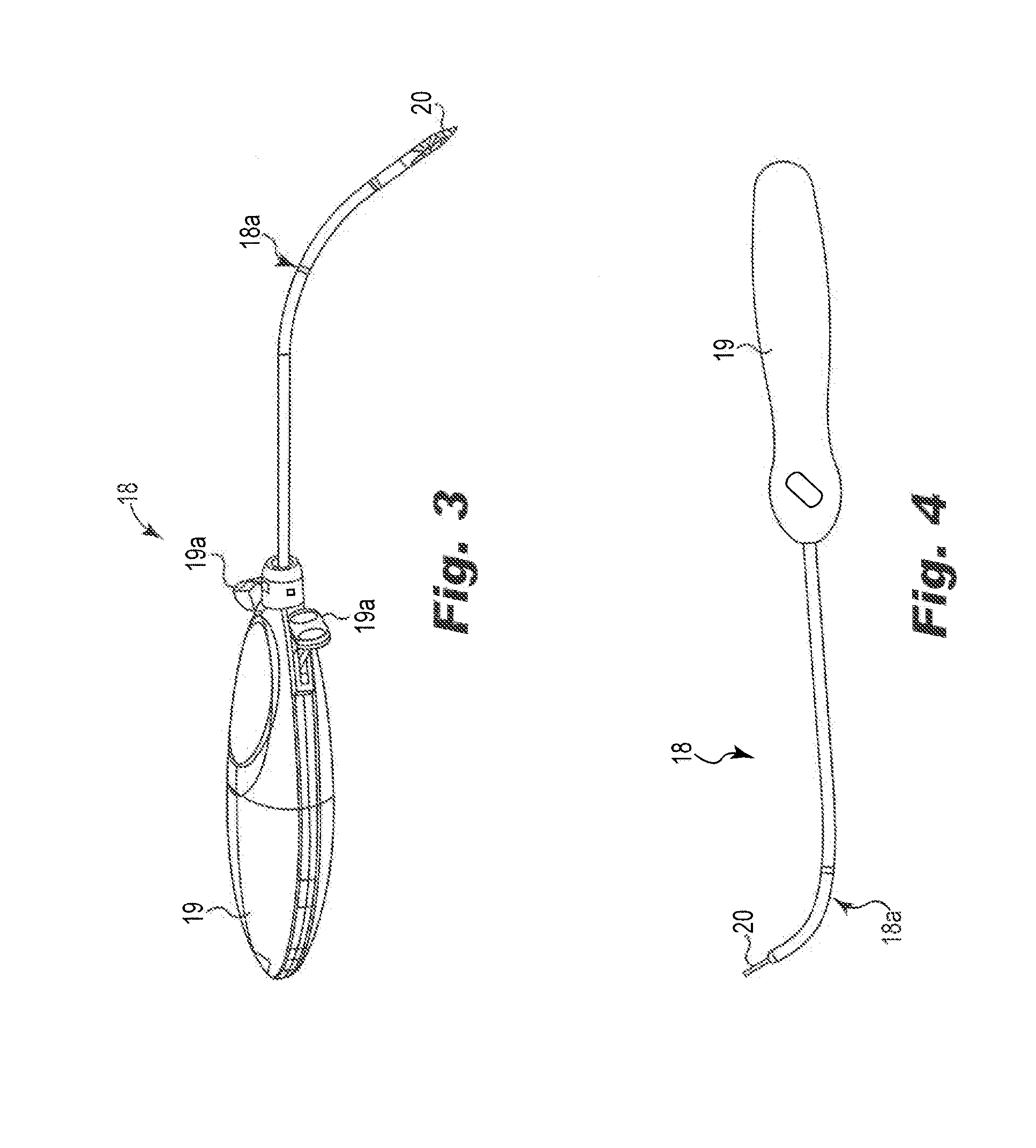

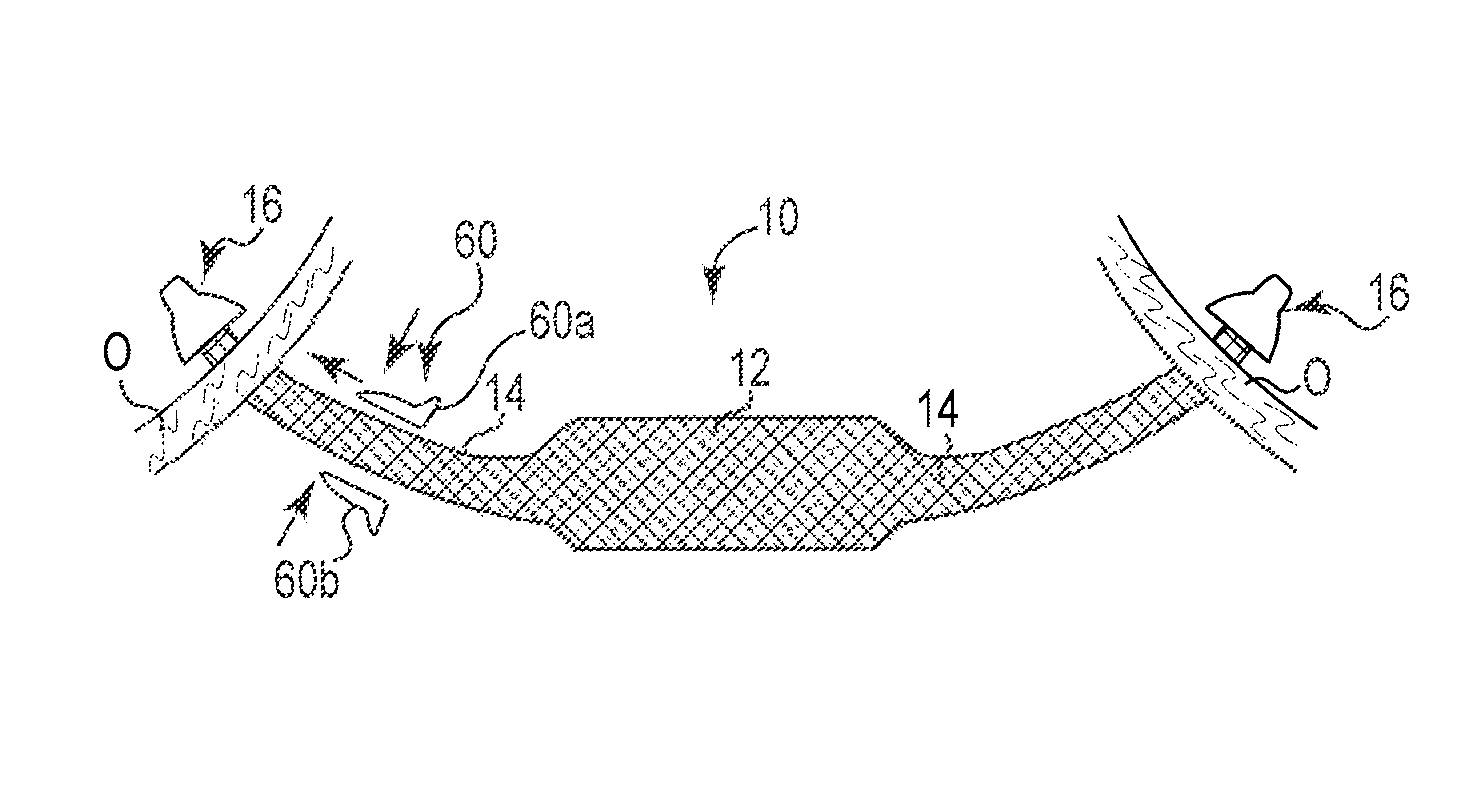

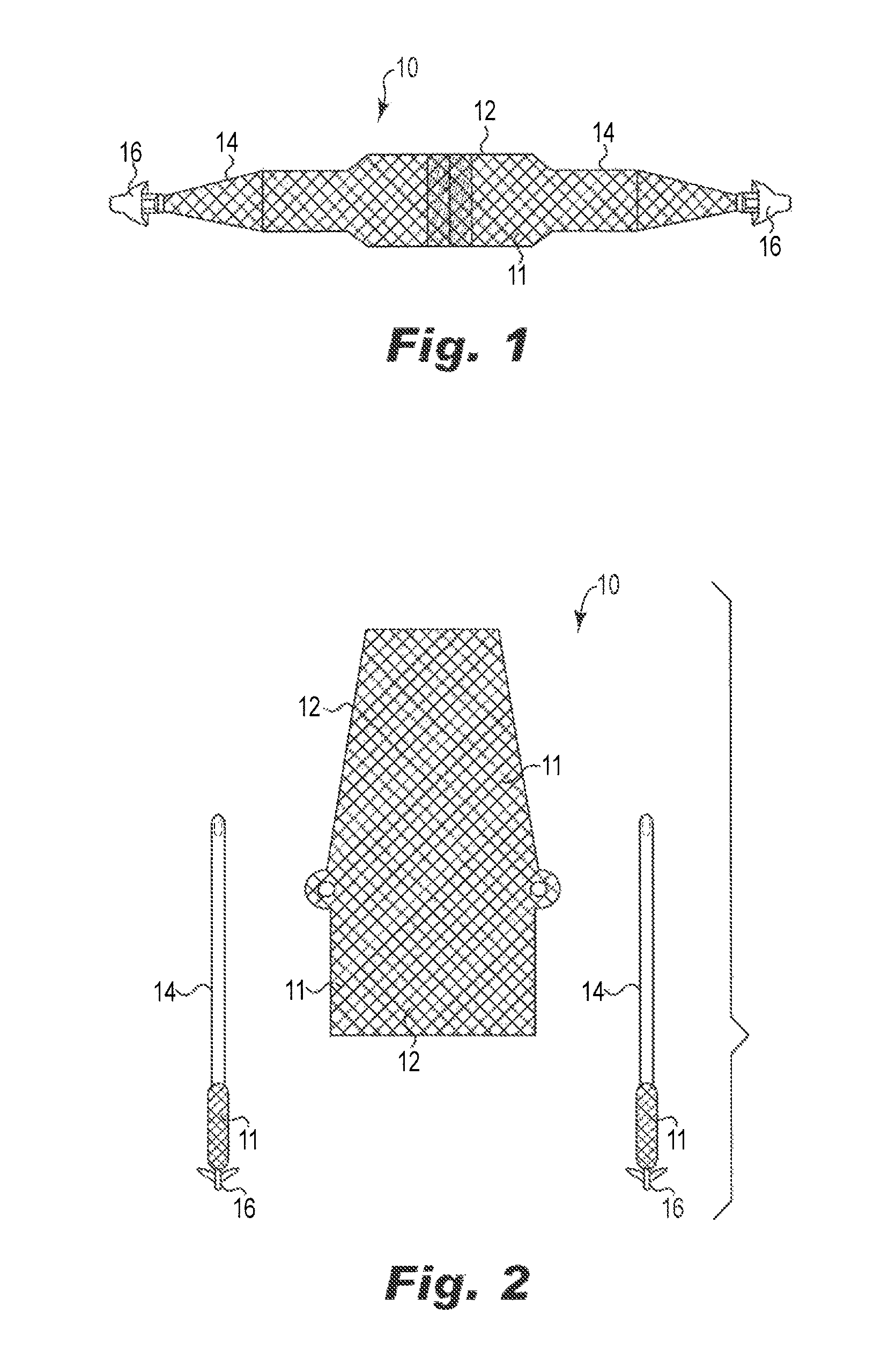

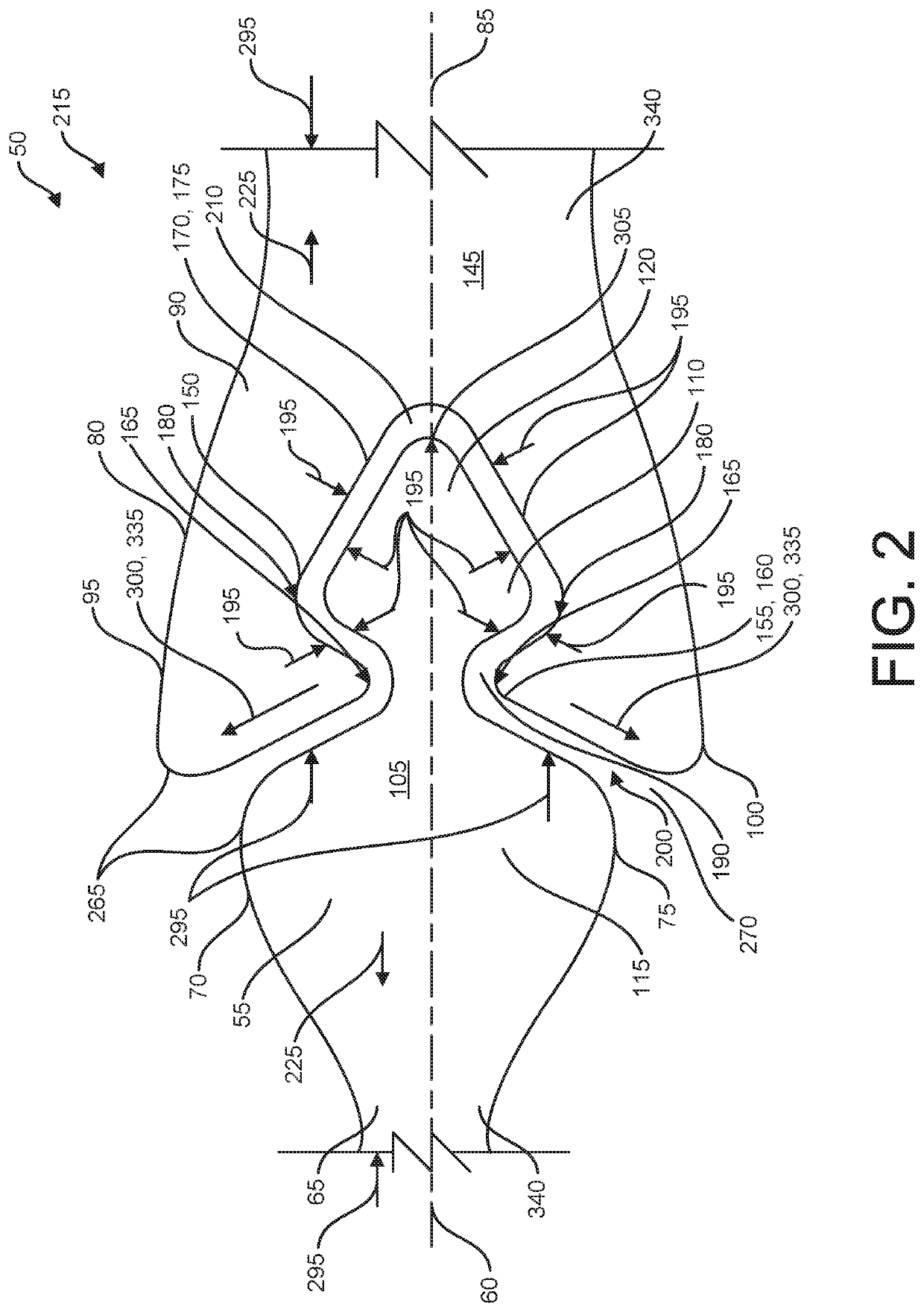

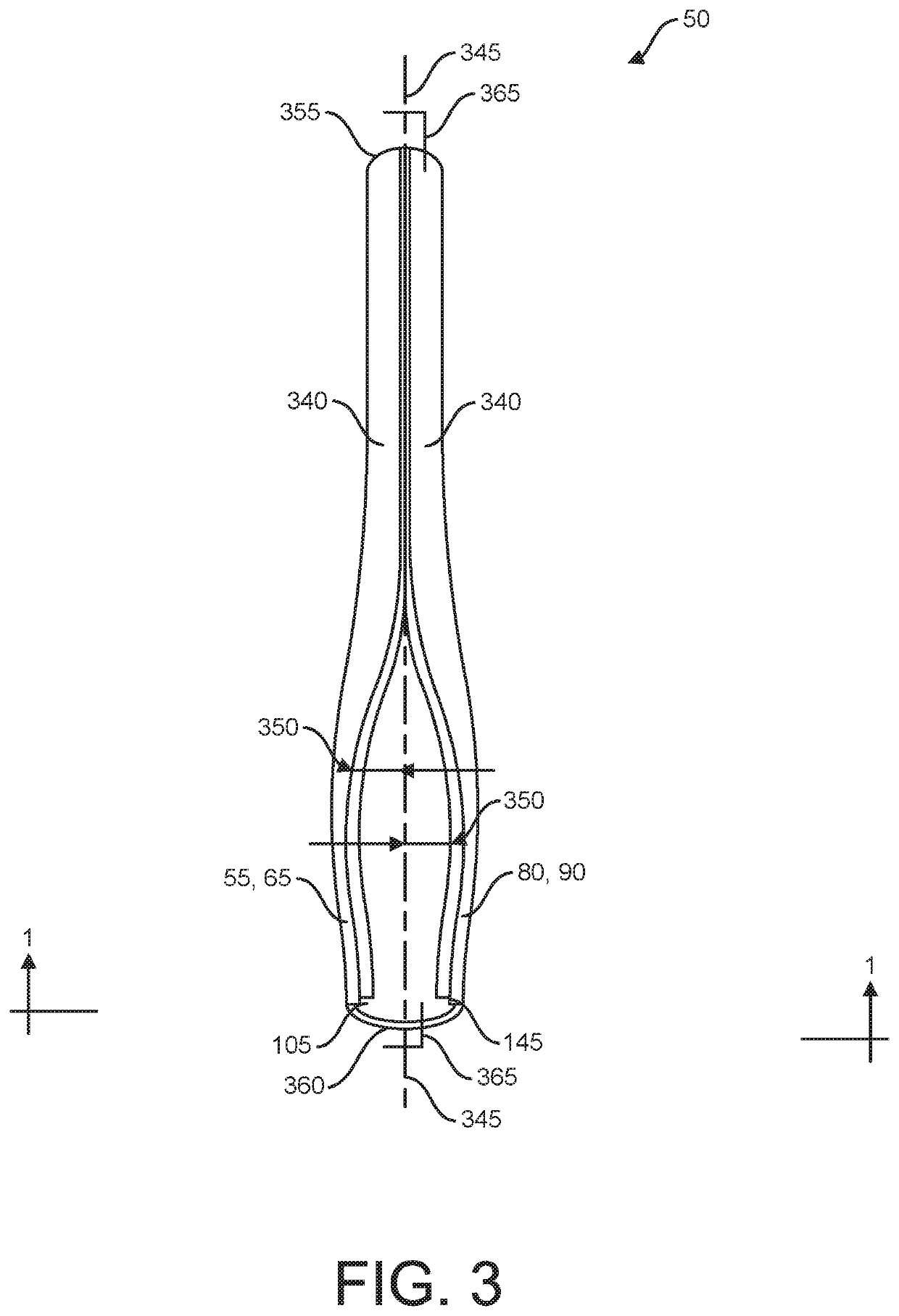

Implantable Slings and Anchor Systems

ActiveUS20120157761A1Easy tension adjustmentSuture equipmentsAnti-incontinence devicesBiomedical engineeringFinger extension

Various embodiments of a mesh or implant systems are provided. The implants can include one or more anchors, arms and the like. The anchors can include hingeable or patterned finger extension to facilitate tissue penetration and retention. Various tensioning and adjustment mechanisms, devices and methods are further provided for the implant systems.

Owner:BOSTON SCI SCIMED INC

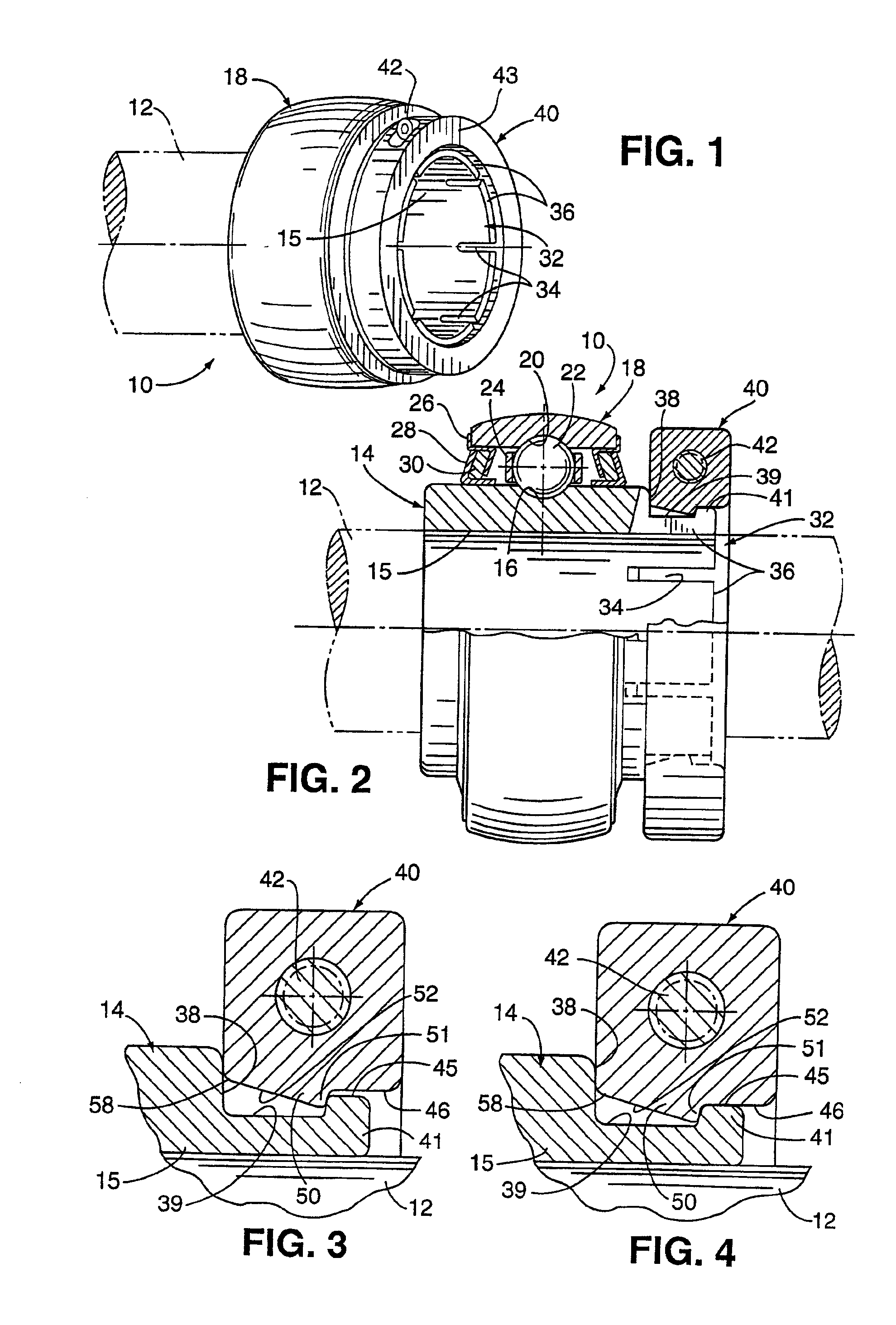

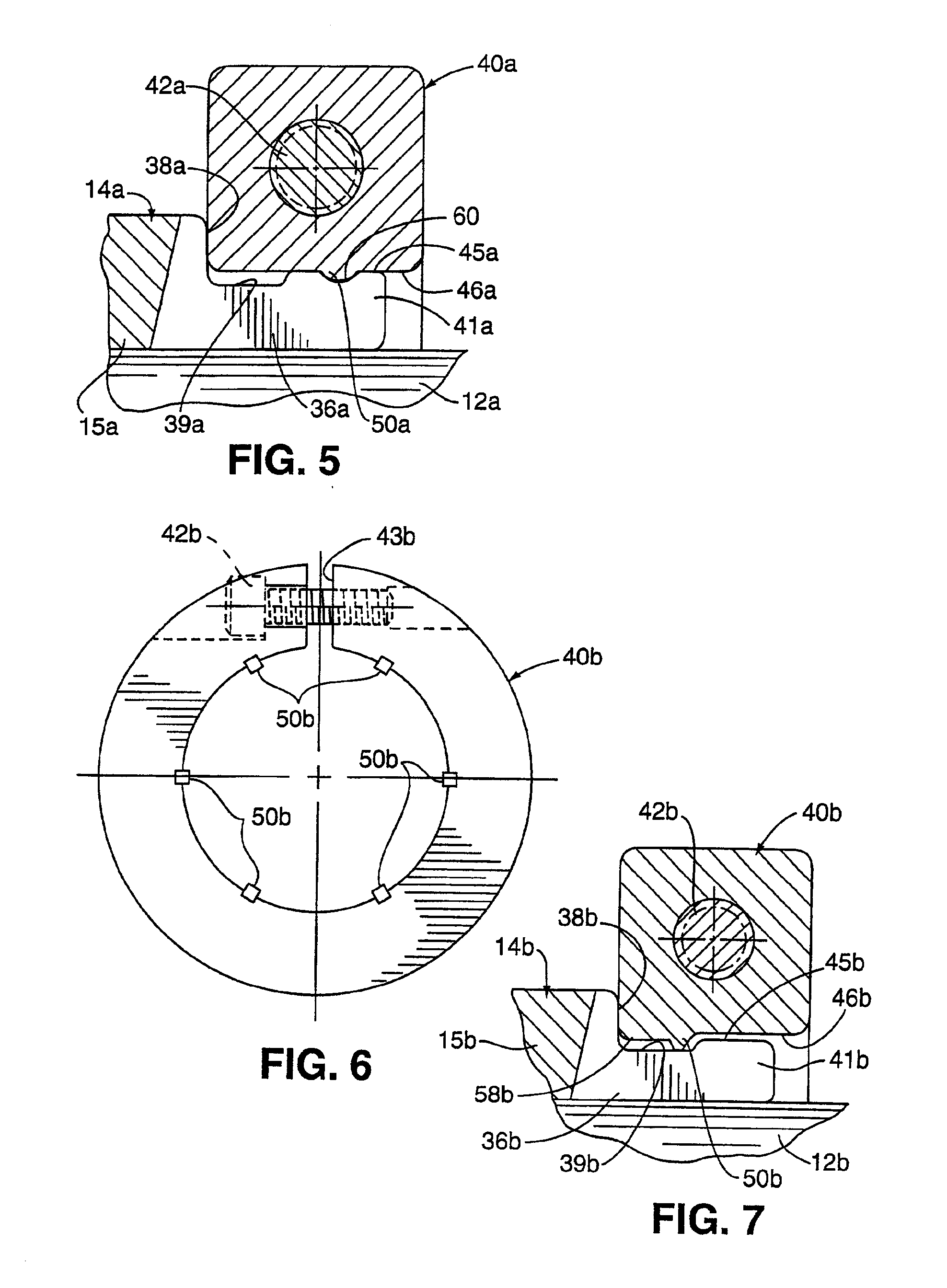

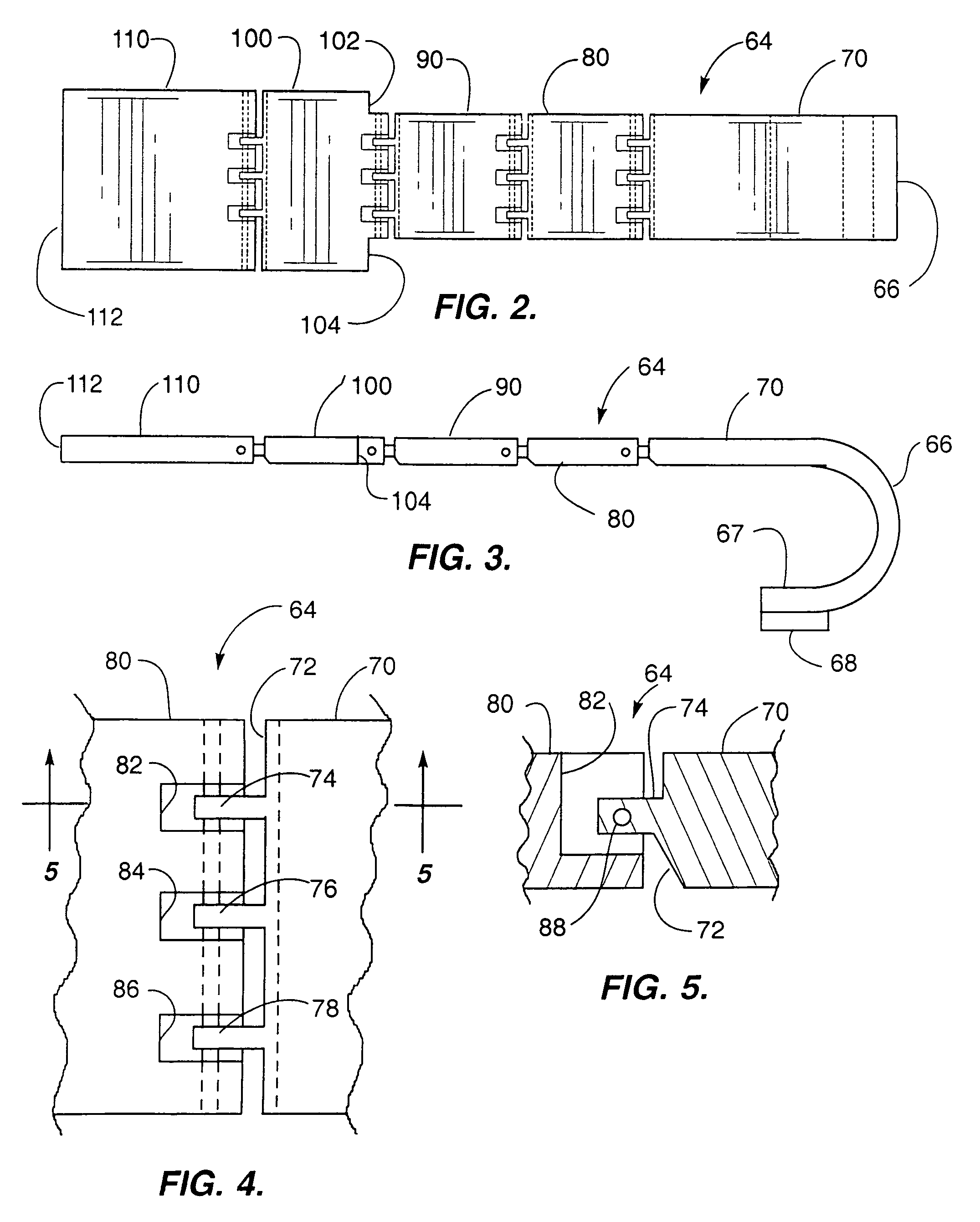

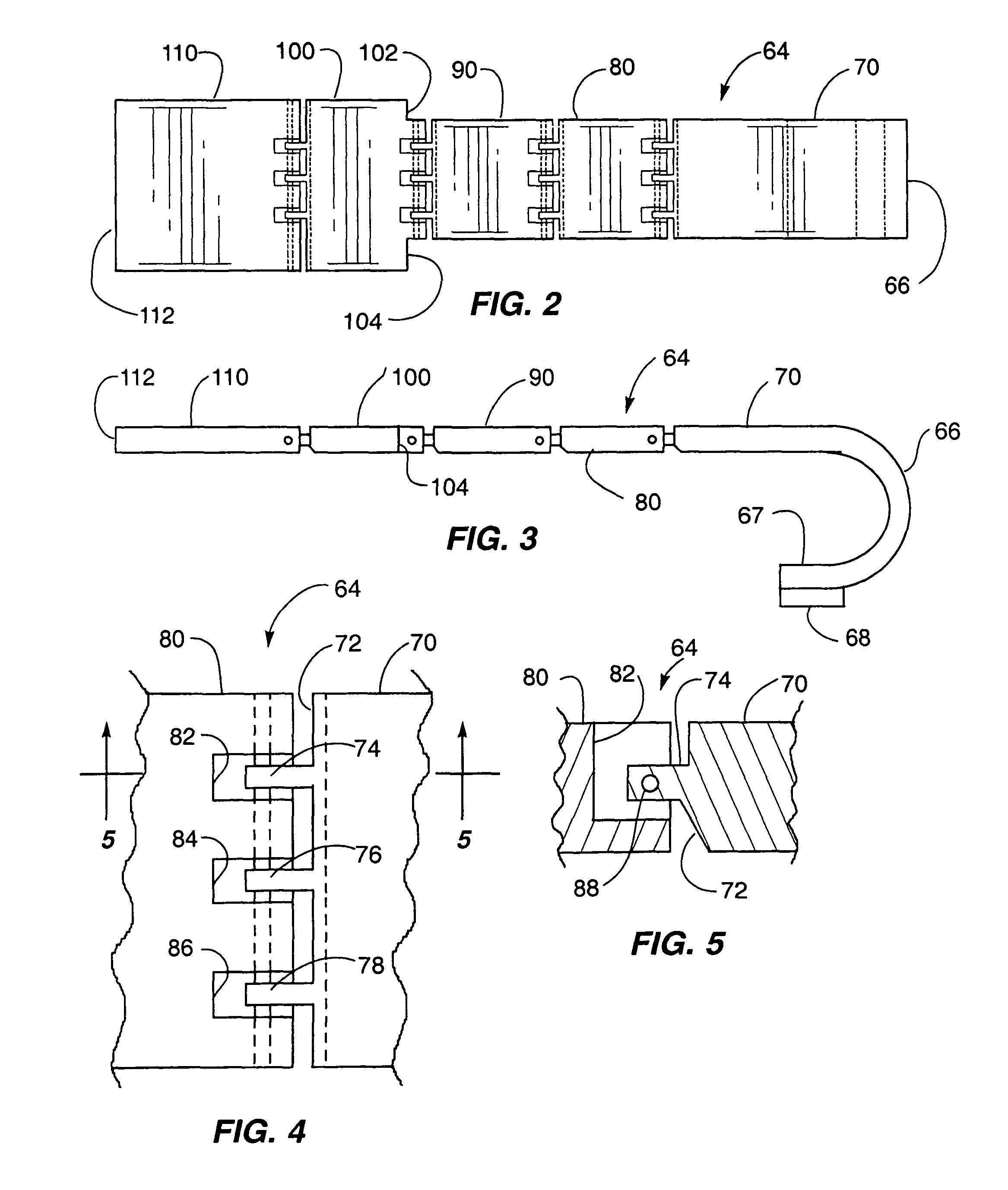

Shaft locking device for bearing assemblies

InactiveUS6908230B2Efficiently pre-assembledFacilitates subsequent reliable installationBearing assemblyBall bearingsEngineeringScrew thread

A bearing assembly wherein the inner diameter of the slotted compressible annular locking collar is provided with a protrusion which extends radially inwardly, and finger extensions of the inner ring are provided with a recessed groove which extends at least partially along the collective outer annular surface of the finger extensions. When the locking collar is disposed about the finger extensions of the inner ring, the protrusion is disposed within the recessed groove to retain the locking collar on the inner ring. The inner ring finger extensions and the locking collar are relatively sized such that when they are in their free states, the inner diameter of the protrusion is slightly smaller than the outer diameter of the recessed groove, such that the collar may be snapped over the finger extensions and into proper position on the inner ring prior to installation on a shaft. The protrusion may be an integrally formed part of the locking collar or a separate resilient member. In one embodiment, the locking collar and finger extensions are formed with cooperating threads.

