Circuit breaker operating mechanism test fixture

A technology of operating mechanism and testing tooling, which is applied in the direction of circuit breaker testing, machine/structural component testing, mechanical component testing, etc. It can solve the problems of low testing efficiency of operating mechanism, improve testing efficiency and reduce overall The effect of high size and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

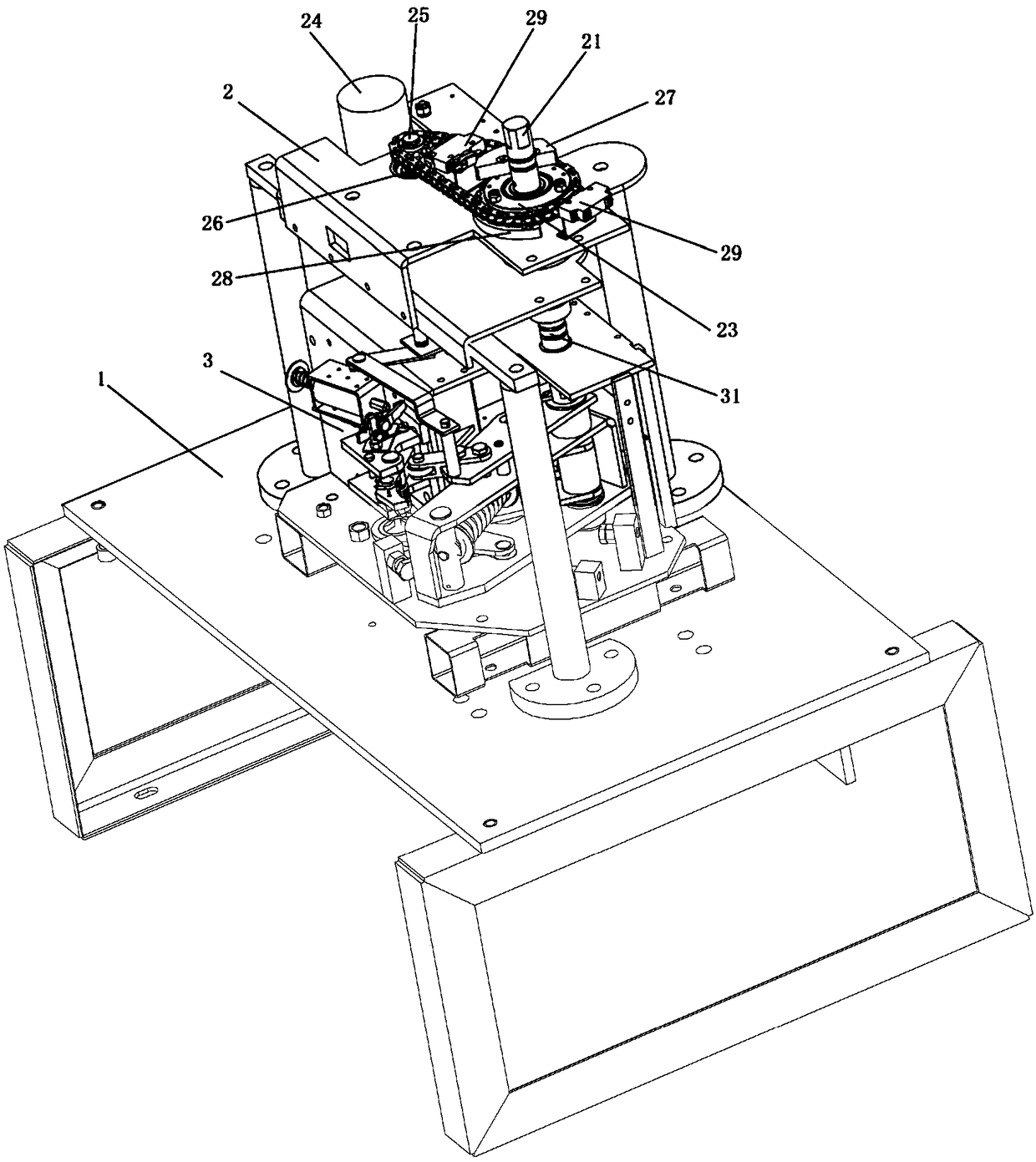

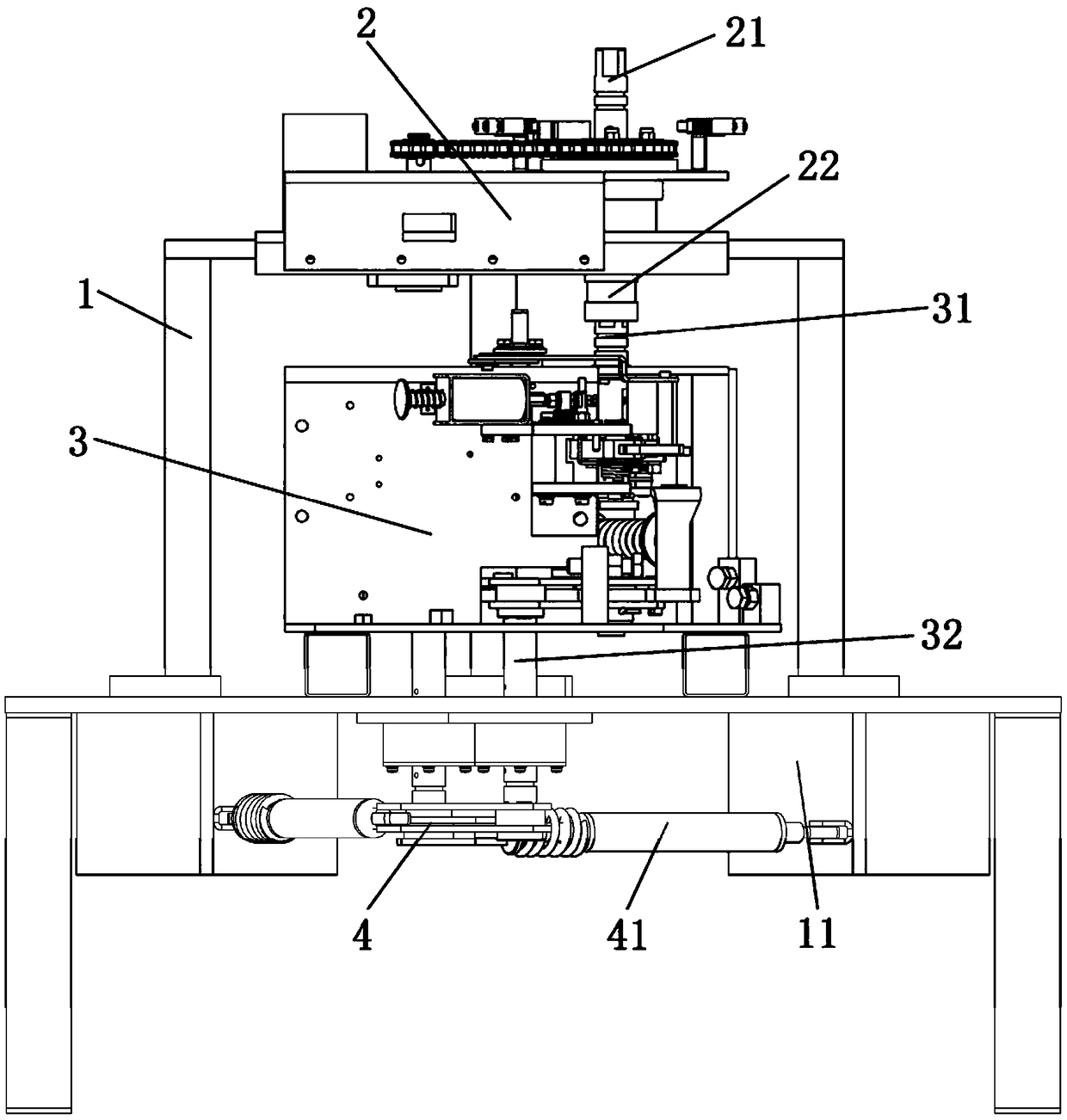

