Patents

Literature

66 results about "Magnetic testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetic particle testing (MT) is a non-destructive testing technique utilized to detect defects or discontinuities (such as cracks) at or near the surface in ferromagnetic metals such as iron, steel, nickel, cobalt, etc.

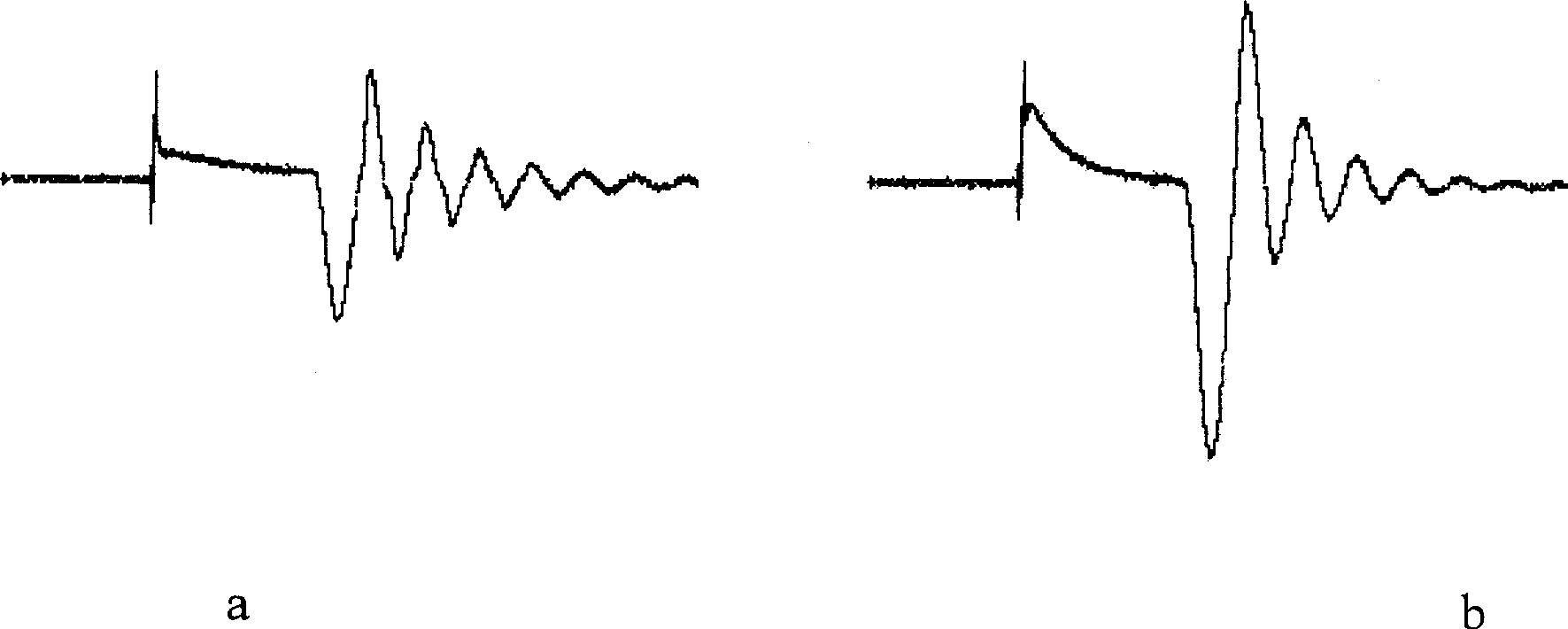

Resonance eddy detection method for surface crack

InactiveCN1924568AEasy to manufactureNon-destructiveMaterial magnetic variablesRough surfaceMagnetic testing

Owner:TSINGHUA UNIV

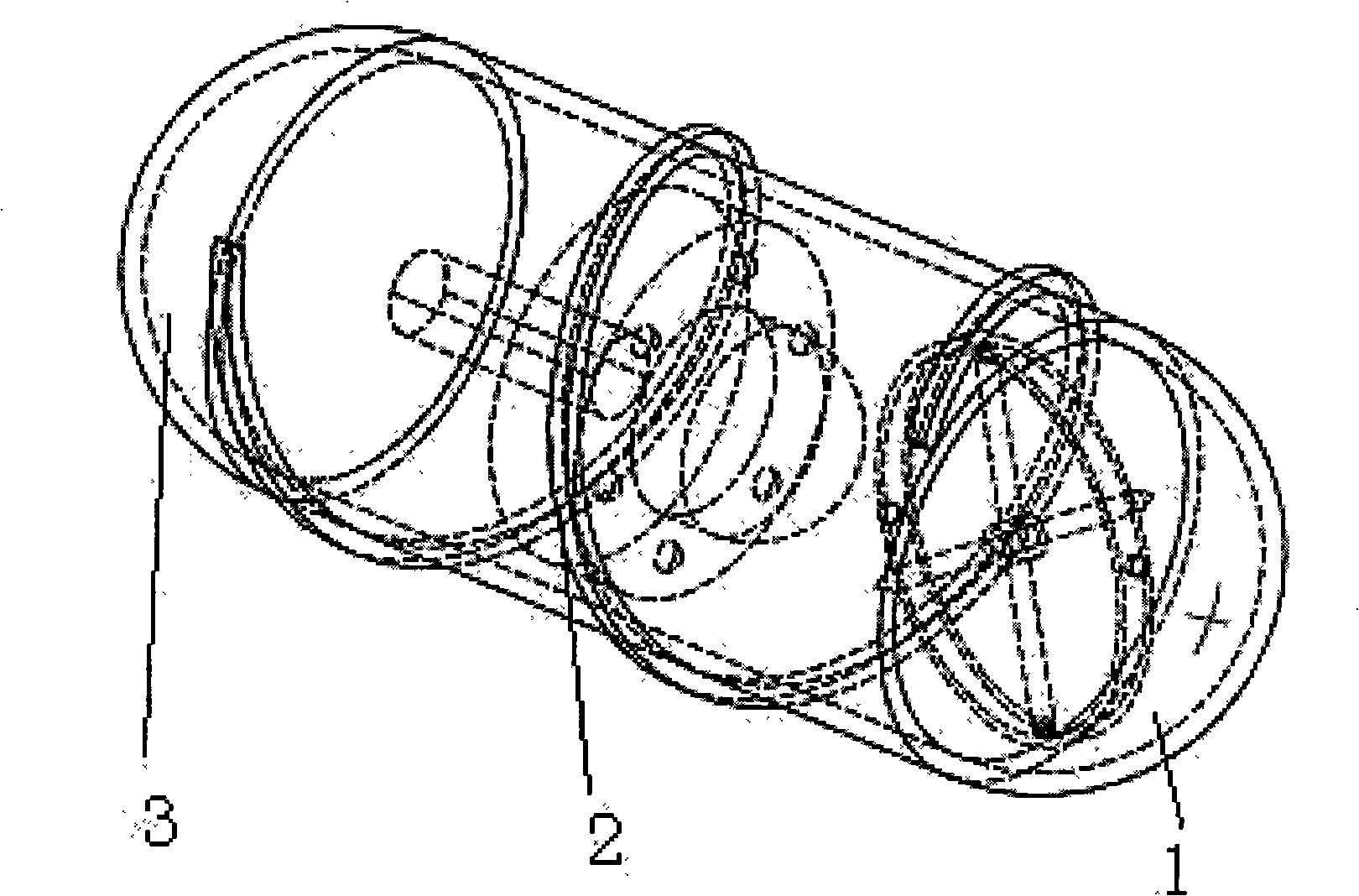

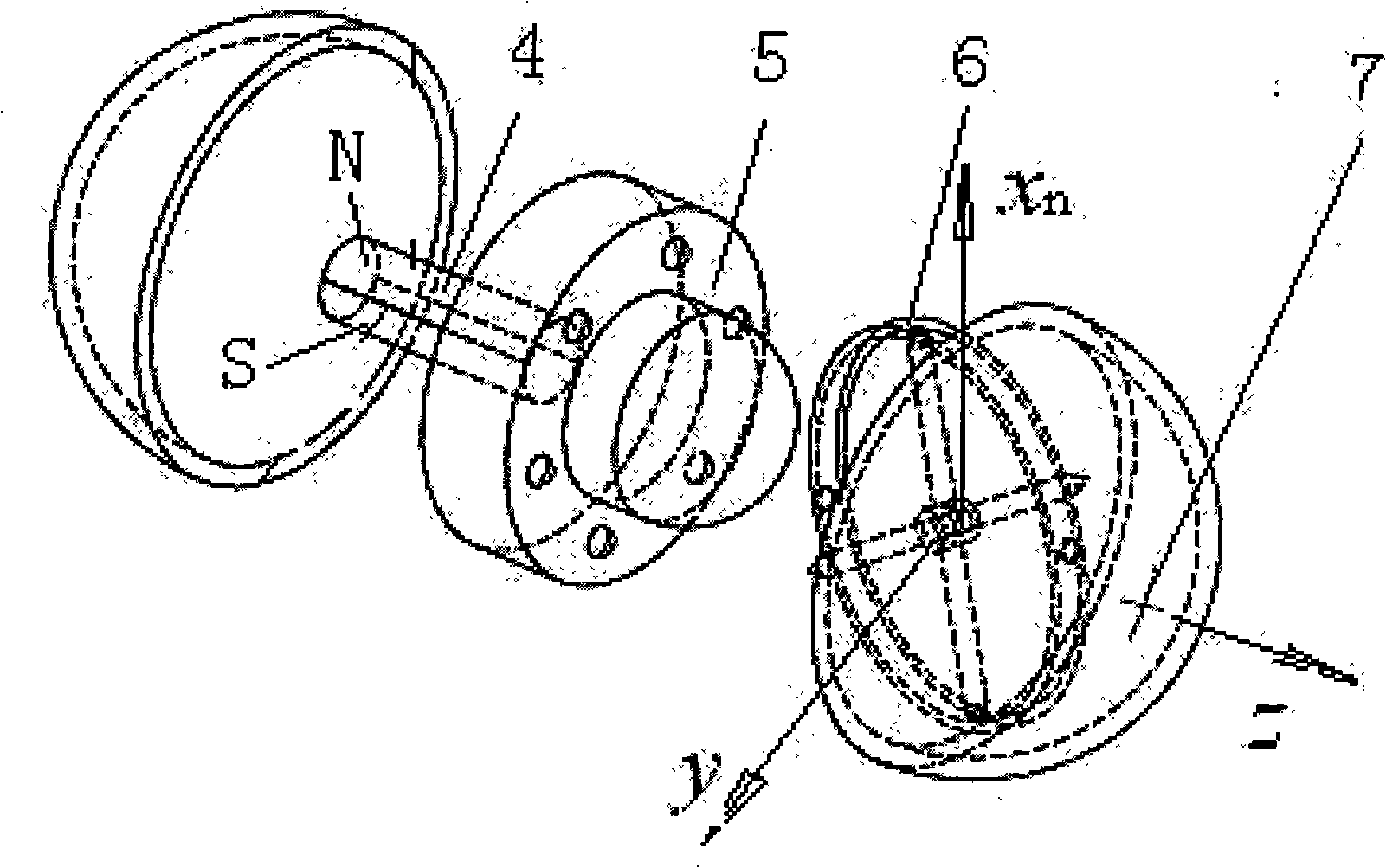

Combined method of magnetic field and vision for locating gesture of medical micro type robot in vivo

InactiveCN101297756AAvoid computational complexityEasy to detectDiagnostic recording/measuringSensorsHelmholtz coilMagnetic testing

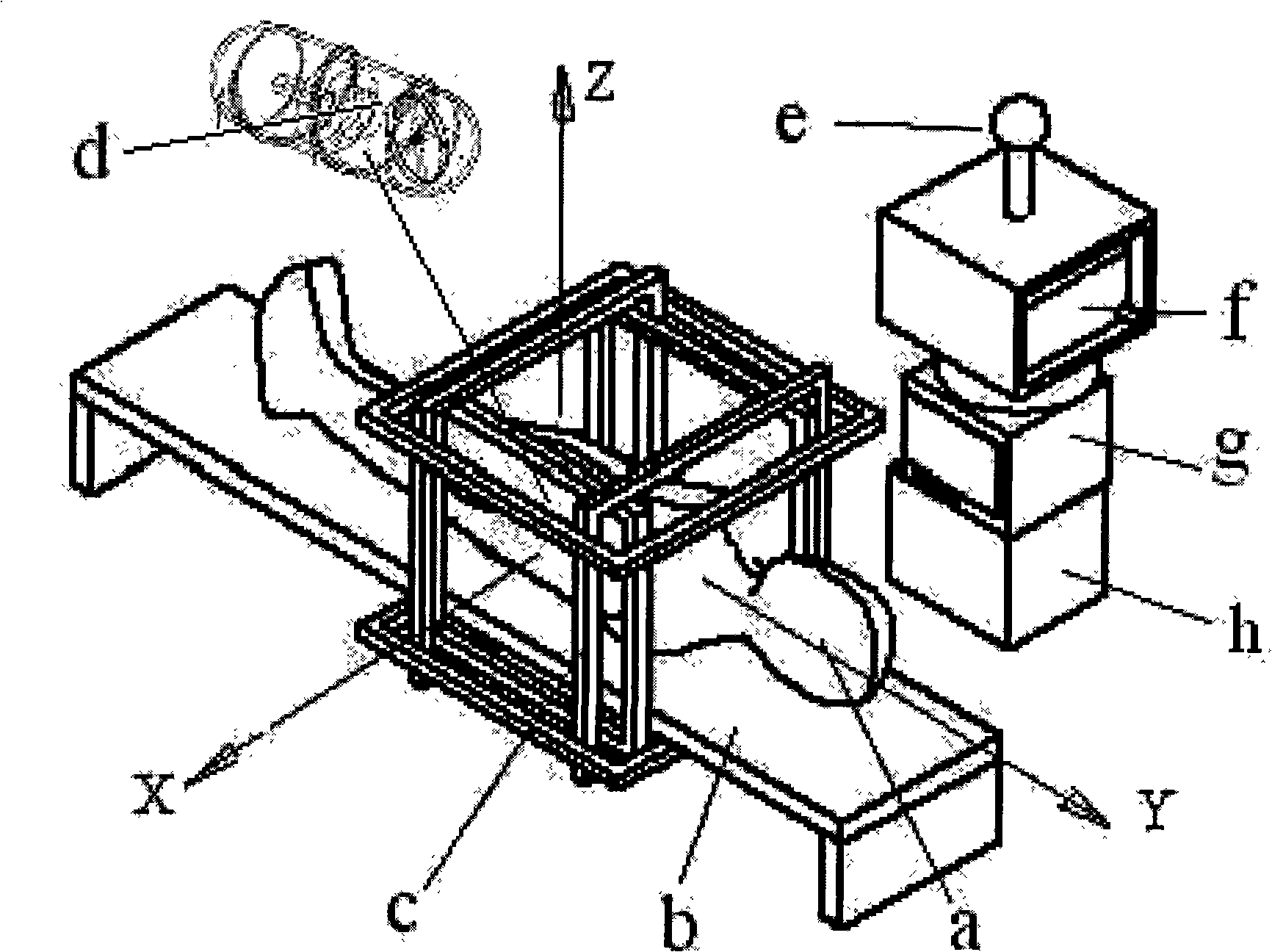

This invention belongs to the technical field of the medical engineering, disclosing a basic method for applying a direct current superposed magnetic field, an azimuth of which can be adjusted, to an Helmholtz coil device of triaxial orthogonal nesting and achieves an attitude orientation in the body by combination of embedding the medical micro-robot in which embedded radial magnetized NdFeB magnet is screwed-in in a screwing mode into a wireless visual transmission system in the body and a magnetic testing. The invention is characterized in that a small magnetic needle is observed to turn superposition with the axis of the medical micro-robot in the external field by embedding the medical micro-robot into a wireless visual system, transfers the detection problem of a complex attitude azimuth into a known variable in which the azimuth of external direct current magnetic field can be readout directly. The invention has the beneficial effects of avoiding that a plurality of sensors are needed in detection and a complex computational process in the traditional method, detecting the attitude azimuth of the medical micro-robot in the body quickly by a non-contact mode, providing a position parameter for the revolving magnetic field which produces the corresponding azimuth, and improving the operability of the medical micro-robot in the bend environment.