Owner:REGAL BELOIT AMERICA

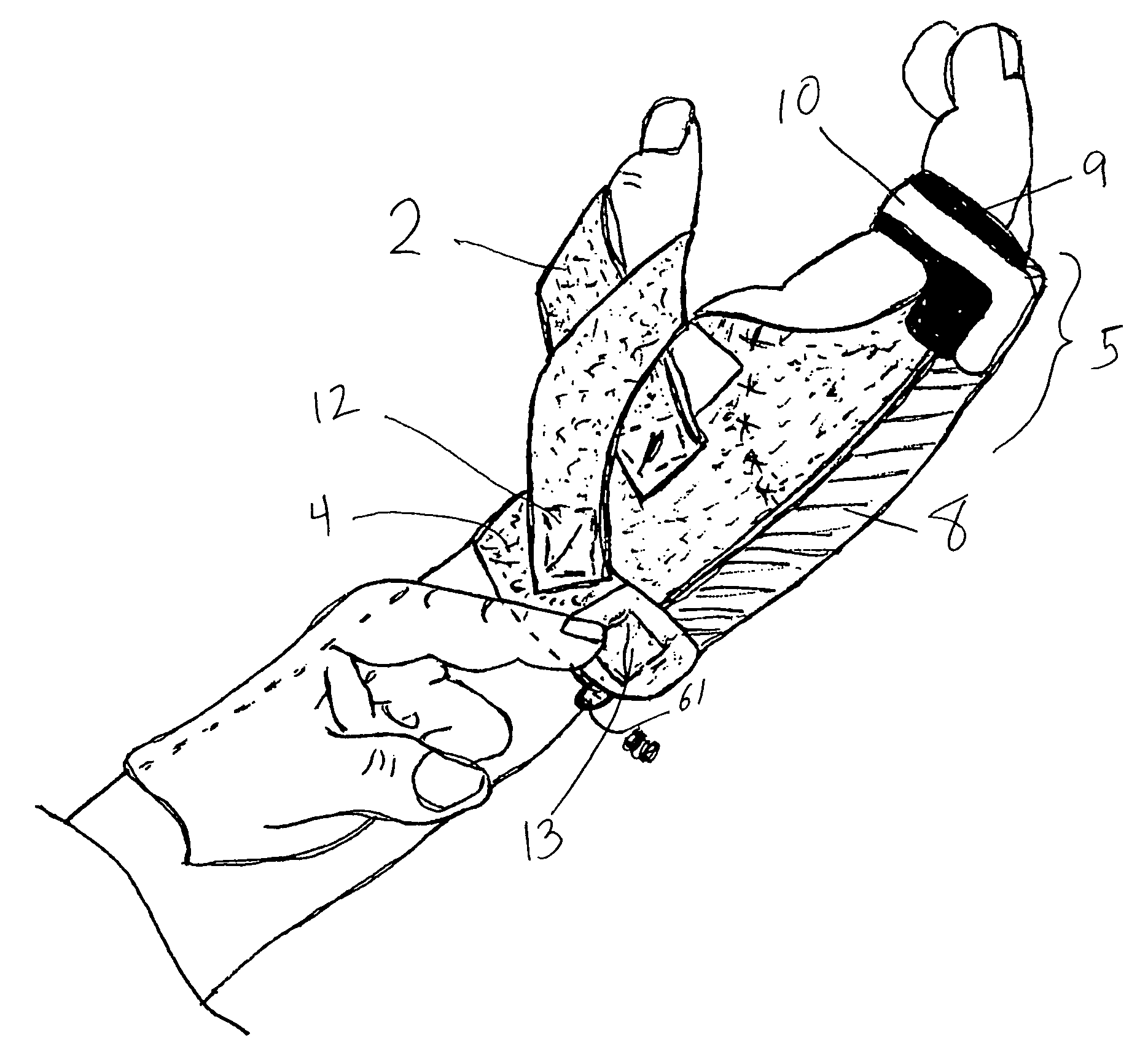

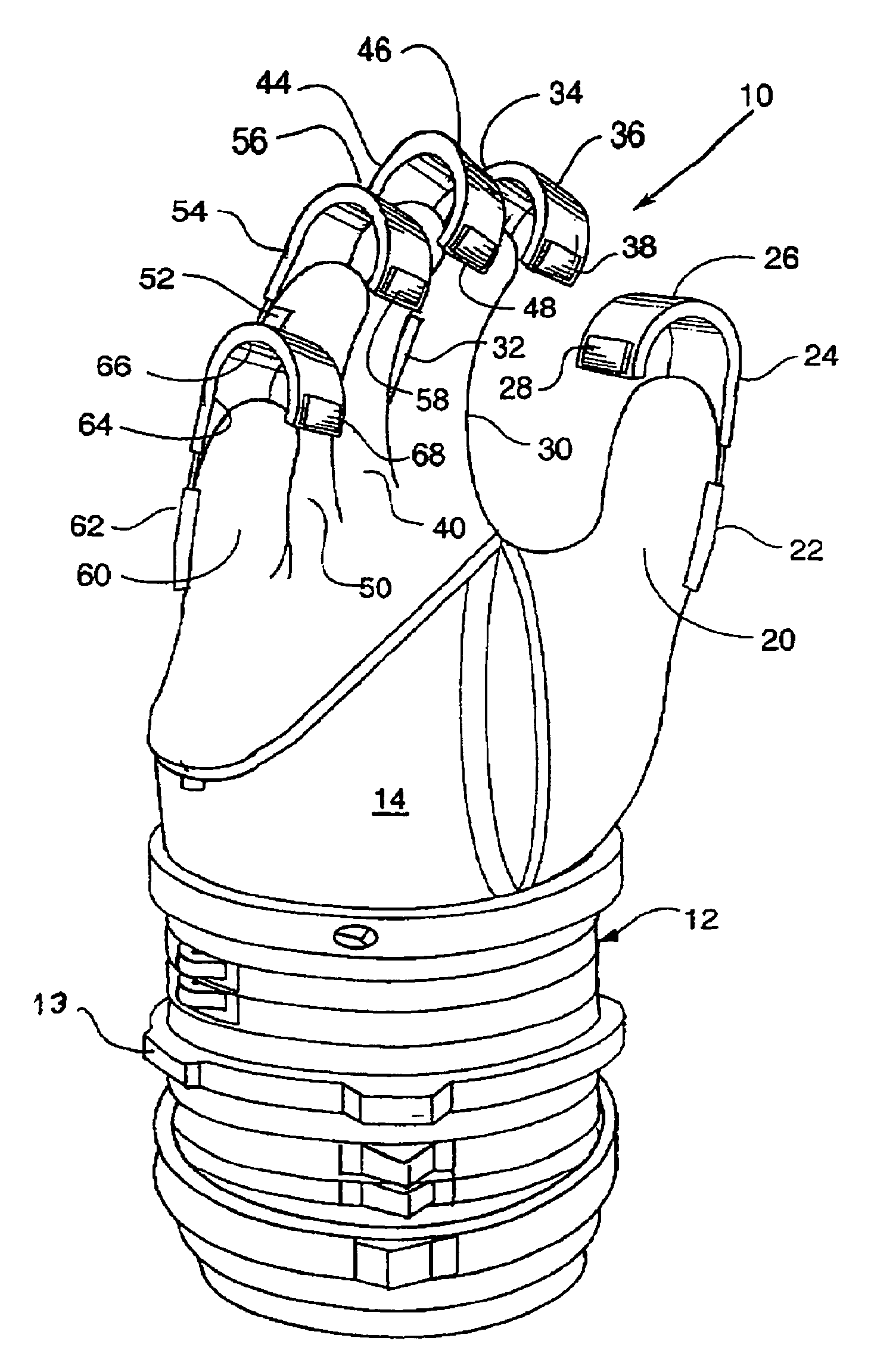

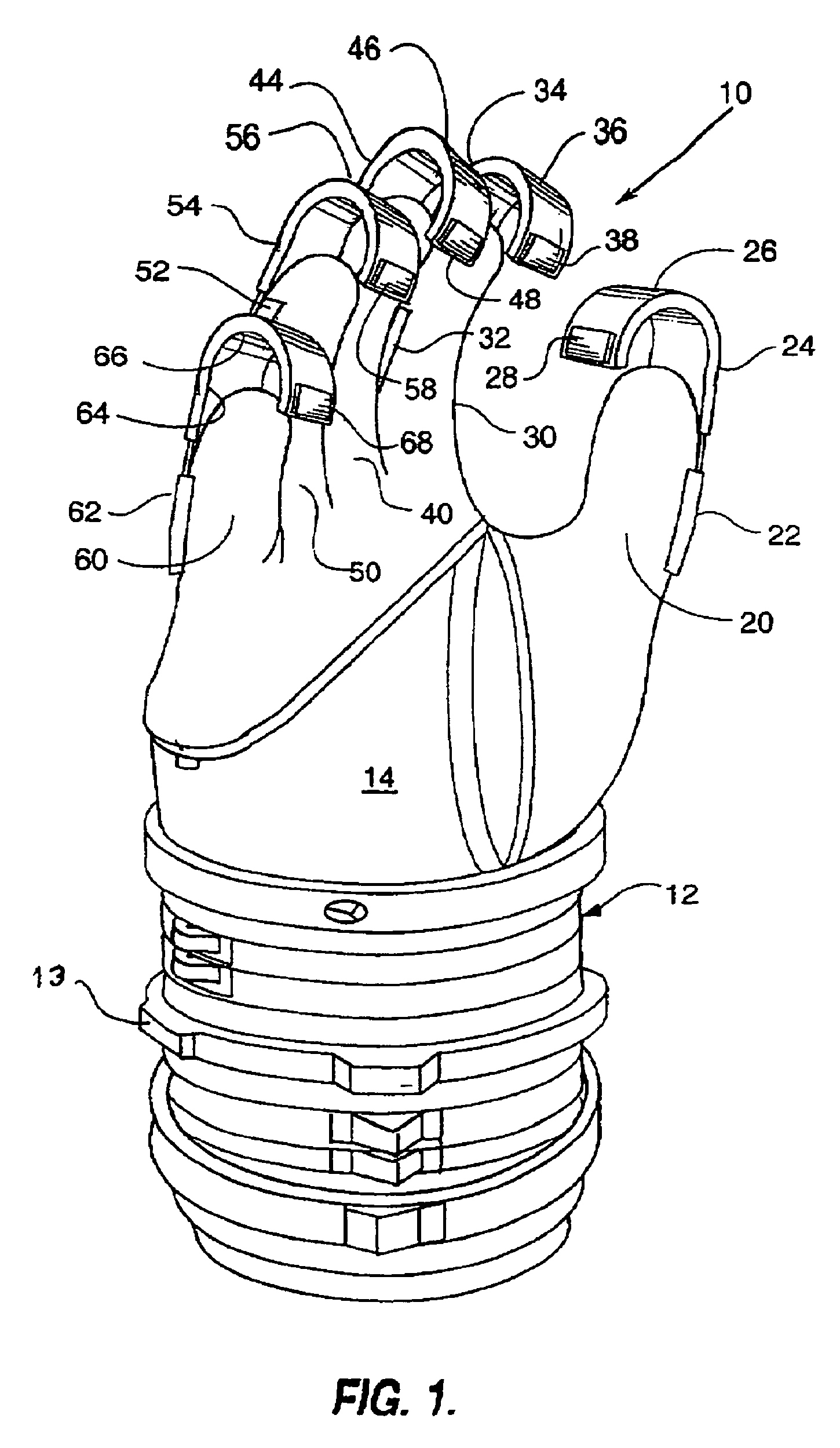

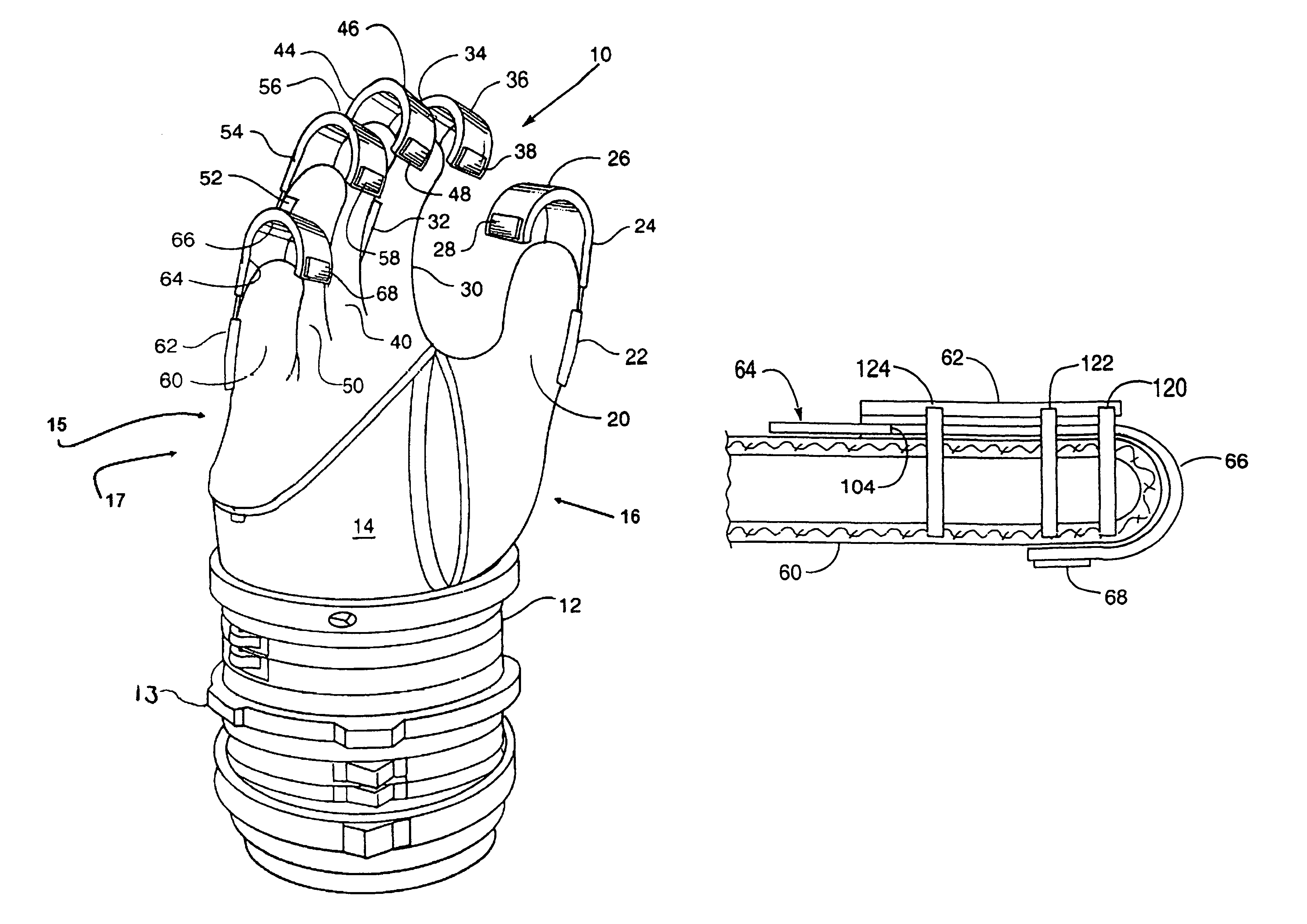

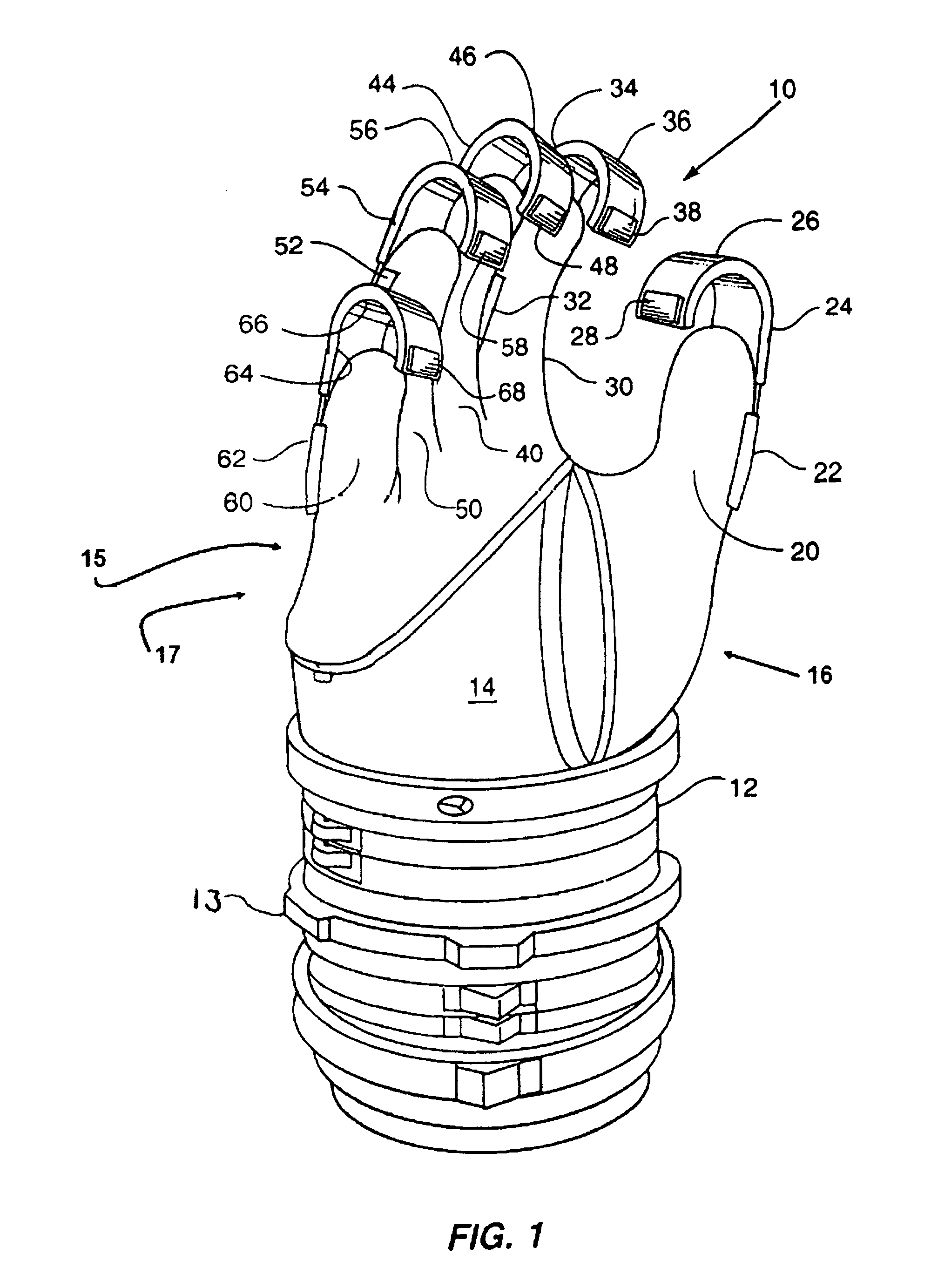

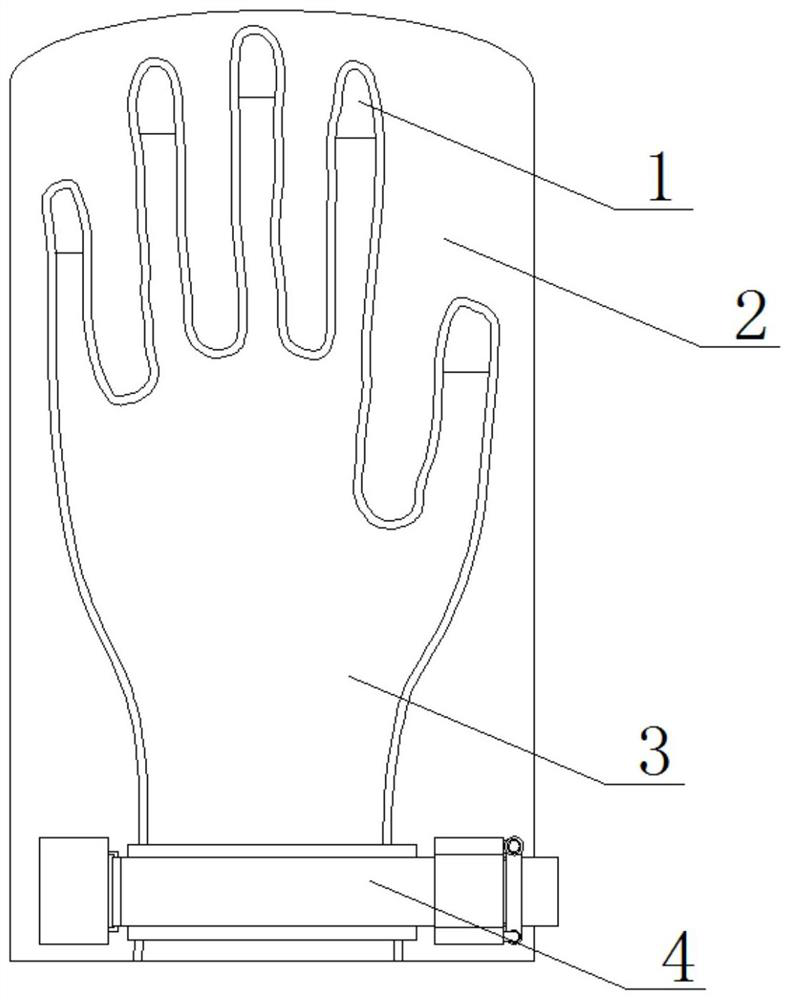

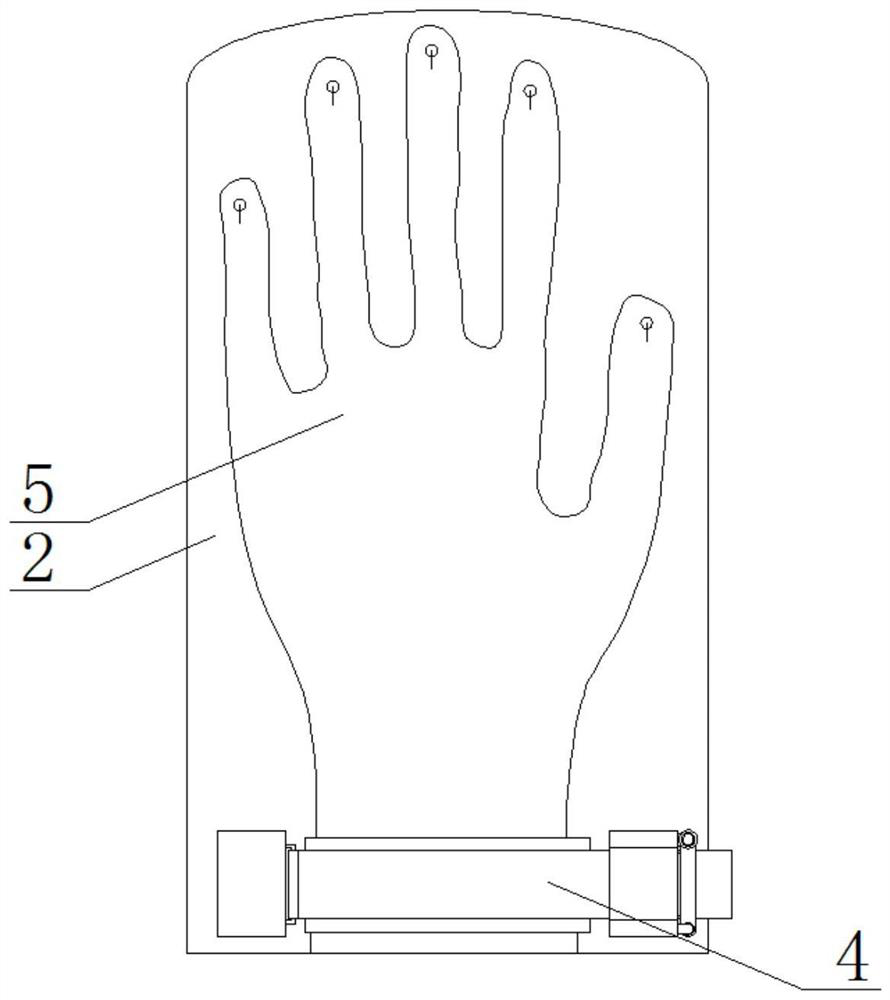

Astronaut glove with finger extensions

InactiveUS8955166B1Limited sideways movementPreventing reverse bendingChemical protectionHeat protectionEngineeringContact element

