A vertical water simulation experimental device and experimental method for the purification process of aluminum melt

A technology for simulating experimental device and aluminum melt, which is applied in the field of metallurgical engineering, can solve the problems of inability to realize gas, cannot achieve a similar level, and insufficient attention to research and development, and achieves the effect of reasonable device structure, simple preparation method and optimized process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

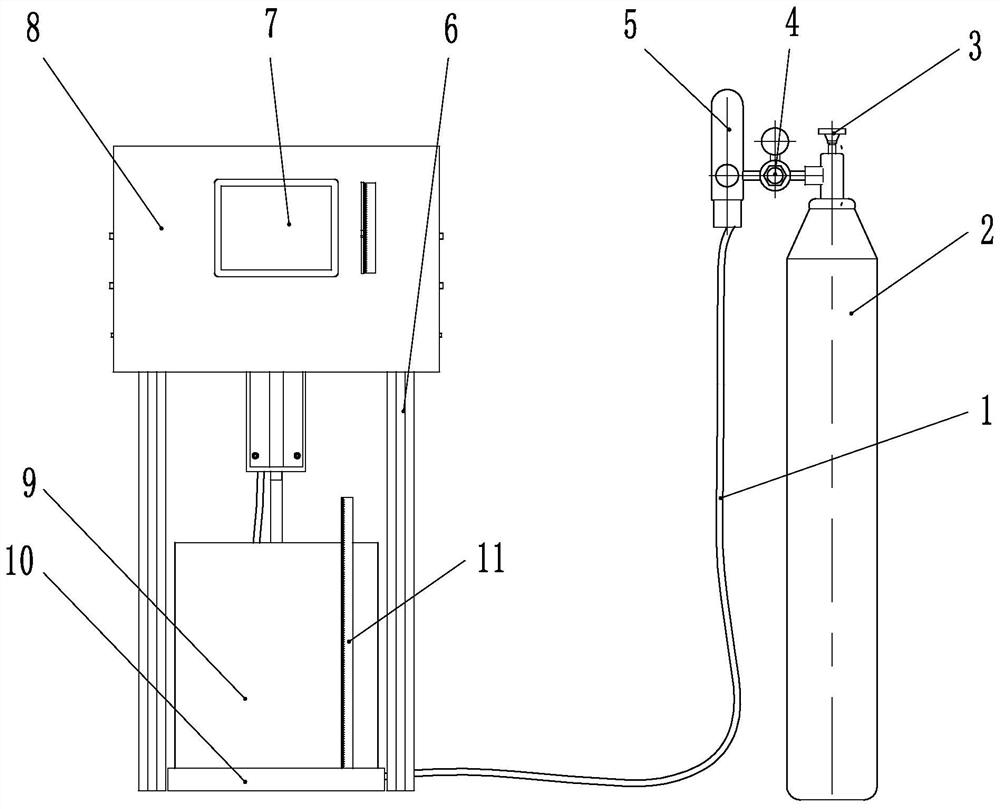

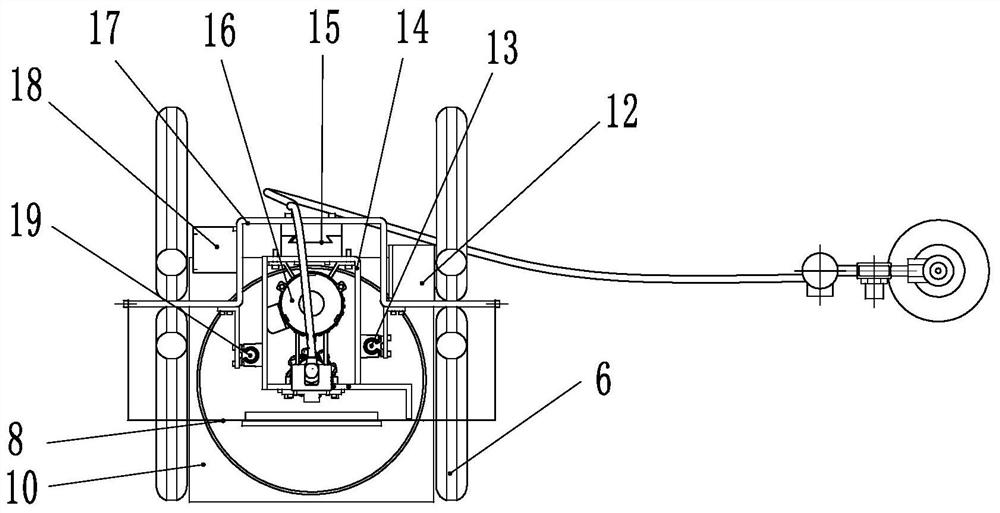

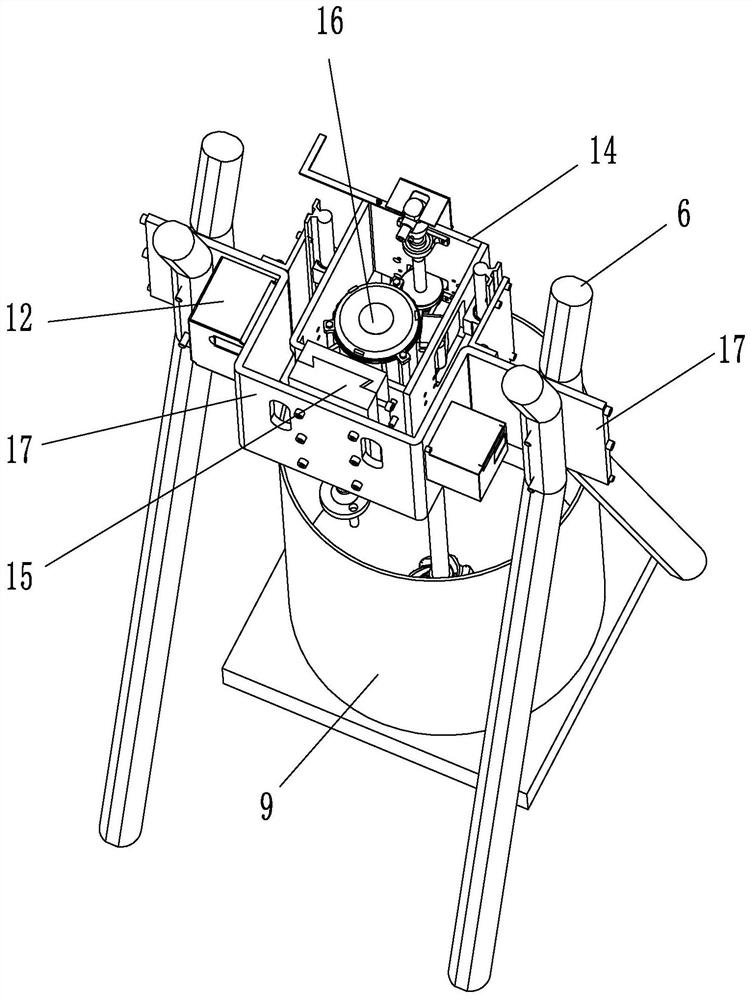

[0064] Embodiment 1: a kind of vertical water simulation experimental device of aluminum melt purification process, such as Figure 1-Figure 15 As shown, it includes an air source device 2, a bracket 6, a seat plate assembly 14, a sliding table assembly 15, a transmission assembly 16, a beam assembly 17, a frequency converter 12, a panel 8, a transparent container 9 and a PLC single-chip microcomputer 18 for controlling the transmission assembly . The PLC single-chip microcomputer and the frequency converter are installed on the beam assembly.

[0065] The seat plate assembly 14 includes a U-shaped frame 142, a clamping plate 141, a lower support plate 143, a cover plate 145 and a pointer 144, the cover plate is installed on the side of the U-shaped frame, and the clamping plate and the lower support plate are respectively installed on The upper end and the lower end of the front face of the U-shaped frame, the pointer is fixed on the U-shaped frame.

[0066] The slide assem...

Embodiment 2