Owner:DALIAN UNIV OF TECH

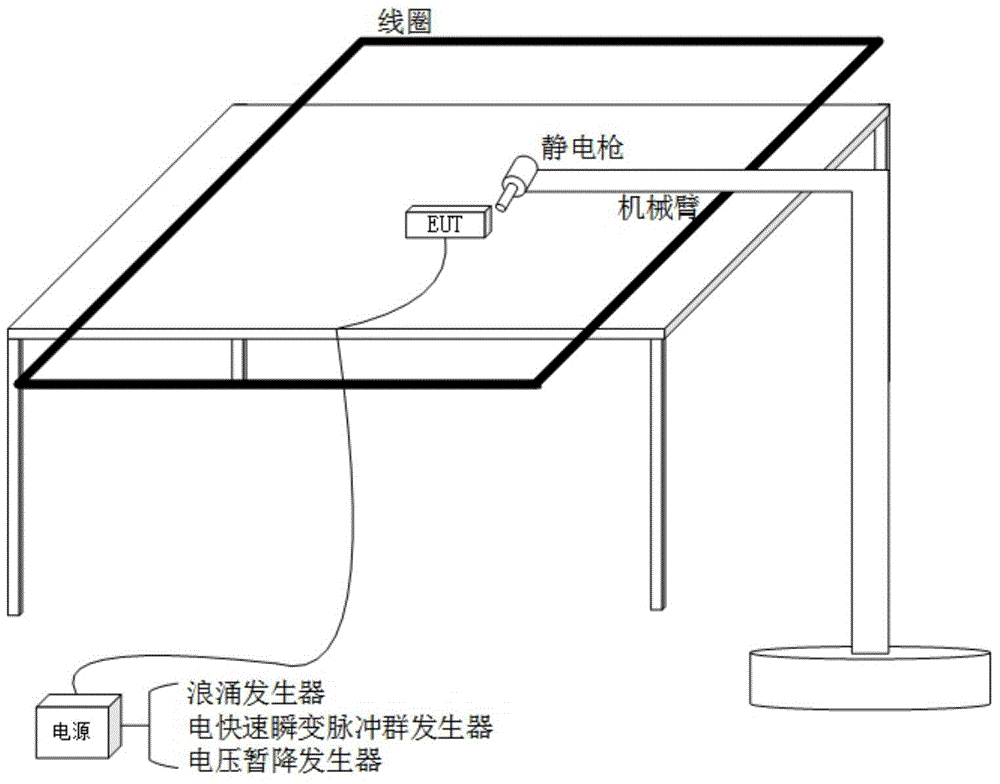

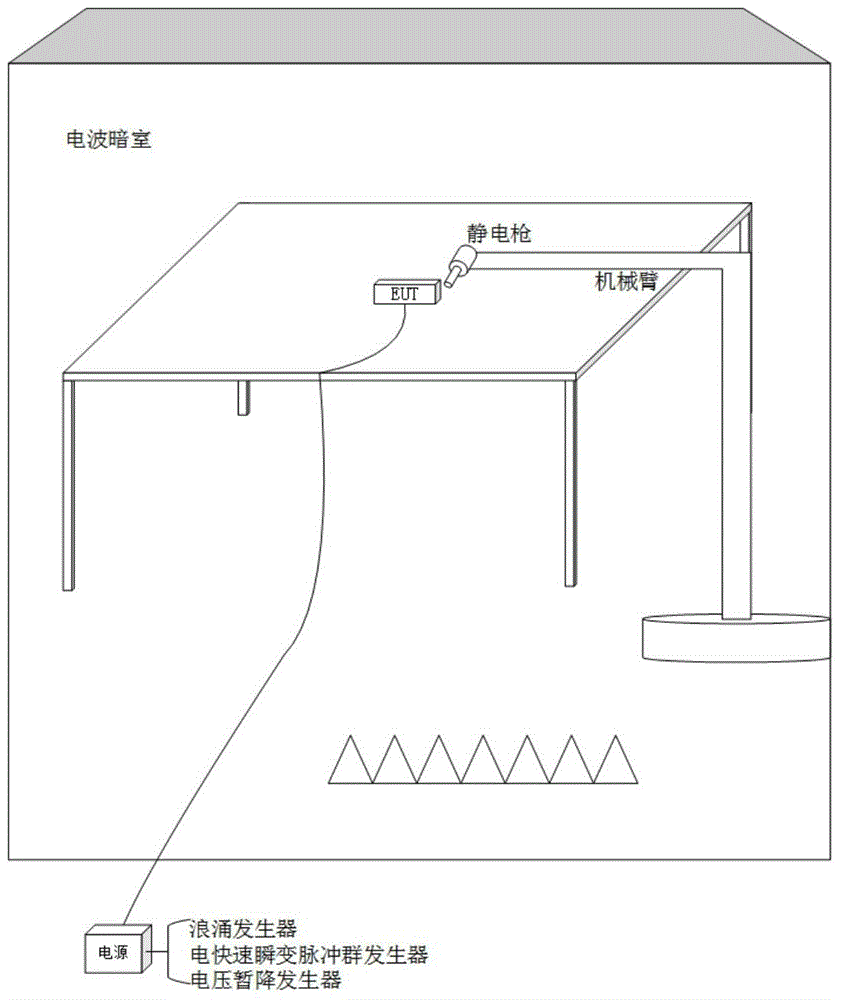

Transformer station intelligent electronic device multi-source anti-interference degree characteristic testing method

The invention provides a transformer station intelligent electronic device multi-source anti-interference characteristic testing method. The testing method comprises a mixed power frequency magnetic field testing method and a mixed radio frequency radiation anti-interference degree testing method. The mixed power frequency magnetic testing method is characterized in that during the power frequency magnetic field test, the surge test and the static test can be carried out; during the power frequency magnetic field test, the electrical fast transient burst test and the static test can be carried out; during the power frequency magnetic field test, the voltage dip test and the static test can be carried out. The mixed radio frequency radiation anti-interference degree testing method is characterized in that during the radio frequency anti-interference degree test, the surge test and the static test can be carried out; during the radio frequency radiation anti-interference degree test, the electrical fast transient burst test and the static test can be carried out; during the radio frequency anti-interference degree test, the voltage dip test and the static test can be carried out. The method provided by the invention is capable of simulating a plurality of interference ways, which are applied to the intelligent electronic devices at the same time, and then the anti-interference degree can be tested, and the acquired testing result can be used to reflect the actual condition, and therefore the credibility and the authority of the anti-interference degree test can be improved greatly.

Owner:STATE GRID CORP OF CHINA +3

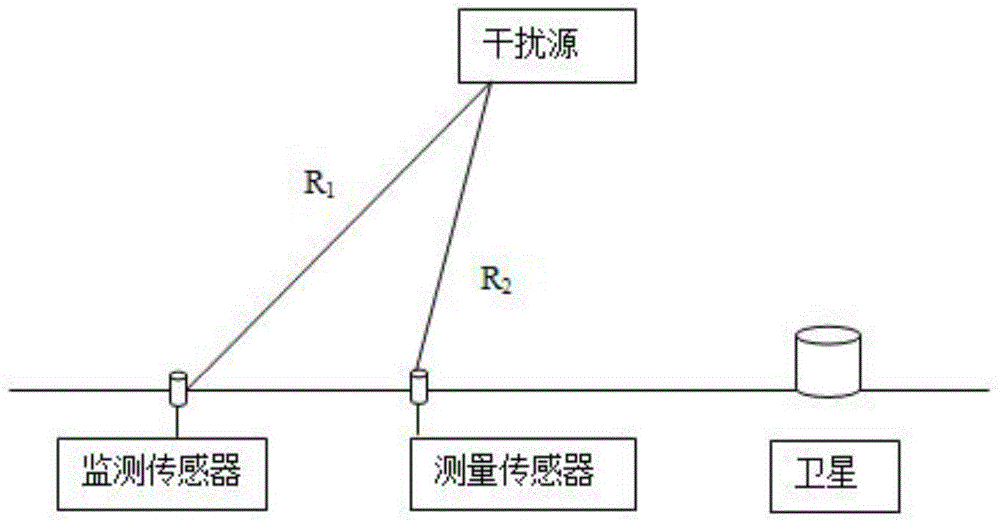

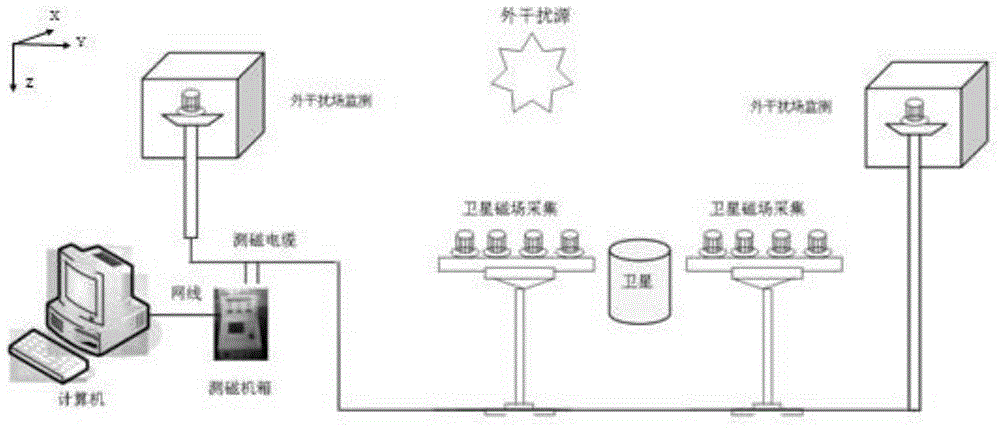

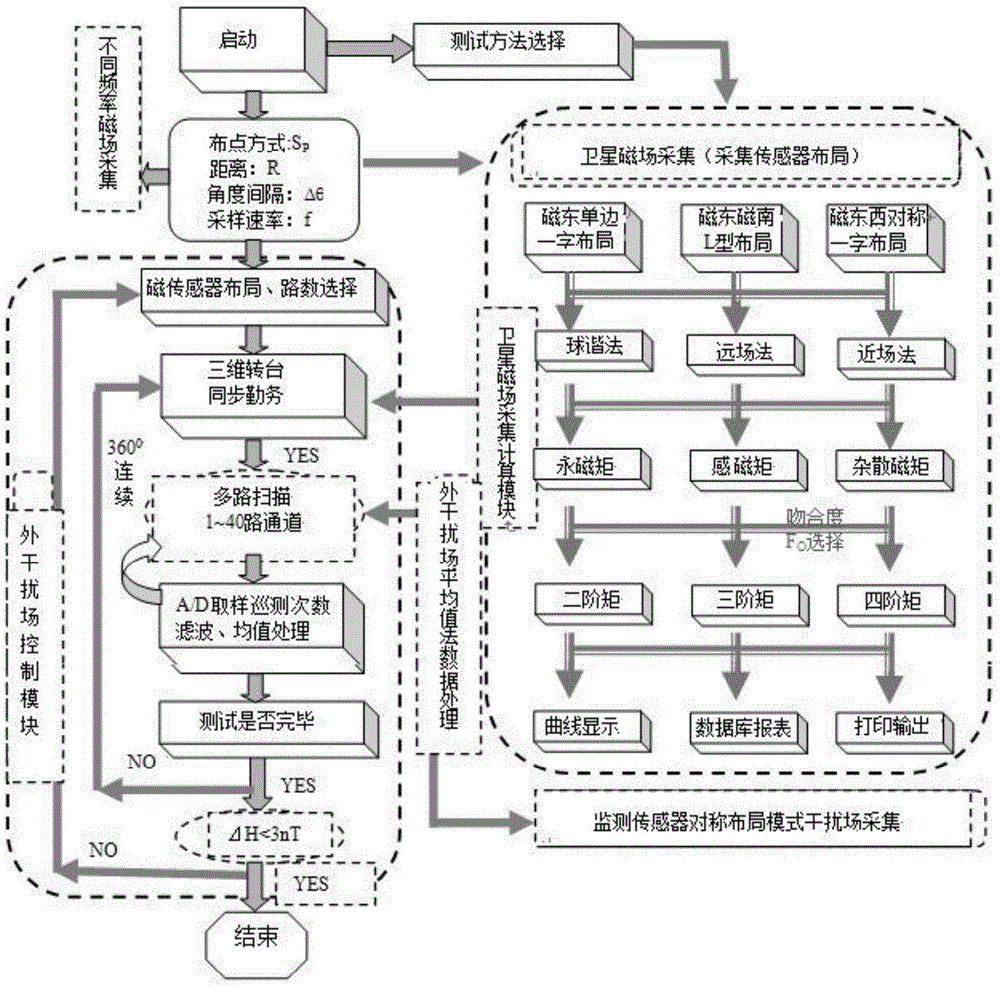

Satellite magnetic test external interference magnetic field closed-loop control method under geomagnetic environment

The invention discloses a satellite magnetic test external interference magnetic field closed-loop control method under the geomagnetic environment. An external interference magnetic field value affecting satellite magnetic test accuracy is controlled under 3 nT, and under the condition that large zero-magnetism test equipment is not established, effective closed-loop control, automatic tracking, compensation and correction are conducted on a satellite magnetic test local area dynamic external interference magnetic field are achieved under the geomagnetic environment, and the 24-hour satellite quasi-zero-magnetism environment test condition under the geomagnetic environment is acquired, wherein automatic compensation is conducted on random interference values of geomagnetic field fluctuation and an industrial magnetic field.