Owner:MADDEN JR JAMES R

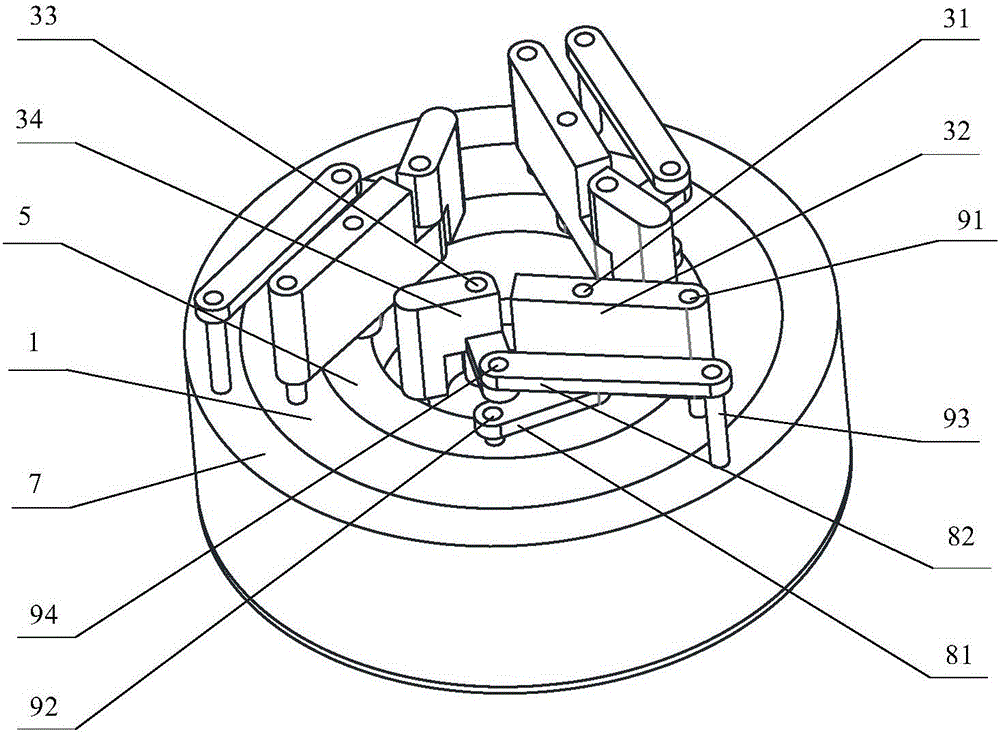

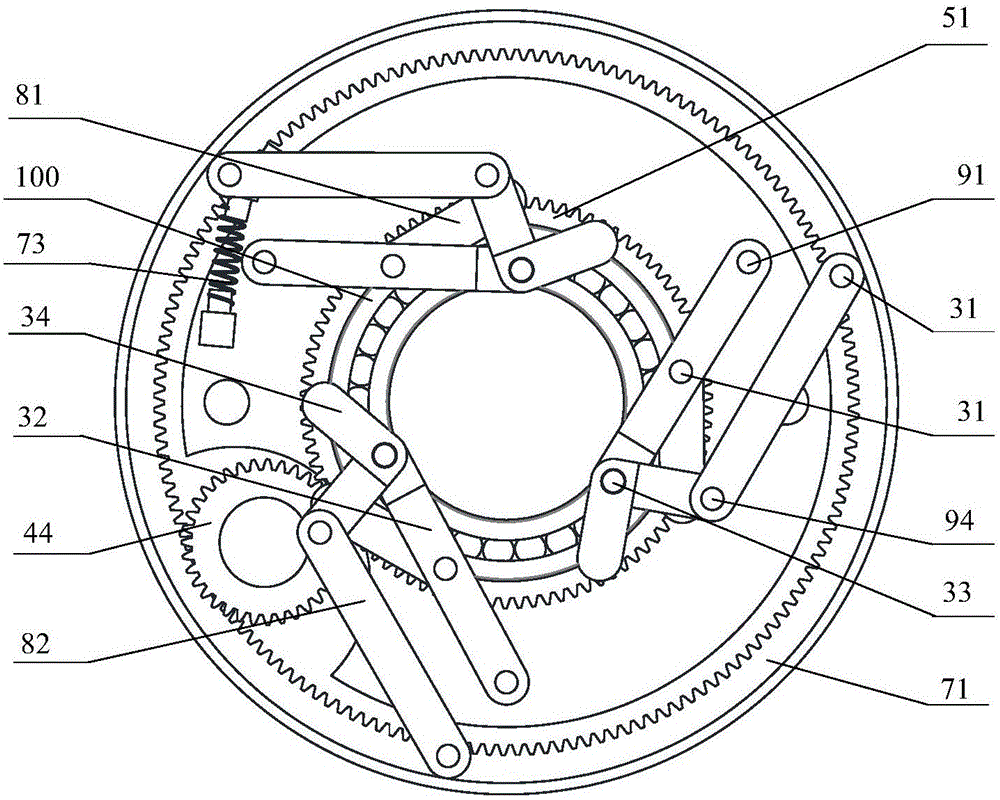

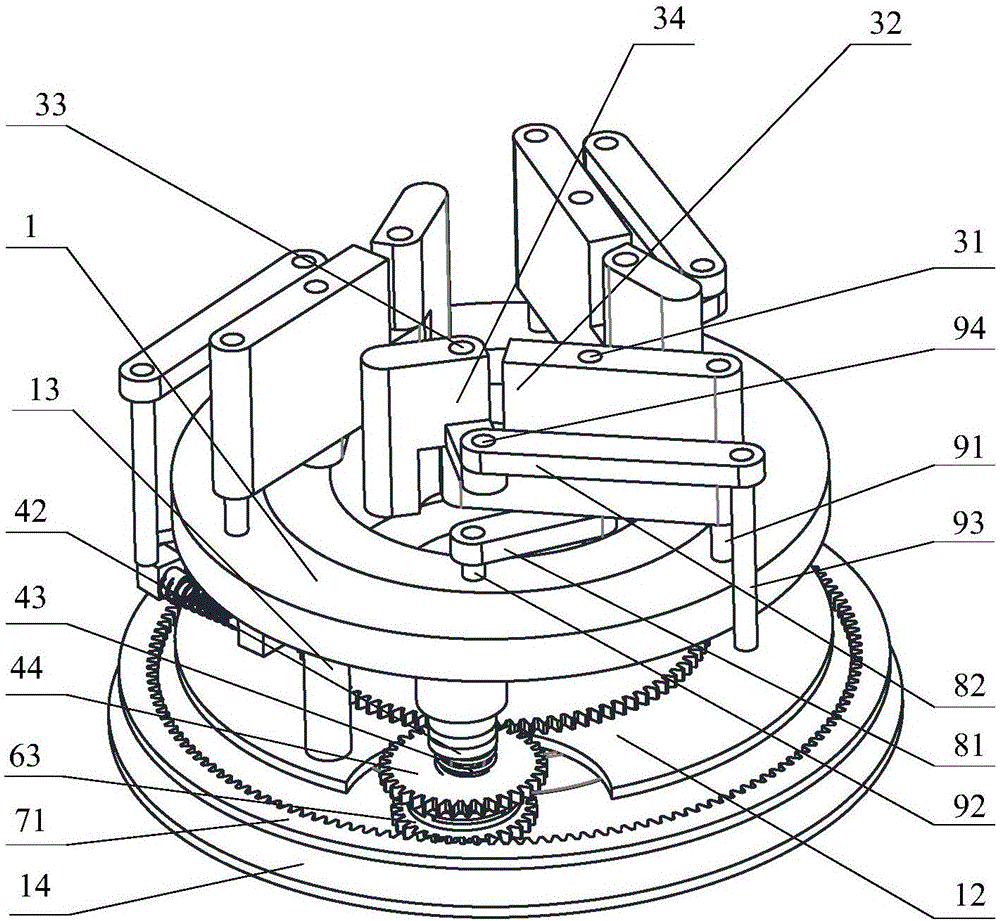

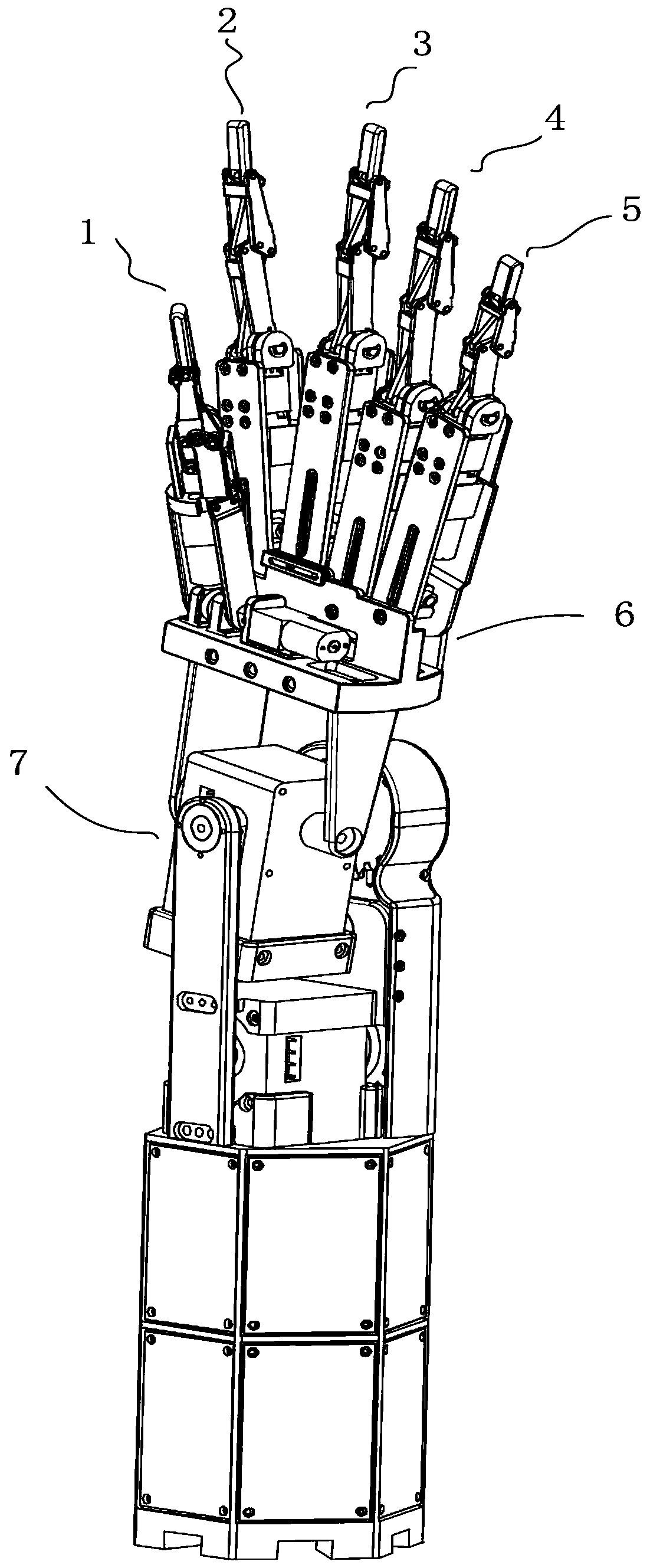

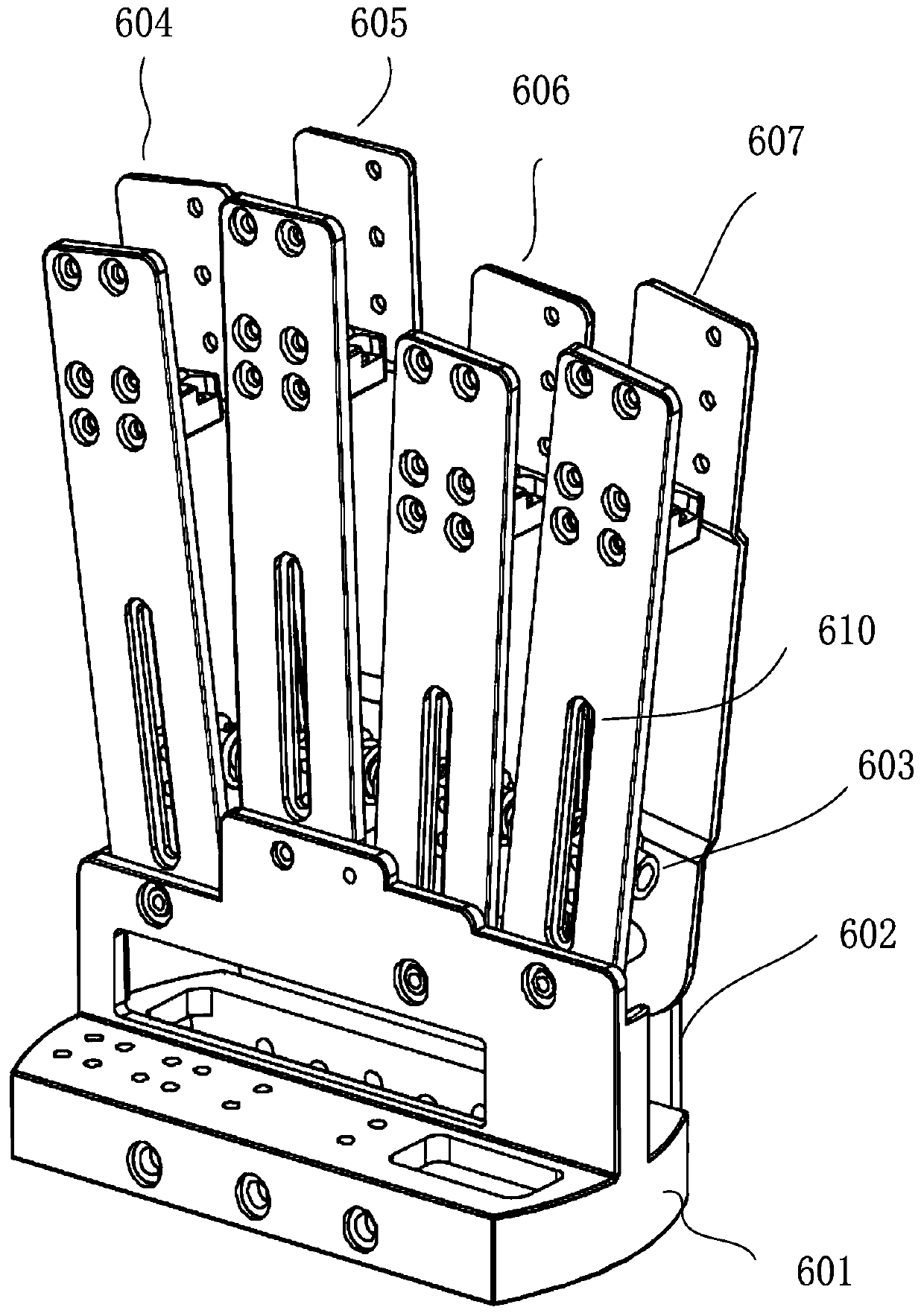

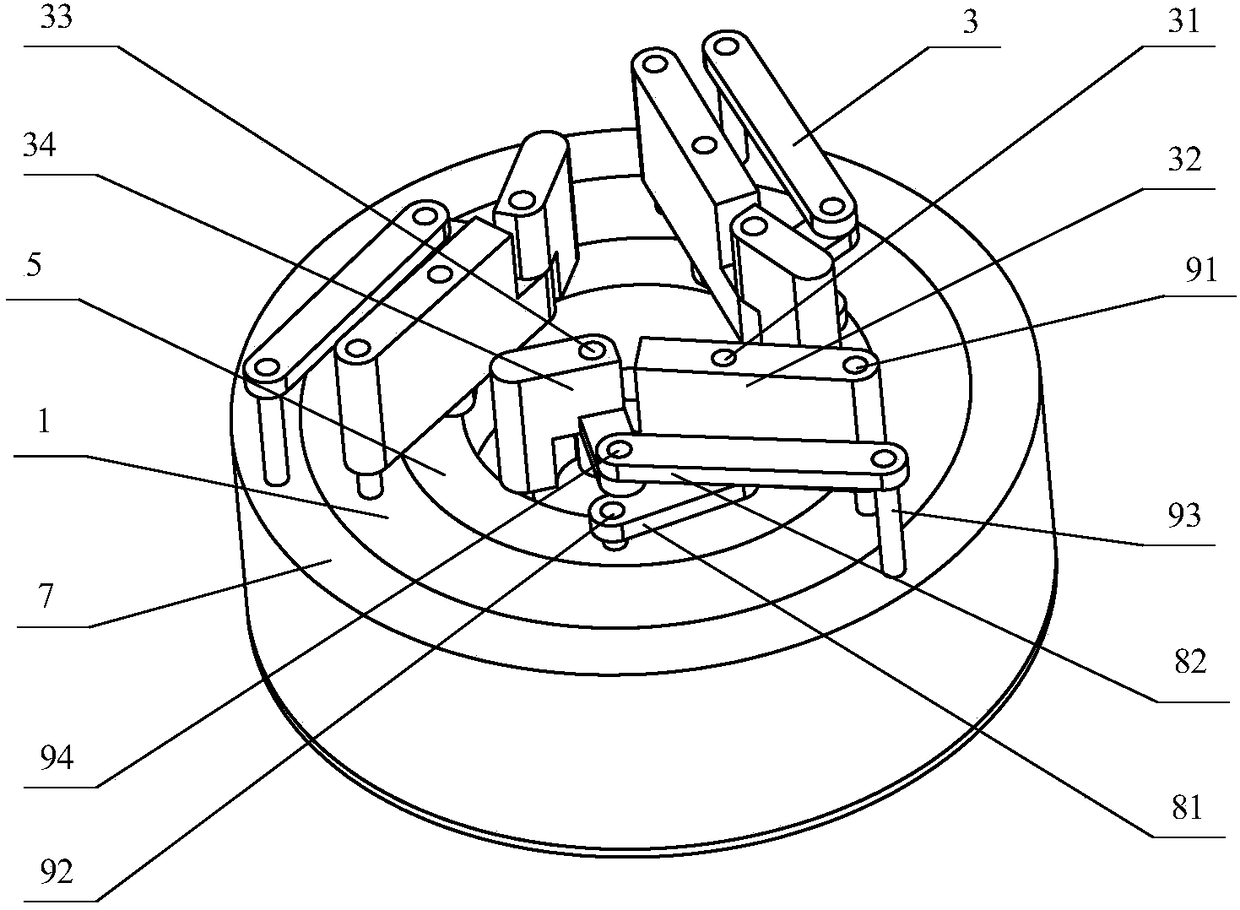

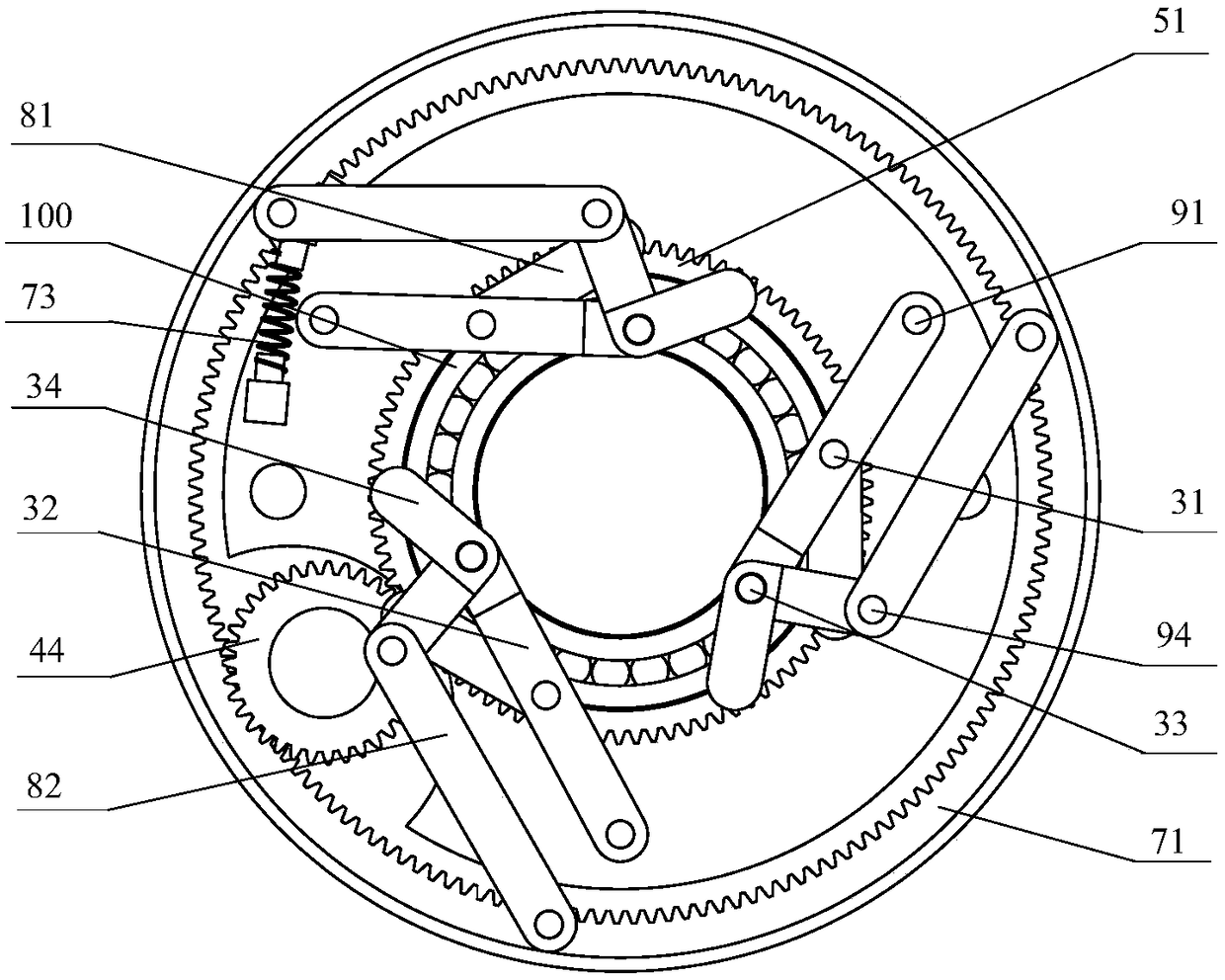

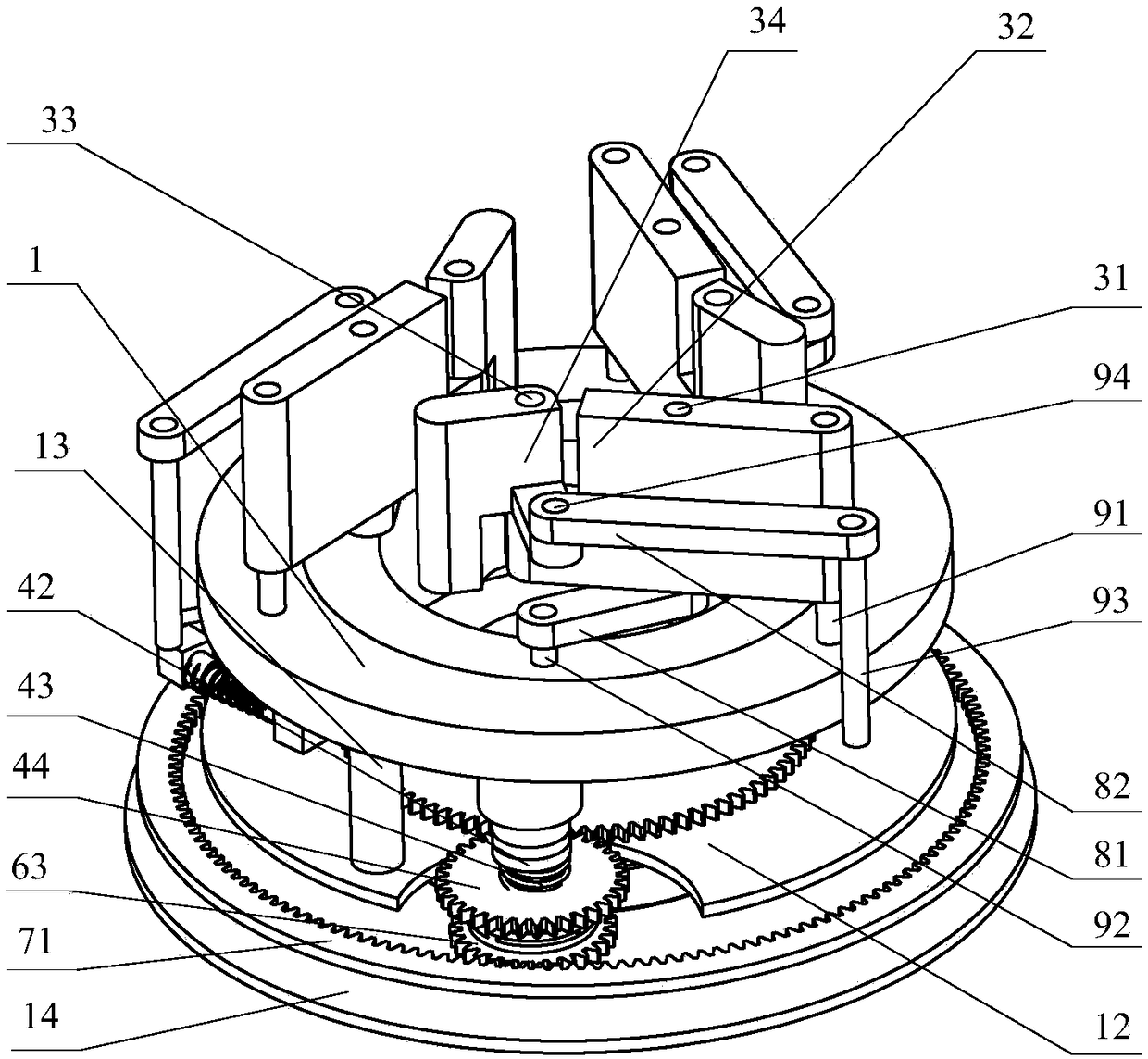

Double-ring rotating multi-finger parallel clamping self-adaptive under-actuated robot hand device

The invention provides a double-ring rotating multi-finger parallel clamping self-adaptive under-actuated robot hand device, and belongs to the technical field of robot hands. The double-ring rotating multi-finger parallel clamping self-adaptive under-actuated robot hand device comprises a base, an actuator, at least two fingers, a driving shaft, a driving wheel, two spring parts, two gears, an inner ring gear ring, an inner ring, a driving stirring disk, a driven stirring disk, an outer ring gear ring, an outer ring, a limiting block and the like. According to the device, the function that a plurality of robot fingers conduct parallel clamping and self-adaptive capture is fulfilled by the use of the double rotatable rings and a link mechanism; the single actuator is used for driving a plurality of joints of the fingers, and the mode of parallel clamping and the mode of self-adaptive capture can be automatically switched according to the differences of the object shapes and the positions; second finger sections can be horizontally moved to clamp objects, the device can also automatically rotate the second finger sections to make contact with the objects after first finger sections make contact with the objects, the greater-strength holding effect is obtained is achieved, and the device can automatically adapt to capture of the objects with different shapes and sizes; and the self-adaptive enveloping direction is perpendicular to the finger extension direction, and capture is stable and reliable.

Owner:广州市轻工职业学校

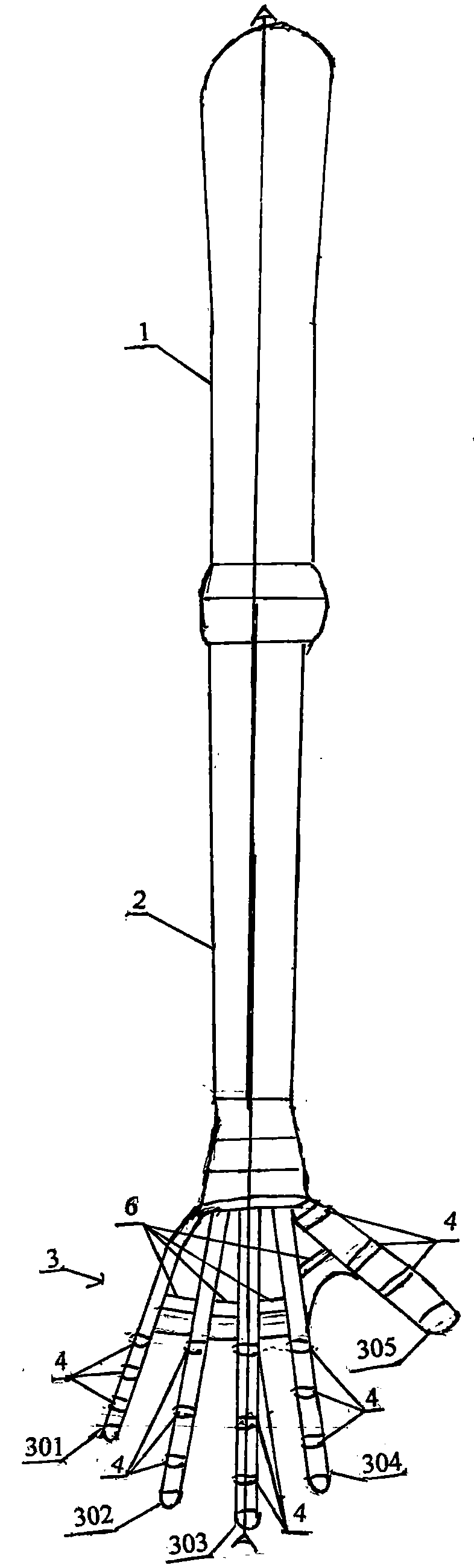

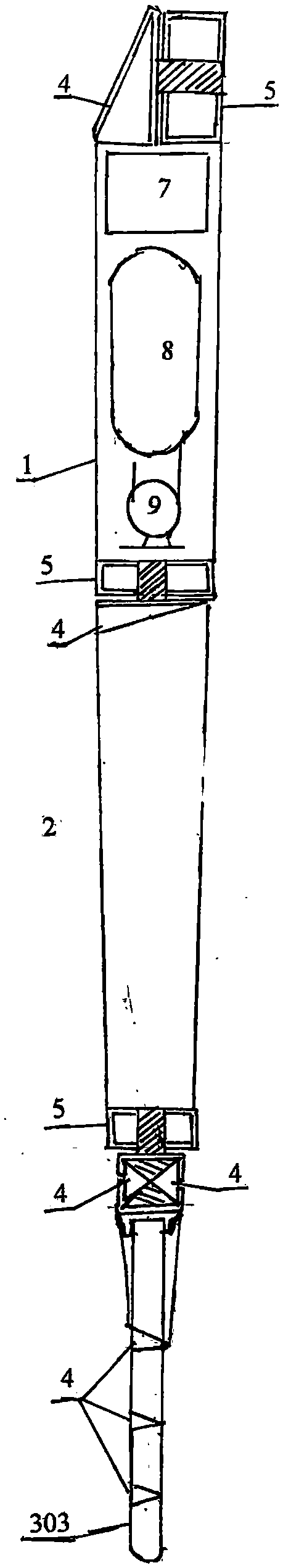

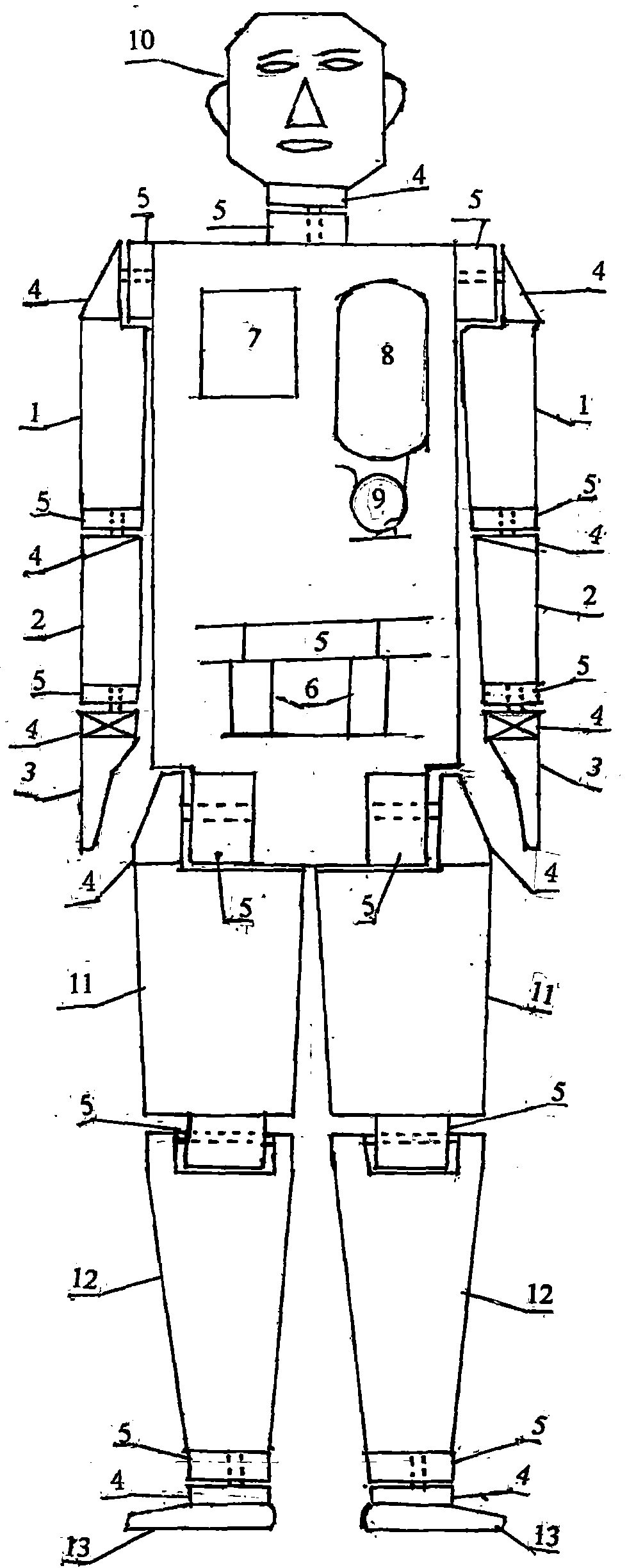

Prosthesis mechanical arm, robot and robot control method

The invention discloses a prosthesis mechanical arm, a robot and a robot control method. Each of a shoulder joint, an elbow joint and a wrist joint is formed by a pneumatic or hydraulic steering device and a sector-shaped air bladder or hydraulic bladder. Finger joints are formed by sector-shaped air bladders or hydraulic bladders, and a pneumatic or hydraulic jack is mounted between each two adjacent finger extension bones of a palm. By electromagnetic waves sent by a biochip connected with upper limb nerves to a computer in an upper arm, the prosthesis mechanical arm controls electromagnetic valves to further control feeding and discharging of compressed air or liquid in the pneumatic or hydraulic jacks, the sector-shaped air bladders or hydraulic bladders and the pneumatic or hydraulic steering devices in the prosthesis mechanical arm, and consequently the prosthesis mechanical arm is enabled to operate. A robot arm of the robot is identical to the prosthesis mechanical arm. Joints of mechanical legs and feet and neck joints of the robot are formed by pneumatic or hydraulic steering devices and the sector-shaped air bladders or hydraulic bladders, and two pneumatic or hydraulic jacks and a sector-shaped air bladder or hydraulic bladder are hidden in a body of the robot. The robot is controlled by the aid of a computer.

