Electromagnetic clutch peristaltic pump

An electromagnetic clutch and peristaltic pump technology, applied in the field of peristaltic pumps, can solve the problems of complex structure and large volume, and achieve the effect of convenient replacement of water pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

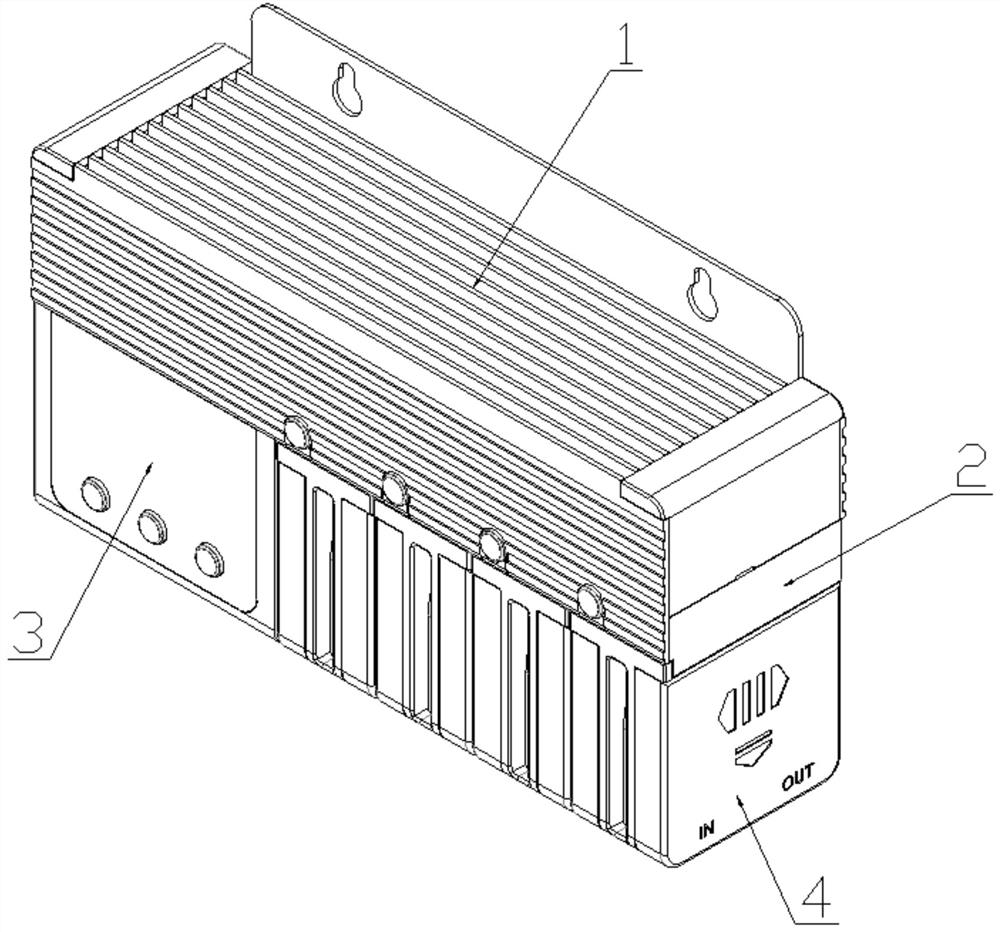

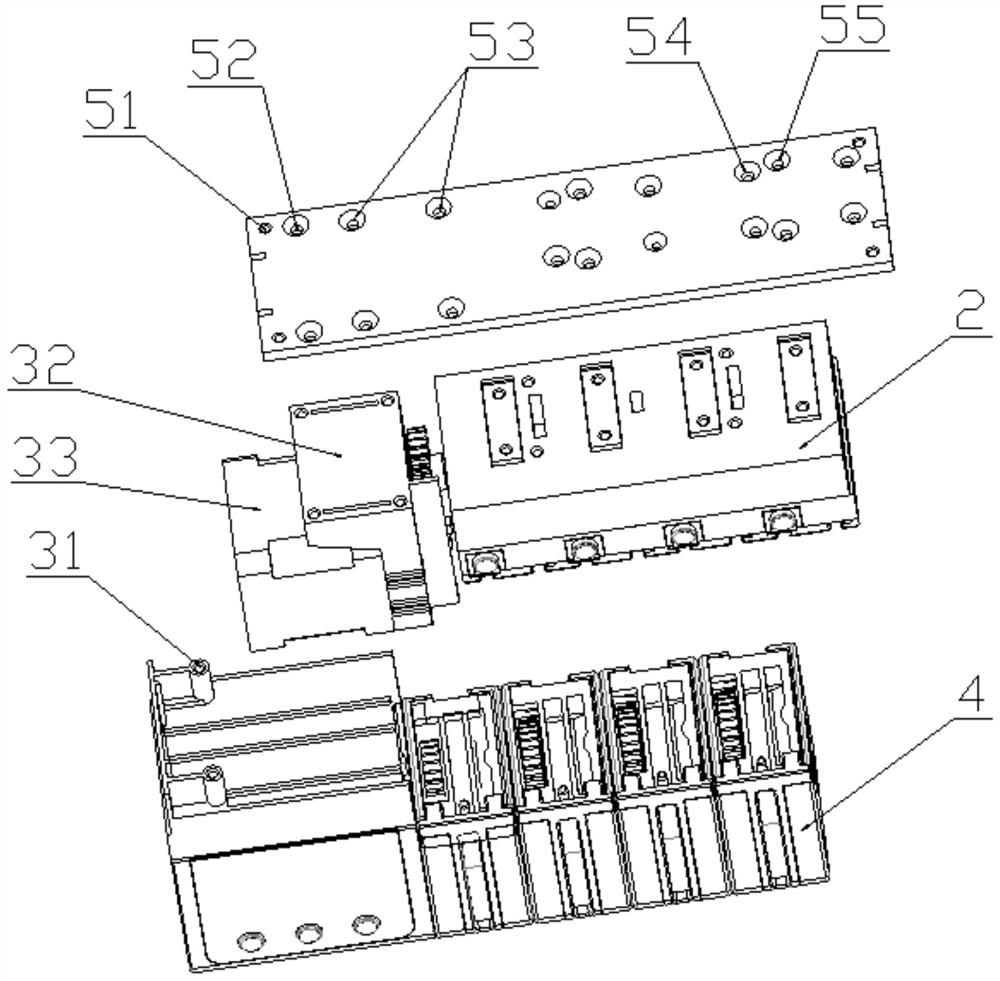

[0030] refer to Figure 1-11 , the present embodiment 1 provides an electromagnetic clutch peristaltic pump, including a mounting frame 1, a transmission device 2, a power device 3, a mounting plate 5 and several peristaltic pump heads 4; the mounting plate 5 is arranged on the inside of the mounting frame 1; The mounting plate 5 is threadedly connected with the mounting frame 1; the transmission device 2 and the power device 3 are all threaded on the mounting plate 5; the peristaltic pump head 4 is detachably connected with the transmission device 2; each of the peristaltic pump heads 4 are independently controlled by the transmission device 2; with this scheme, one or more of the peristaltic pump heads 4 can be independently controlled, and the forward and reverse, timing, and quantitative control of the peristaltic pump heads 4 can also be achieved. Each peristaltic pump head 4 It can be disassembled separately for easy replacement of water pipes.

[0031] In this embodime...