Owner:SHANGHAI INST OF SATELLITE EQUIP

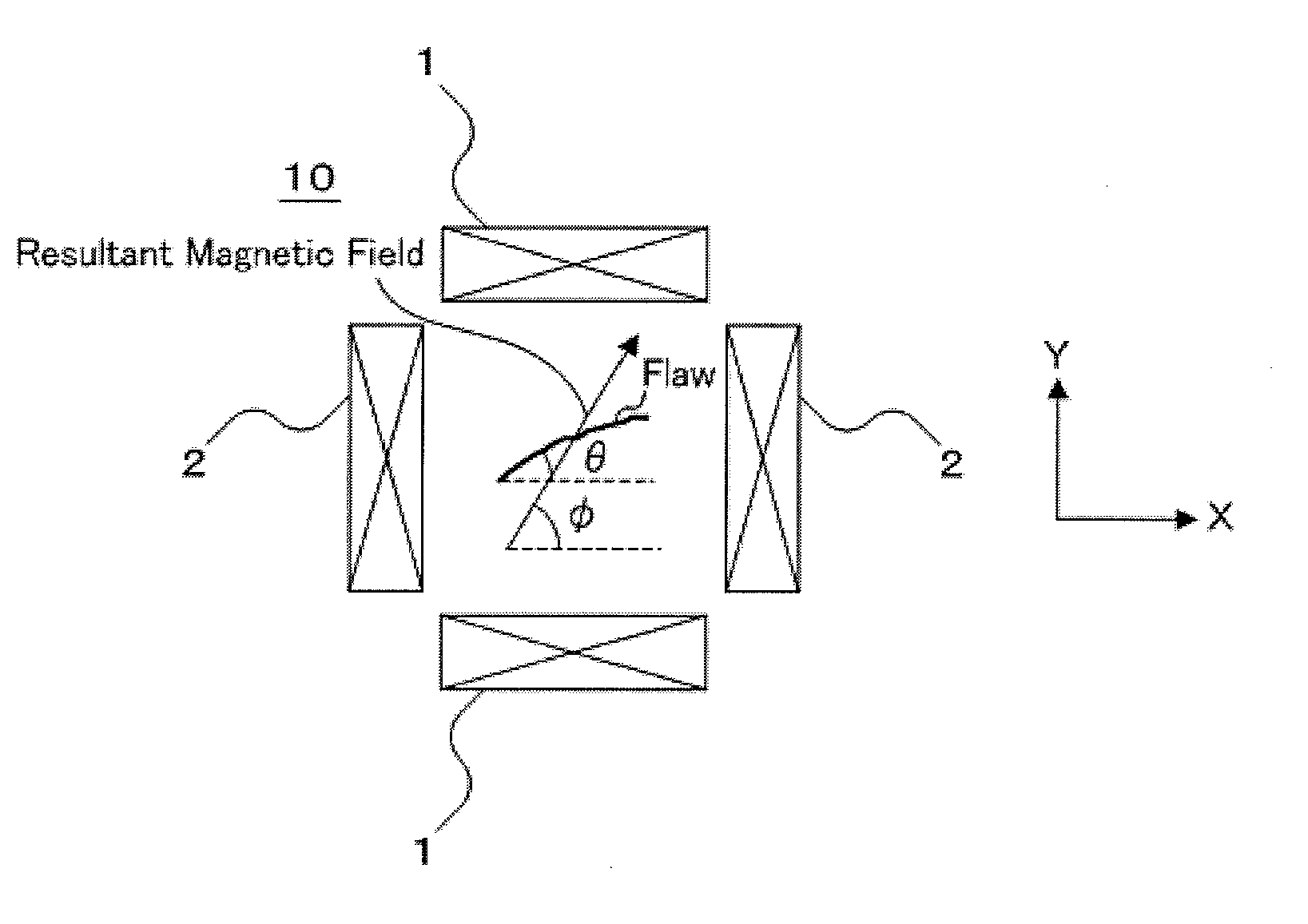

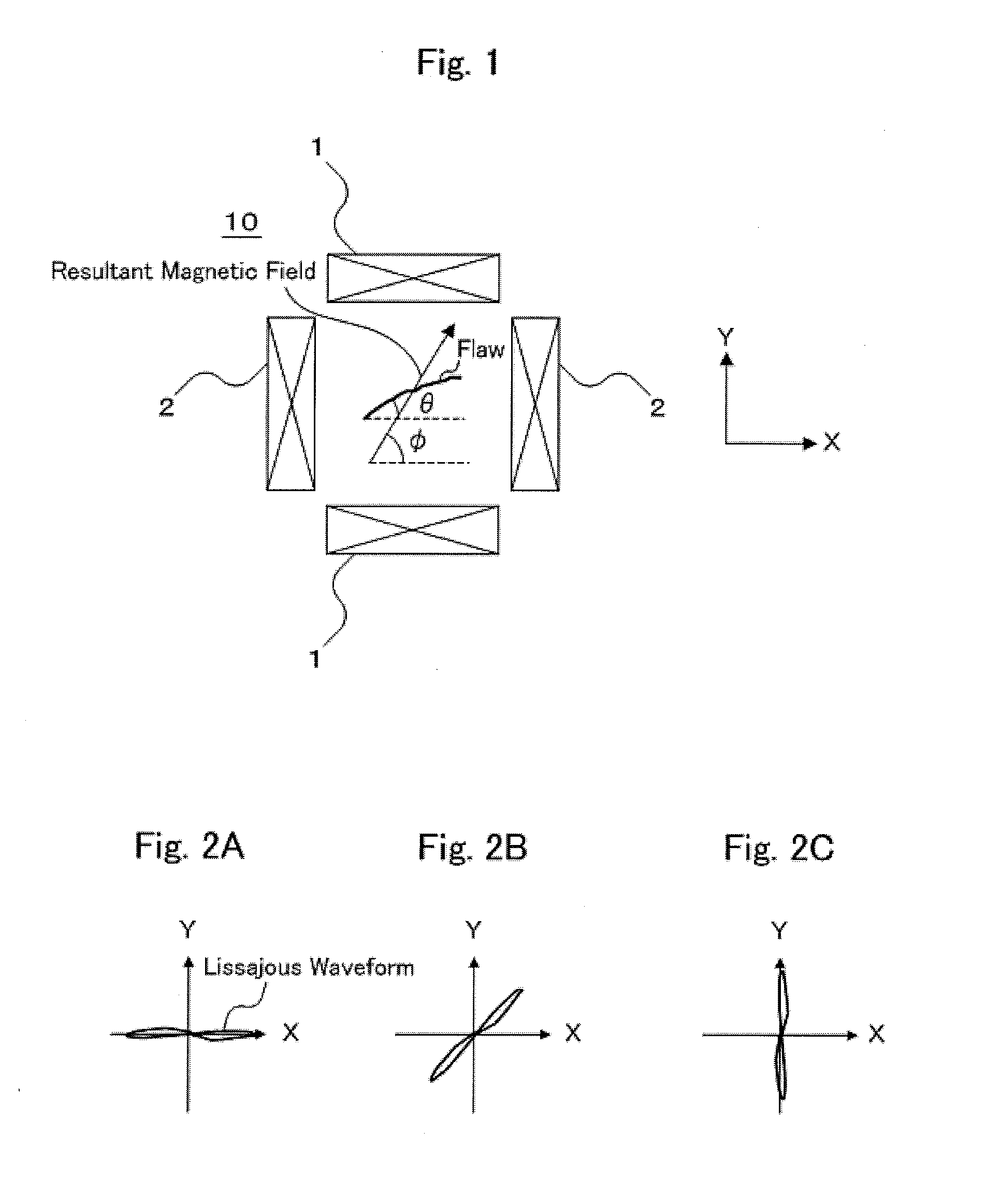

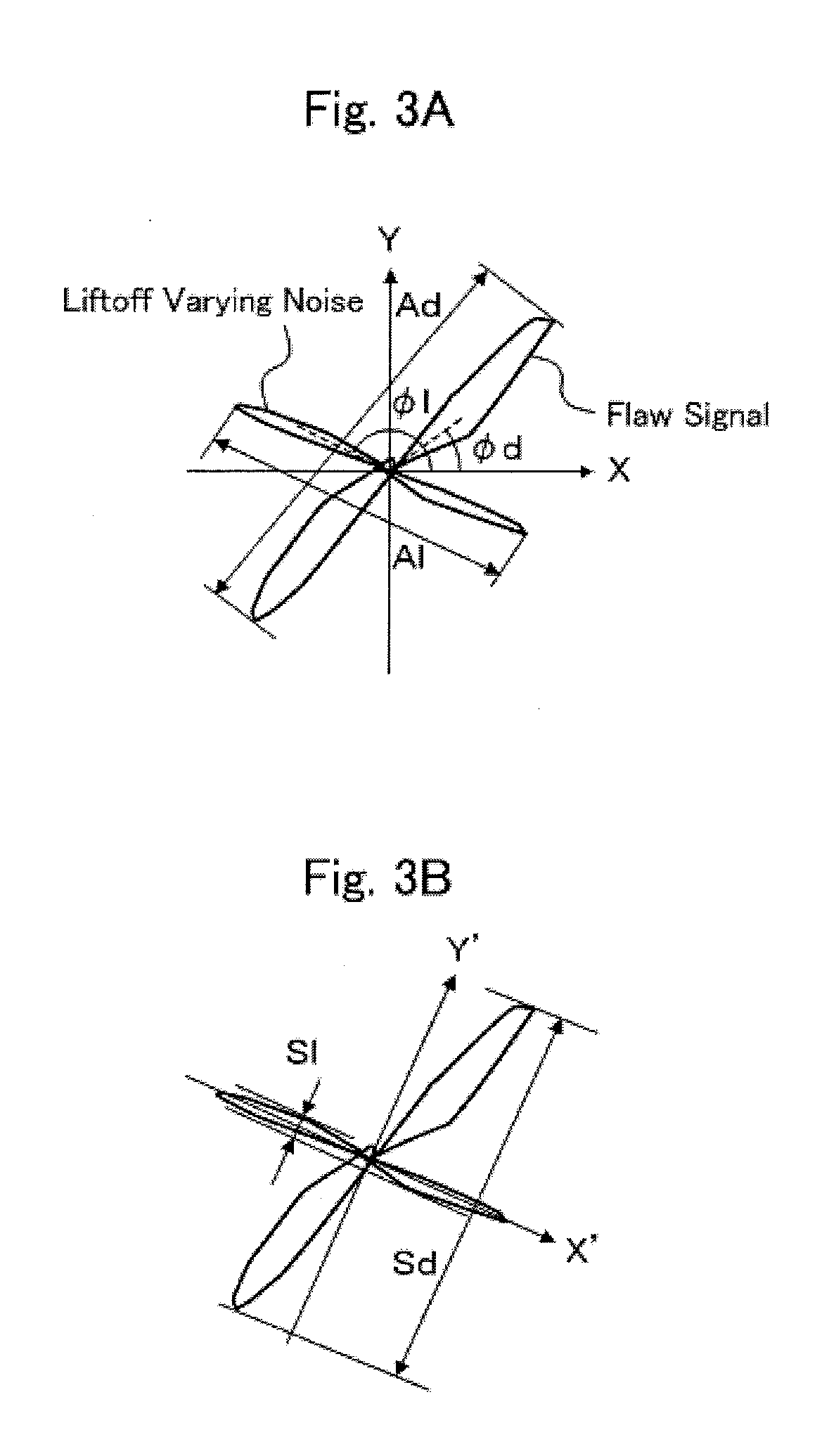

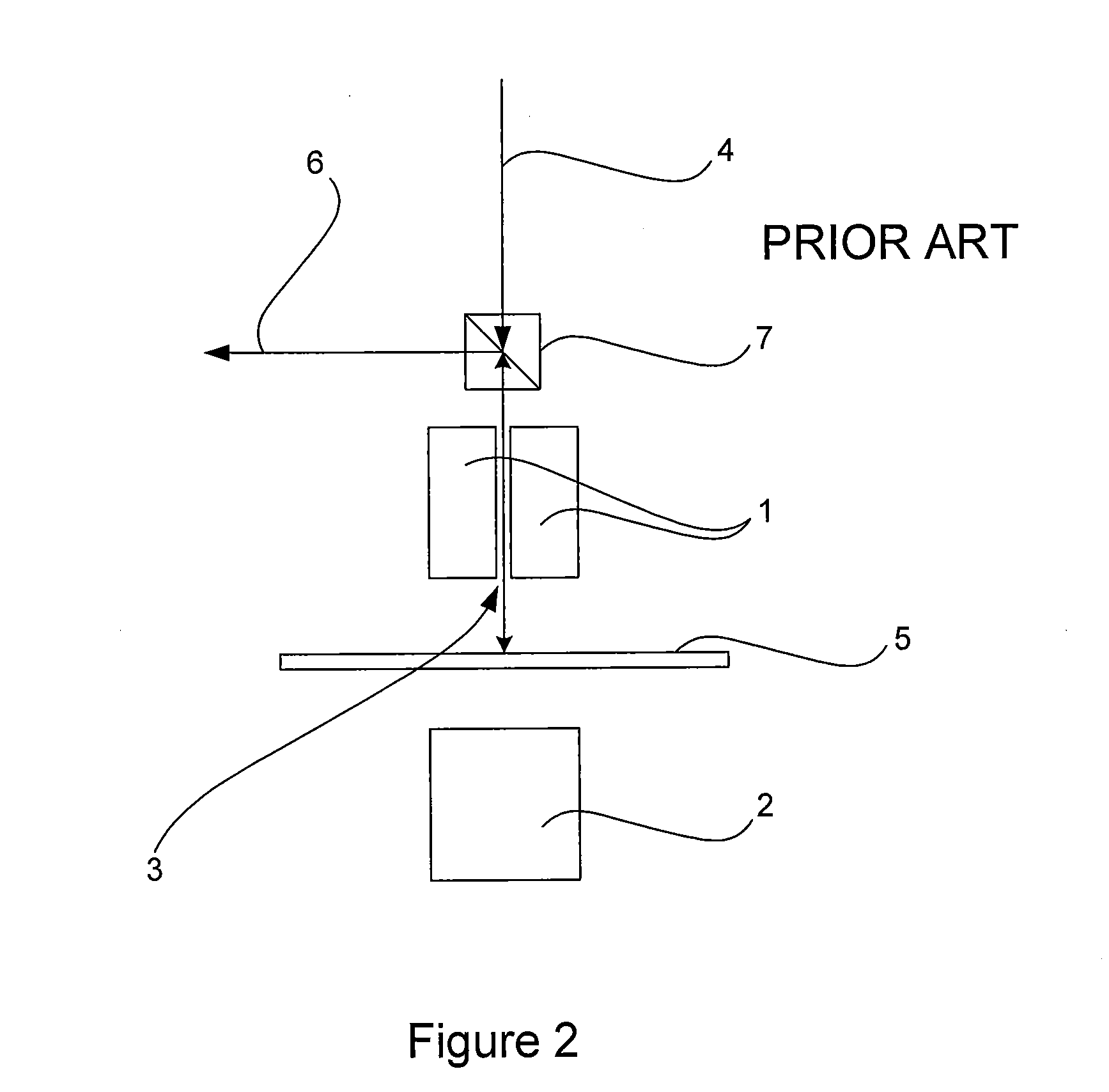

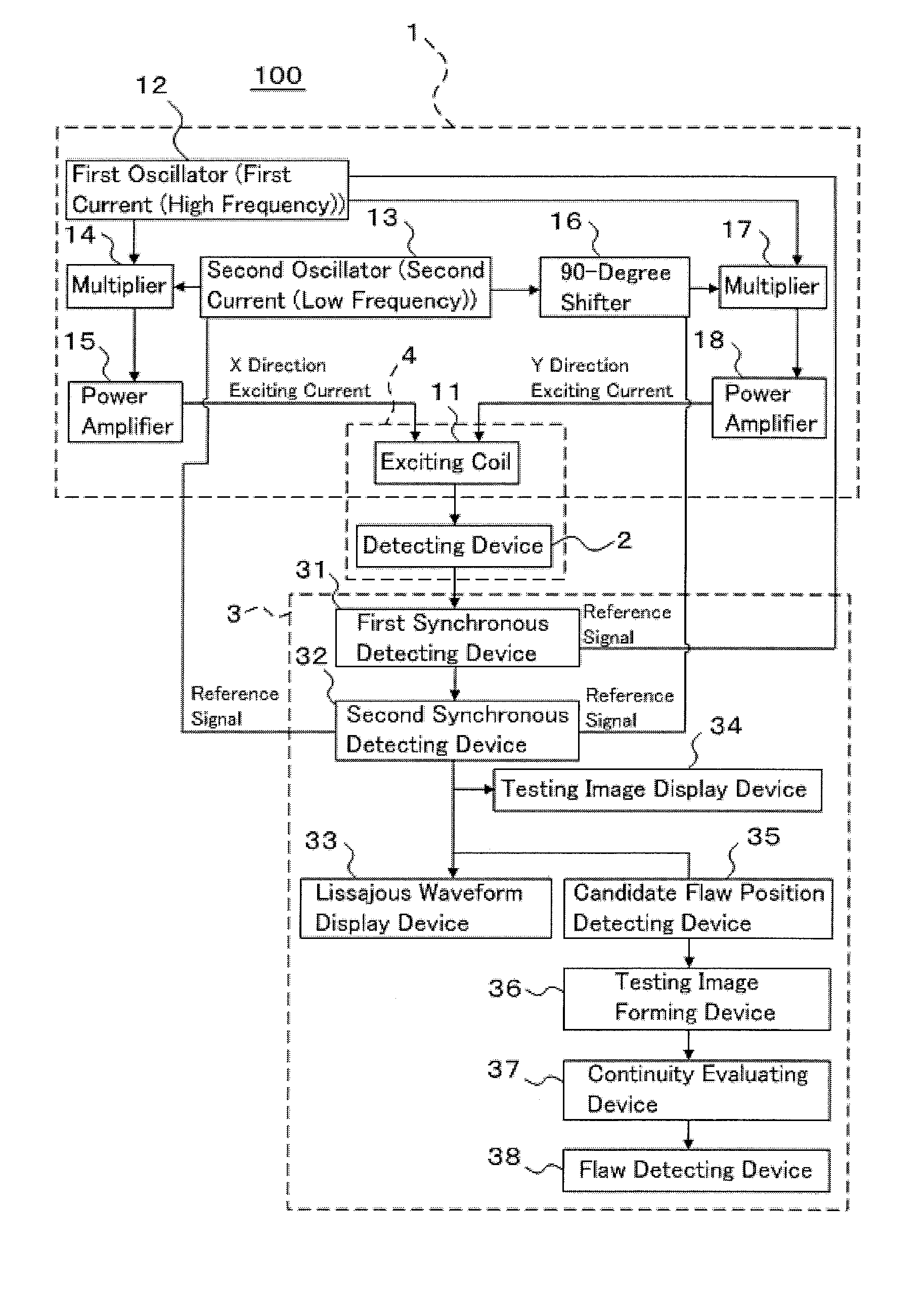

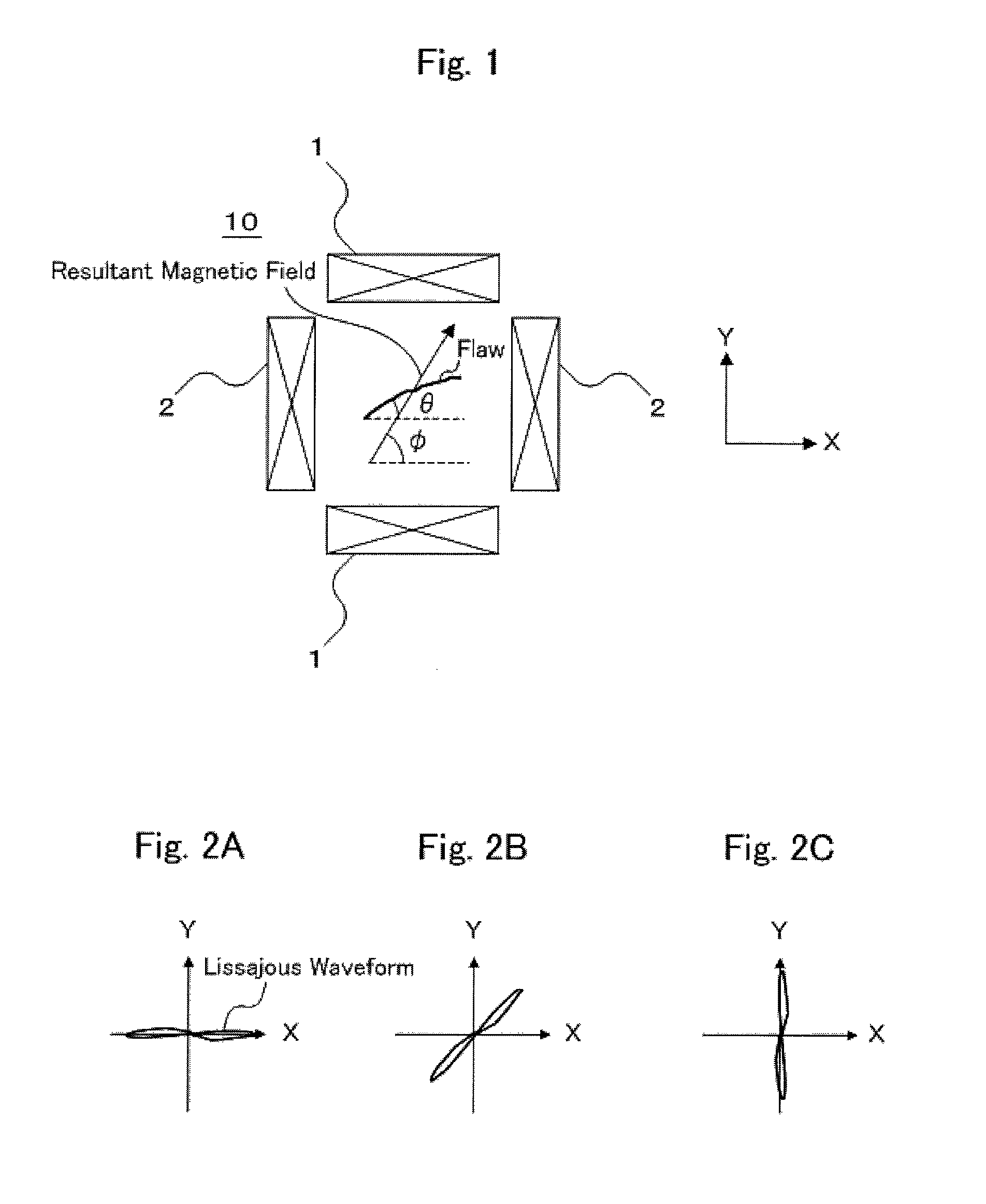

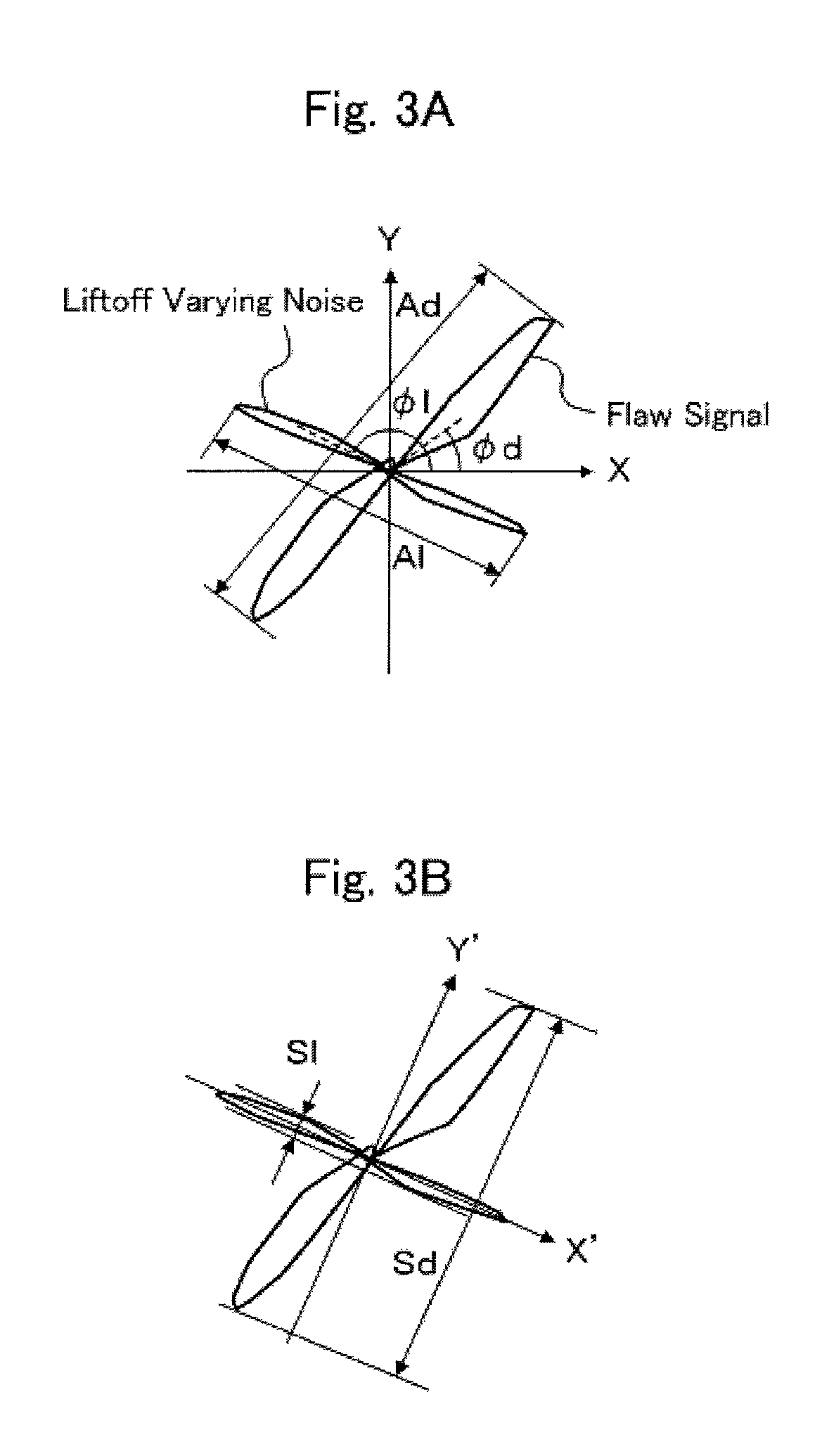

Magnetic testing method and magnetic testing apparatus

ActiveUS20110163741A1Accurate detectionInhibition effectMaterial magnetic variablesMagnetic testingGray level

A magnetic testing apparatus has a magnetizing device applying a rotating magnetic field to a material to be tested, a testing signal detecting device, and a signal processing device applying signal processing to the testing signal. The signal processing device has a first synchronous detecting device detecting a testing signal by using the first current as a reference signal, a second synchronous detecting device detecting an output signal of the first synchronous detecting device by using the second current as a reference signal to extract a candidate flaw signal, and a testing image display device displaying a testing image in which each of pixels has a gray level corresponding to an intensity