Owner:张英华

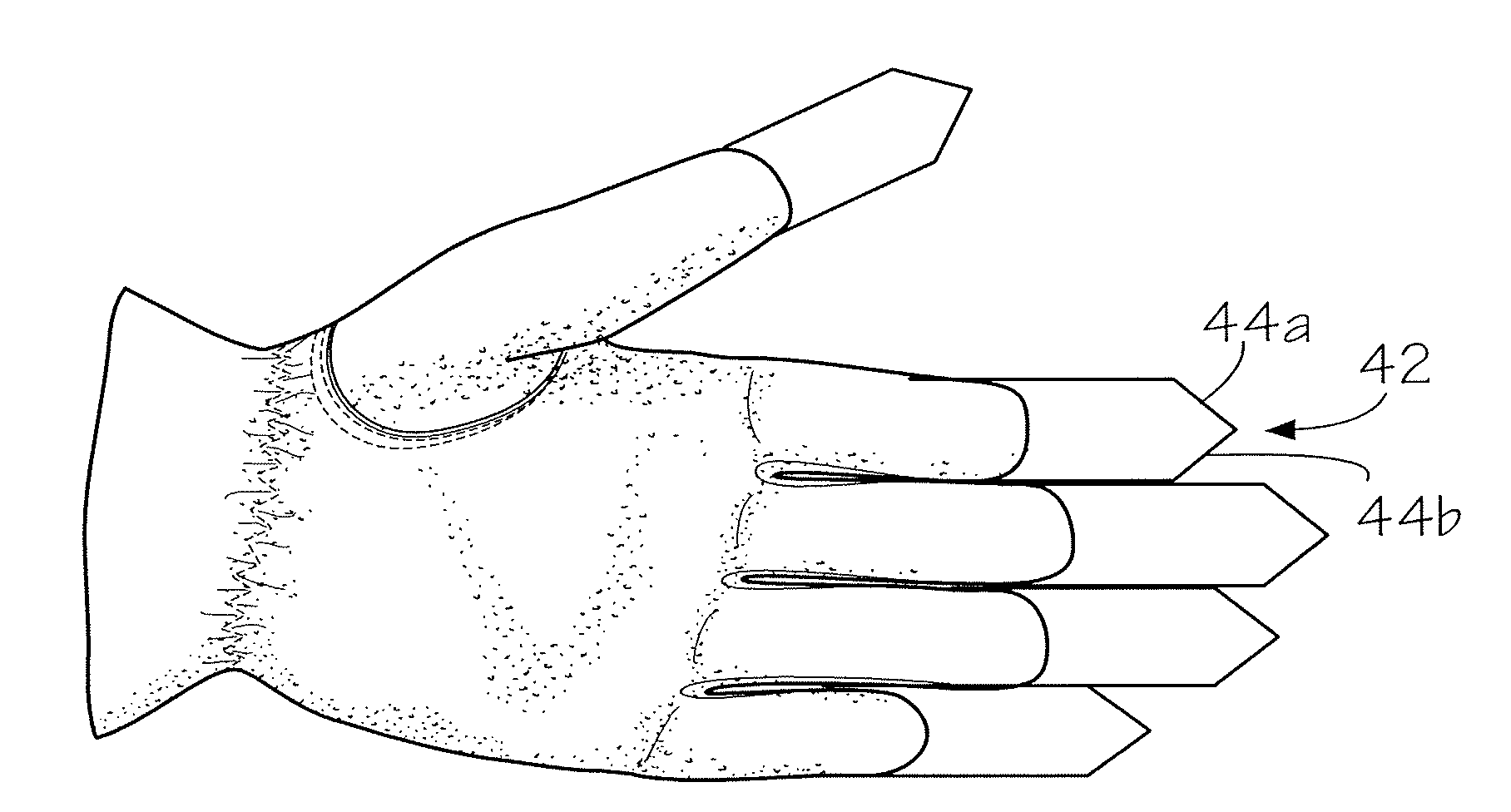

Astronaut gloves with finger extensions

InactiveUS9420836B1Preventing reverse bendingChemical protectionHeat protectionEngineeringContact element

Owner:MADDEN JR JAMES R

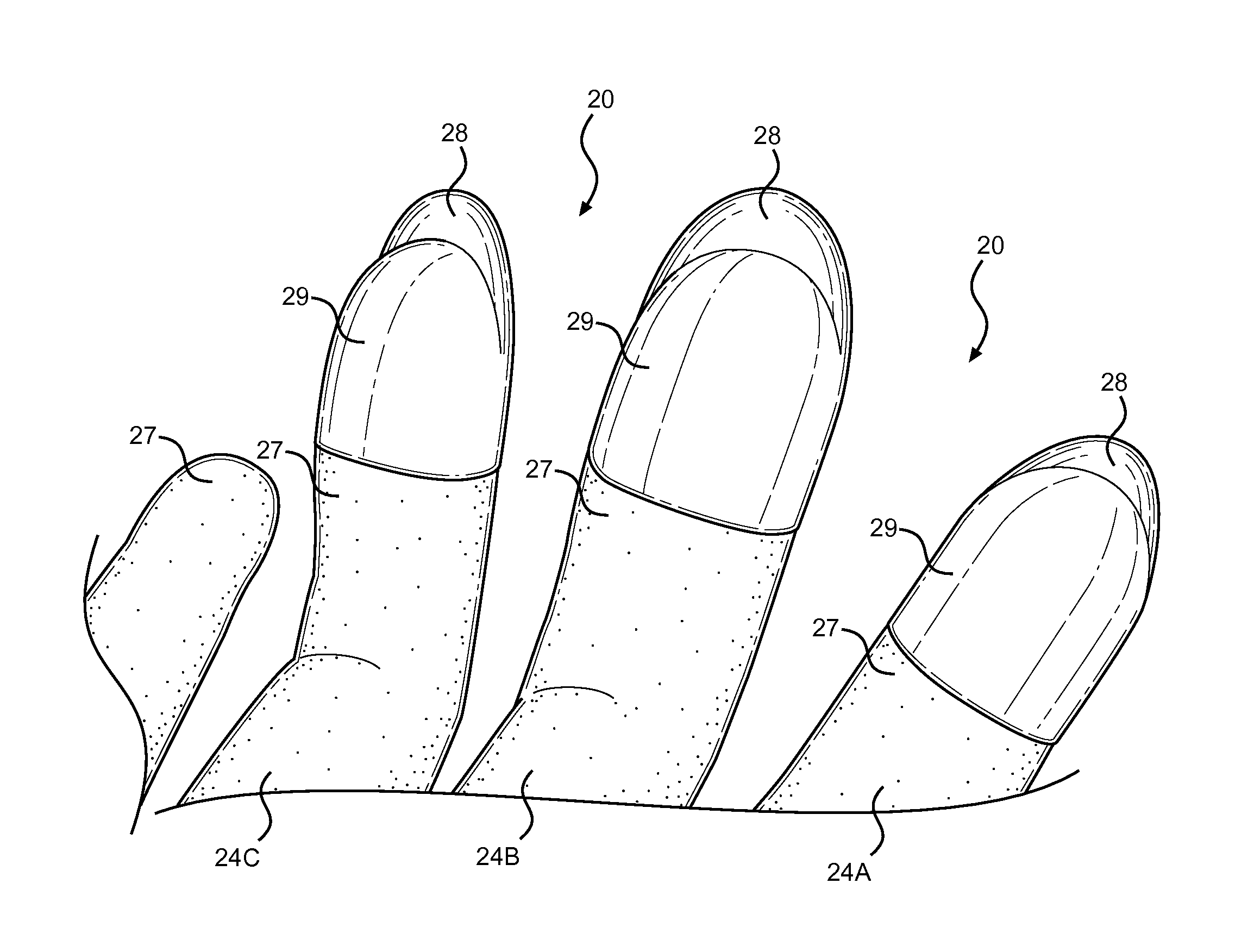

Gardening Glove

A gardening glove is provided. The gardening glove is configured to facilitate the removal of weeds from a yard or garden. The gardening glove includes a palm side, a back side, and a wrist encircling cuff that forms an interior volume configured to receive and support a user's hand. The gardening glove further includes finger extensions and a thumb extension that extend from the palm configured to receive and support a user's fingers. The finger extensions for a user's ring finger, middle finger, and index finger further include a cap portion disposed on the distal end of the finger extensions. Each cap portion includes a blade extending outwardly therefrom configured to facilitate the removal of weeds. Each blade forms a sharp apex configured to allow for digging and can be substantially shaped like a shovel or garden trowel blade.

Owner:PRICE DEBRA S

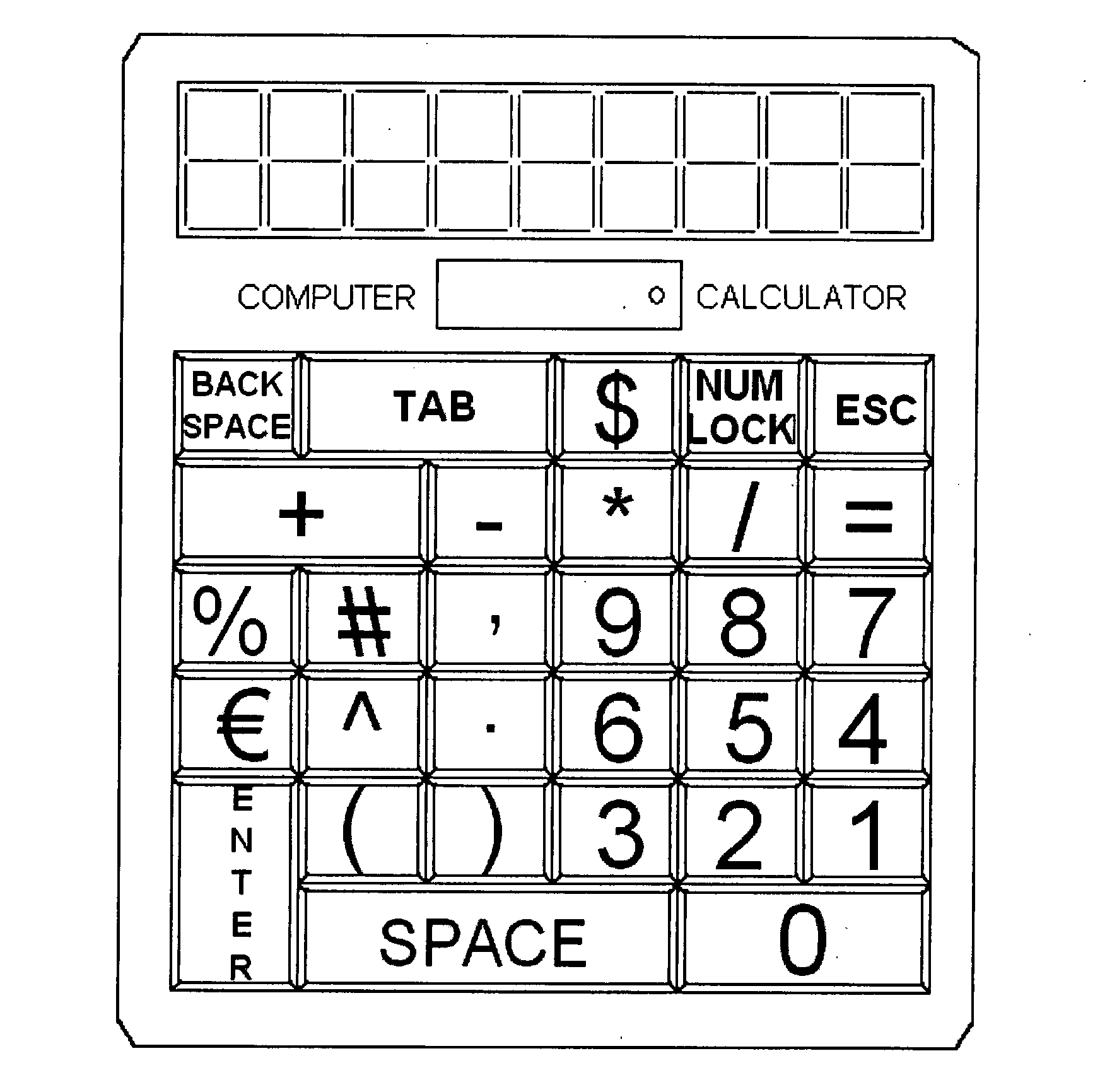

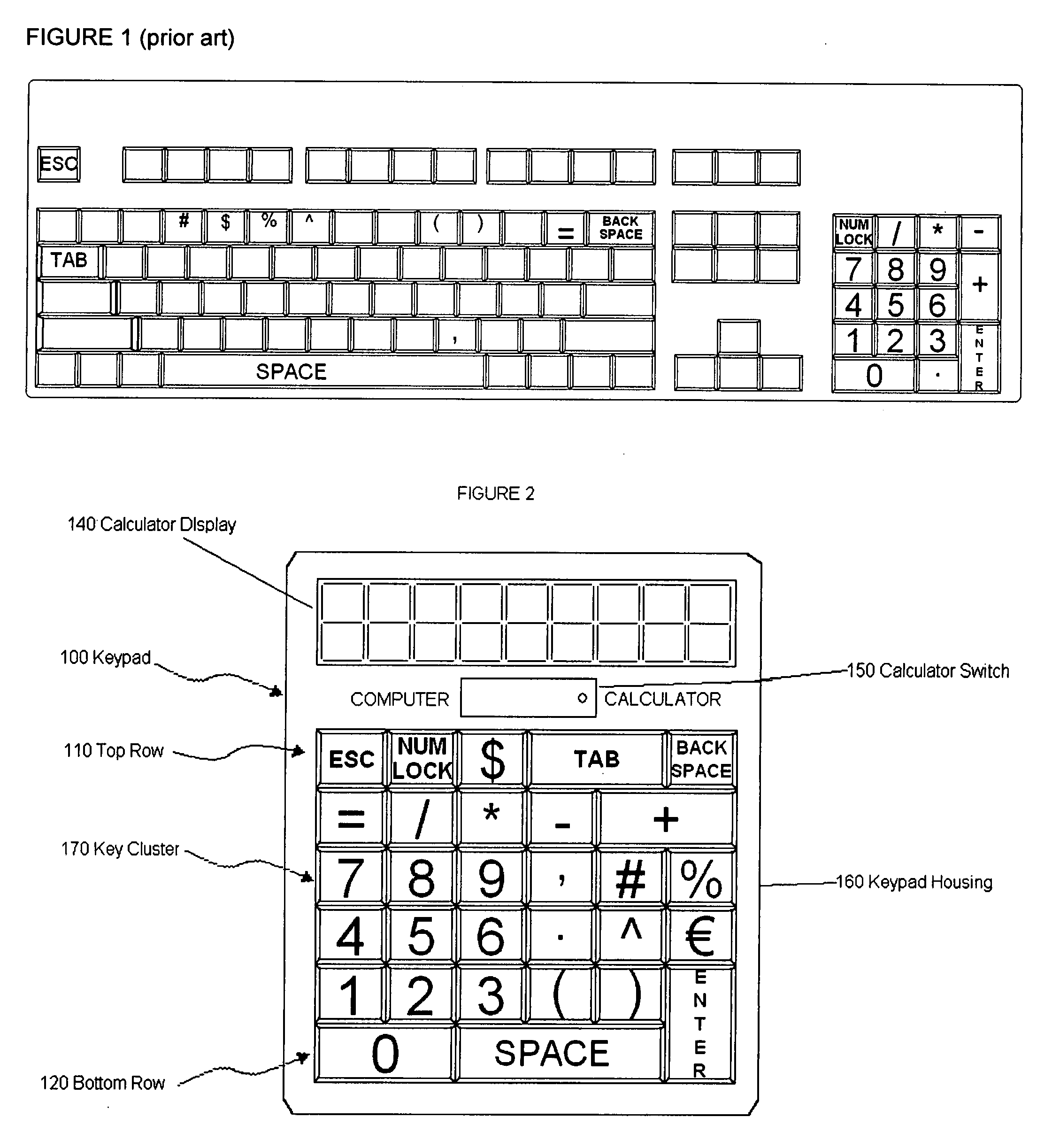

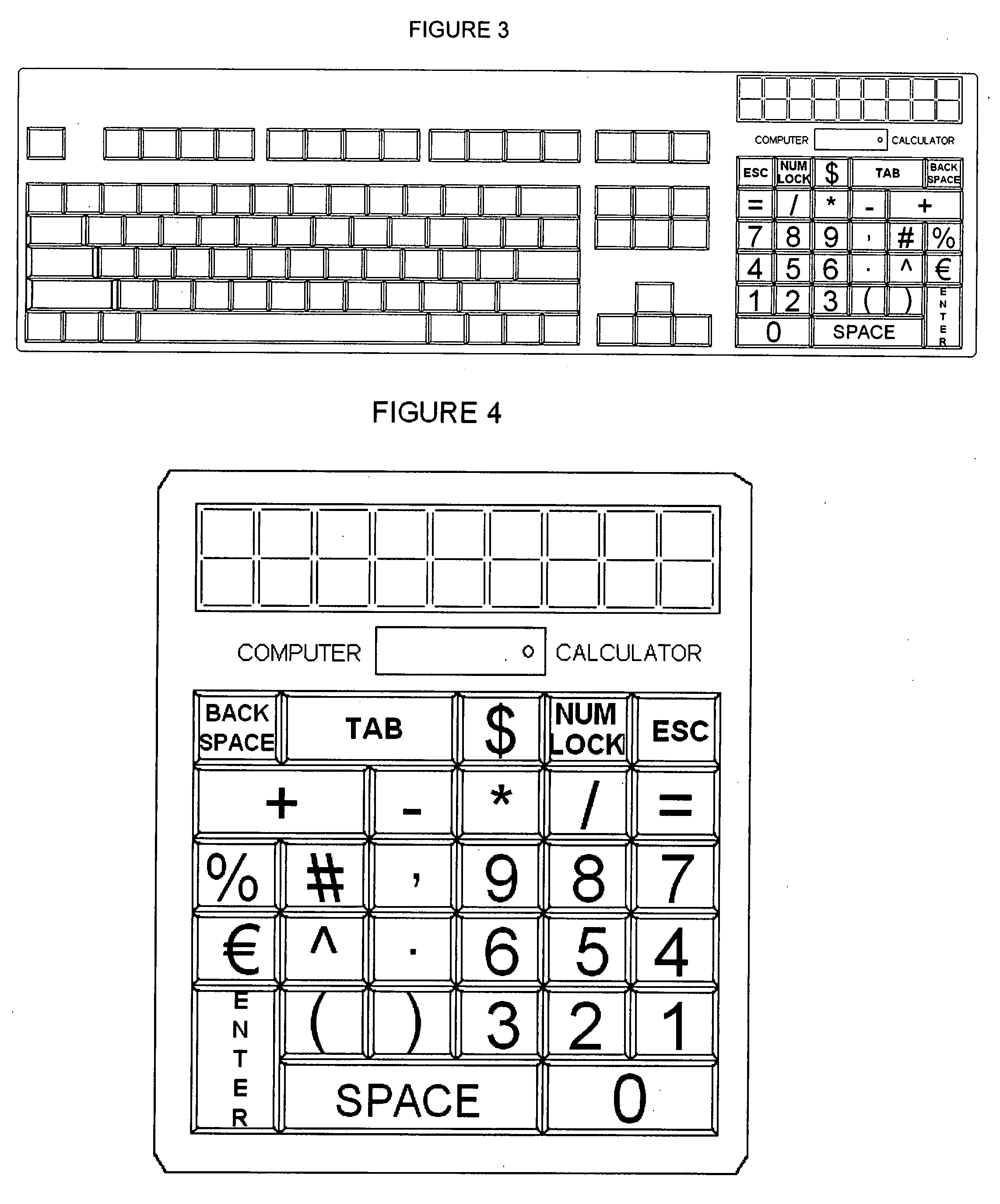

Computer keypad for improved input efficiency

InactiveUS20080224897A1Improve input efficiencyData augmentationElectronic switchingInput/output processes for data processingAlgorithmSoftware engineering

A numeric key pad is provided for efficiently entering numbers and symbols into a computer. The numeric key pad includes a number region having digits 1-9 arranged in a 3×3 grid, the 3×3 grid having N, S, E, W, NE, SE, NW, SW, and Central positions. The numeric keypad also includes a nearest neighbor symbol region having a first plurality of symbols, each symbol being at a nearest neighbor position of the 3×3 grid, the first plurality of symbols being selected from the set including: esc, $, Tab, Backspace, =, comma, #, %, ,, (, ), space. The numeric keypad includes all of the standard keys, along with non-standard yet often-used keys. The non-standard keys are located with the standard keys such that they all fall within the natural finger extension range of a user. The numeric key pad can also be advantageously incorporated into an alphanumeric keyboard.

Owner:SILVA DAVID P

Gardening Utility Tool

An improved gardening utility tool comprising: a glove; a set of finger extensions attached to the glove wherein the finger extension can move independently in an open arrangement; a first portion include in each finger extension having a first resiliency; a second potion attached to the first portion having a second resiliency having a proof resilience higher relative to the first portion; a plurality of releasable connections disposed on an internal later surface of the finger extensions releasably connecting the finger extension to form a composite tool in a closed arrangement of the finger extensions; a forward edge included in each finger extension having a shape taken from the group consisting of: flat, curved, concave, angled, concave angled, point and any combination thereof.

Owner:BLOCK SASHA

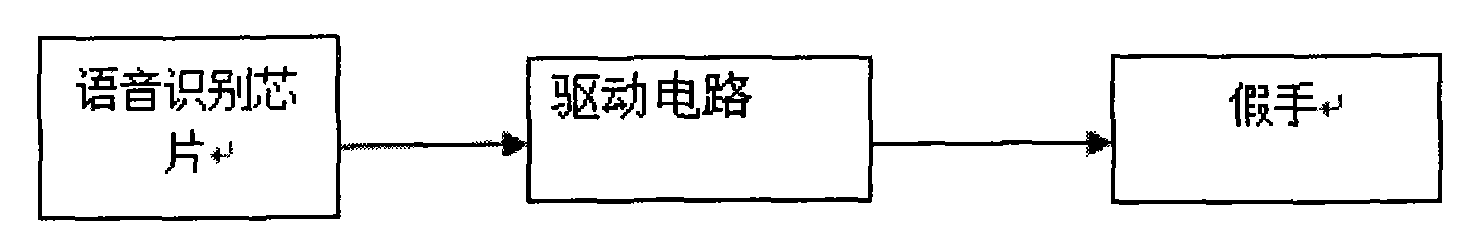

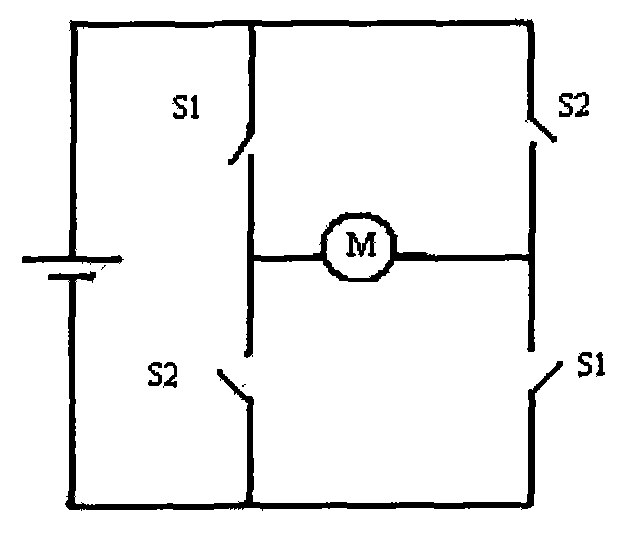

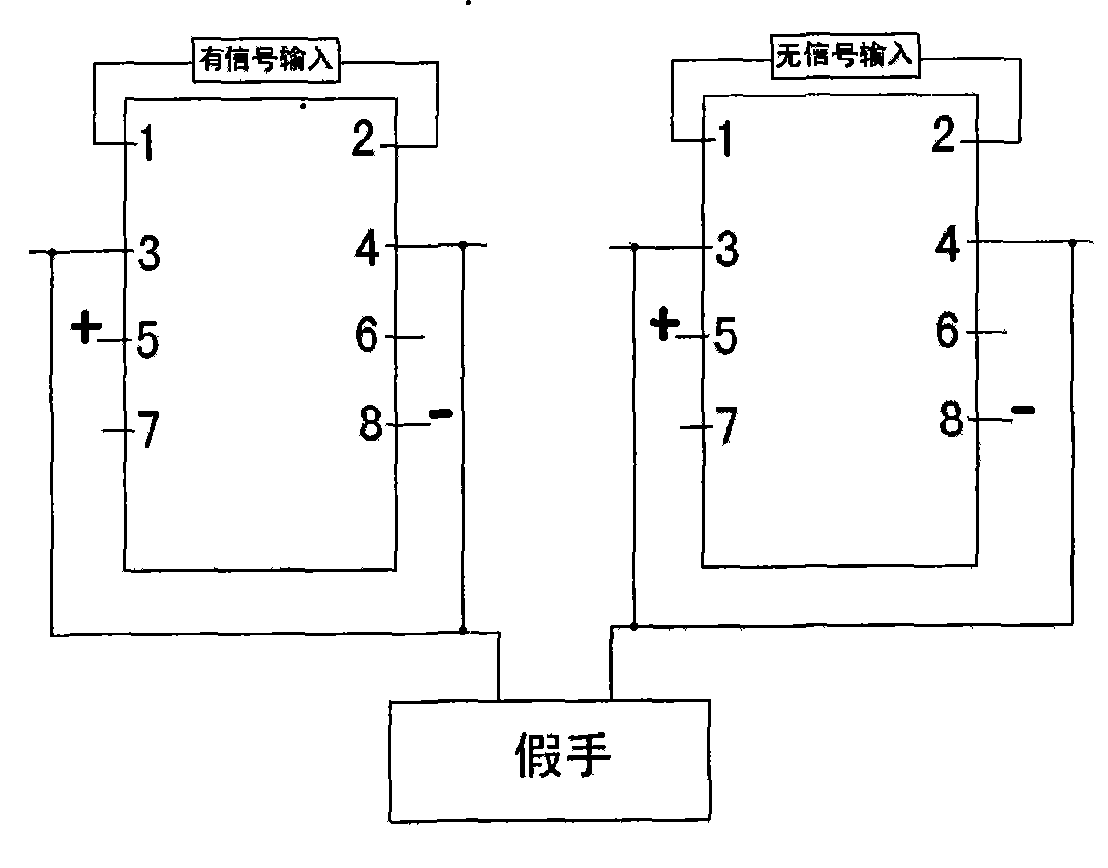

Electronic artificial hand based on sound control

InactiveCN101584616AAchieve outputRealize functionSpeech recognitionProsthesisThree degrees of freedomElectric machinery

The invention relates to an electronic artificial hand based on sound control, which includes an artificial hand speech recognition module, a signal amplification output chip and a signal relay control circuit. And the speech recognition module is composed of a speech recognition chip which can only recognize the user's own speech signal; and the speech recognition chip input end receives at least 7 kinds of speech instructions, one speech instruction is used for specialized training of urgency stop controls of any actions of artificial hand, other six instruction are outputted for the artificial hand electric relay control circuit, two to six instruction output signal are respectively used for controlling one to three freedom degrees of artificial hand, thereby finishing six actions of finger extension, finger bending, wrist internal rotation, wrist outward rotation, wrist extension and wrist bending. The invention can realize speech study function and recognition function, and realize outputs of two to more than six control instructions. The electric relay is used for controlling positive and negative rotation of electric motor, thereby realizing opening and closing functions of artificial hand controlled by two signals.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