Embodiment 2

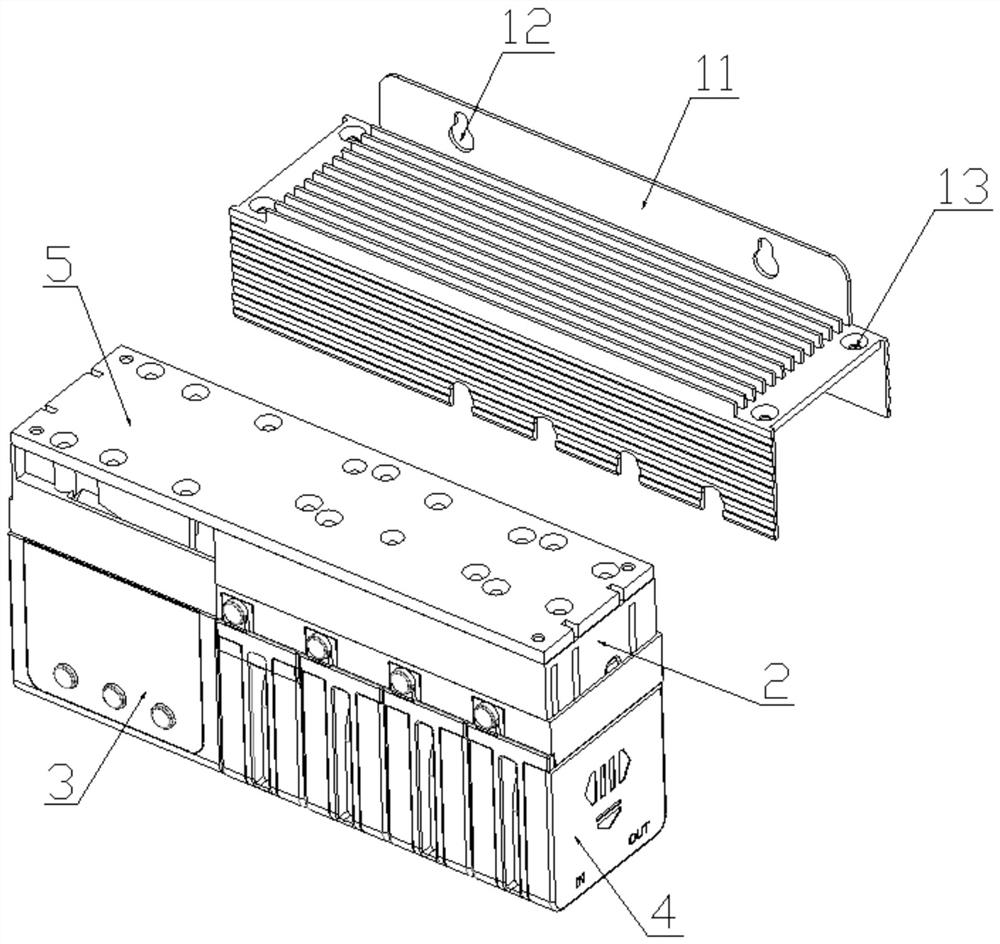

[0036] refer to Figure 1-11 , this embodiment 2 includes all the technical features of implementation 1, the difference is: a flange 11 is provided at the edge of the mounting frame 1; a first mounting slot 12 is symmetrically opened on the flange 11, which is convenient for the whole peristaltic pump fixed installation; the four corners of the mounting frame 1 are provided with a first mounting hole 13; the four corners of the mounting plate 5 are provided with a fourth mounting hole 51 corresponding to the first mounting hole 13; the mounting plate 5 It is fixed with the mounting frame 1 through bolt connection.

[0037] In this embodiment, the mounting plate 5 is further provided with a fifth mounting hole 52 , a sixth mounting hole 53 , a seventh mounting hole 54 and an eighth mounting hole 55 .

[0038] In this embodiment, the motor box is provided with connecting studs 31; the connecting studs 31 are set correspondingly to the fifth mounting hole 52 and are fixed by bo...

Embodiment 3

[0042] refer to Figure 1-11 , this embodiment 3 includes all the technical features of Embodiment 1, the difference is: the electromagnetic clutch peristaltic pump also includes a cover plate 6; one end of the cover plate 6 is provided with a third block 61, and the other end is provided with a third card slot 62 ; The third clamping block 61 is matched with the first clamping slot 210 , and the third clamping slot 62 is matched with the first clamping block 211 .

[0043] With this solution, when the peristaltic pump head 4 is separated from the transmission device 2, the cover plate 6 can be covered on the station to prevent the transmission gear 28 from being exposed to the outside world and prevent dust from entering the transmission device 2 and causing damage to components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com