of the candidate flaw signal at each of positions of the material to be tested, and a phase of the candidate flaw signal at each of the positions is capable of being identified.

Owner:NIPPON STEEL CORP

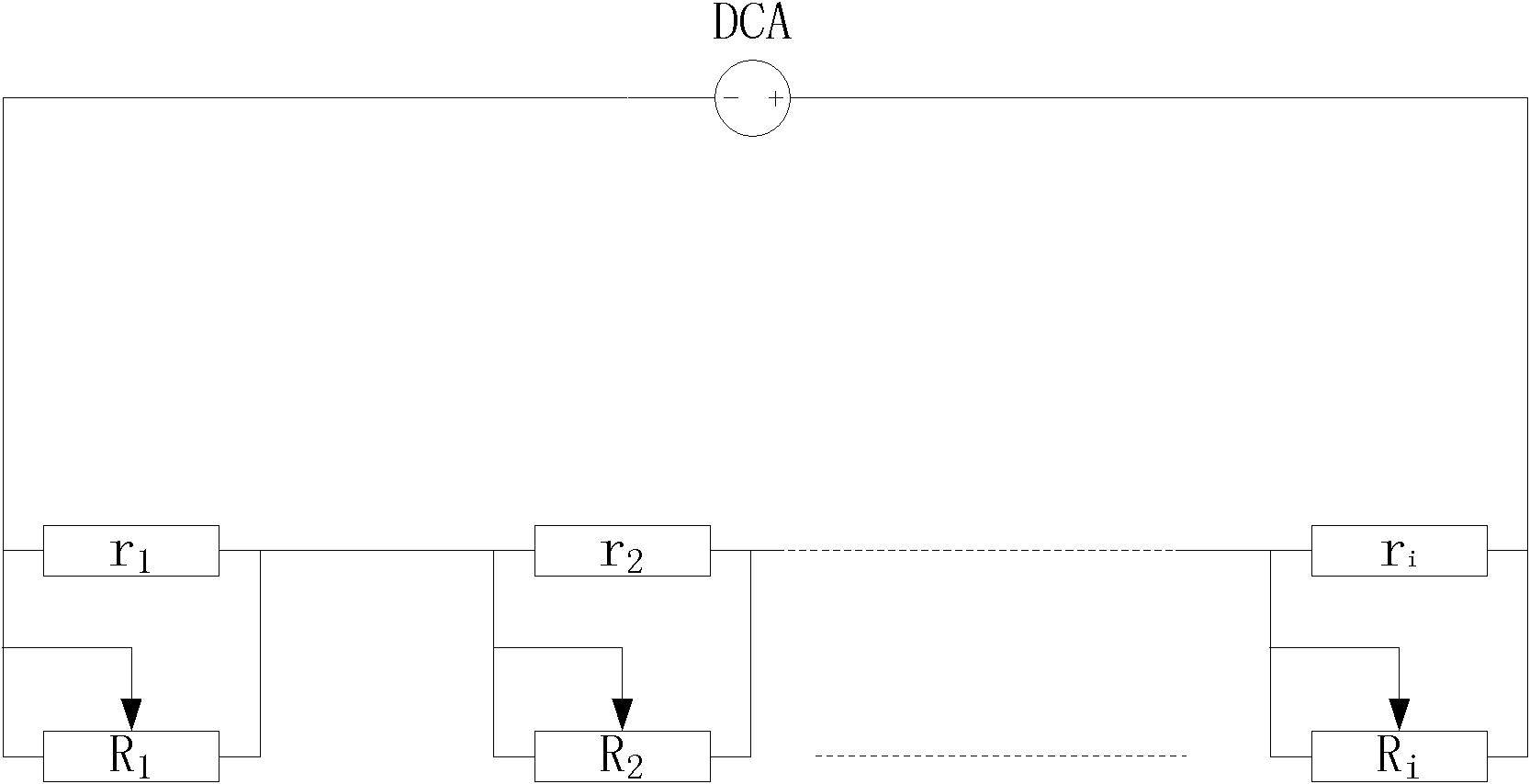

Method for compensating heterogeneity of magnetic field coil by shunting

InactiveCN102136336ACompensation for magnetic field inhomogeneityCoils manufactureCoilsMagnetic testingSingle coil

The invention discloses a method for compensating heterogeneity of a magnetic field coil by shunting, in particular relates to a method for compensating heterogeneity of a magnetic field coil system consisting of a plurality of coils. The magnetic field coil is a carrier for a magnetics testing experiment; each coil is connected in parallel with a current adjusting resistance box for adjusting current flowing through a single coil; and the current flowing through a singe coil is finely adjusted by using a shunting resistance box, so that the proportion of an equivalent number of turns of each coil is up to a theoretical optimum value, and the magnetic field heterogeneity caused by the number of turns of the coil and the machining error is compensated.