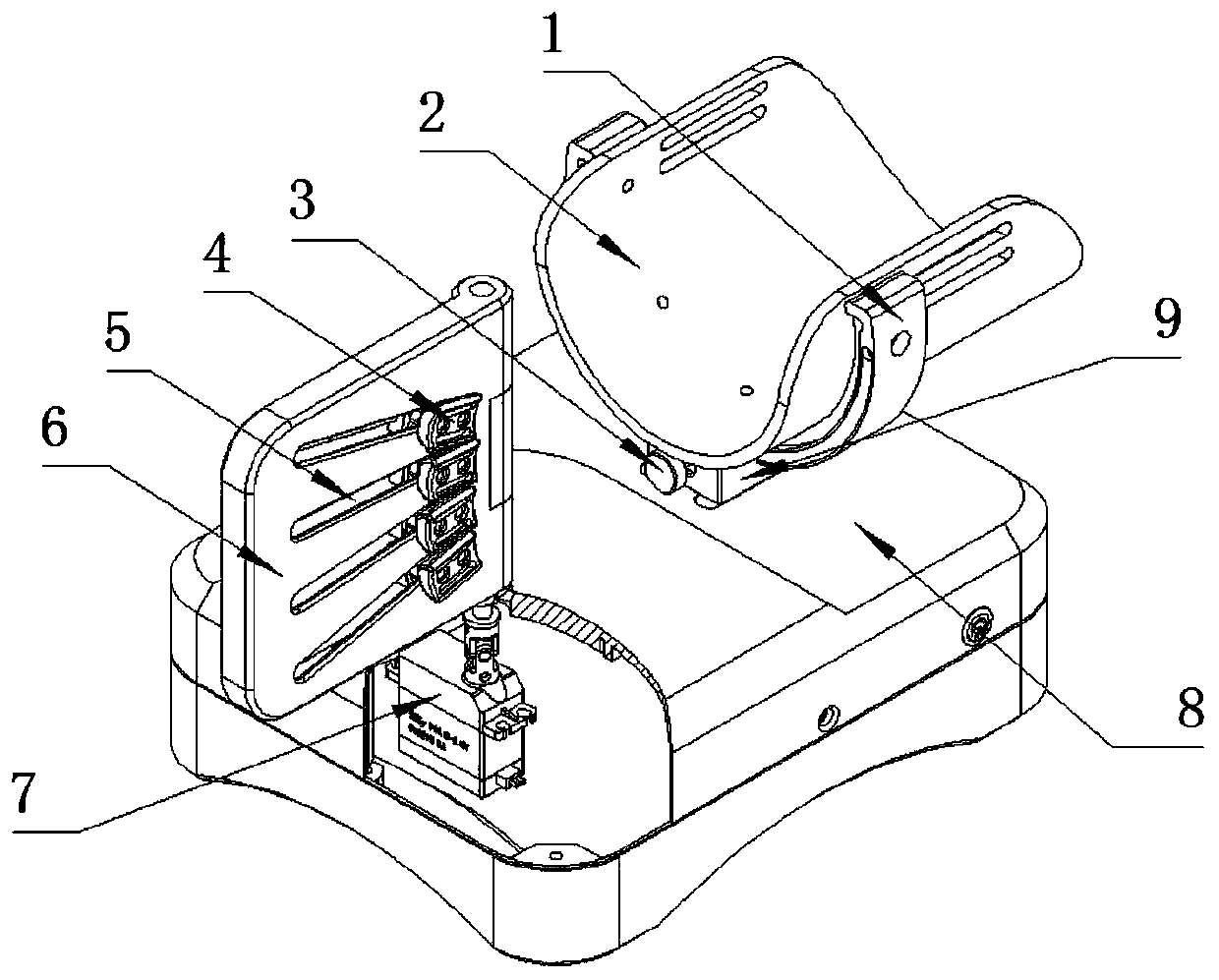

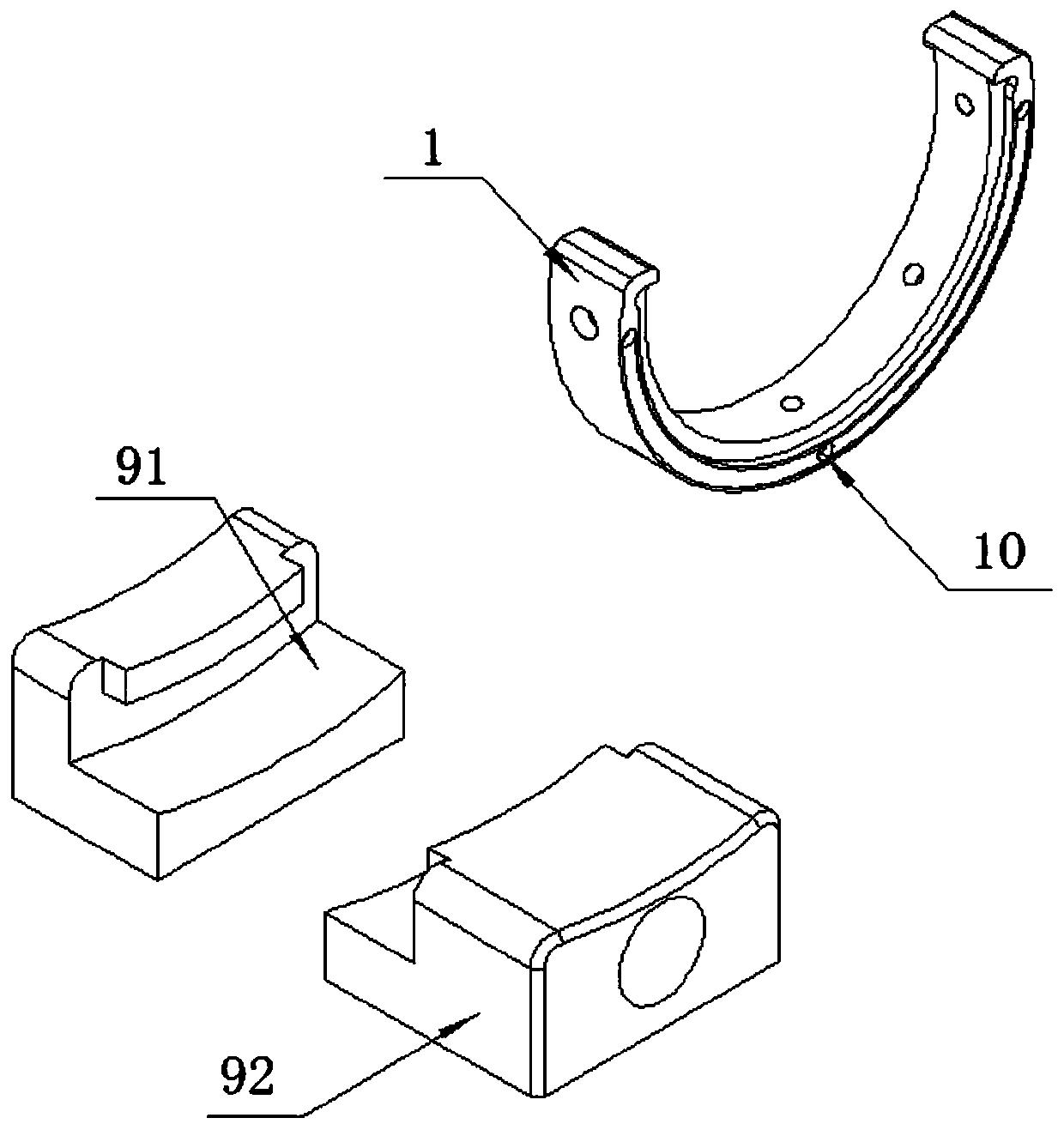

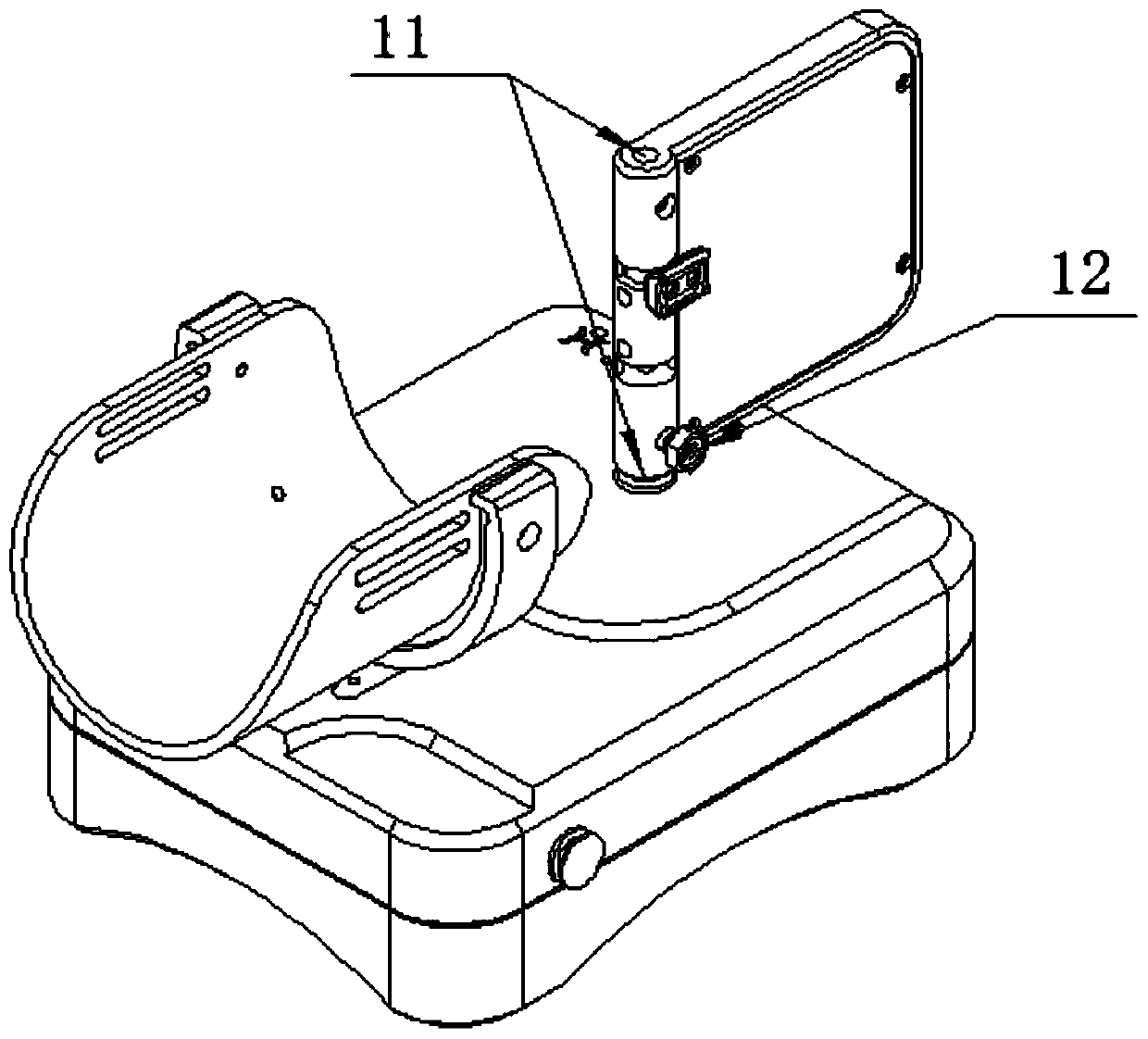

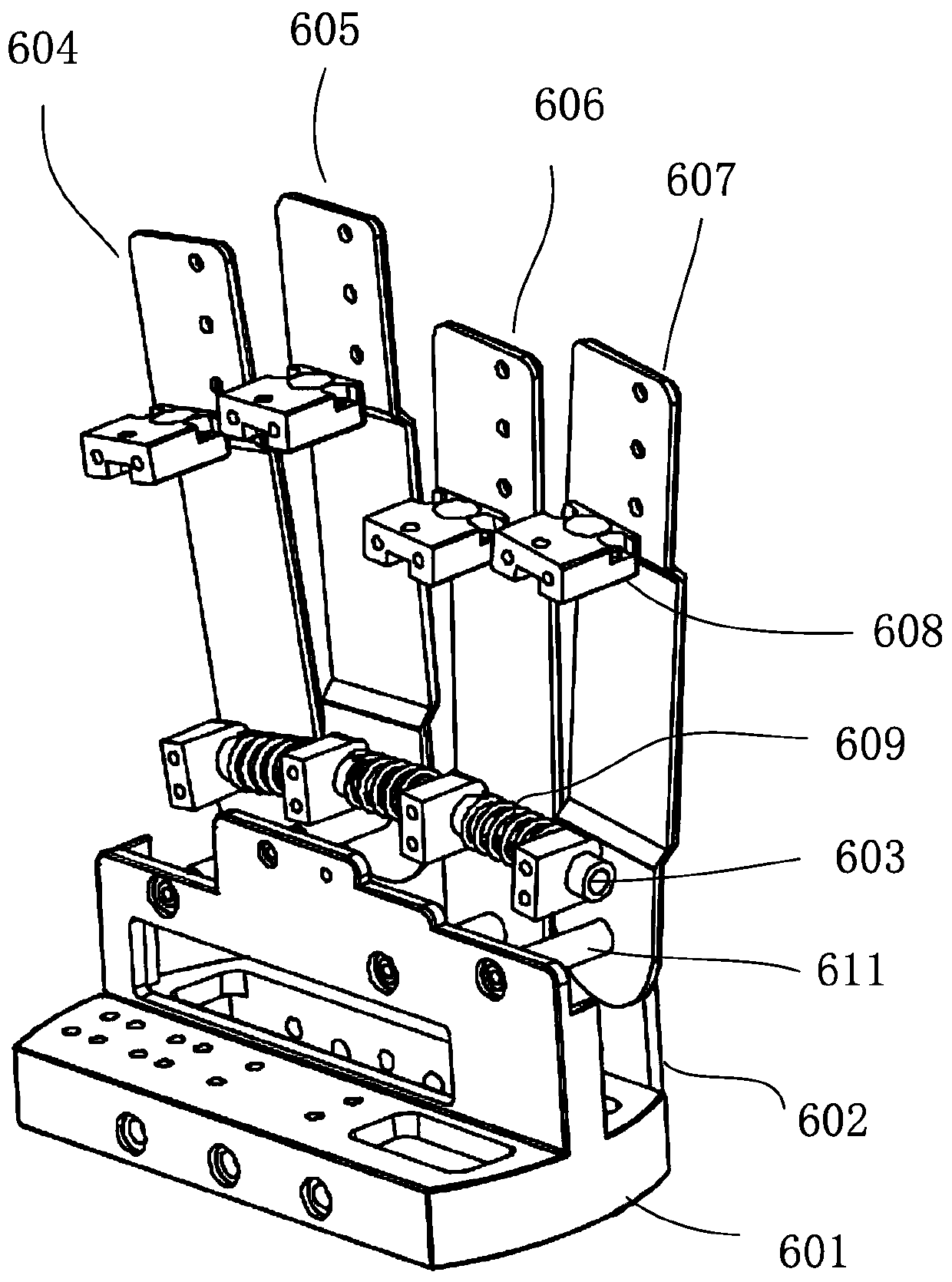

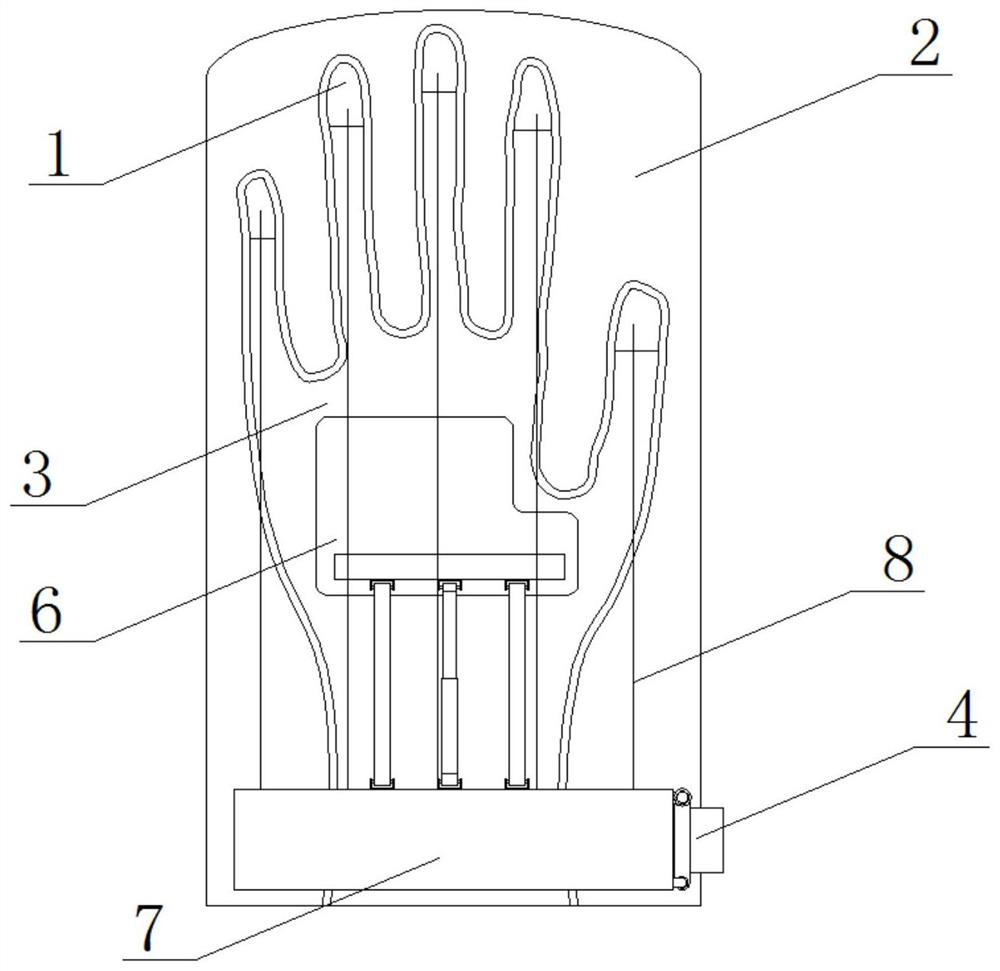

Brain-controlled finger stretching rehabilitation training instrument

InactiveCN111467183AQuick swapFast implementation of interchangeDiagnosticsChiropractic devicesMechanical engineeringFinger extension

The invention discloses a brain-controlled finger extension rehabilitation training instrument, and relates to the technical field of finger exercise devices. The instrument comprises an arm supporting device, a finger fixing device and a main control box, and the arm supporting device and the finger fixing device are arranged on the main control box; the arm supporting device comprises an arm support and a guide block, an arm support guide is fixedly connected to the lower portion of the arm support, and the arm support is installed on the guide block in a sliding mode through the arm supportguide; the finger fixing device is installed in front of the arm supporting device and comprises finger fixing blocks, a holding plate and a steering engine, four sliding rails are arranged on the holding plate at an angle, the number of the finger fixing blocks is four, and the four finger fixing blocks are installed on the four sliding rails in a sliding mode respectively; and the holding plateis detachably installed on the steering engine, and the steering engine drives the holding plate to rotate. The instrument achieves stretching movement of four fingers and finger separating movementof the four fingers, and achieves rehabilitation training of the fingers of a patient.

Owner:山东海天智能工程有限公司

Implantable slings and anchor systems

ActiveUS9572648B2Easy tension adjustmentSuture equipmentsAnti-incontinence devicesMedicineBiomedical engineering

Various embodiments of a mesh or implant systems are provided. The implants can include one or more anchors, arms and the like. The anchors can include hingeable or patterned finger extension to facilitate tissue penetration and retention. Various tensioning and adjustment mechanisms, devices and methods are further provided for the implant systems.

Owner:BOSTON SCI SCIMED INC

Thumb Stylus for Capacitive Touch Screens

A thumb or finger extension device for touchscreen use may be manufactured in a generic shape or may be custom-fitted to a particular user's thumb or finger, for example to accommodate a user who has lost all or part of the thumb or other finger. The device, whether generic or custom-fitted, fits firmly and comfortably on the thumb or finger. In a second embodiment, the device provides one or more bands for affixing the device on the thumb or other finger of a user. Each embodiment is manufactured from a flexible material, and provides a protrusion at the center of the bulb of the device, which may be used to operate the touchscreen and the keys of a smartphone or other electronic device.

Owner:MARTIN RYAN

Under-actuated dexterous hand with bifurcated palm and coaxial rotating wrist

The invention discloses an under-actuated dexterous hand with a bifurcated palm and a coaxial rotating wrist. The under-actuated dexterous hand comprises five under-actuated fingers, the bifurcated palm and the coaxial rotating wrist, the under-actuated structure realizes the motion coupling of three knuckles, through driving of a DC deceleration motor at the root of each finger, the thumb realizes the motion coupling of the upper and middle knuckles through the under-actuated structure, and the lower knuckle is driven by a separate motor to realize the opposition motion of the thumb; and theinitial opening and closing angle of the palm is determined by a cylindrical spiral spring and an initial steel wire between two spring fixing seats between every two fingers, in the process of grasping, the opening and closing angle of the palm is controlled by two traction steel wires corresponding to each finger, one end of each steel wire is connected with the root of the corresponding finger,the middle of each steel wire is connected with the root of the corresponding finger through a wire wheel, the other end of each steel wire is connected with a driving motor, and the coaxial rotatingwrist achieves the perpendicular intersection of the rotation axes of the two-degree-motion wrist through gear driving. The under-actuated dexterous hand has the advantages of being high in flexibility and high in controllability and reliability of finger extension and flexion movement and separation and closing movement.

