Paying-off robot and application thereof on erecting optical cables on 110kV circuit

A robot and wire technology, applied in the direction of optical fiber/cable installation, etc., can solve the problems of physical fatigue of the climbing staff, complicated unmanned helicopter unmanned helicopter equipment, nylon rope is easy to be washed away by water, etc., to achieve convenient use Electricity users, reduce line outage time, and increase construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Best practice:

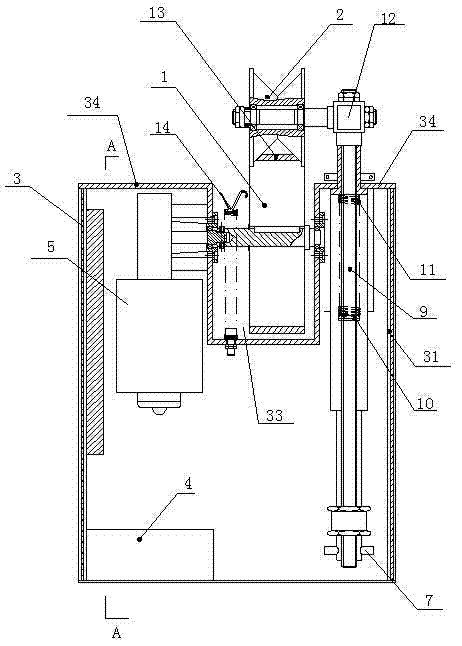

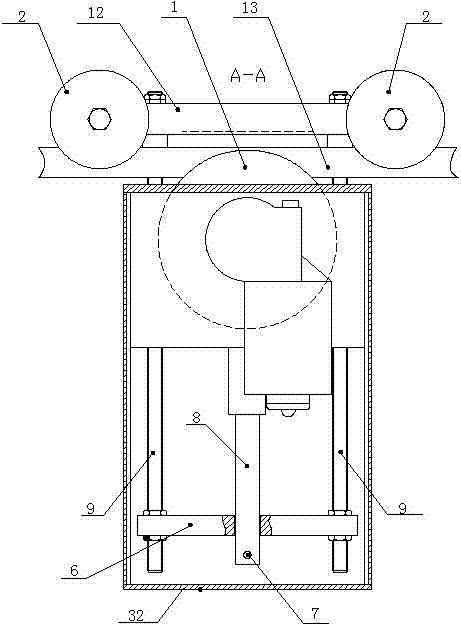

[0046] Refer to attached figure 1 And attached figure 2 , The wire-paying robot includes a power control device, a driving wheel 1, two load-bearing wheels 2, a box body 3 with a U-shaped opening groove and a push rod assembly.

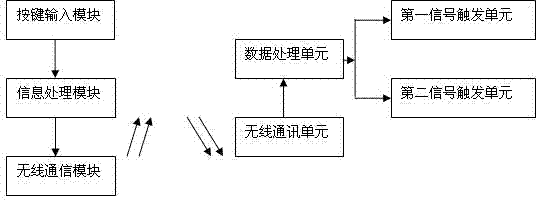

[0047] The power control device includes a power supply 4, a motor 5 and a control circuit (not shown in the figure); the power supply 4 uses a lithium battery to provide the electric energy required by the equipment, which respectively supplies power to the motor 5 and the control circuit; the motor 5 is a turbo-reduced motor The control circuit is a remote control circuit, which is wirelessly connected to a hand-held remote controller, the control output end of the remote control circuit is connected to the motor 5, and the output shaft end of the motor 5 is connected to the driving wheel 1;

[0048] The box body 3 includes four side plates 31 , a bottom plate 32 , a U-shaped opening 33 and two shoulder upper cover plates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com