Processing method of flexible circuit board with thin hollow fingers

A processing method and finger technology, applied in chemical/electrolytic methods to remove conductive materials, printed circuits, printed circuit manufacturing, etc., can solve problems such as wrinkling, distortion, and disconnection of fingers in hollowed out areas, and improve product yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

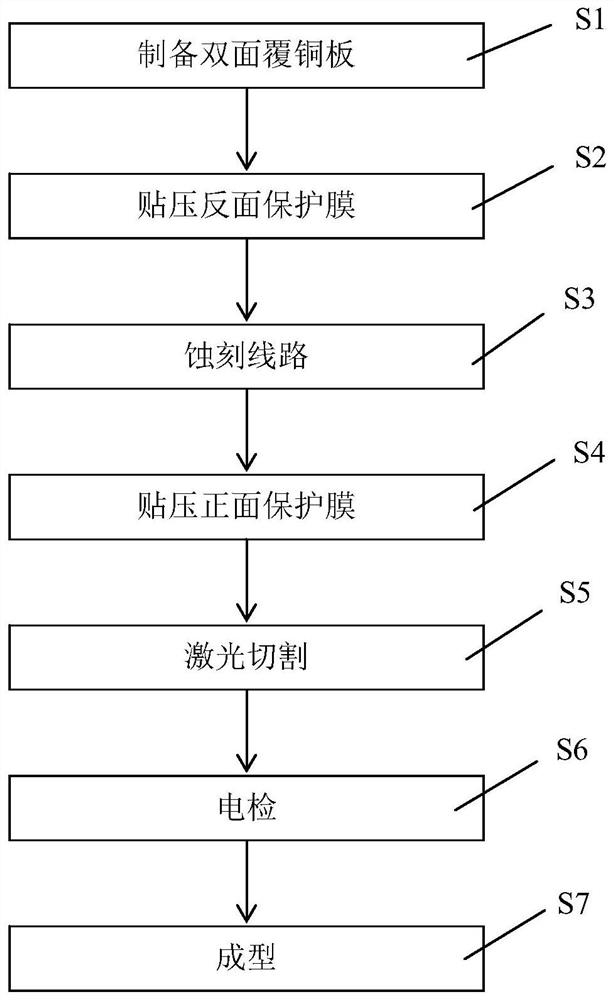

[0028] Such as figure 1 Shown, a kind of processing method of the flexible circuit board that has fine hollow finger (line width less than 0.2 millimeter) can comprise the following steps:

[0029] S1. Prepare a double-sided copper-clad laminate. Specifically, it includes: cutting out double-sided copper-clad laminates of the required shape and size from the raw material FCCL roll; using laser technology to drill pin holes for alignment, direction holes and connections between the two layers of copper layers on the double-sided copper-clad laminates. Via hole. It should be understood that the above-mentioned pin holes, directional holes and via holes may be made by other processing techniques.

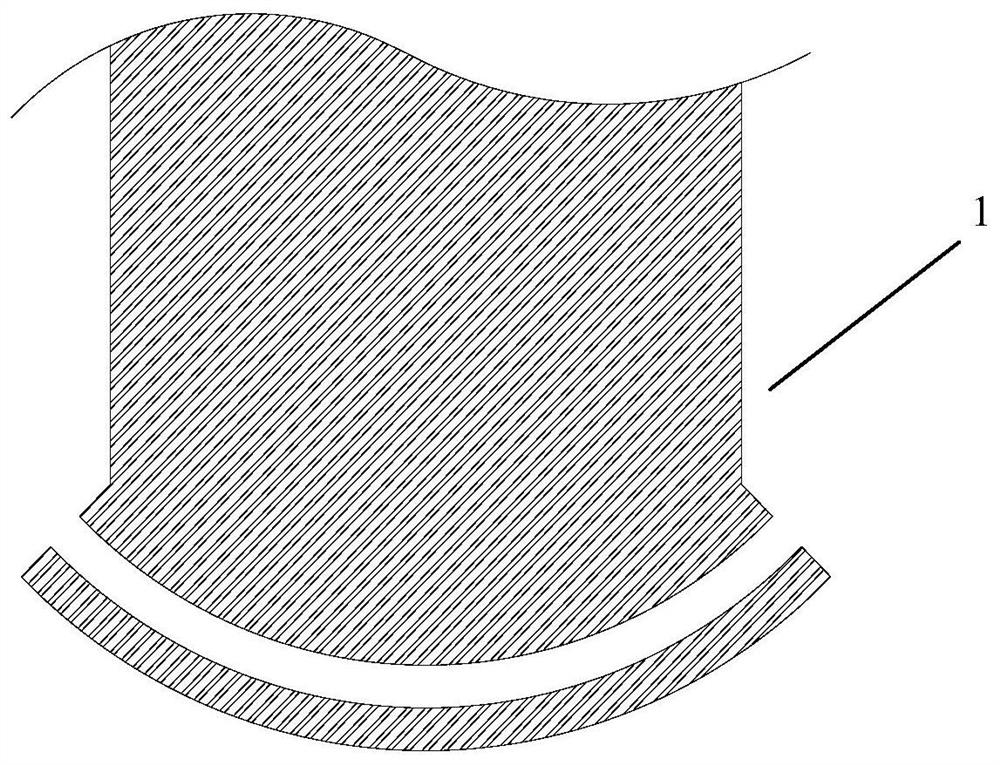

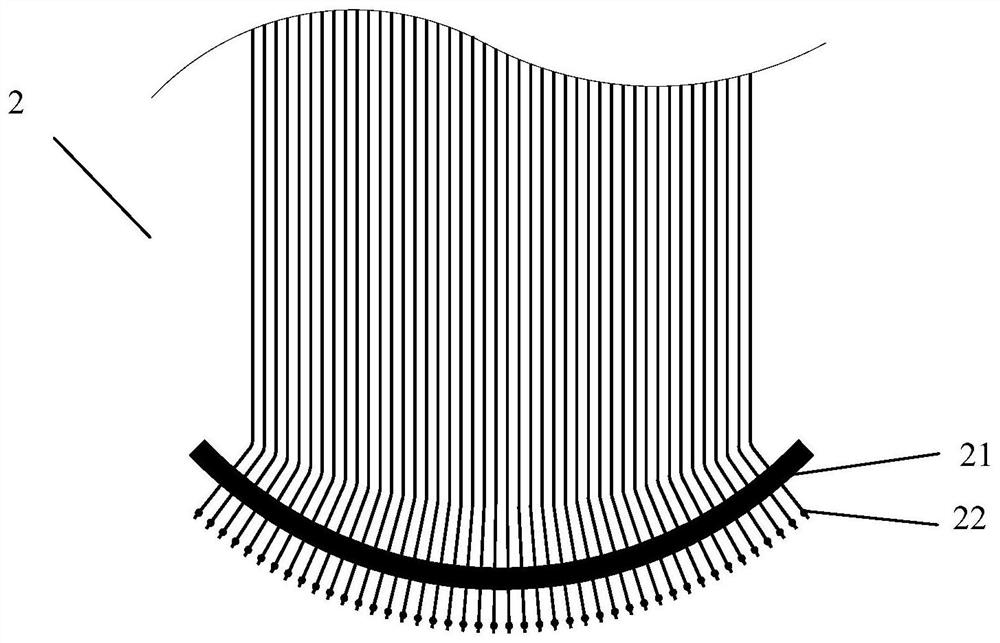

[0030] S2. Paste and press the protective film 1 on the reverse side. First, the reverse protective film 1 is windowed in the hollow area, such as figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com