Owner:TIANJIN UNIV

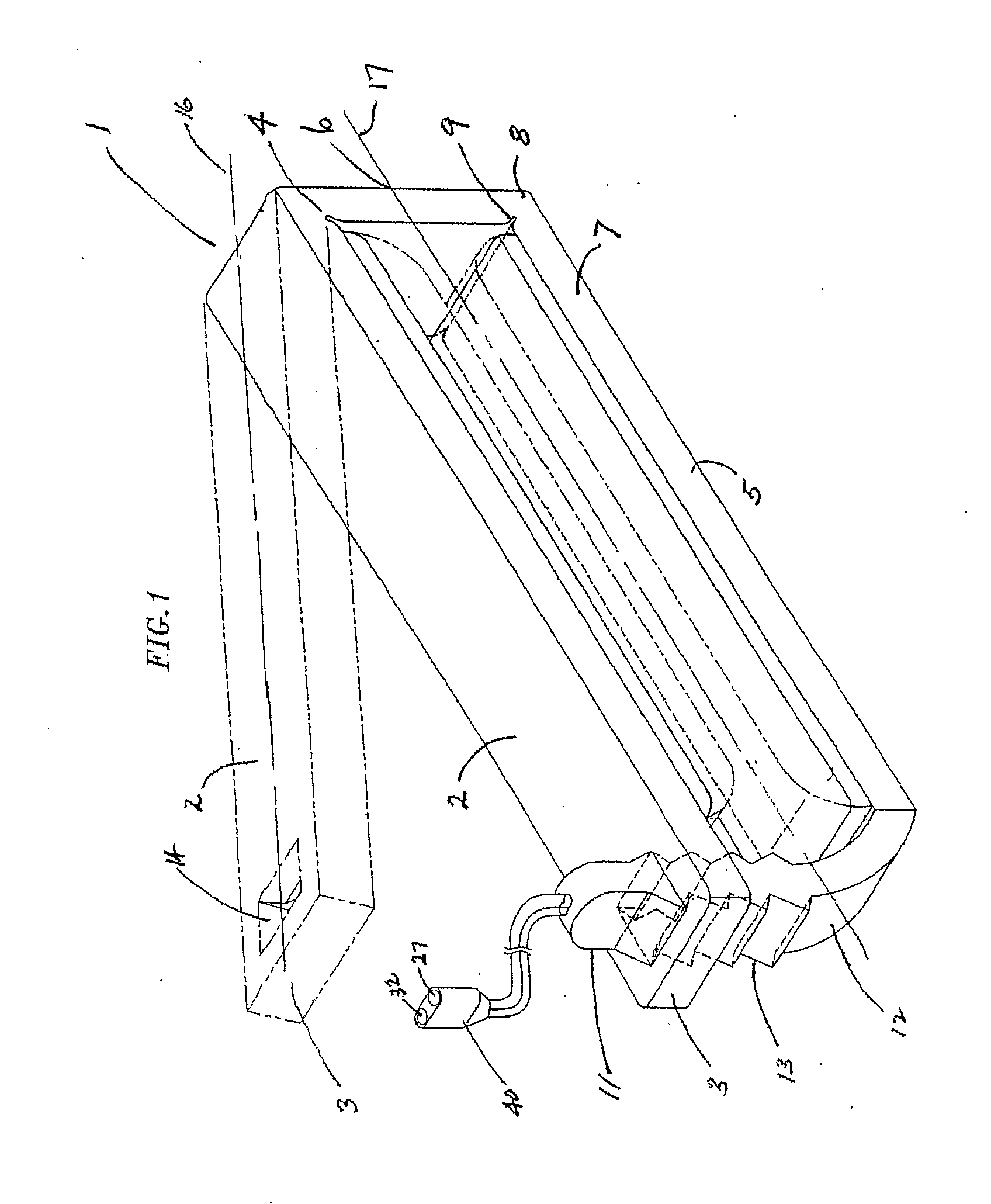

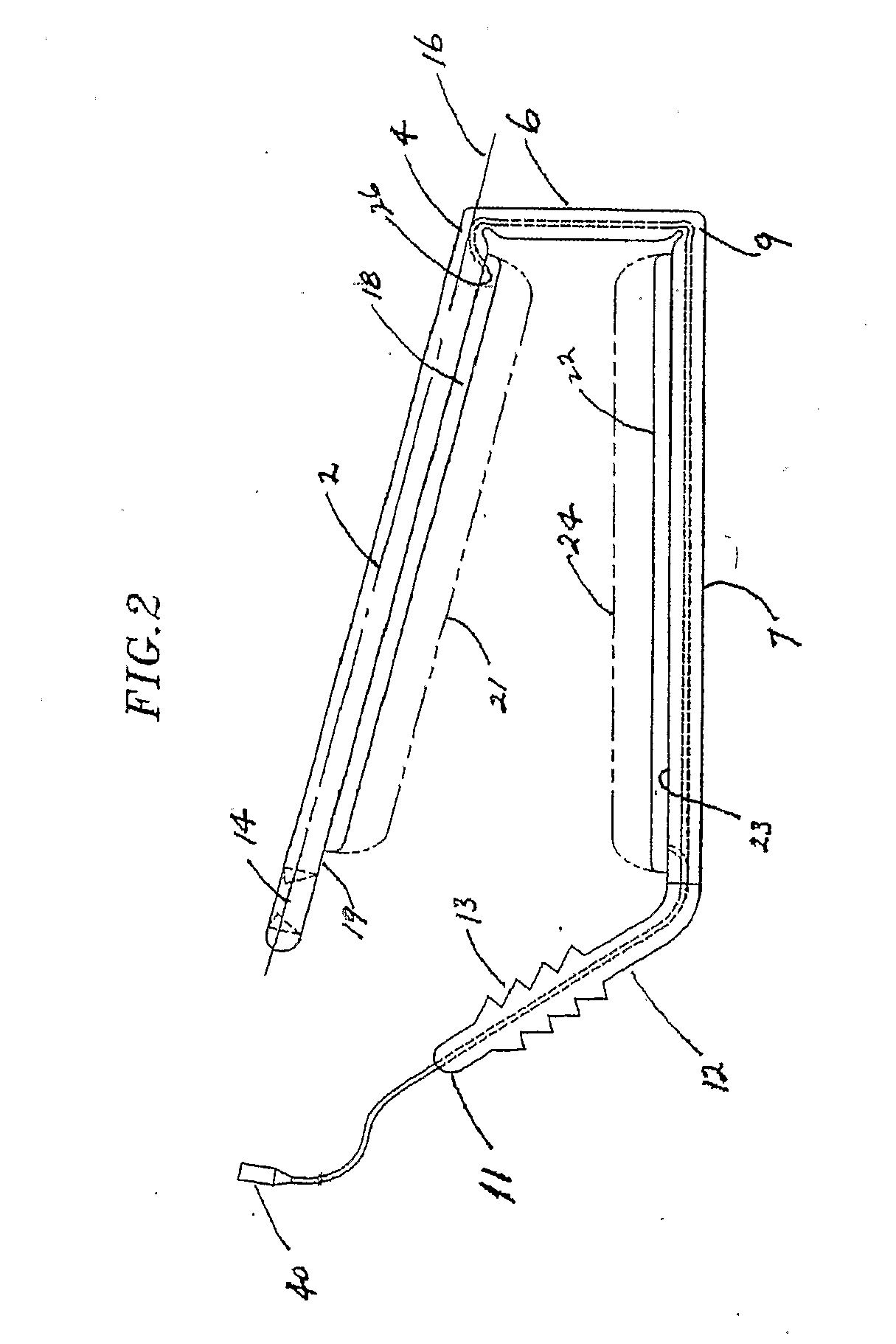

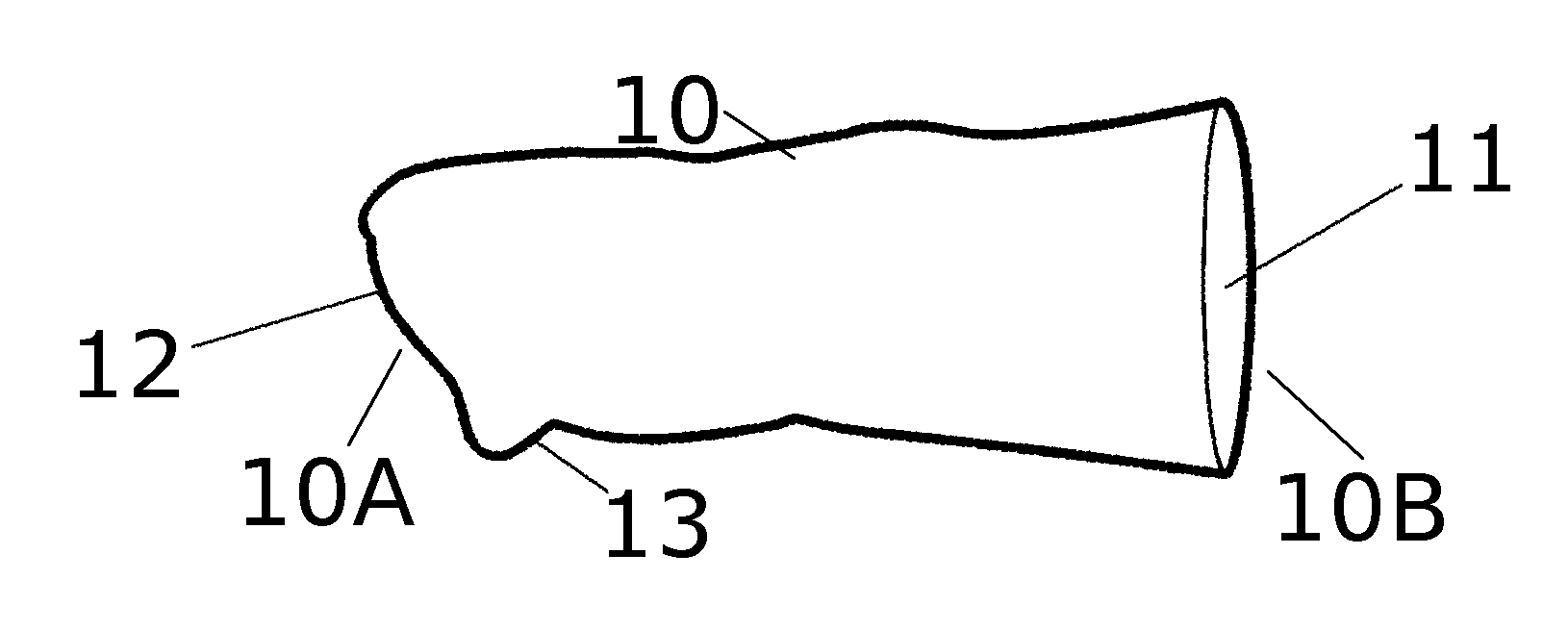

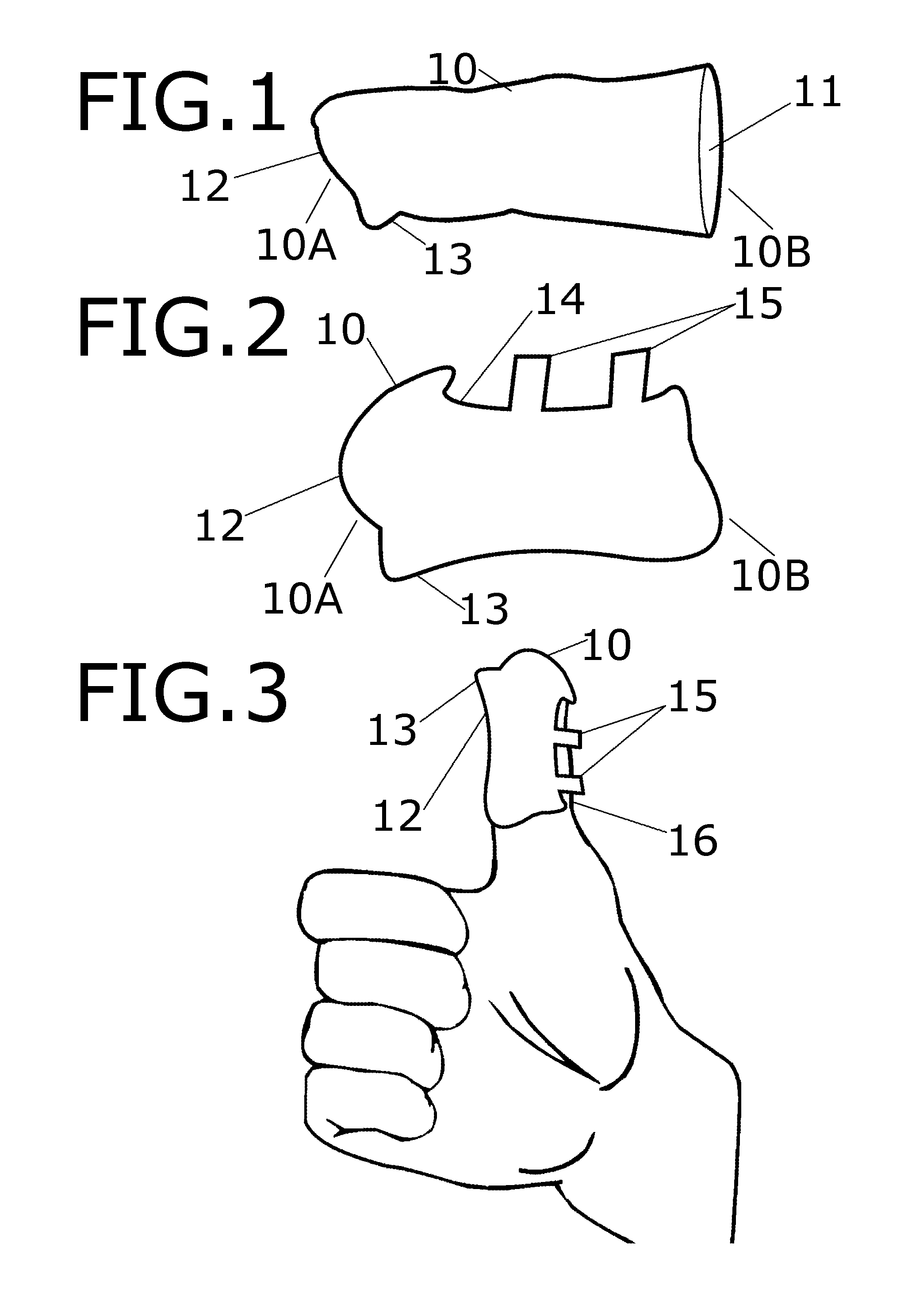

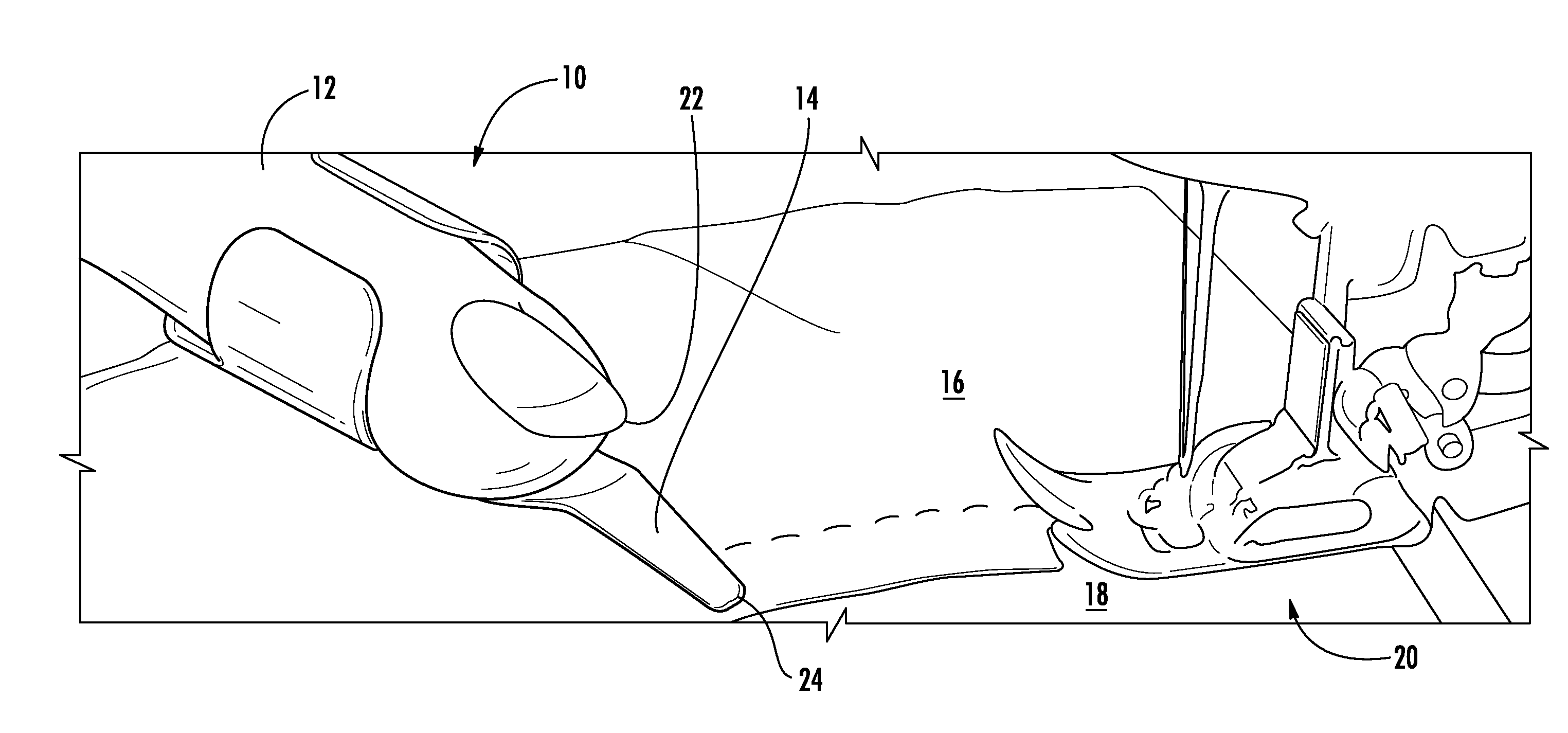

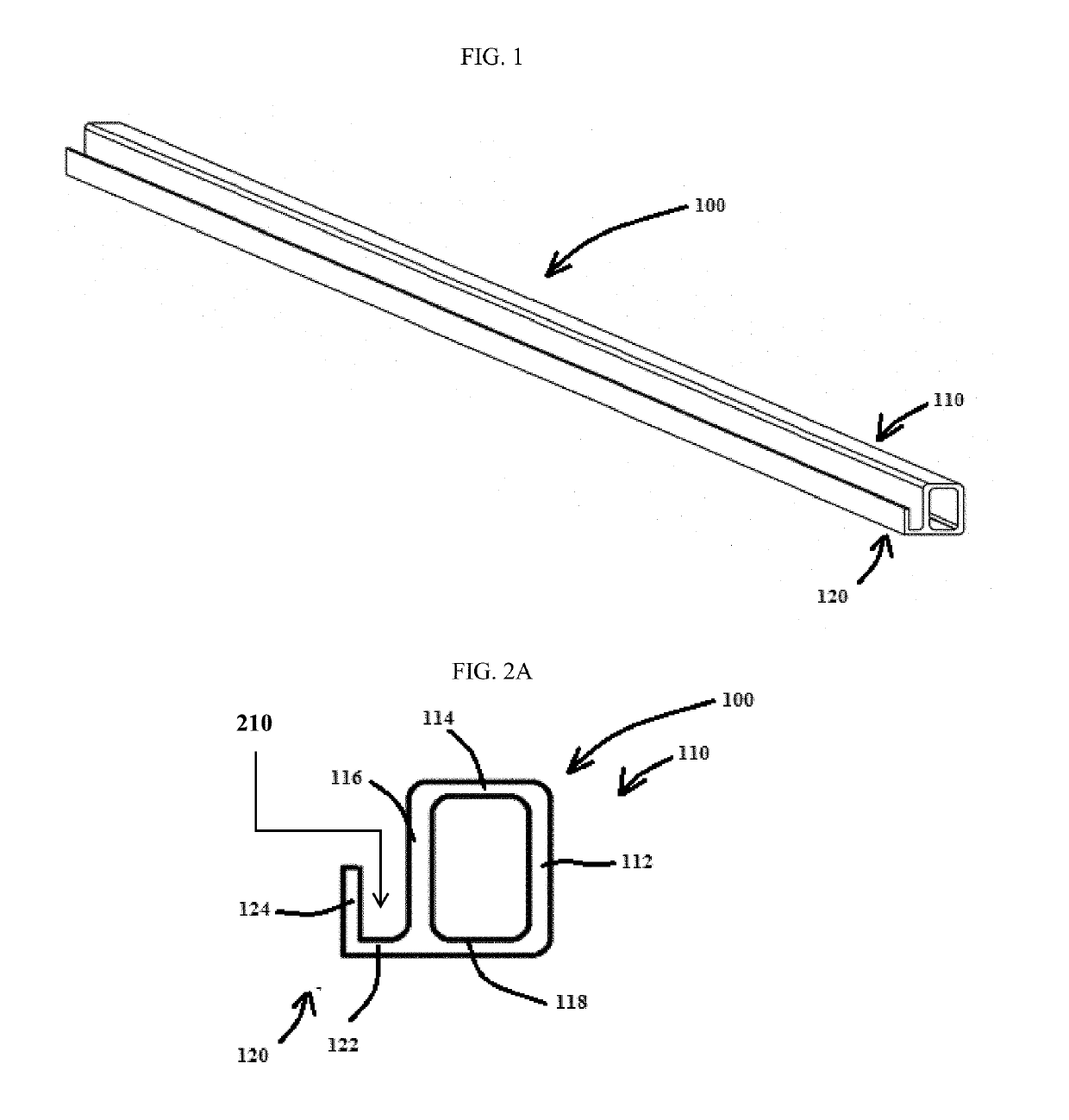

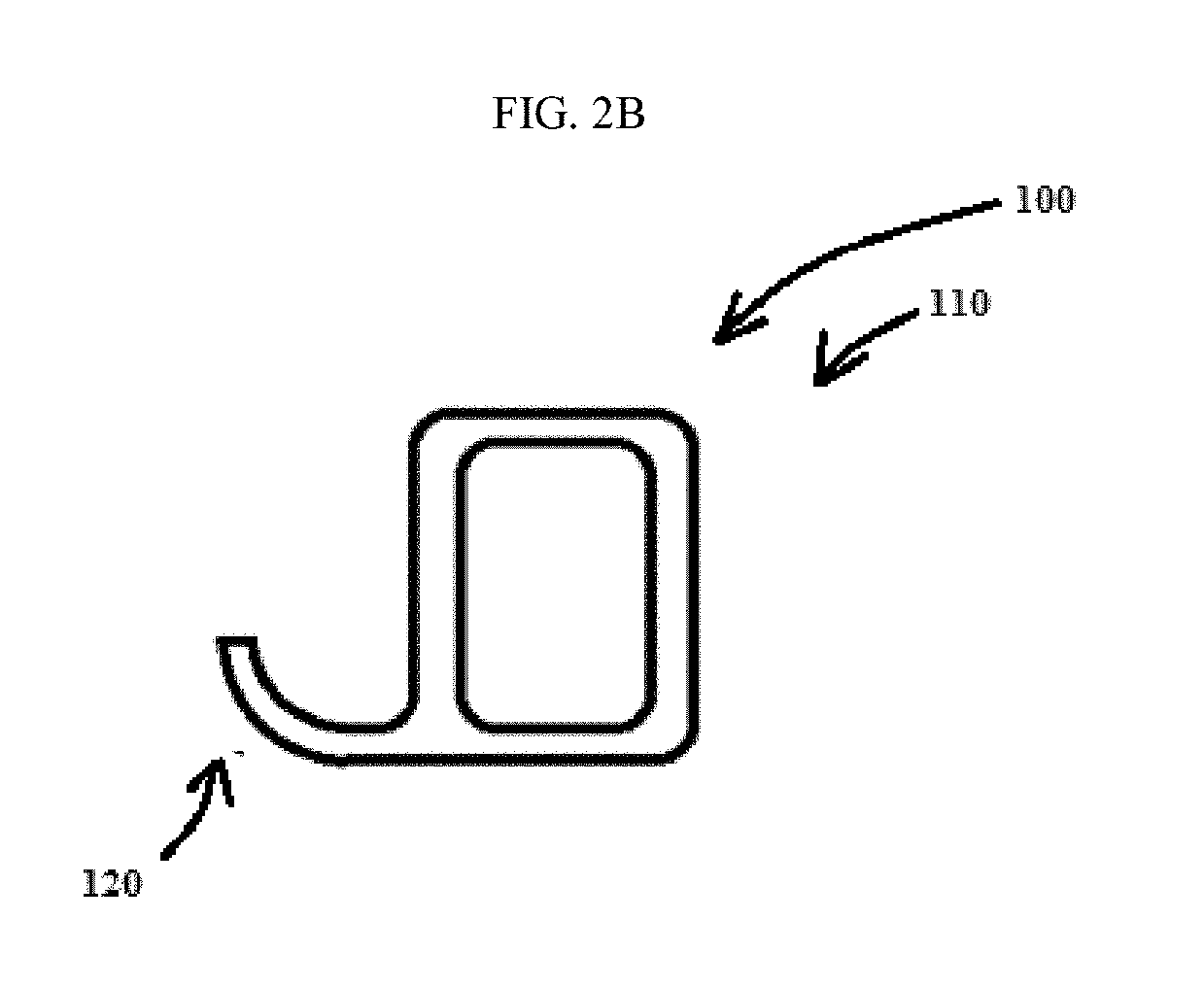

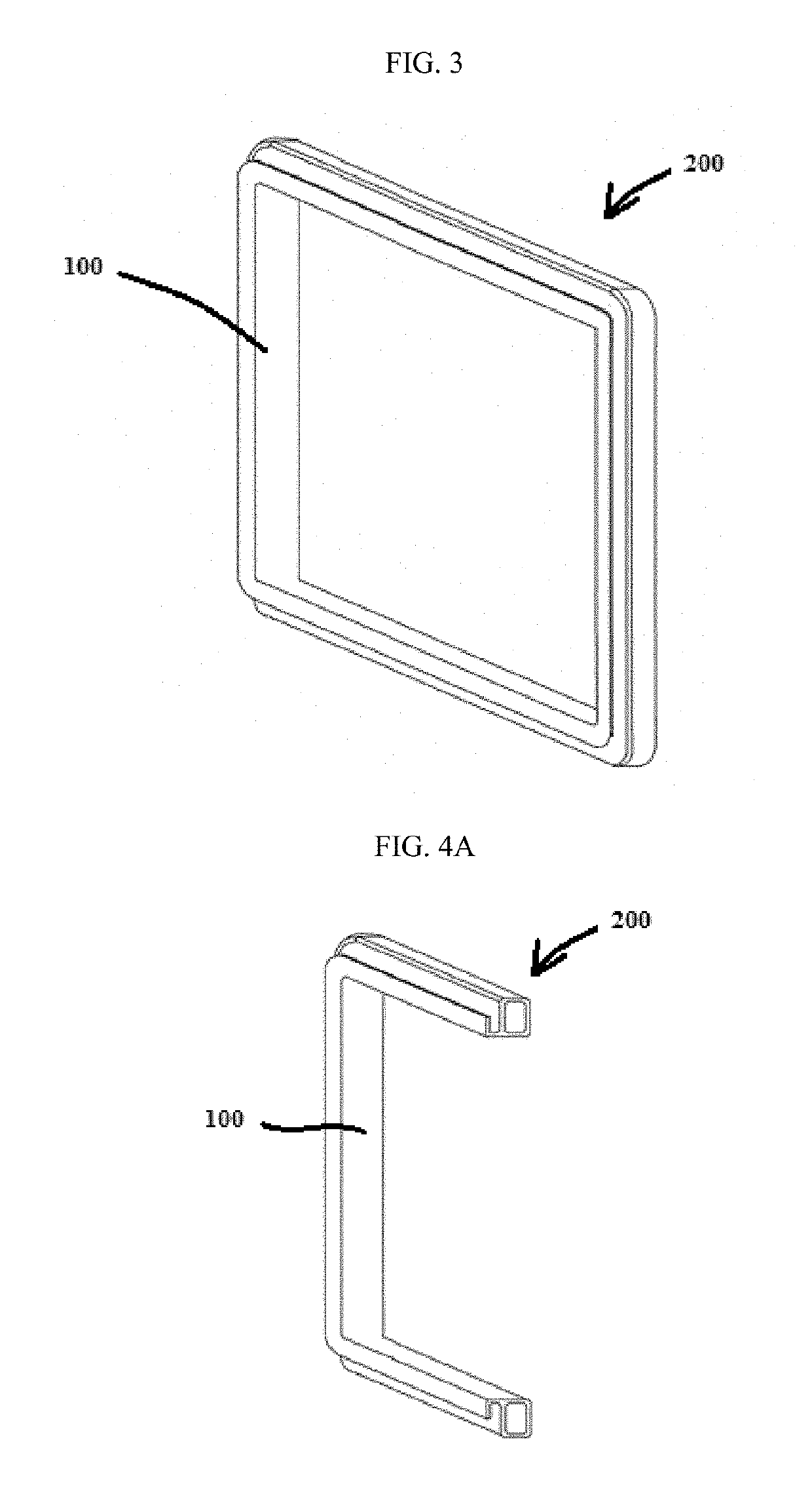

Finger extension

A finger extension is disclosed for assisting a person in holding down material with a finger of the person. The finger extension may comprise a body portion and a pawl. The body extension has side flanges that extend laterally around the finger of the person. The side flanges are malleable so that a person may bend the side flanges against the person's finger so that the finger extension may be retained on the person's finger during use. The pawl extends out from the body portion. A distal tip of the pawl is used to hold down the material and allows the person to keep his or her finger away from a work head (e.g. sewing head) at a safe distance.

