Roller shutter dust catcher

A dust-catching net and rolling shutter technology, which is applied to safety devices, dust-proofing, mining equipment, etc., can solve the problems of poor use of dust-catching nets, easy rust of the bearings of the runway, and inflexible movement, etc., and achieves a simple installation process. Easy to operate, easy to maintain and easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

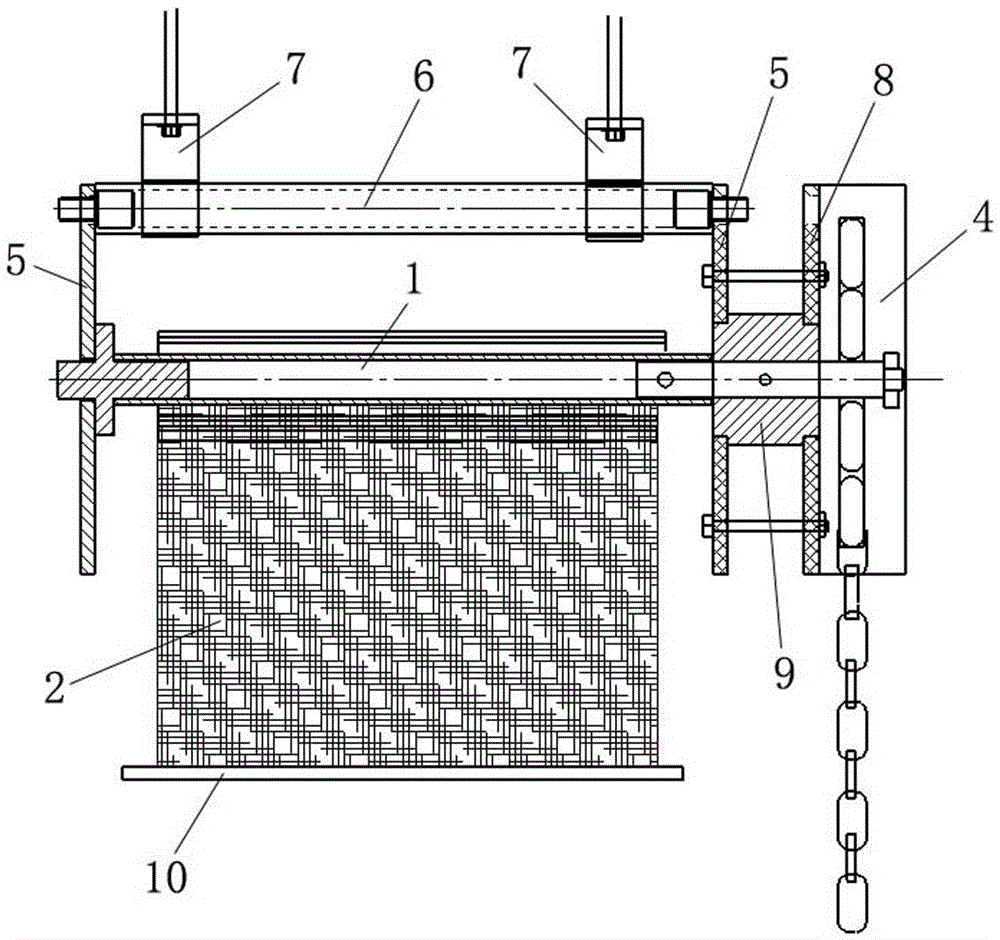

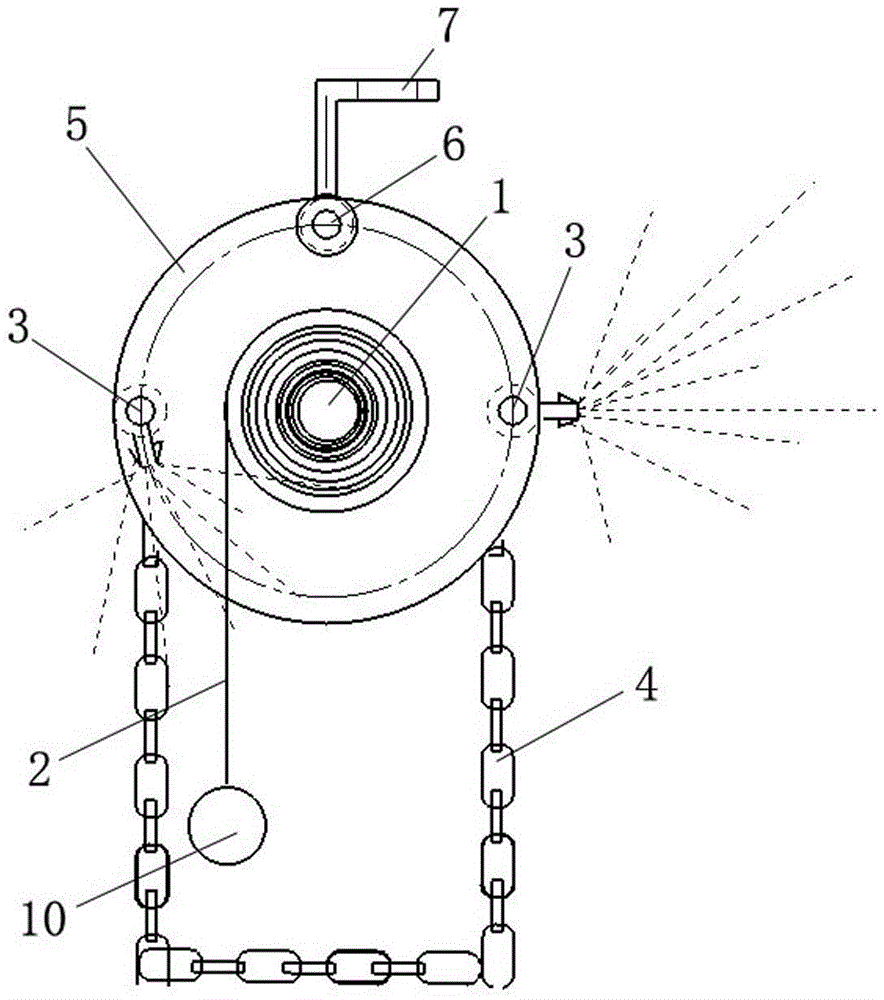

[0015] Such as figure 1 , 2 As shown, a shutter-type dust-catching net device includes a frame body, a rotating shaft 1, a nylon net 2, a spray pipe 3 and a chain hoist 4; the frame body includes two left and right support plates 5, and two support plates The top of 5 is fixed with supporting beam 6, and the two ends of supporting beam 6 are provided with connecting seat 7; At the center of the support plate 5, and the rotating shaft 1 can rotate freely; one side of the nylon mesh 2 is connected and fixed on the rotating shaft 1; the spray tube 3 is fixed between the two support plates 5 on the frame, and the spray tube 3 is provided with a water inlet joint and a nozzle; the outer side of one of the support plates 5 of the frame body is fixed with a mounting plate 8, and a nylon sleeve 9 is provided between the mounting plate 8 and the support plate 5, and several long ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com