Owner:CSIC NO 710 RES & DEV INST

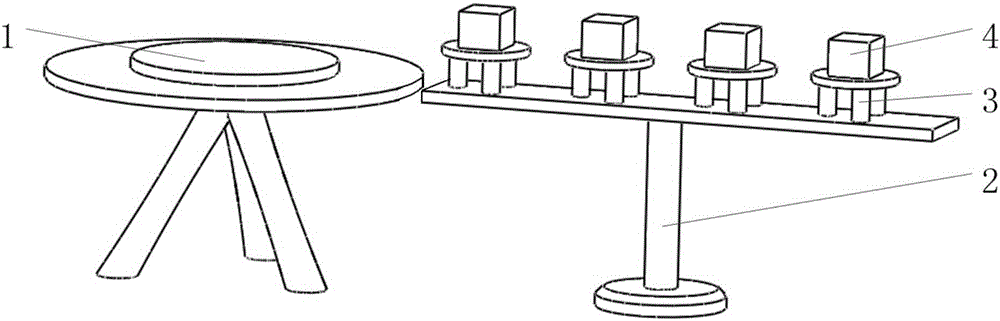

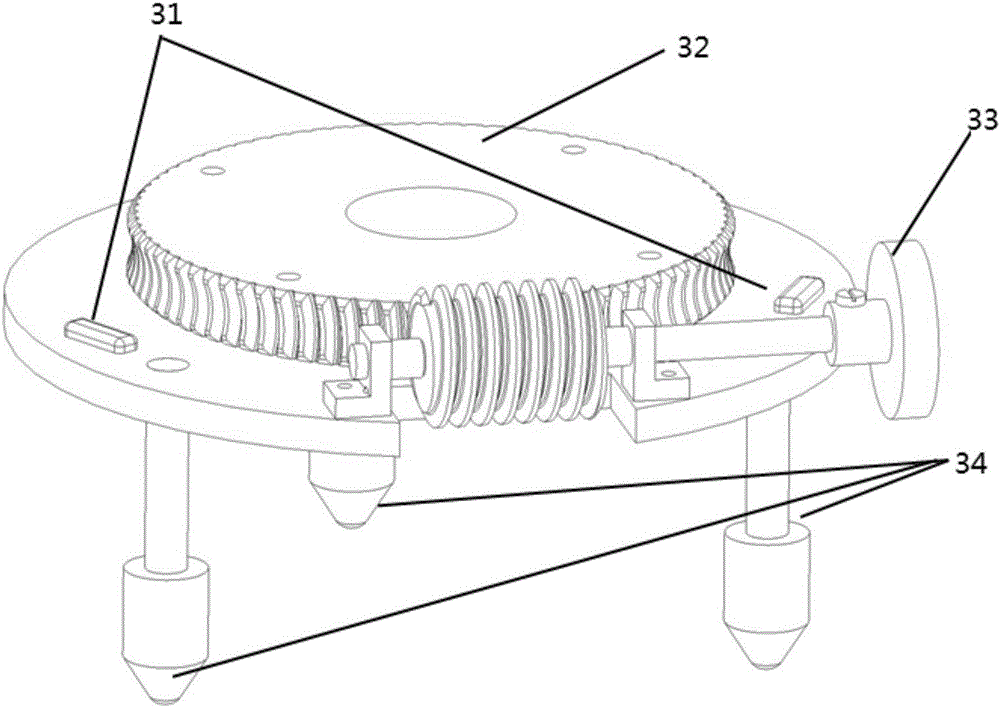

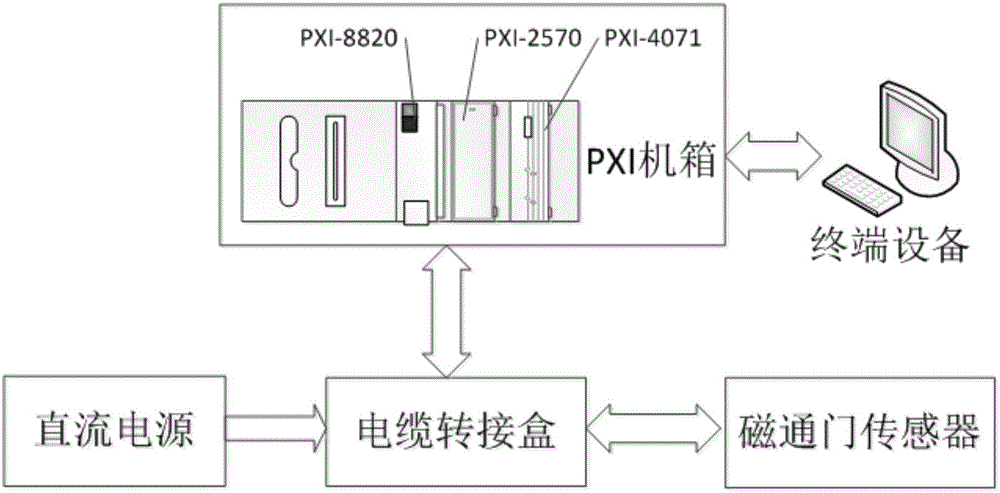

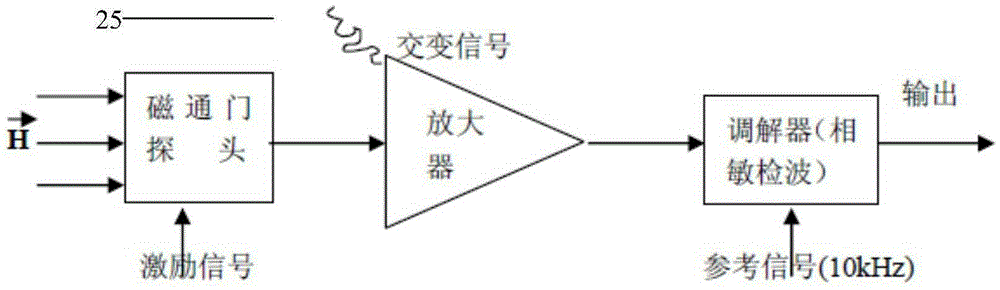

High-precision magnetic testing method and device

ActiveCN106556811ASave resourcesImprove acceleration performanceMagnetic property measurementsMagnetic testingData acquisition

The invention discloses a high-precision magnetic testing method and a device. The device comprises a nonmagnetic turntable, a sensor support, a nonmagnetic sensor mounting and adjusting base, a three-axis fluxgate sensor, a cable transfer box, a voltage-stabilizing power supply, a PXI case, and an input and display terminal device, wherein the three-axis fluxgate sensor is connected with the mounting surface of the nonmagnetic sensor mounting and adjusting base through a screw; the mounting surface of the nonmagnetic sensor mounting and adjusting base is provided with a gradienter; the nonmagnetic sensor mounting and adjusting base is placed on the sensor support; a tested object is placed on the sensor transfer block nonmagnetic turntable, and the center and the nonmagnetic turntable are located on the same vertical line. The data acquisition hardware resources are saved, and the scalability of the data acquisition channel is added. Due to the use of the cable transfer box, wiring of the device becomes simpler. The device can automatically complete the magnetic testing on the tested object, and forceful support is provided for evaluation on the magnetic material and the finished product performance.

Owner:SHANGHAI YUDA IND

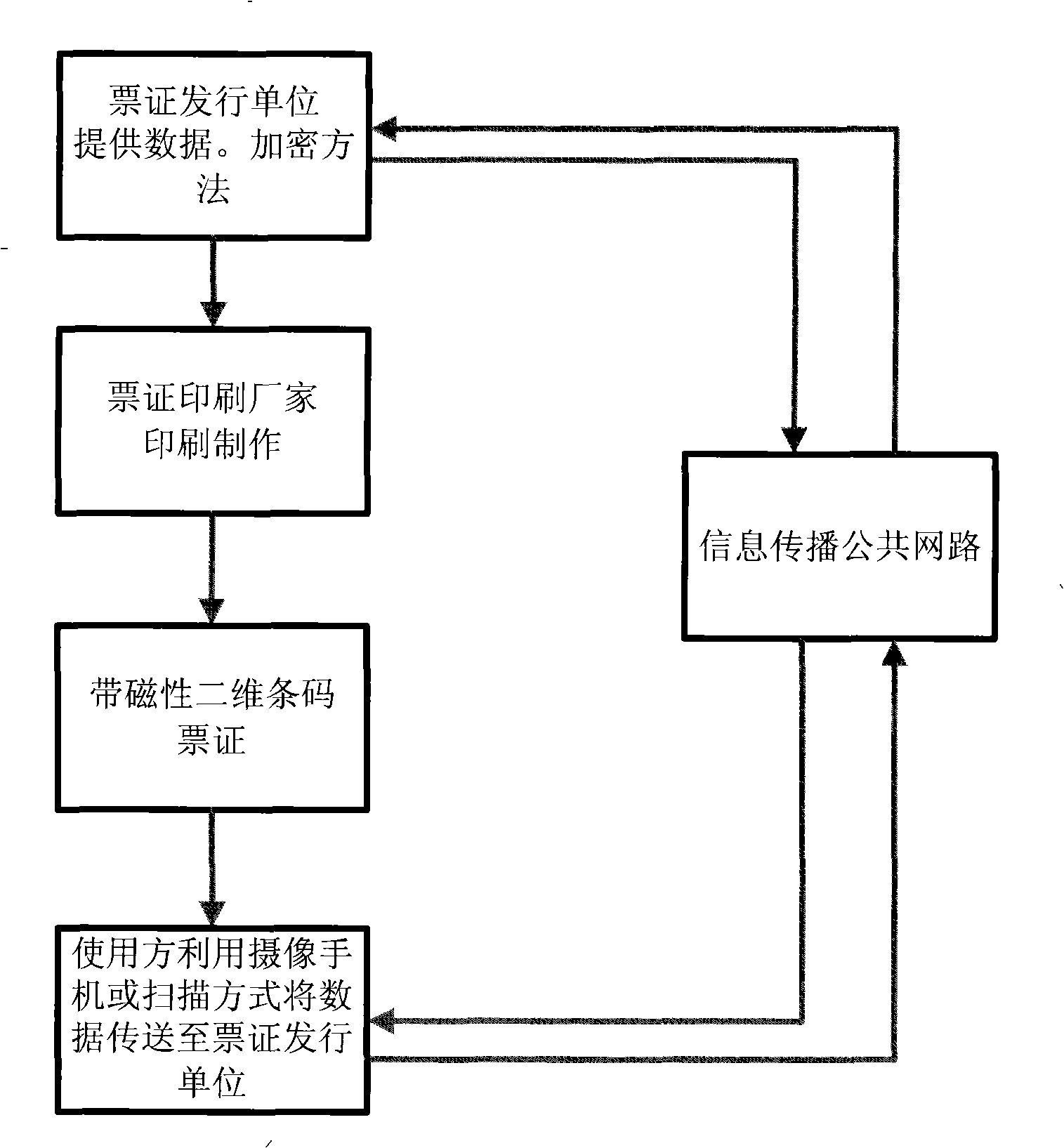

Method for preventing false bills

InactiveCN101281665APrevent Simple Copy CopyingImprove anti-counterfeiting functionPaper-money testing devicesMagnetic testingTechnical standard

The invention relates to a method of the anti-fake ticket, characterized in that, the method includes the steps: the operator provides the two-dimension code content through the two-dimension code technical standard and encrypt to the making company, and prints the magnetic two-dimension code on the ticket through the printer or the off-line digital printer and generates the encrypt characters through the encrypt, then prints the two-dimension code service instrument on the back of the ticket; the operator build a two-dimension code reading decrypt inquiry terminal and opens to the outsides; when the operator gets the ticket, first checks the truth of the ticket through the magnetic testing device, or transmits to the decrypt terminal for normally reading after the handset shoots in the normal optical source; the decrypt terminal answers the feeding information to the operator when judging the truth of the decrypt terminal. The invention has the advantages of enhanced ticket anti-fake function and convenient usage.

Owner:上海伊诺尔实业集团有限公司

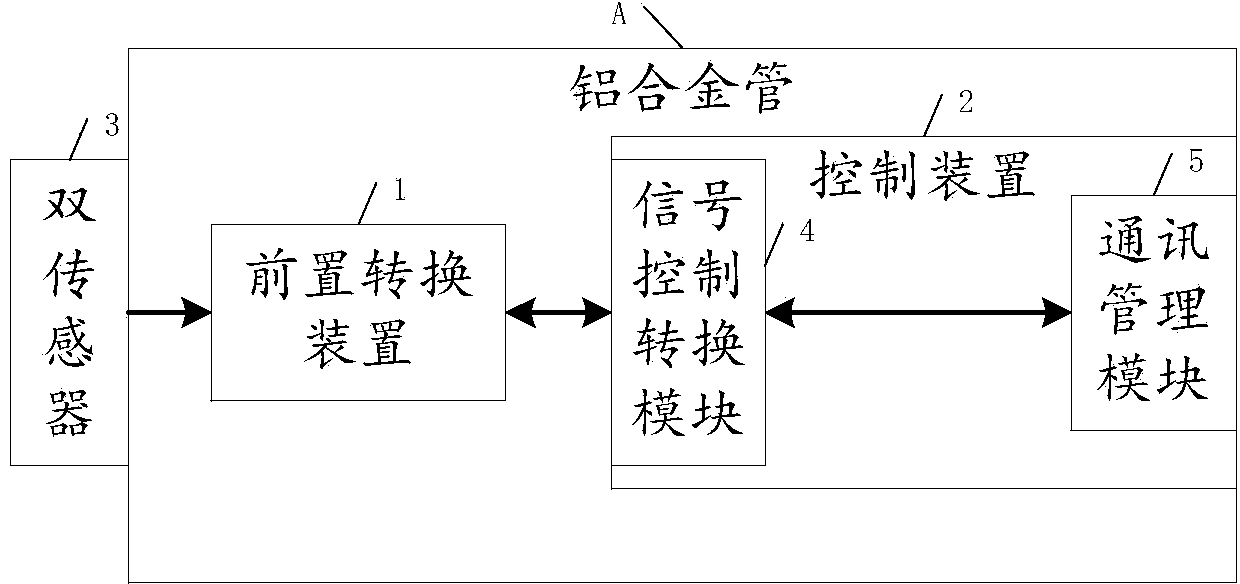

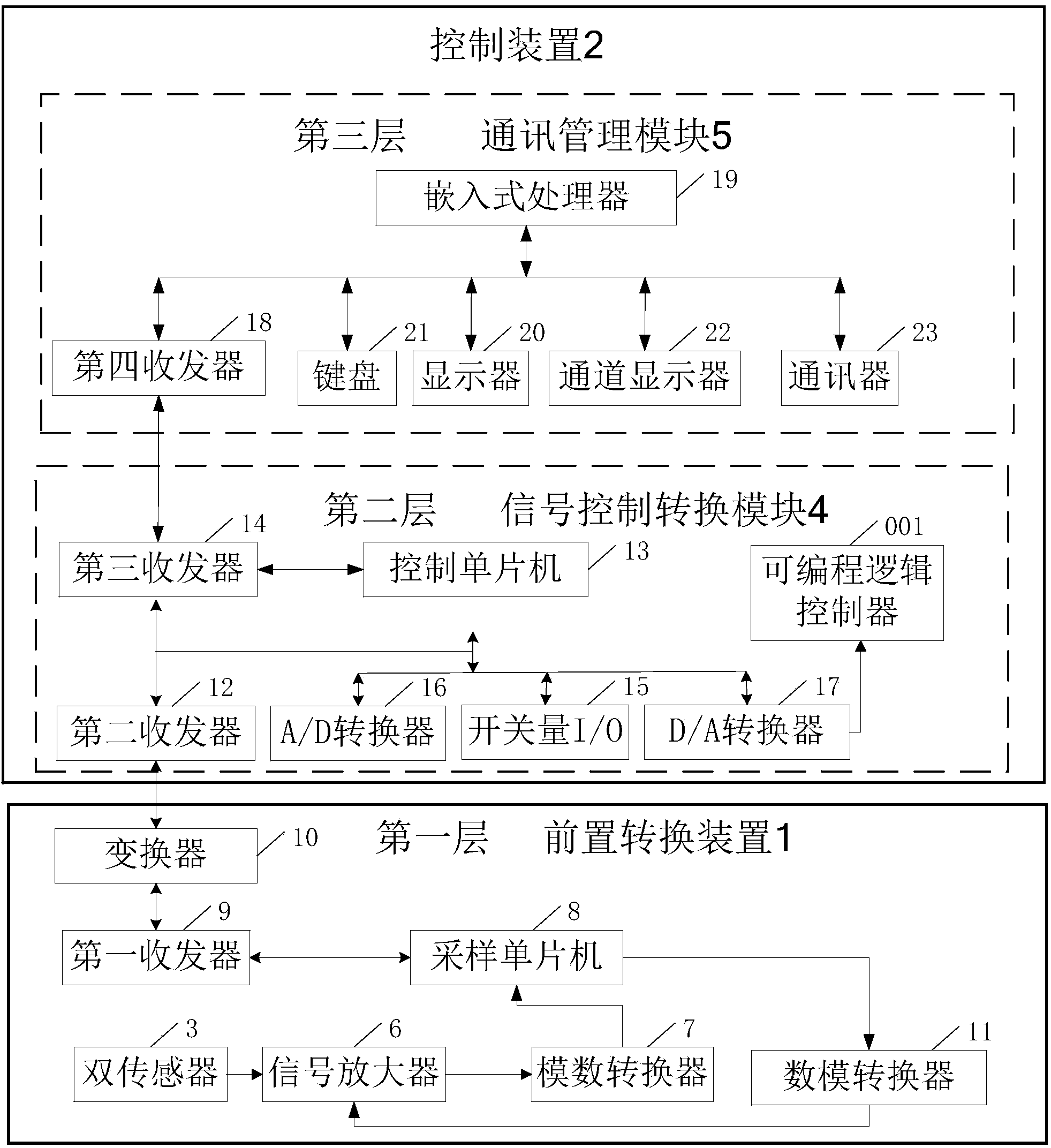

Double-sensor molten steel liquid level measuring equipment

InactiveCN104061979AImprove stabilityEliminate the effects ofLevel indicators by physical variable measurementMagnetic testingEngineering

The invention discloses double-sensor molten steel liquid level measuring equipment. The equipment is based on non-contact type liquid level eddy type sensors, and multi-disciplinary technologies such as an electro-magnetic induction technology, a signal processing technology and a computer technology are fused. Compared with a traditional single sensor, double sensors have the advantages that a false liquid level can be well detected, and stability is great. A crystallizer is a key part in continuous casting equipment and is the heart of the continuous casting equipment. Detecting and controlling of a crystallizer liquid level are the premise of normal working of the crystallizer, the double-sensor molten steel liquid level measuring equipment has better measuring effect on a large continuous casting machine plate blank crystallizer than that of a single-sensor detecting mode, the double sensors are arranged on the two sides of a crystallizer water opening, a symmetrical liquid level collecting mode is used, influence on the liquid level from false liquid fluctuation can be well removed, the shortcomings that a traditional single sensor is small in detecting range and poor in single-point measuring stability are overcome, and the shortcoming of influence on the liquid level from electro-magnetic testing is overcome.