[0076] Embodiment 2: A vertical water simulation experiment device for the purification process of aluminum melt, its basic structure is the same as that of Embodiment 1, the difference is that the diameter of the porous impeller is 90 mm, and 120 radial jets of 0.5 mm are arranged in the radial direction The hole (according to the actual size of the impeller in the aluminum alloy refining process is 220mm, according to the ratio of 1:2.5, the porous impeller is formed by high-precision plastic wire fusion deposition 3D printer), the diameter of the transparent acrylic cylinder is 350mm, and the height is 350mm (the aluminum alloy refining process The diameter of the inner container of the transfer bag is 880mm, the height of the inner container is 800mm, the height of the aluminum alloy melt is 610mm, and the size of the transparent acrylic cylinder is prepared according to the ratio of 1:2.5).

Embodiment 3

[0077] Embodiment 3: A vertical water simulation experiment device for the purification process of aluminum melt, its basic structure is the same as that of Embodiment 1, the difference is that the diameter of the porous impeller is 70 mm, and 96 radial jets of 0.5 mm are arranged in the radial direction The hole (according to the actual size of the impeller in the aluminum alloy refining process is 220mm, according to the ratio of 1:3, the porous impeller is formed by high-precision plastic wire fusion deposition 3D printer), the diameter of the transparent acrylic cylinder is 300mm, and the height is 350mm (the aluminum alloy refining process The diameter of the inner container of the transfer bag is 880mm, the height of the inner container is 800mm, the height of the aluminum alloy melt is 610mm, and the size of the transparent acrylic cylinder is prepared according to the ratio of 1:3).

[0078] Design concept and working principle of the present invention are:

[0079] 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com