Owner:MOSLEY EVELYN M

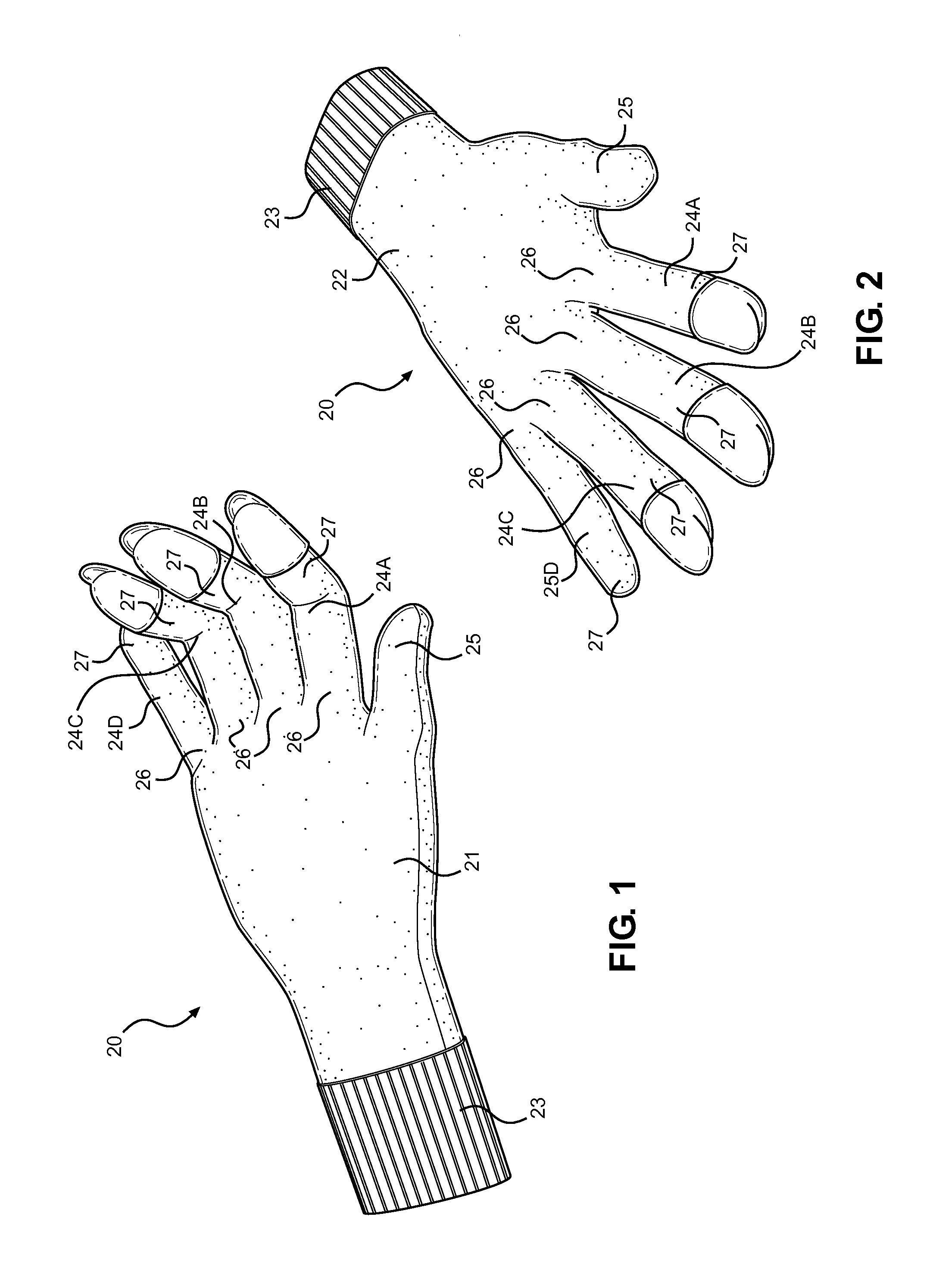

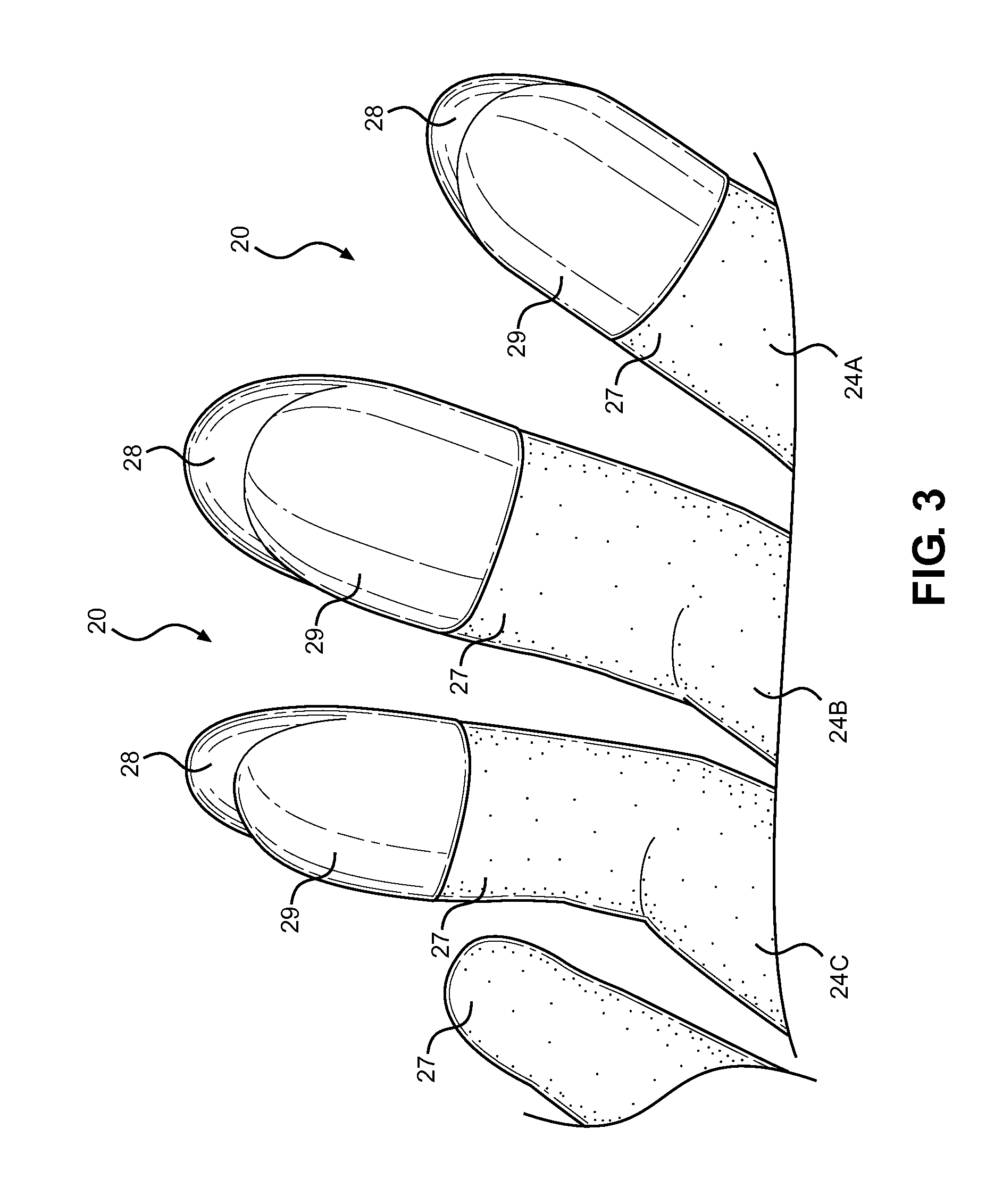

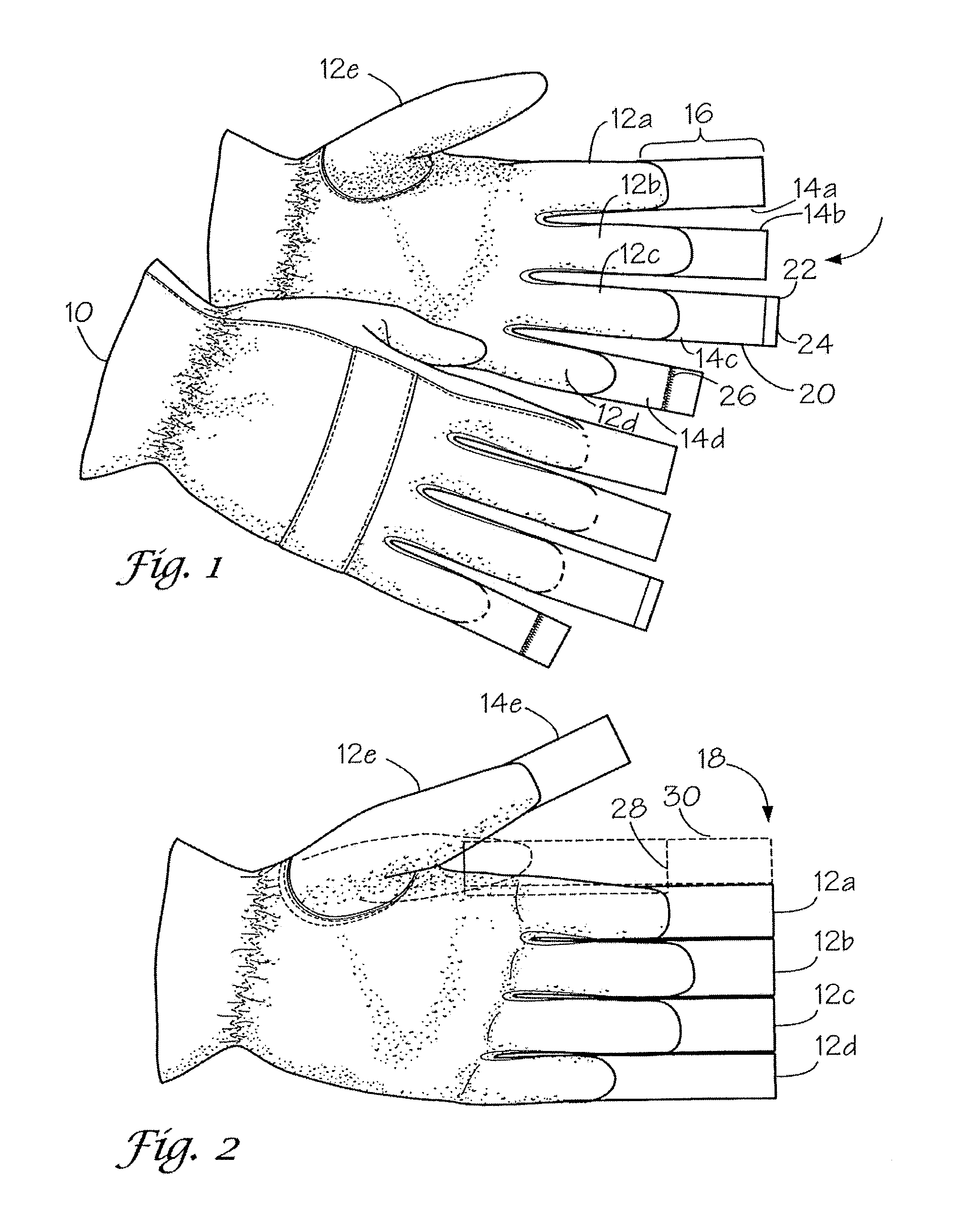

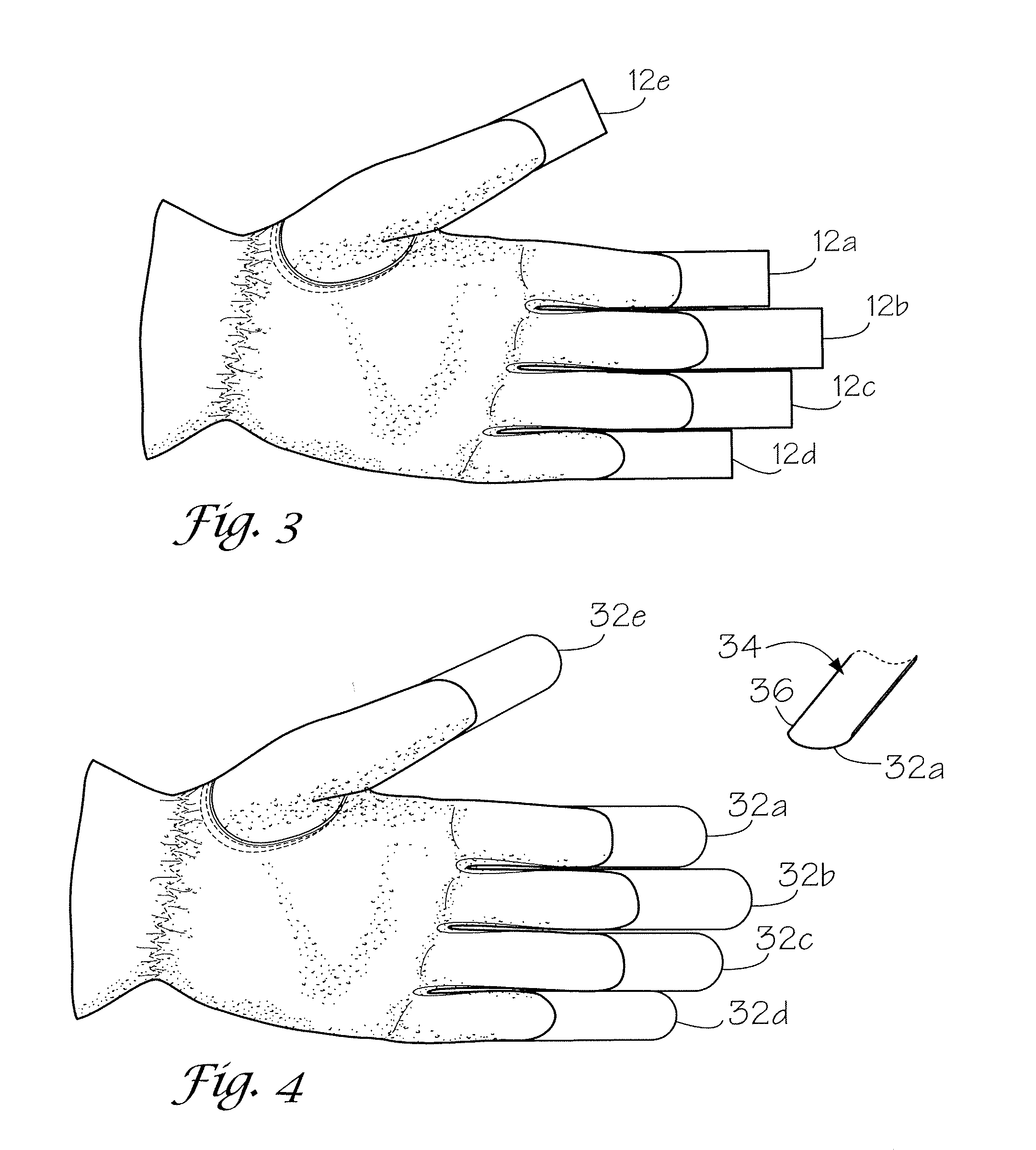

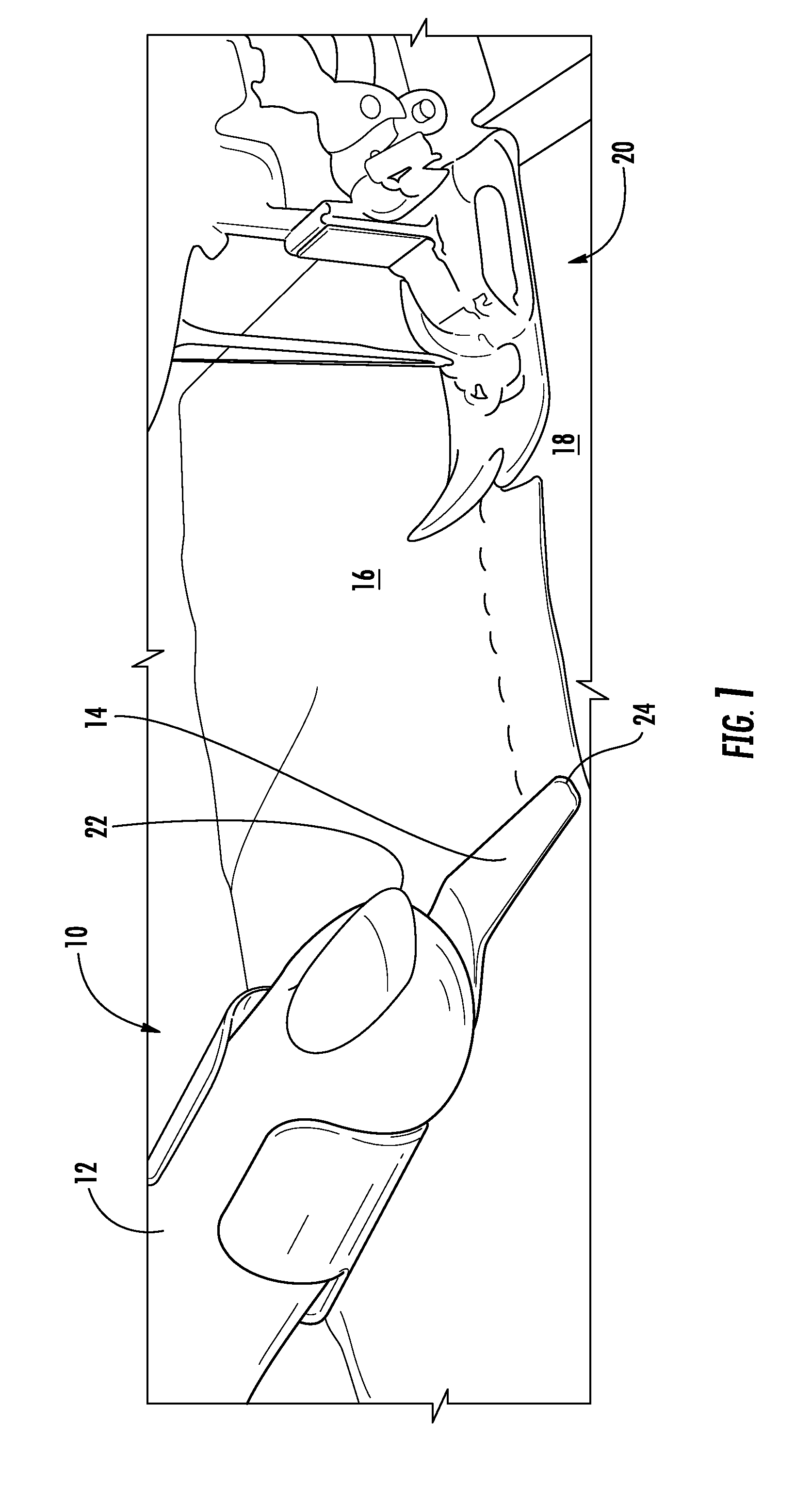

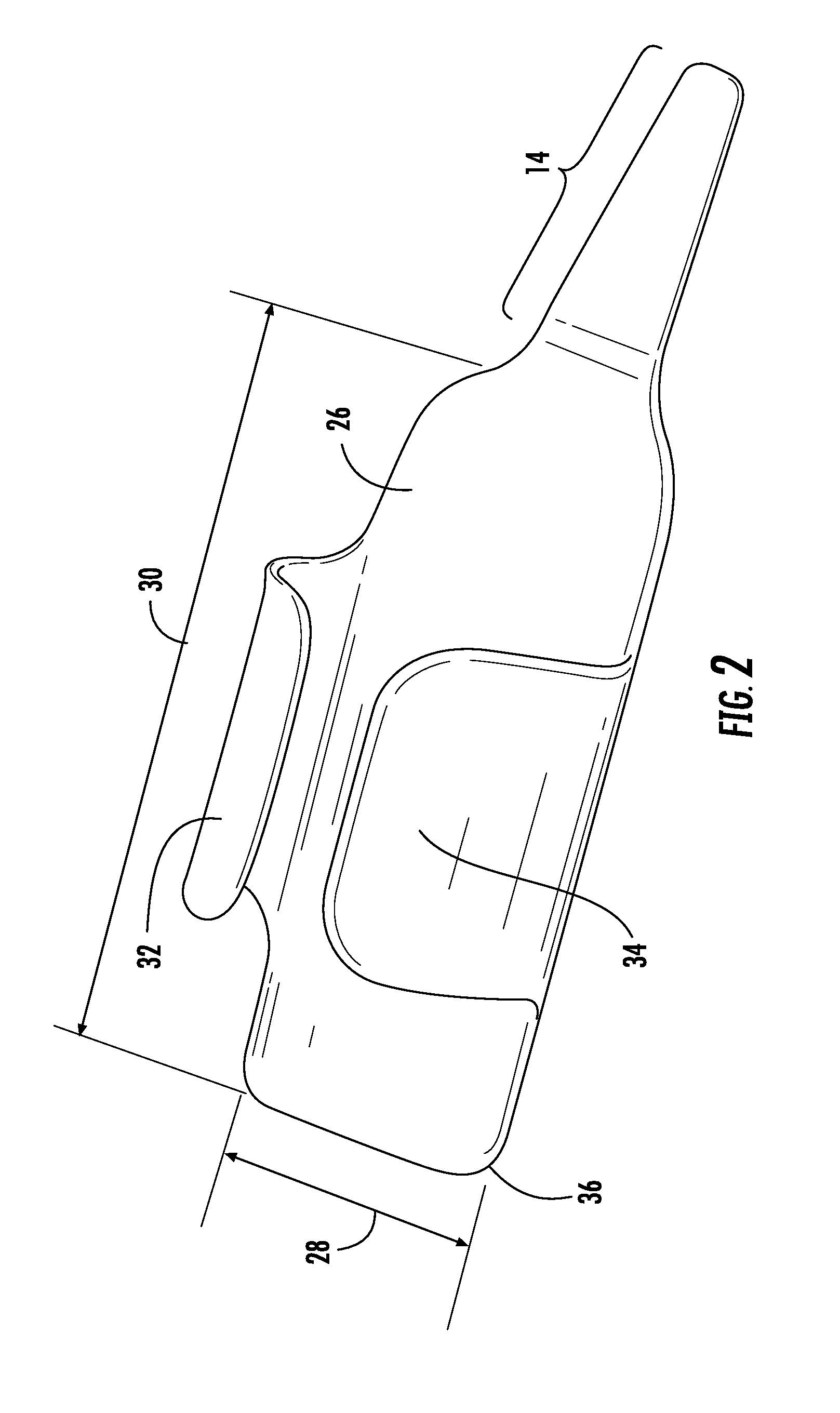

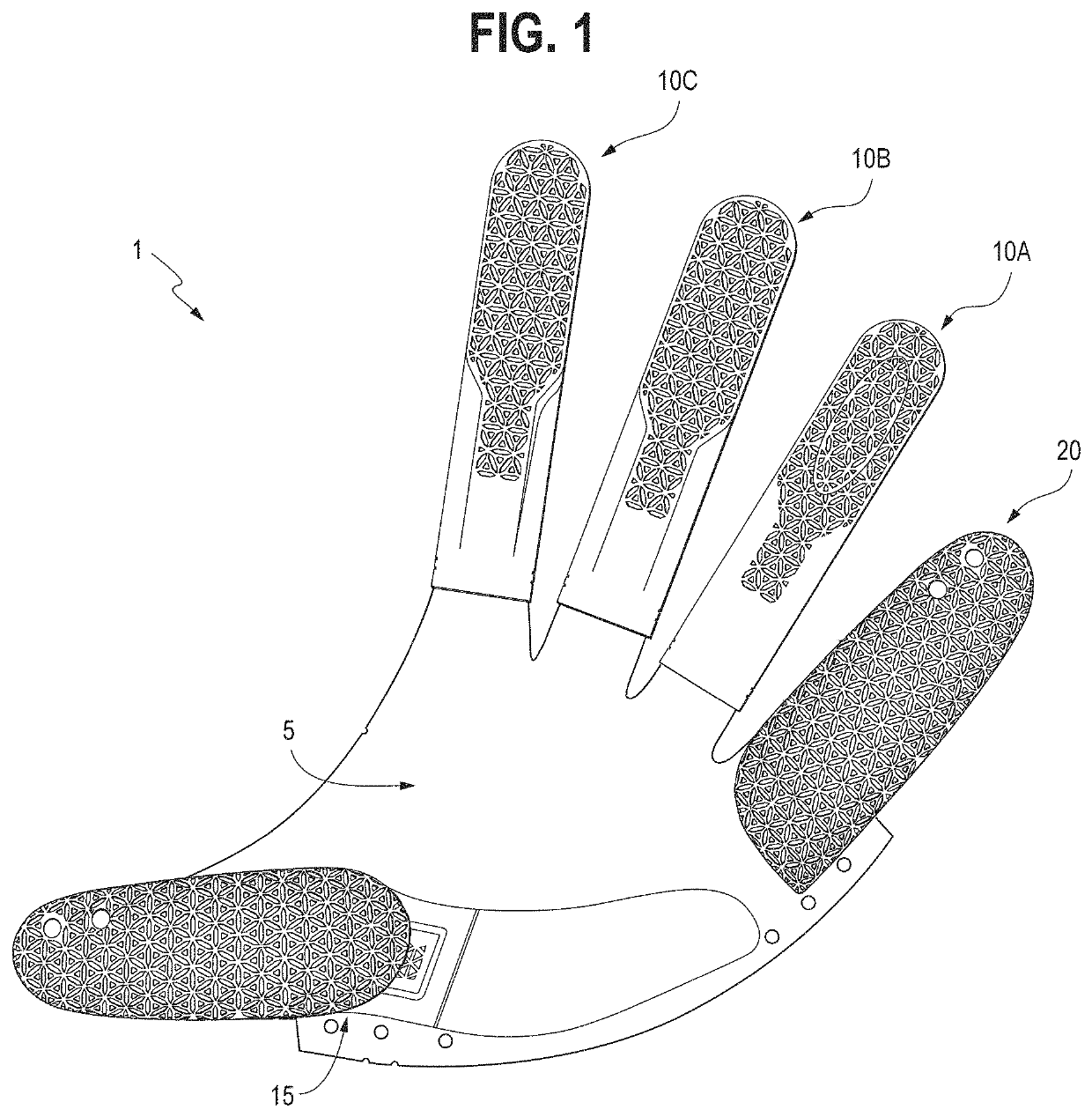

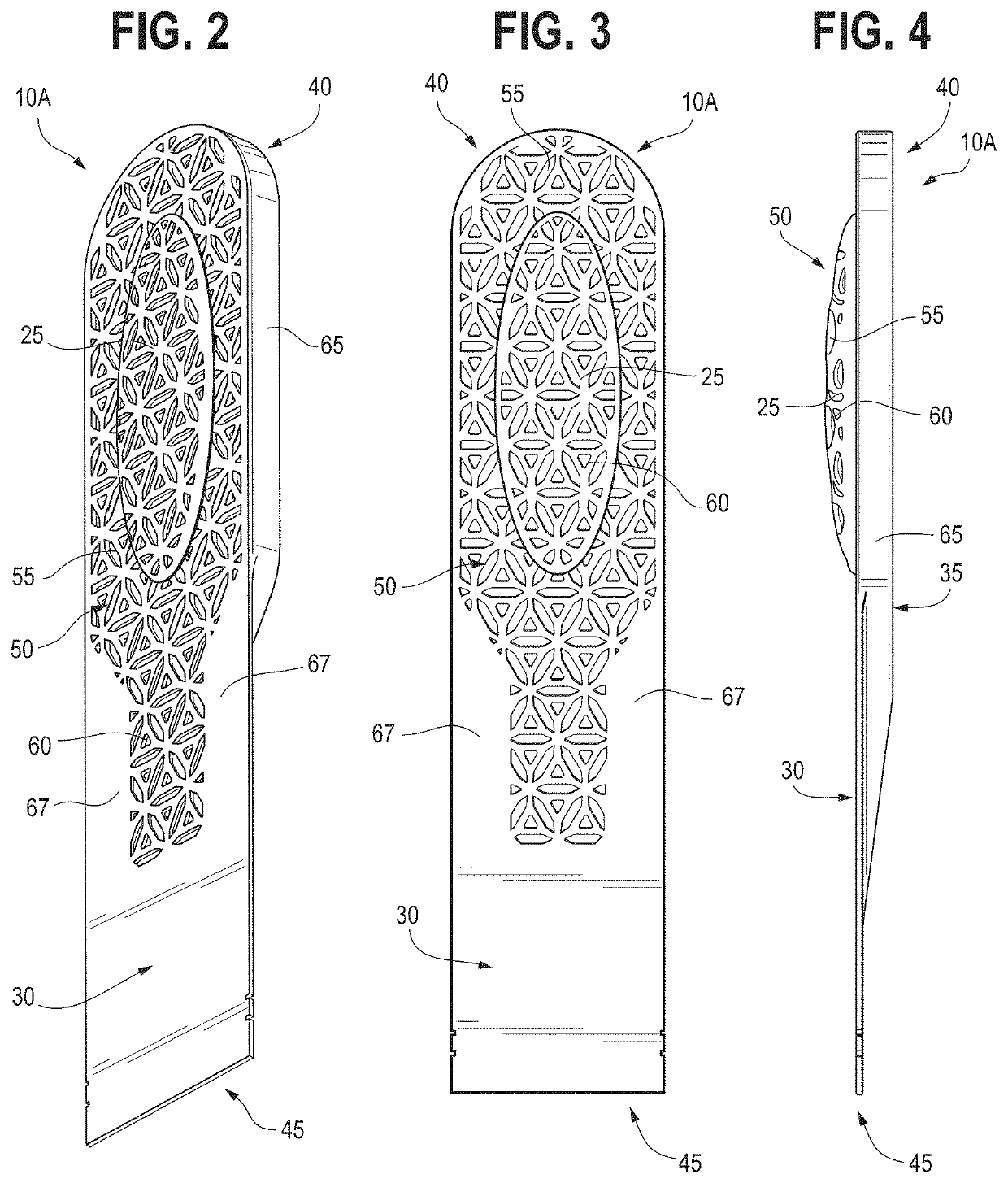

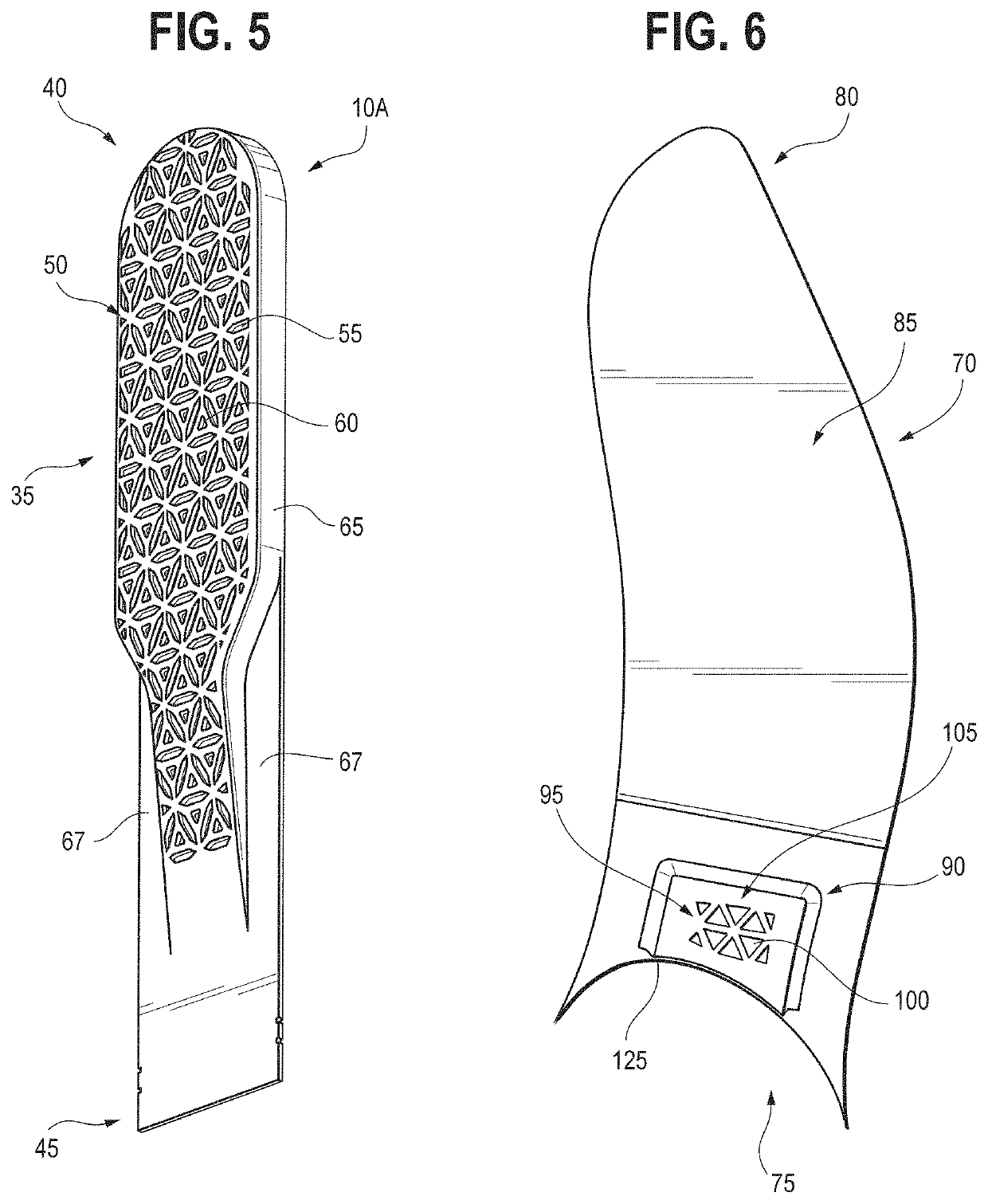

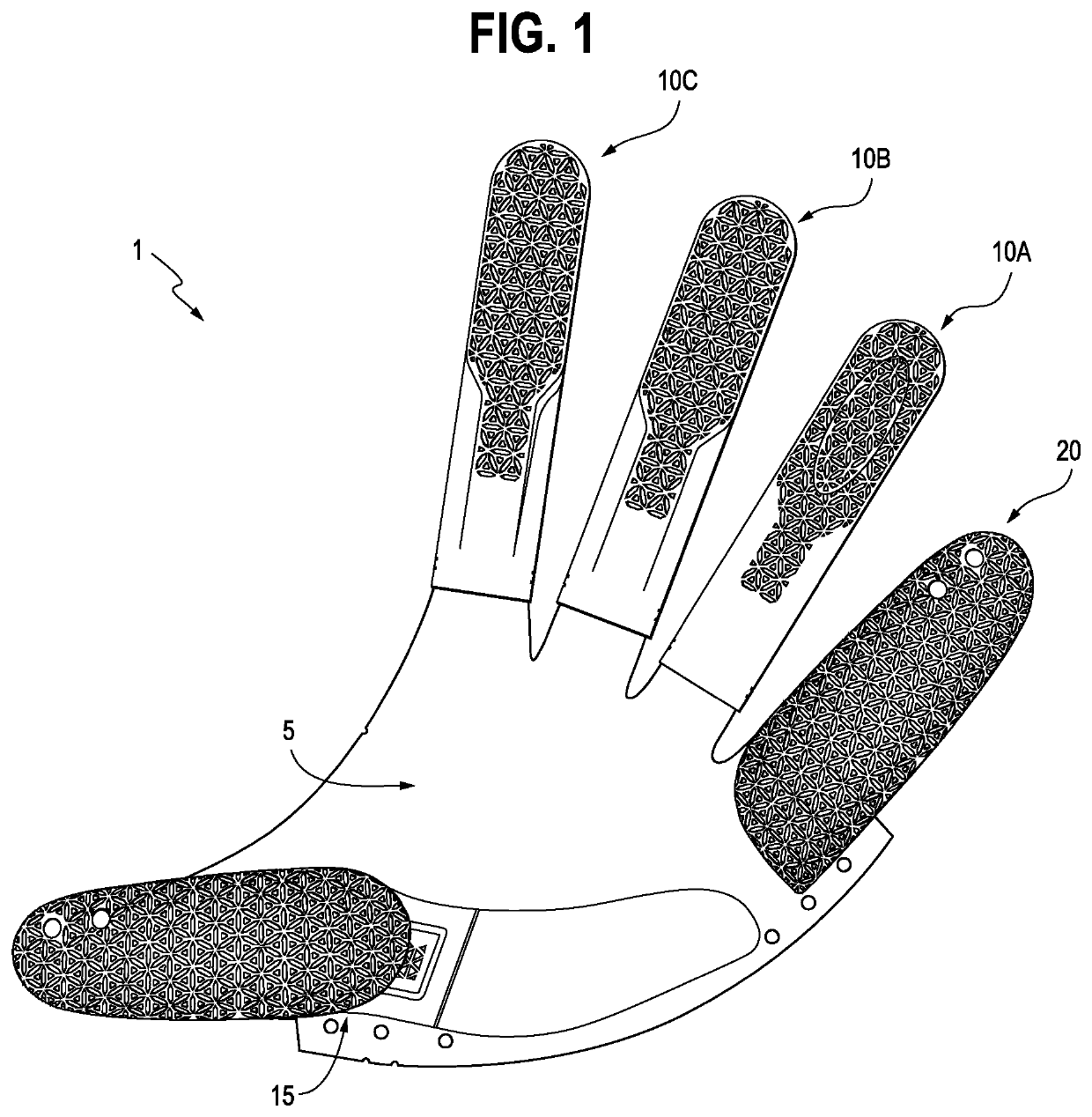

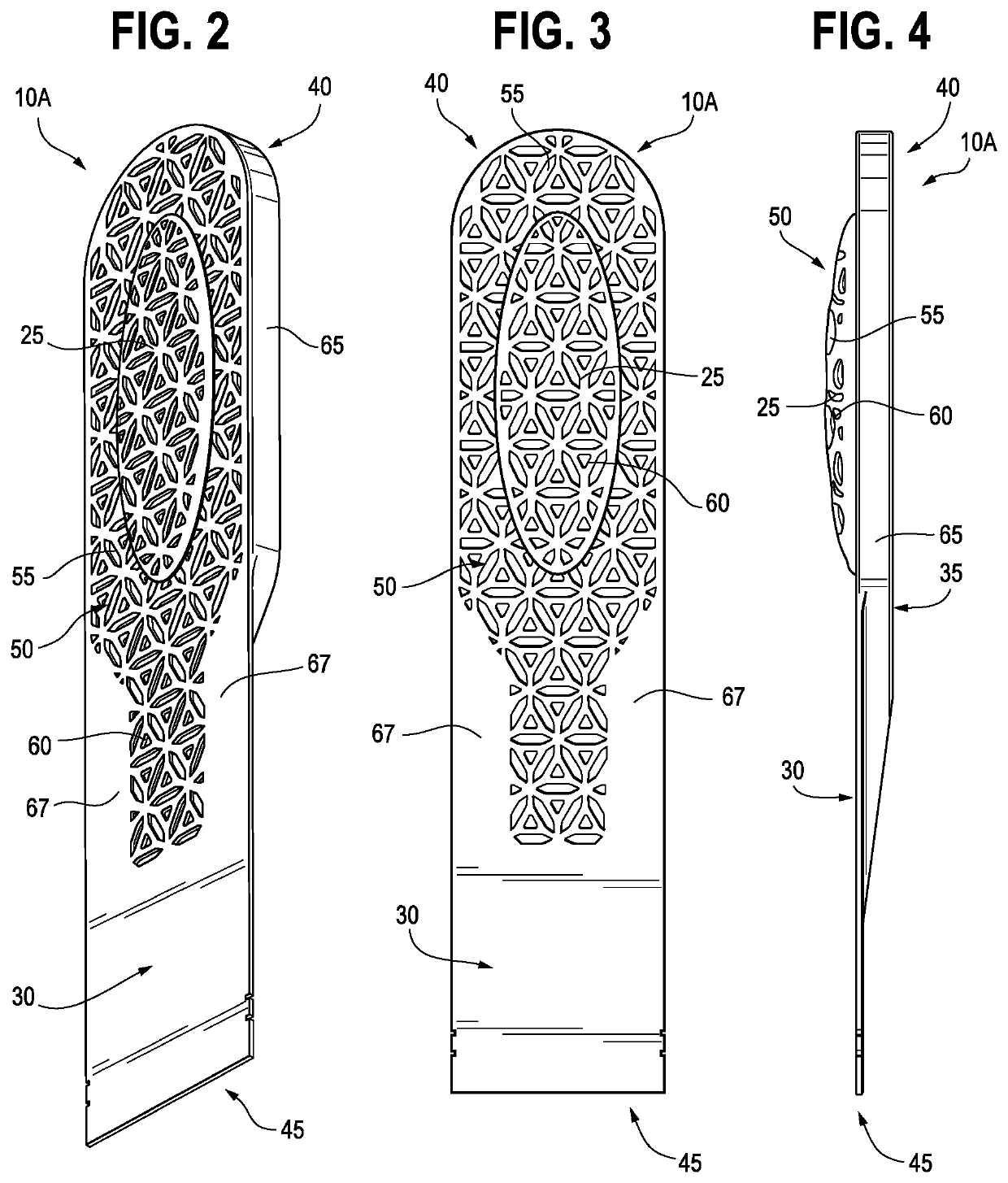

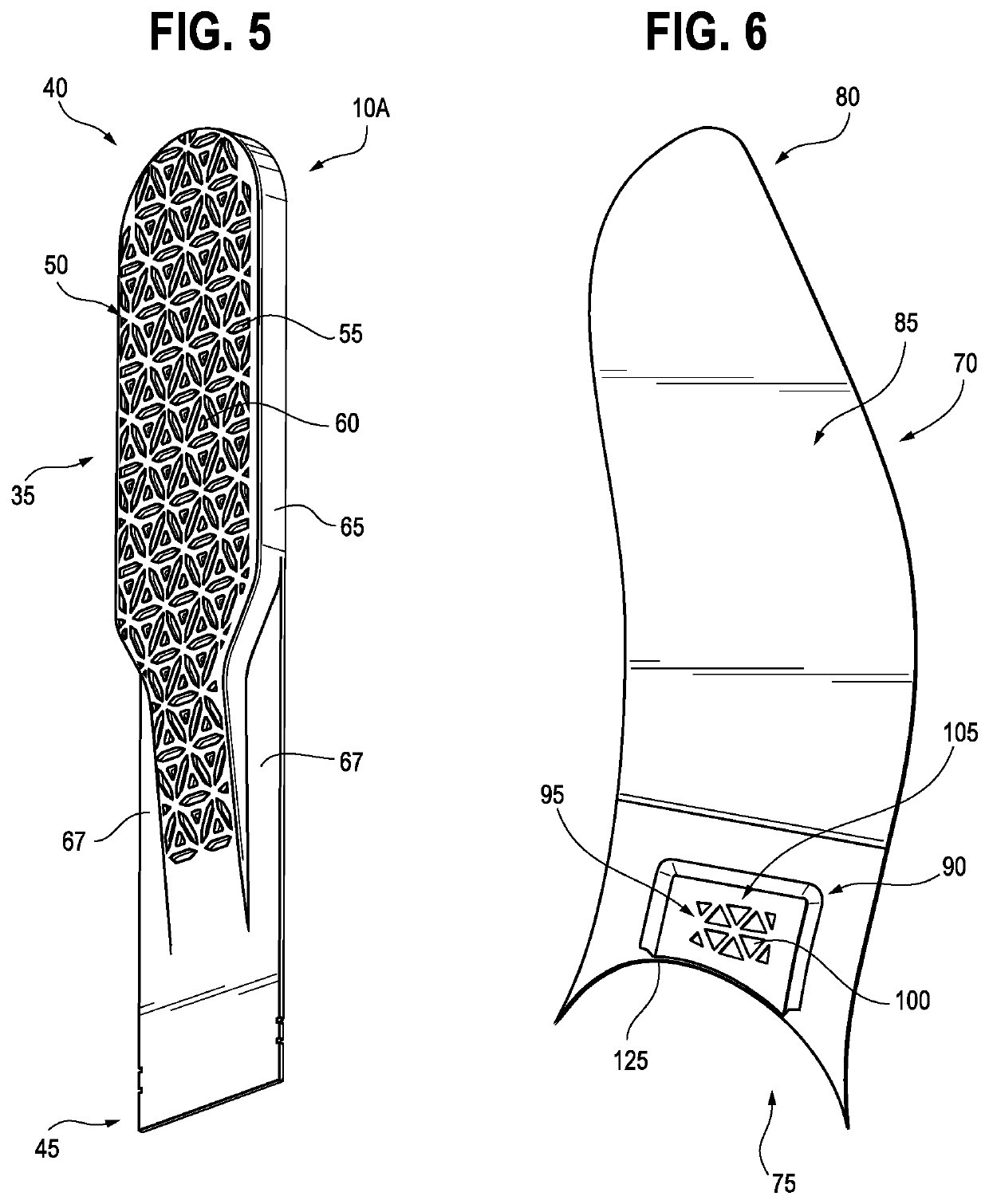

Glove with structural finger reinforcements

PendingUS20200268080A1Reduce weightExcellent ease of useGlovesProtective garmentEngineeringStructural engineering

An assembly is provided for use in a sports glove for use in baseball or softball. The assembly includes finger extension members that align with a wearer's thumb and fingers when worn. The finger extension members are made of a lightweight material such as a polymer and include at least one lattice portion. By including the more lightweight finger extension members, a glove including the assembly may have a lower moment of inertia about the heel to allow a fielder to more easily and quickly move his or her glove during play.

Owner:RAWLINGS SPORTING GOODS

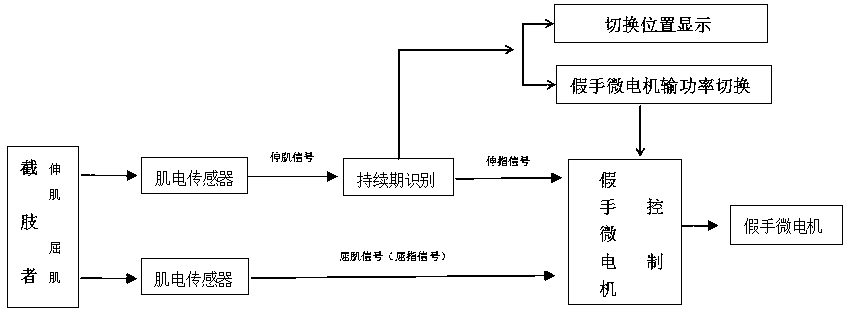

Innovative control method for myoelectric control arm prosthesis

The invention relates to a control method for a myoelectric control arm prosthesis. Since currently, the myoelectric signal intensity of part of amputees can meet the requirement of using proportionalcontrol myoelectric arms, but most amputees only use switch control myoelectric arms, the innovative control method can overcome the defects in the prior art; according to the method, the myoelectriccontrol arm prosthesis has two or more control states with different finger speeds and gripping forces, the control states of the arm prosthesis are circularly switched by using a third myoelectric signal code except finger extension and flexion, a feedback signal is adopted for indicating the current control state of the arm prosthesis, and it is proved through practice that the control method is very convenient to use and practical.

Owner:SHANGHAI KESHENG PROSTHESES

Gardening utility tool

An improved gardening utility tool including a glove; a set of finger extensions attached to the glove wherein the finger extension can move independently in an open arrangement; a first portion included in each finger extension having a first resiliency; a second portion attached to the first portion having a second resiliency having a proof resilience higher relative to the first portion; a plurality of releasable connections disposed on the finger extensions releasably connecting the finger extensions together to form a composite tool in a fixed arrangement of the finger extensions; a forward edge included in each finger extension having a shape taken from the group consisting of: flat, curved, concave, angled, concave angled, point and any combination thereof.