Owner:武汉钢铁有限公司

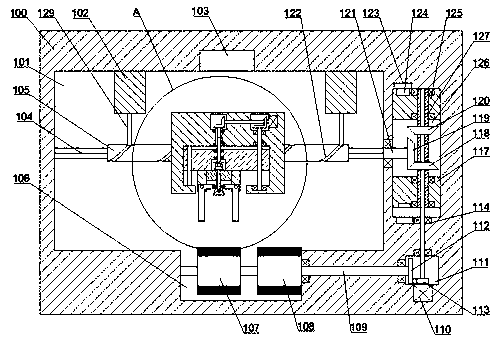

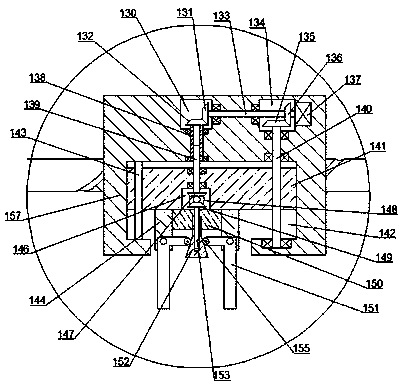

Magnetic force testing equipment for earphone

InactiveCN109168121AControl positive and negativeAchieve clampingElectrical apparatusMagnetic testingPower switching

The invention provides magnetic force testing equipment for an earphone. The testing equipment includes a main body. A working chamber is arranged in the main body. A fixture mechanism is arranged inthe working chamber. A conveyor belt cavity is arranged on the bottom wall of the working cavity. A conveyor belt mechanism is arranged in the conveyor belt cavity. A transmission chamber is arrangedin the main body on the right side of the conveyor belt mechanism. A power mechanism is arranged in the transmission chamber. A switch chamber located on that right side of the working chamber is arranged in the host body at the top of the transmission chamber. A power switching mechanism is arranged in the switching cavity. The device can realize the clamping of the earphone head through the clamping mechanism, and at the same time, the earphone head can be sent into the detecting mechanism for magnetic testing by turning 180 degrees, and the qualified and unqualified earphone heads can be separated by the conveyor belt mechanism, so that the conveyor belt mechanism can realize the feeding of the earphone head, the automation degree is high, and the production efficiency is improved.

Owner:廖瑶丽

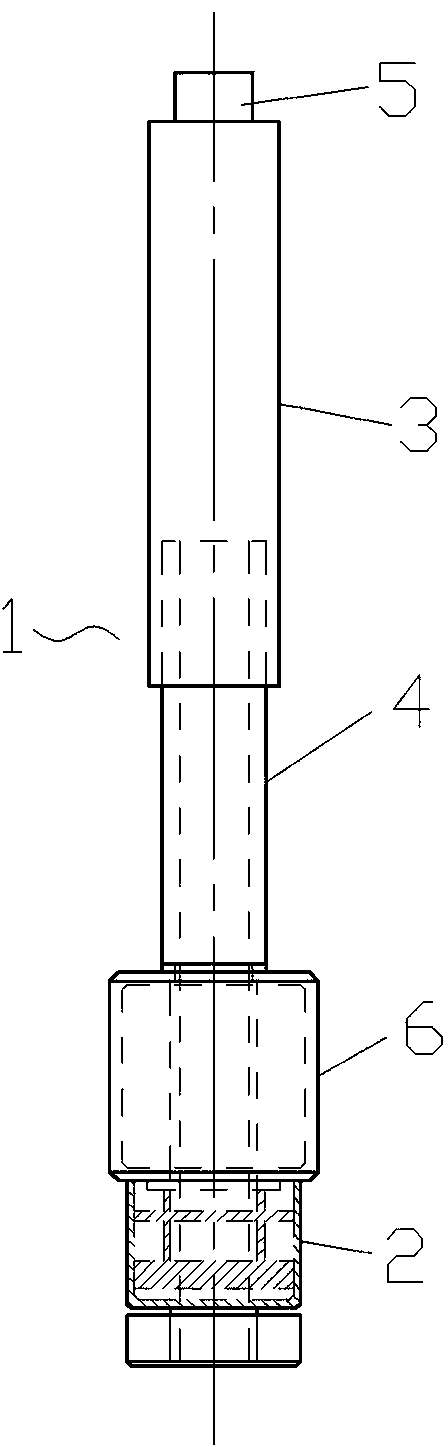

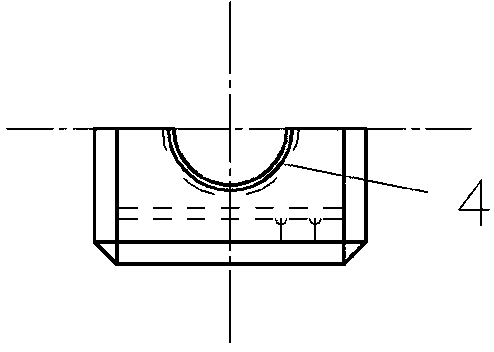

Hardometer

InactiveCN103954515ASolve the fragileImprove accuracyInvestigating material hardnessExternal dataMagnetic testing

The invention discloses a hardometer which comprises a supporting pipe, a hardness sensor, a magnetic testing body which is arranged in the supporting pipe in a sliding mode, and a transmission device arranged in the supporting pipe, wherein the transmission device drives the magnetic testing body to impact the surface of a workpiece so as to generate impact speed and rebound speed; a data processing transmitter is arranged on the hardness sensor; the data processing transmitter comprises a shell, and a data processing unit, a data emission and transmission unit and a battery which are fixedly arranged in the shell; data measured by the hardness sensor is directly transmitted to the data processing unit for processing and is wirelessly transmitted to an external receiver through the data emission and transmission unit. The data processing transmitter is directly arranged on the hardness sensor, so that the data processing transmitter is directly combined to the hardometer, and the problem that a transmission line of an external data processor is easily damaged is solved. Meanwhile, the inclination angle of the hardometer is detected through a triaxial sensor, so that data compensation is calculated, and the measurement accuracy is improved.