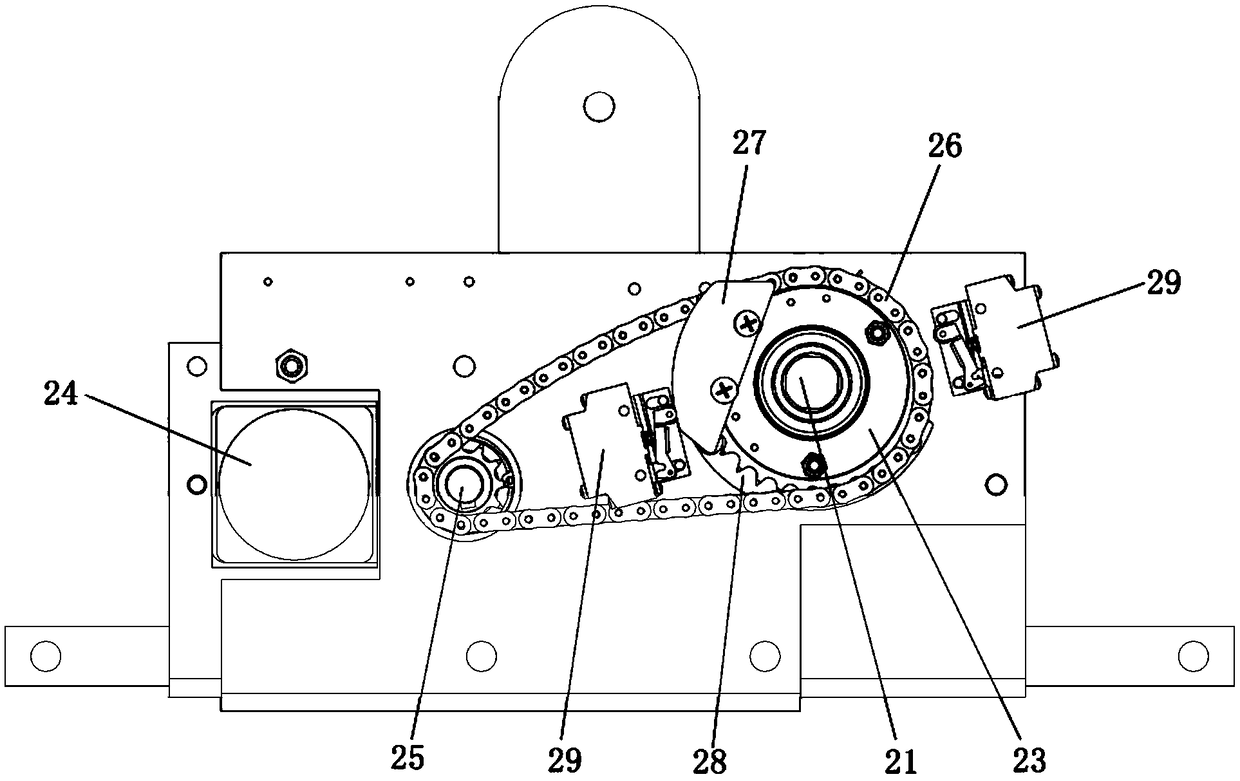

[0030] The specific implementation of the circuit breaker operating mechanism test tooling in the present invention will now be described in conjunction with the accompanying drawings, as figure 1 and figure 2 As shown, the circuit breaker operating mechanism test tool includes a base 1, the base 1 is formed by a combination of plates and pipes, and the base 1 is arranged sequentially from top to bottom with a rotating test mechanism 2 that drives the input shaft 31 of the operating mechanism 3 to be tested to rotate. , the load mechanism 4 connected with the output shaft 32 of the operating mechanism 3 to be detected, the operating mechanism 3 to be detected is arranged between the rotating testing mechanism 2 and the loading mechanism 4, and the input shaft 31 is driven by the rotating testing mechanism 2 Rotate, and transmit power to the output shaft 32 in the operating mechanism, and the output shaft 32 drives the load mechanism 4 to move to simulate the opening and closi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com