Owner:BLOCK SASHA

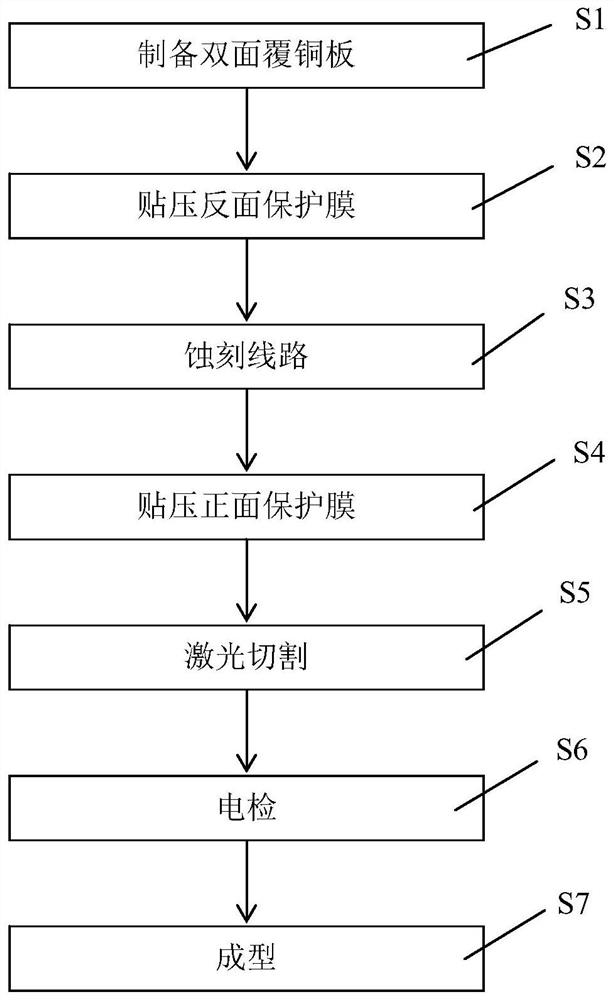

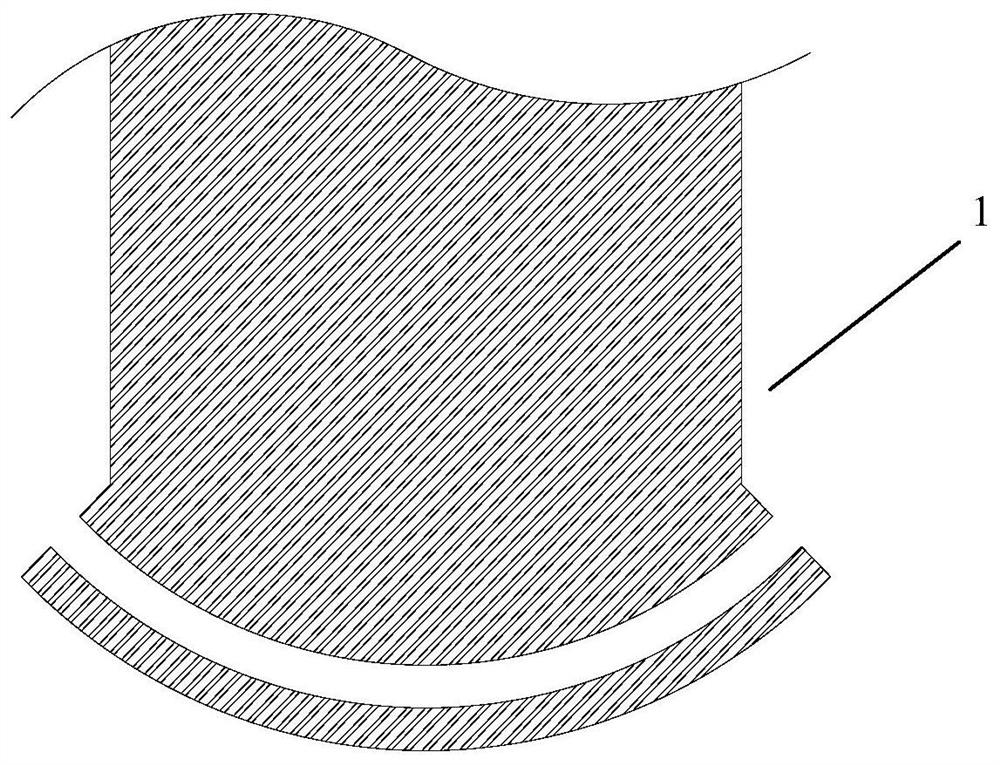

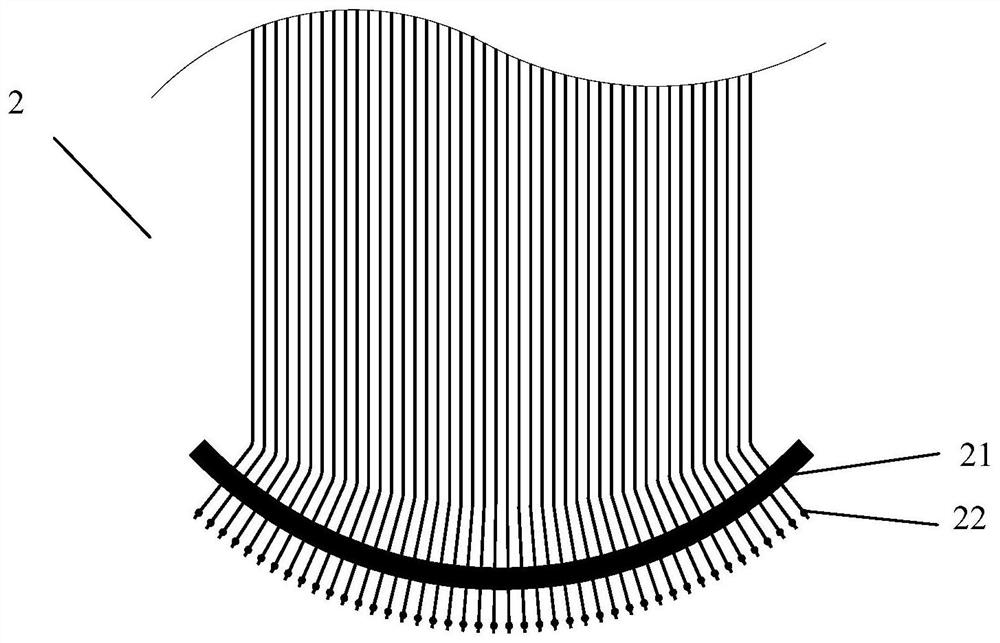

Processing method of flexible circuit board with thin hollow fingers

PendingCN113966089ANo creasesNo distortionConductive material mechanical removalConductive material chemical/electrolytical removalFlexible circuitsEngineering

The invention relates to a processing method of a flexible circuit board with thin hollow fingers. The processing method comprises the following steps: preparing a double-sided copper-clad plate; pasting and pressing a reverse side protection film, windowing the reverse side protection film in the hollow area, and then pasting and pressing the reverse side protection film on the reverse side of the copper-clad plate; etching a circuit, designing thin fingers in the hollow area into a whole, designing a finger extension area exceeding the appearance of the product body, and designing a test disc in the finger extension area; pasting and pressing a front protection film, windowing the front protection film in the hollow area and a test disc, and then pasting and pressing the front protection film on the front surface of the product; carrying out laser cutting, wherein specifically laser cutting is conducted in the hollow area along the edges of the two sides of the fingers, connecting copper between the fingers is cut off, and a hollow finger pattern is completed; carrying out electric detection, wherein an electric detection test needle is placed on the test disc of the finger extension area for electric detection; and forming, wherein specifically, laser or punching forming is adopted, the finger extension area is removed, and final product forming is completed. According to the invention, the hollow finger does not have the problems of wrinkling, deformation and the like in the machining process, and the product yield is greatly improved.

Owner:XIAMEN BOLION CIRCUIT

Connection Device

A connection device between a first member and a second member that includes a flexible male configuration disposed on the first member, the male configuration includes a finger extension that has a necked portion and an expanded terminating head portion. Also included is a flexible female configuration disposed on the second member, the female configuration includes a cavity having a narrow duct portion that expands into a chamber portion. The male and female configurations are removably engageable to one another, as the expanded head portion is manually pushed into the narrow duct portion and continuing further to manually push the expanded head portion into the chamber portion until the expanded head portion bottoms out into the chamber portion resulting in the first and second members being in a substantially fluid tight connection to one another.

Owner:TRAN TRANG +1

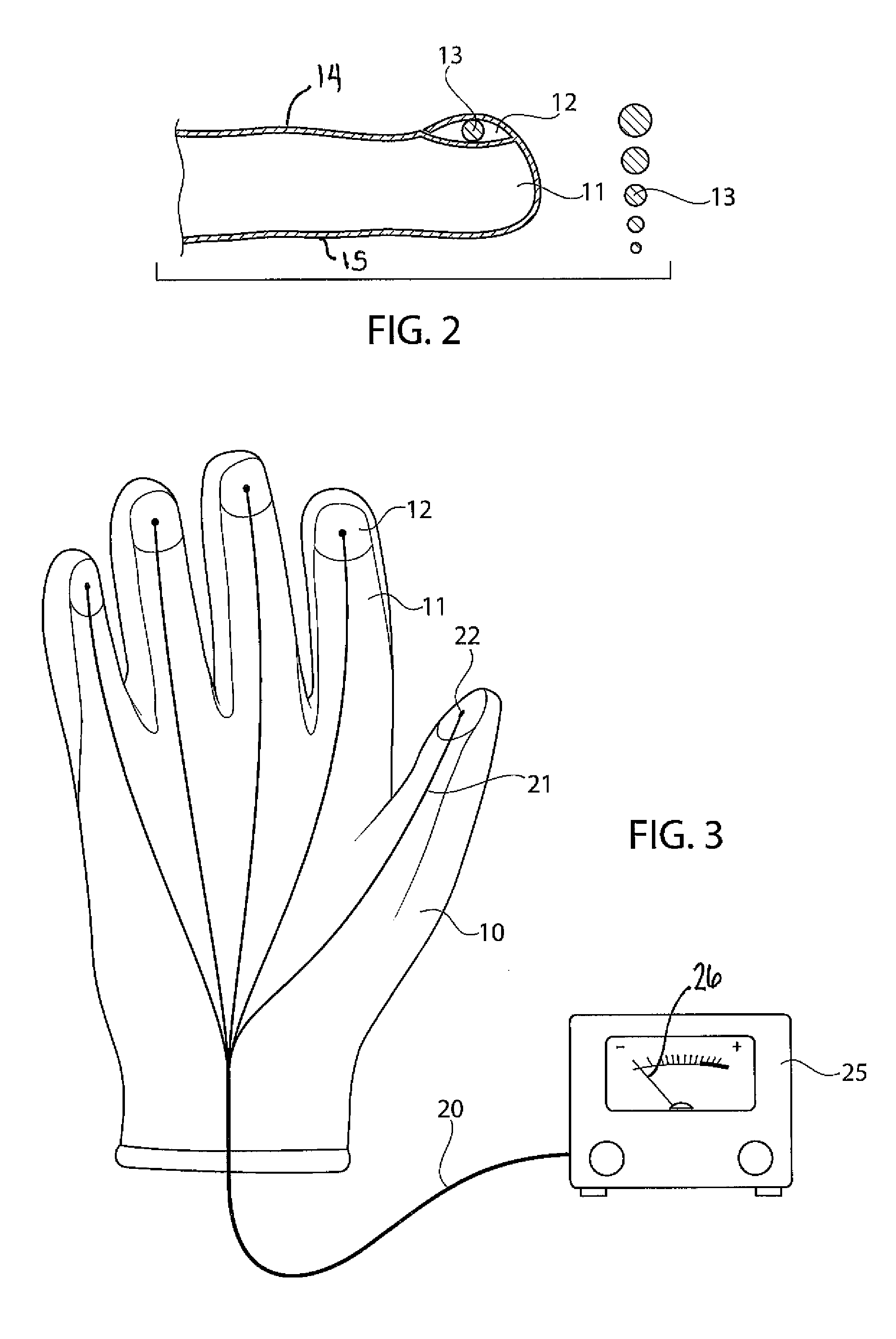

Acupressure glove

A glove for administering acupressure therapy has a front side having five finger extensions and a pocket at a tip of each of the finger extensions, and a rear side connected to the front side to form a glove with an opening at a bottom edge thereof. There are a plurality of projections that are adapted to be removably placed in each one of the pockets. The projections are of various sizes, so that the acupressure therapist can formulate a glove that is customized to the therapy to be administered.

Owner:SPECTOR DONALD

Glove with structural finger reinforcements

PendingUS20200268077A1Reduce weightExcellent ease of useGlovesRacket sportsStructural engineeringMechanical engineering

An assembly is provided for use in a sports glove for use in baseball or softball. The assembly includes finger extension members that align with a wearer's thumb and fingers when worn. The finger extension members are made of a lightweight material such as a polymer and include at least one lattice portion. By including the more lightweight finger extension members, a glove including the assembly may have a lower moment of inertia about the heel to allow a fielder to more easily and quickly move his or her glove during play.

Owner:RAWLINGS SPORTING GOODS

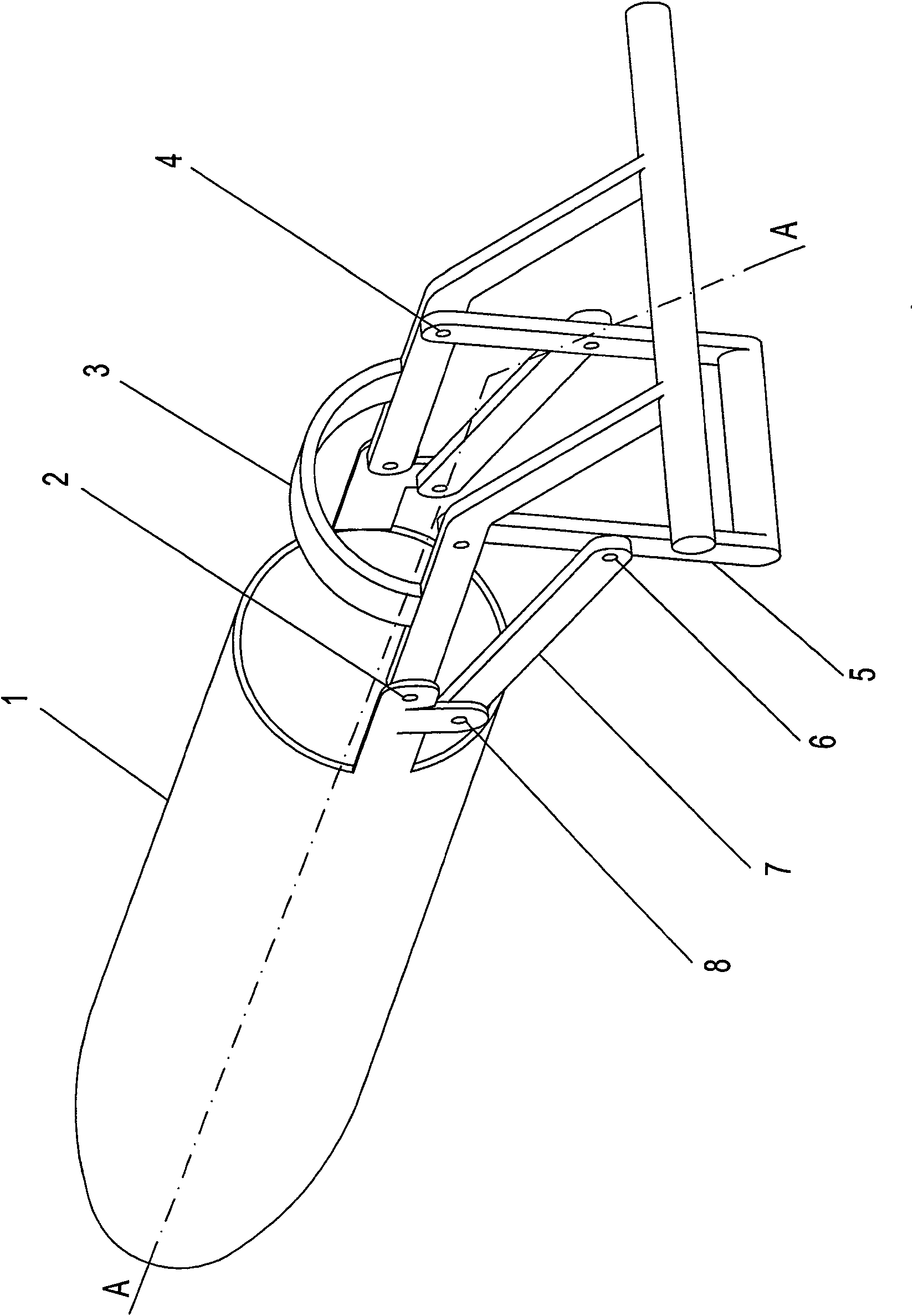

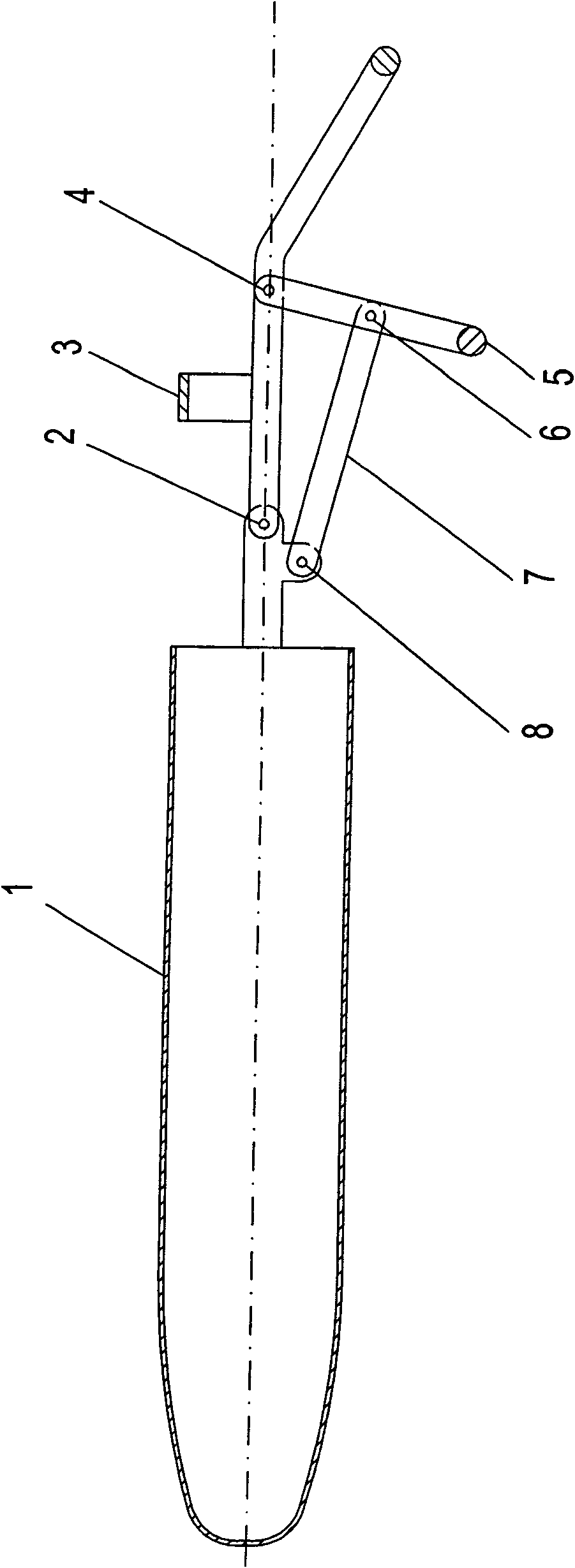

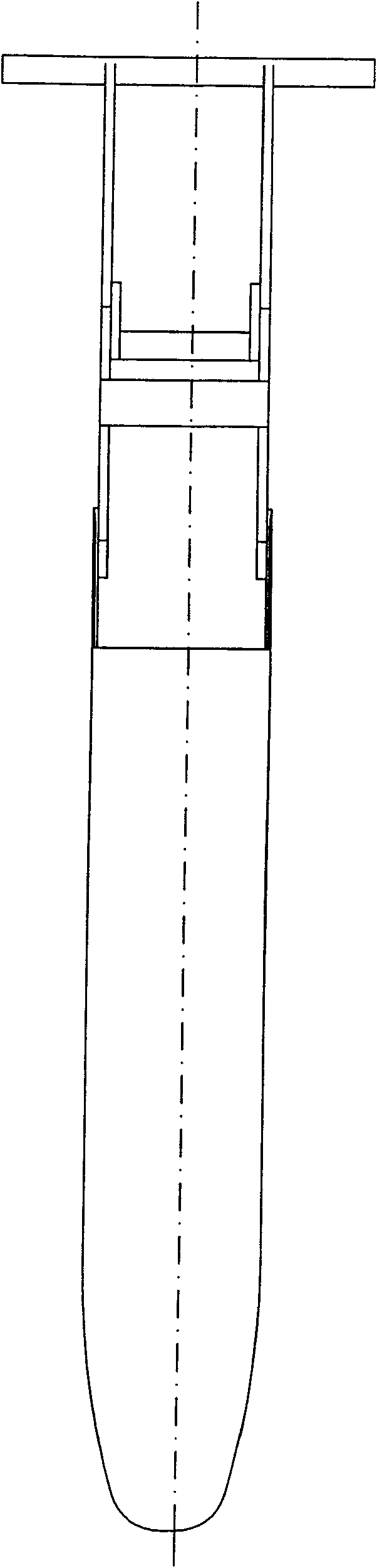

Finger lengthening and force-increasing mechanism

InactiveCN100569198CResolve unreachable depthsPlay a protective effectArtificial handsShort fingerCoupling

The invention discloses a finger extension mechanism, which is composed of a finger cot (1), a handle (3), a power crank (5), a connecting rod (7), and pins (2, 4, 6, 8). Solve the flexibility of the fingers, and conveniently lengthen the length of the fingers and the strength of the fingertips. Finger cot (1) and handle (3) are connected by pin (2), power crank (5) and handle (3) are connected by pin (4), connecting rod (7) and power crank (5) are also connected by pin (6 ) connection, finger cot (1) and connecting rod (7) are connected by pin (8), finger cot (1) rotates around pin (2) and pin (8), power crank (5) rotates around pin (4), The link (7) turns around the pins (6) and (8). By changing the shape of the short end of the fingertip - scalpel, hair comb, etc., it can be conveniently applied in medical, toy and other fields.

Owner:BEIJING JIAOTONG UNIV

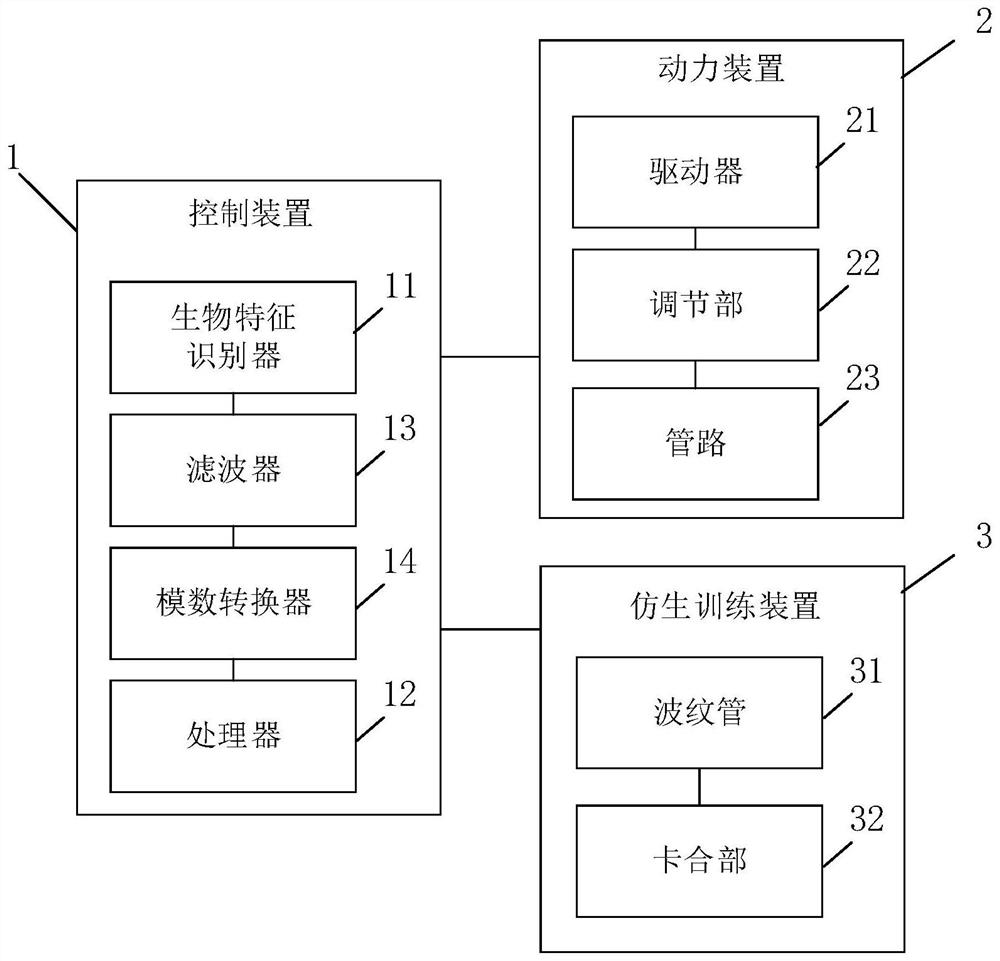

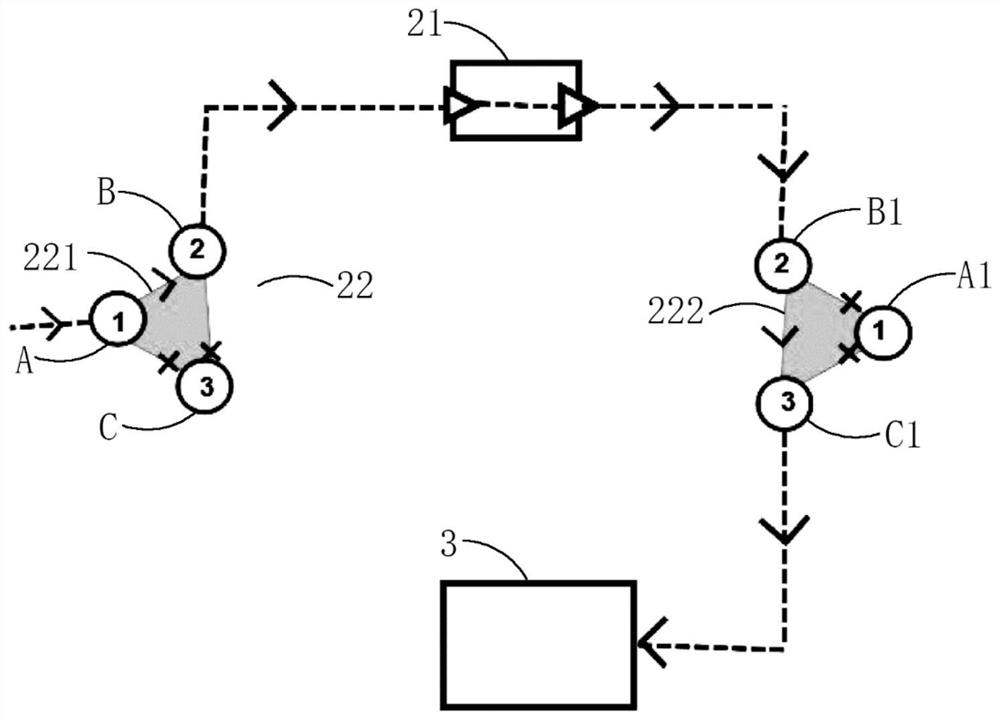

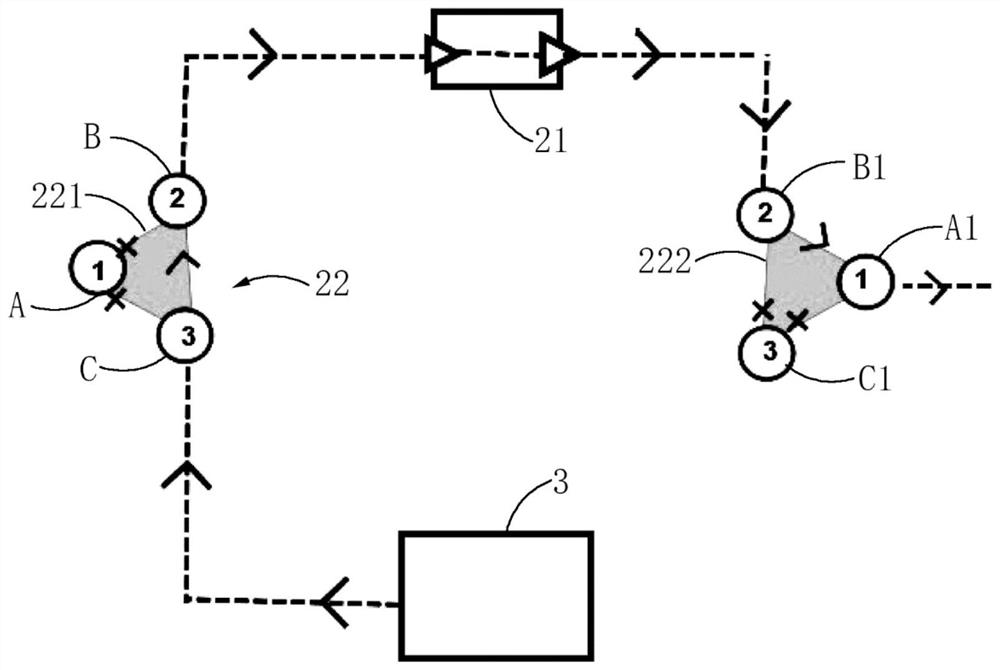

Hand function training and auxiliary system

ActiveCN109044724BConvenient for self-trainingBoost self-confidenceChiropractic devicesInformation controlHand parts

The application provides a hand function training and assistance system, in which the biometric identifier is electrically connected to the processor; the adjustment part is arranged between the driver and the pipeline, and the driver is used to deliver the driving fluid from the fluid source , the processor is electrically connected to the driver and the adjustment part; the corrugated tube is extended along the stretching direction of the finger as the rehabilitation object, and one end of the corrugated tube close to the fingertip is closed and set, and the other end is connected to the pipeline; the engaging part is set to match the finger , the bellows are arranged on the engaging part; the processor is used to control the action of the driver and the adjustment part according to the biometric information recognized by the biometric identifier, so that the adjustment part controls the state of the driving fluid in the bellows through the pipeline, and drives the bellows The stretching and / or bending drives the fingers matched with the engaging part to stretch or contract. The present application realizes the control of hand movements based on biometric information, which facilitates hand rehabilitation training and promotes hand rehabilitation.

Owner:北京京成兴华医疗科技有限公司

Adaptive underactuated robotic hand device with double-ring rotating multi-finger flat gripper

ActiveCN106426230BReliable grabbingHigh underdrive effectGripping headsUnderactuated robotsRobot hand

The invention provides a double-ring rotating multi-finger parallel clamping self-adaptive under-actuated robot hand device, and belongs to the technical field of robot hands. The double-ring rotating multi-finger parallel clamping self-adaptive under-actuated robot hand device comprises a base, an actuator, at least two fingers, a driving shaft, a driving wheel, two spring parts, two gears, an inner ring gear ring, an inner ring, a driving stirring disk, a driven stirring disk, an outer ring gear ring, an outer ring, a limiting block and the like. According to the device, the function that a plurality of robot fingers conduct parallel clamping and self-adaptive capture is fulfilled by the use of the double rotatable rings and a link mechanism; the single actuator is used for driving a plurality of joints of the fingers, and the mode of parallel clamping and the mode of self-adaptive capture can be automatically switched according to the differences of the object shapes and the positions; second finger sections can be horizontally moved to clamp objects, the device can also automatically rotate the second finger sections to make contact with the objects after first finger sections make contact with the objects, the greater-strength holding effect is obtained is achieved, and the device can automatically adapt to capture of the objects with different shapes and sizes; and the self-adaptive enveloping direction is perpendicular to the finger extension direction, and capture is stable and reliable.

Owner:广州市轻工职业学校

Finger exercising device for rehabilitation nursing of neurology department

InactiveCN114533486AIncrease exercisePrevent movementChiropractic devicesStretch exerciseNeurology department

The invention discloses a neurology rehabilitation nursing finger exercise device which comprises a mounting plate, a palm-shaped notch is formed in the mounting plate, a protective sleeve is laid in the palm-shaped notch, five finger sleeves are mounted on the protective sleeve, a cavity is formed in the mounting plate, a reset mechanism is connected in the cavity, and the reset mechanism is connected with the palm-shaped notch. The reset mechanism is connected with the five fingerstalls, a U-shaped mounting part is mounted on the mounting plate, an extrusion mechanism is mounted on the U-shaped mounting part, a pressing plate is arranged on the extrusion mechanism, the pressing plate corresponds to the sheath, a mounting cavity is formed in the U-shaped mounting part, a motor is mounted in the mounting cavity, and the motor is connected with the extrusion mechanism. A swing rod is fixed to the tail end of an output shaft of the motor. The rehabilitation training device is convenient to wear quickly, the stability of the palm center and the arm position can be guaranteed, fingers can automatically stretch in a reciprocating mode, rehabilitation training can be carried out quickly, the finger stretching speed can be controlled according to needs, and use is convenient.

Owner:张芳芳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com