Owner:DRAGON ELECTRONICS

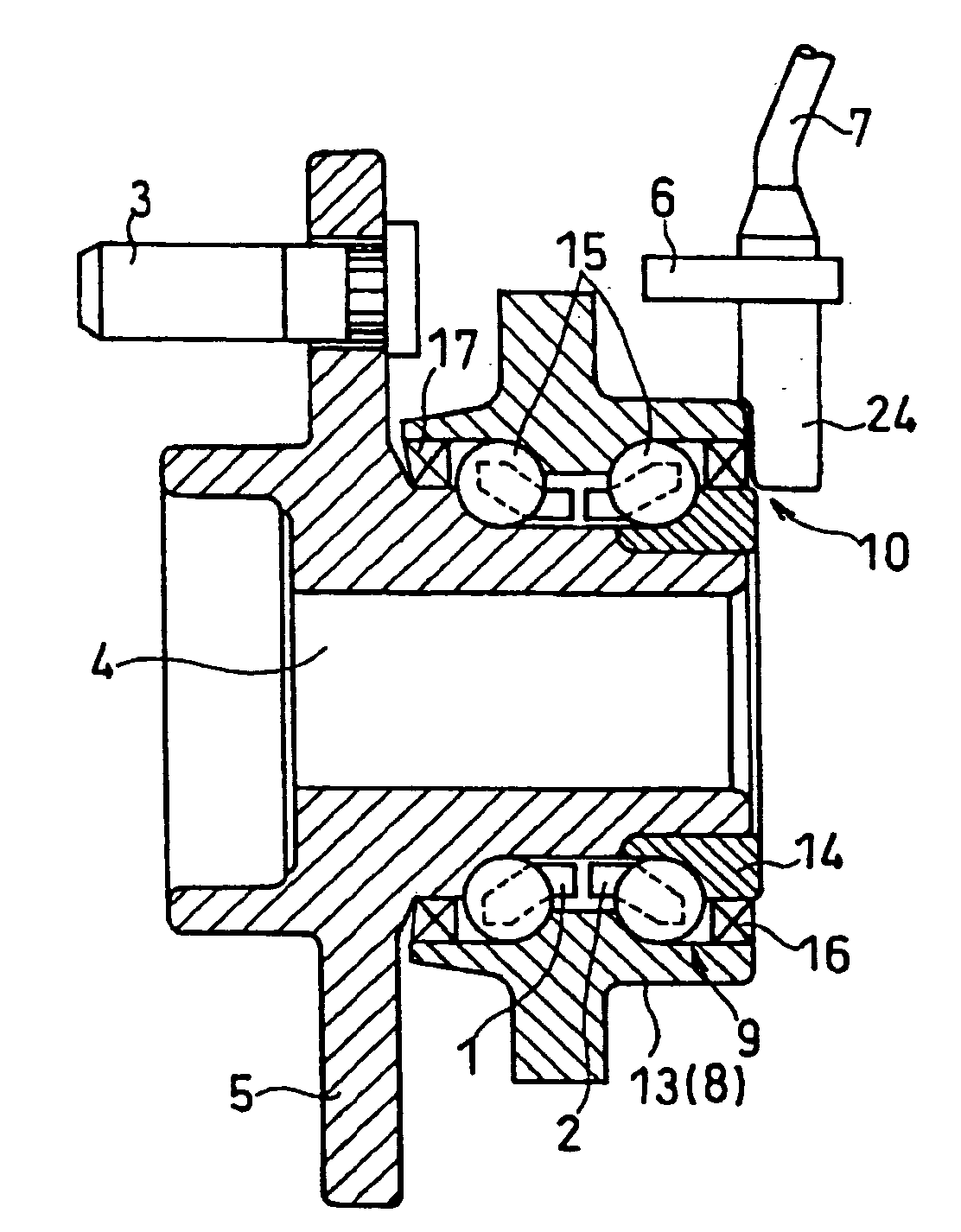

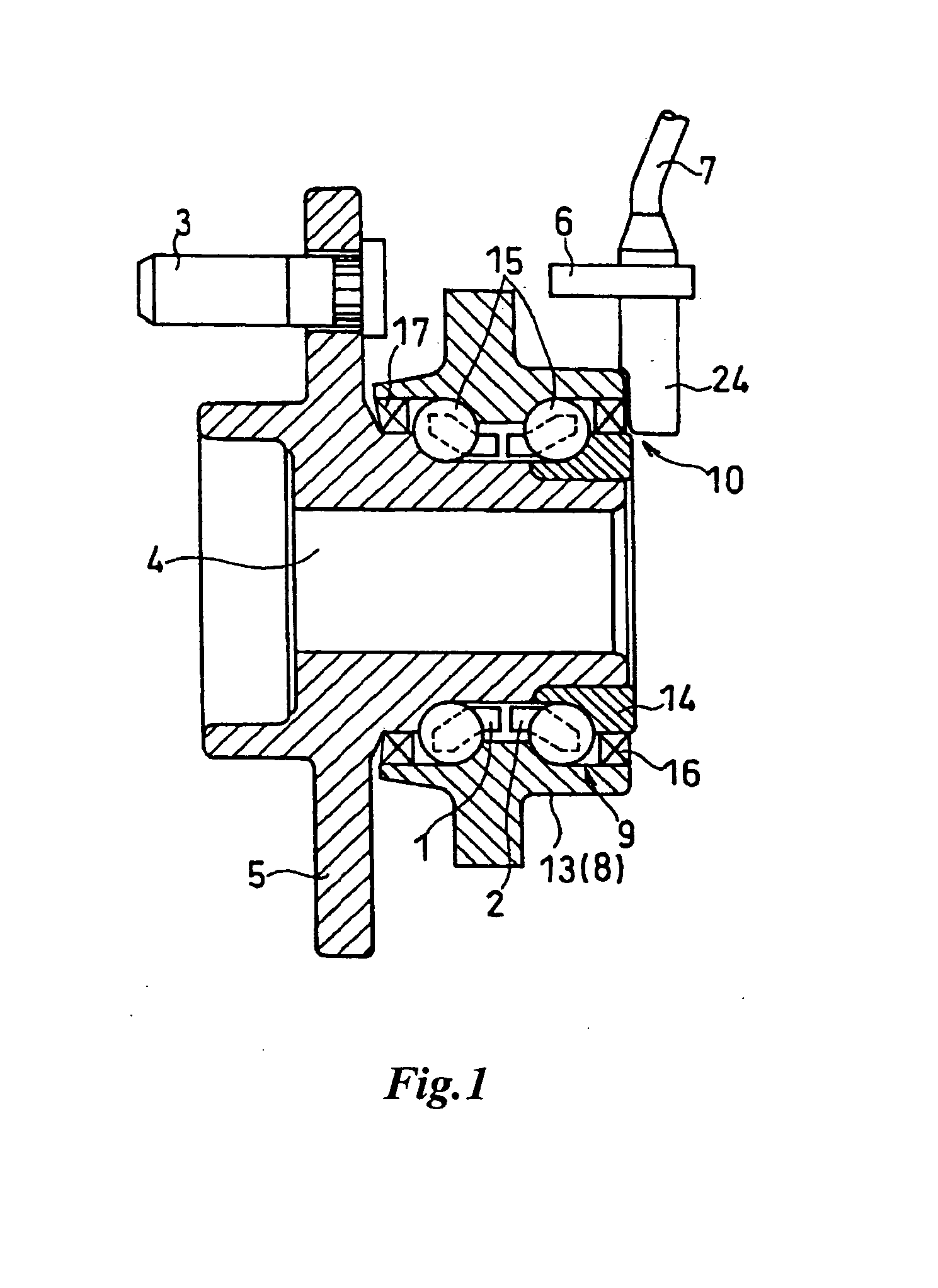

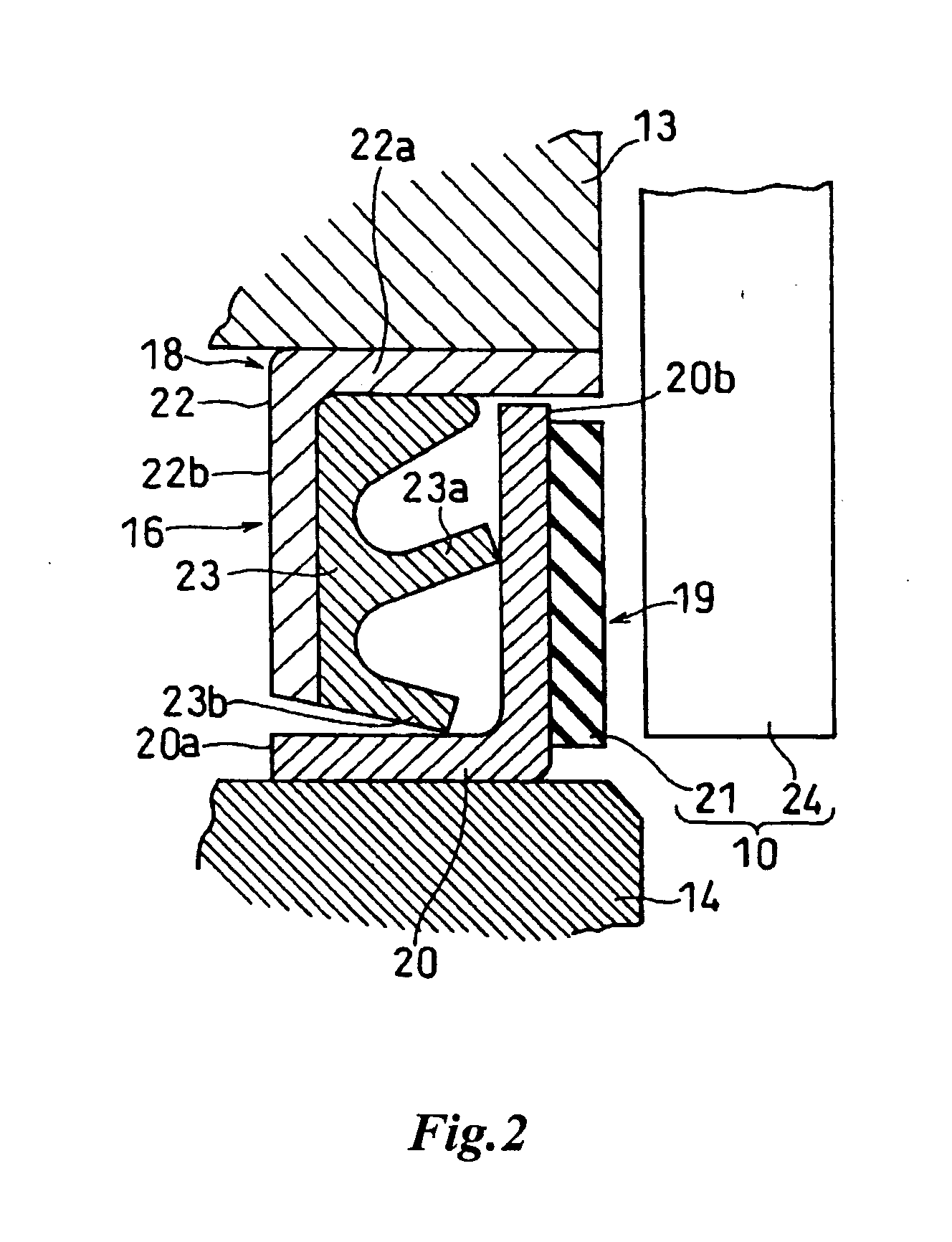

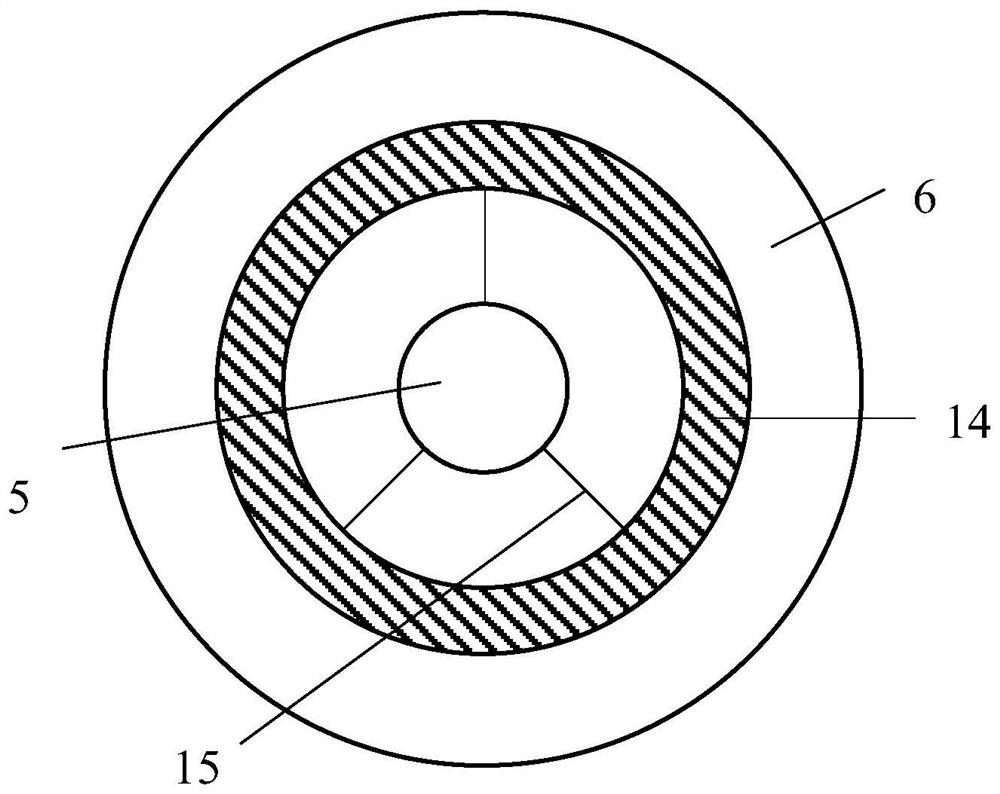

Tone wheel testing apparatus and its test method

ActiveUS20050012643A1Determining the quality of the tone wheelElectric signal transmission systemsRolling contact bearingsMagnetic tension forceMagnetic testing

Tone wheel testing apparatus and the test method using the apparatus are disclosed. Tone wheel testing apparatus comprising a surface adjusting means for holding in the horizontal position an annular object to be tested to which a tone wheel is attached, the means comprising a pair of pressing members between which the object is held, and the one of the pressing members having a reference surface with which the tone wheel is contacted in order to make the tone wheel align in the rotary axis direction of the object, a rotatable chucking means for seizing the object so as to make the center of the object align with its rotary center when the object is held by the surface adjusting means, and a magnetic testing sensor disposed adjacent to the tone wheel of the object so as to face each other. According to which, the up and down appear on the tone wheel surface in the circumferential direction are corrected and the gap between the testing sensor and the tone wheel is accurately maintained, thereby enabling an appropriate setting arrangement of tone wheel for accurate measurement of the array pitch of each pole and the magnetic force.

Owner:UCHIYAMA MFG

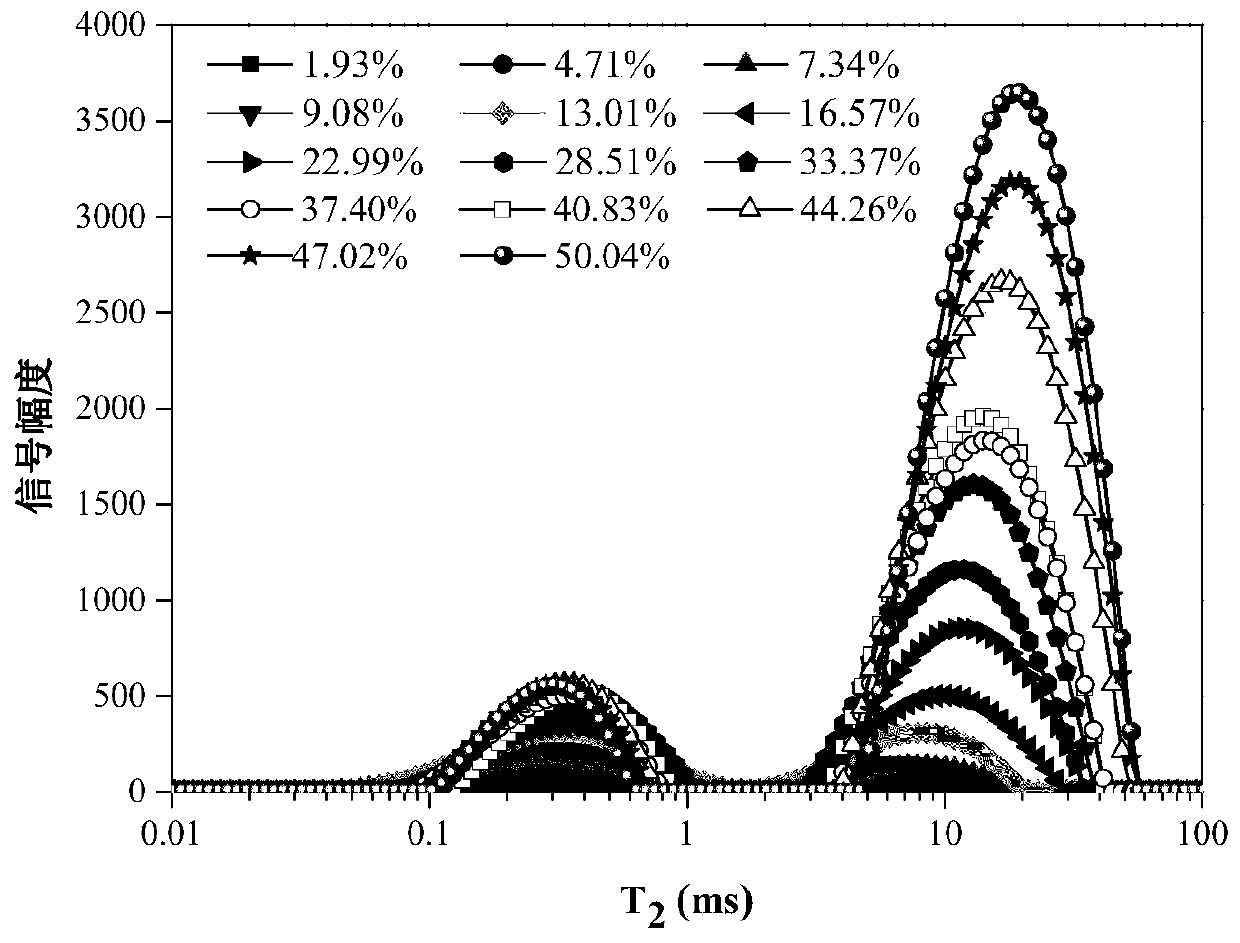

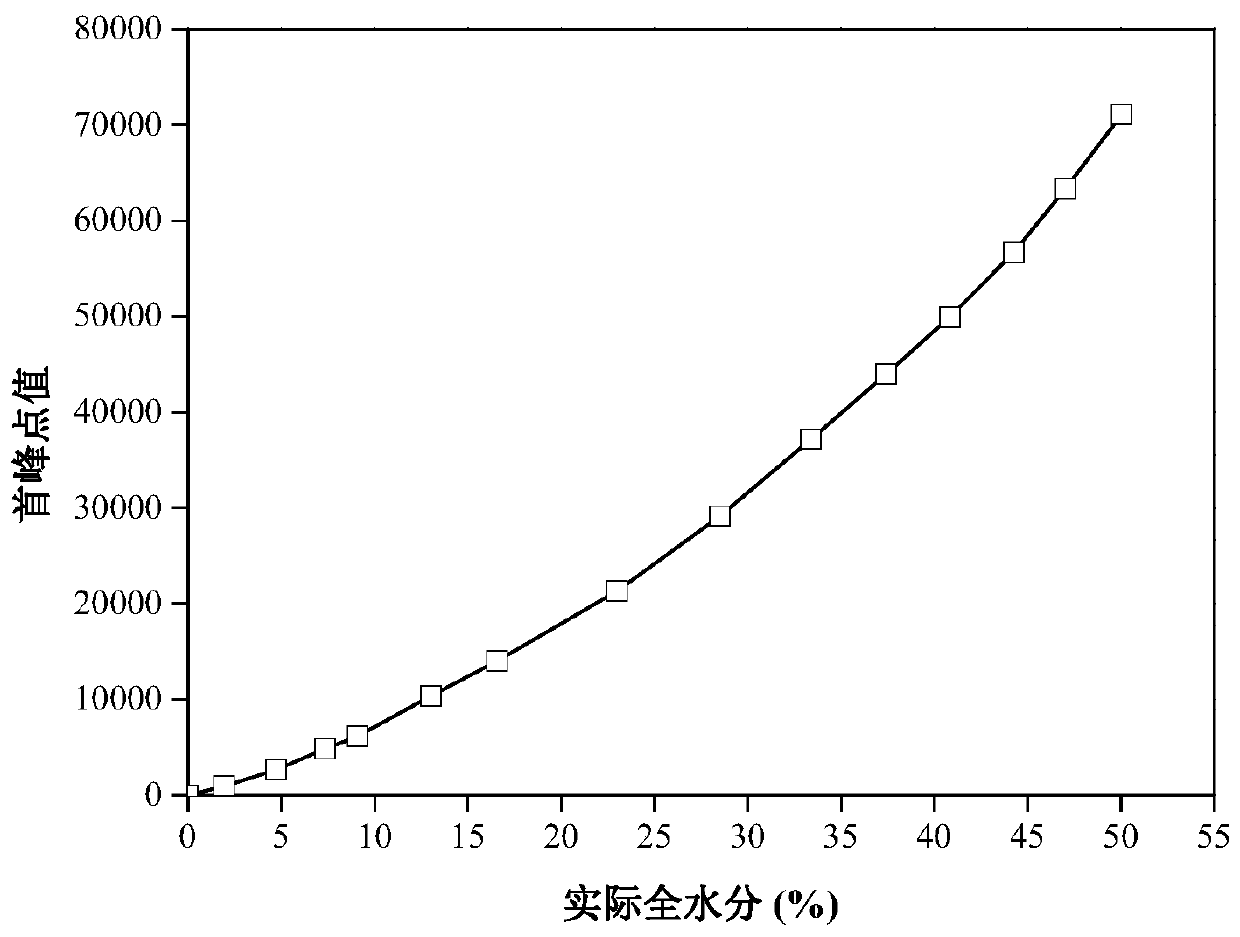

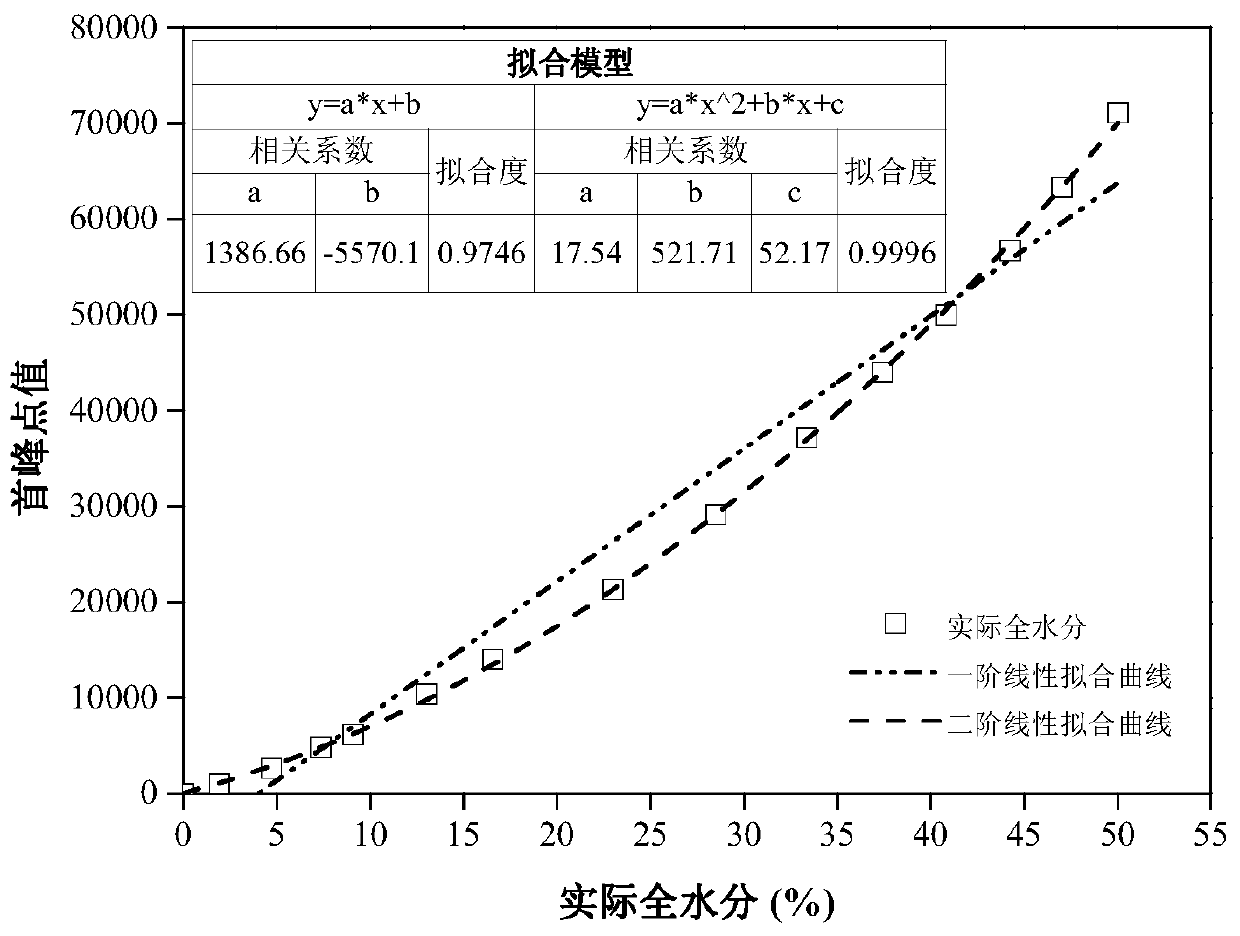

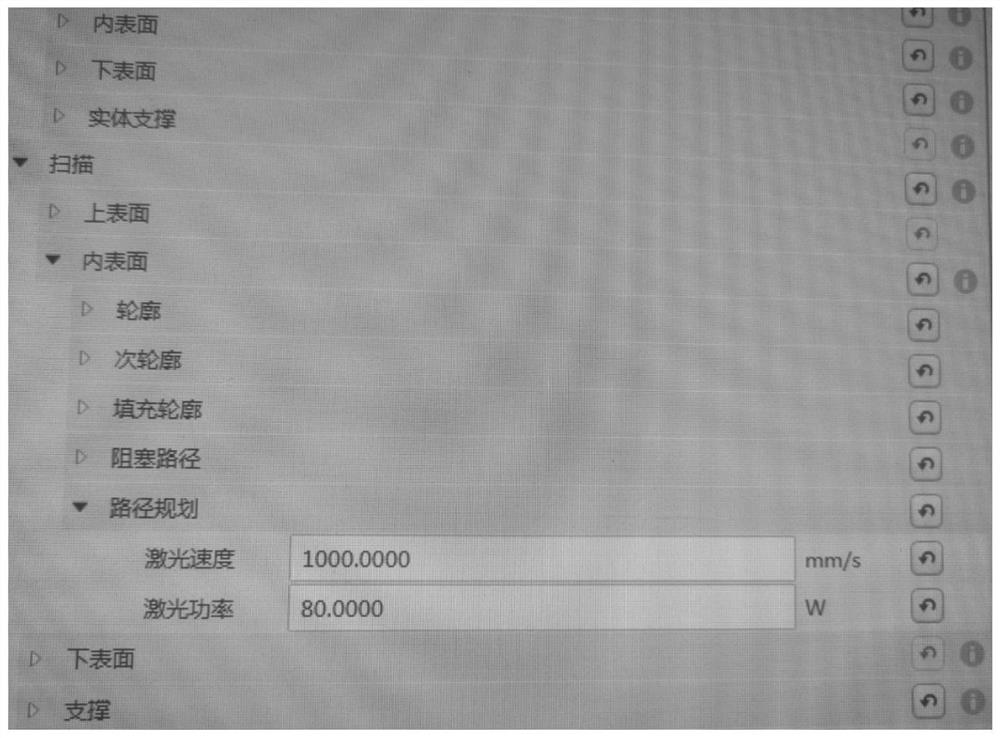

Method for rapidly detecting total moisture of coal based on low-field nuclear magnetic resonance

ActiveCN110879234ASmall maximum errorImprove detection accuracyAnalysis using nuclear magnetic resonanceNMR - Nuclear magnetic resonanceMagnetic testing

The invention relates to a method for rapidly detecting total moisture of coal based on low-field nuclear magnetic resonance. The method is suitable for detecting total moisture of coal quality and comprises steps of taking to-be-tested total-moisture coal for testing under a nuclear magnetic testing condition, obtaining a first peak point value through nuclear magnetic testing software and the T2atlas, and substituting the first peak point value into a relational expression between the first peak point value of the nuclear magnetic signal and the total moisture of the coal to obtain the total moisture. The detection speed is high, the precision is high, the time and labor costs of coal total moisture testing are greatly reduced, and important reference and guiding significance is provided for realizing total moisture online detection; the used low-field nuclear magnetic resonance equipment has the advantages of safety, miniaturization, low cost, easiness in operation, high test speedand the like, can meet various requirements of a coal preparation plant, and has good adaptability.

Owner:CHINA UNIV OF MINING & TECH

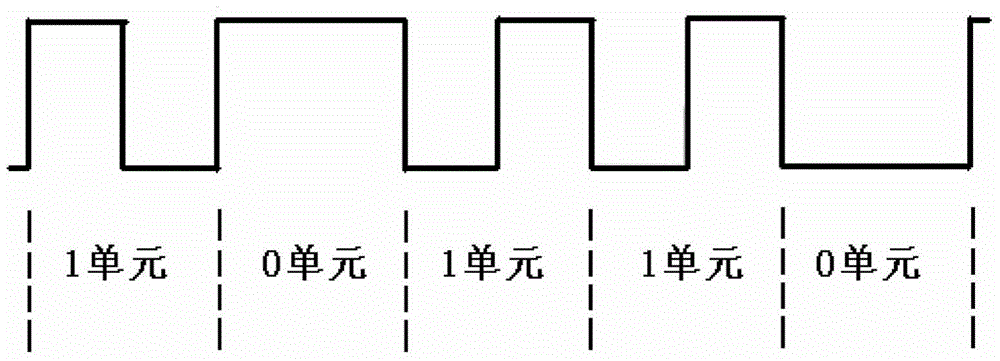

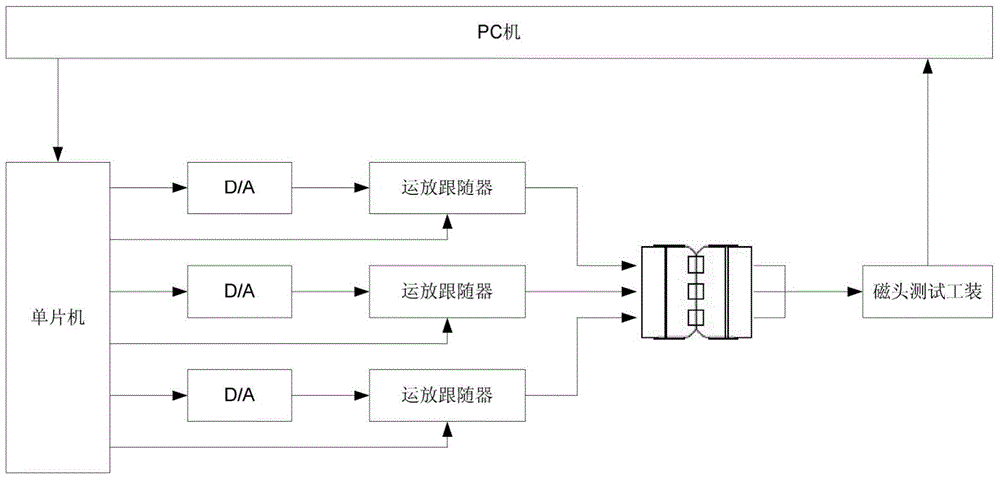

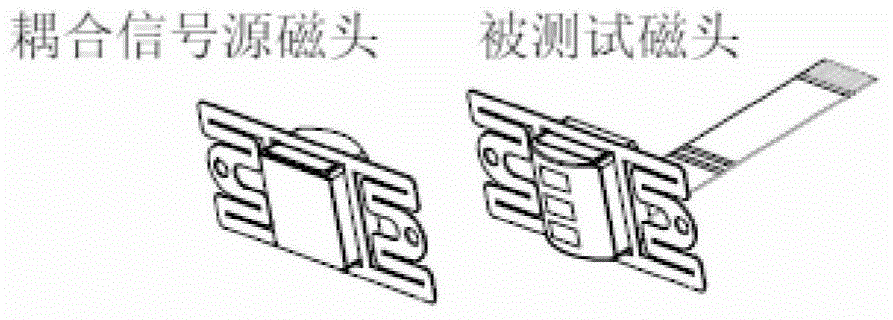

Method and system for testing magnetic head through magnetic coupling method

ActiveCN104134445AImplement automated testingThe test result is accurateFunctional testing of recording headsMicrocontrollerMicrocomputer

The invention provides a method and system for testing a magnetic head through a magnetic coupling method. The magnetic coupling mode is used for sending magnetic signals to a magnetic head to be tested, after the magnetic head to be tested receives the magnetic signals, a magnetic testing tool decodes the received signals, the decoded result is compared with testing data sent to a single-chip microcomputer to judge whether decoding is carried out correctly, and therefore one-time automatic testing can be achieved. By the adoption of the method and the system, manual card swiping is not needed, the decoding function of the finished magnetic head is tested automatically, the magnetic head can be tested automatically, various magnetic heads can be tested, a plurality of sets of testing signals are automatically utilized, the testing signals can be slightly adjusted in real time, different card swiping gestures can be simulated, and therefore the more accurate testing result can be obtained in real time.

Owner:兆讯恒达科技股份有限公司

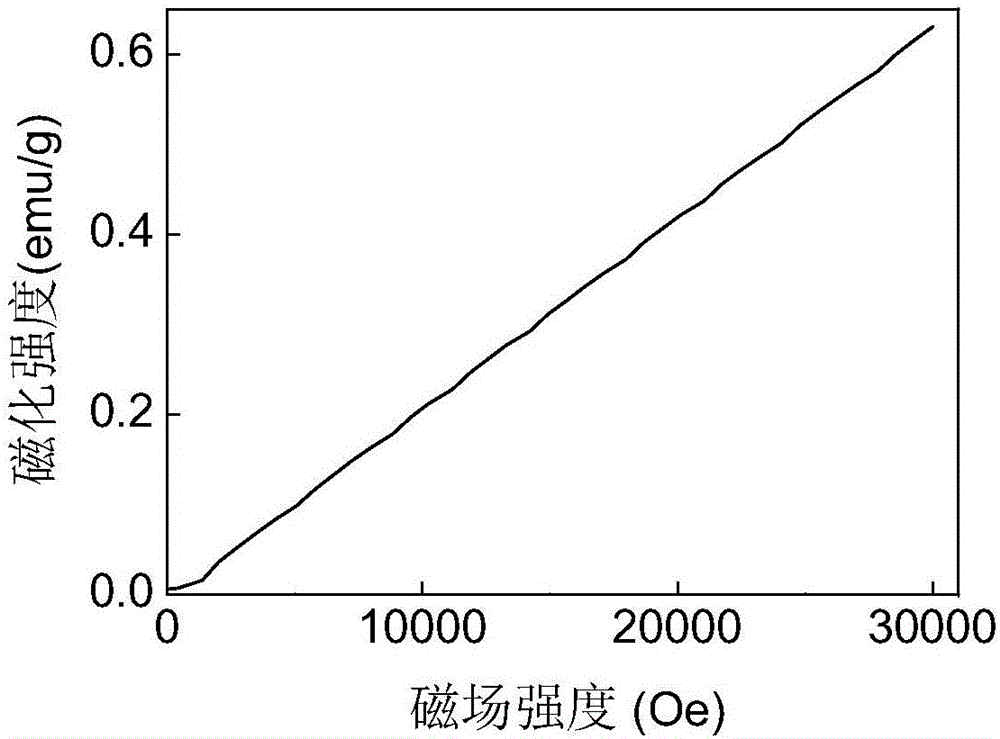

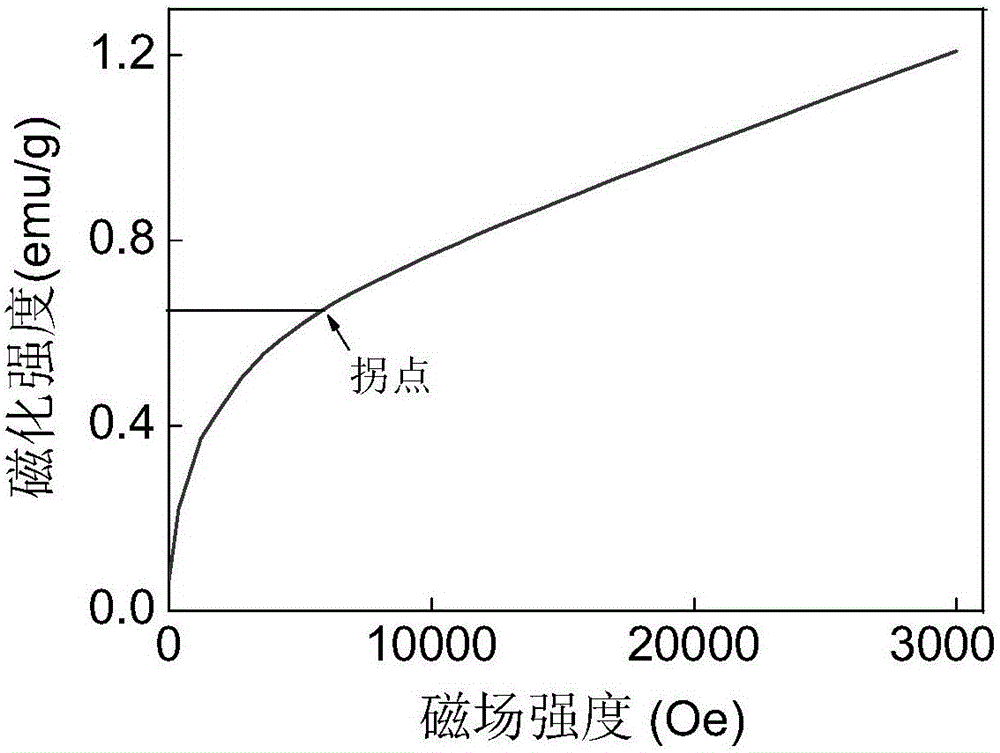

Magnetization intensity based TP304H boiler pipe material damage degree detection method

InactiveCN105842334AImprove accuracySmall sizeMaterial magnetic variablesSmall sampleMagnetic testing

The invention discloses a method for detecting the damage degree of the TP304H boiler tube material based on the magnetization intensity, which comprises the following steps: (1) A round bar-shaped sample is prepared from the TP304H boiler tube sample to the fire side after service, with a diameter of about Φ3 mm and a length of About 15mm, the surface of the sample has been ground and polished; (2) Use the VSM vibrating sample magnetometer to test the magnetic properties of the sample, obtain the magnetization curve of the sample, and obtain the magnetization value at the inflection point, which is used as the material of the TP304H boiler tube sample damage indicator. The invention uses the magnetization intensity to indicate the material damage degree of the TP304H boiler tube after service, considers the material damage factor caused by the phase transition stress, and improves the accuracy of evaluating the material state of the TP304H boiler tube. The invention requires small sample size, simple sample preparation and low cost.

Owner:XIAN THERMAL POWER RES INST CO LTD

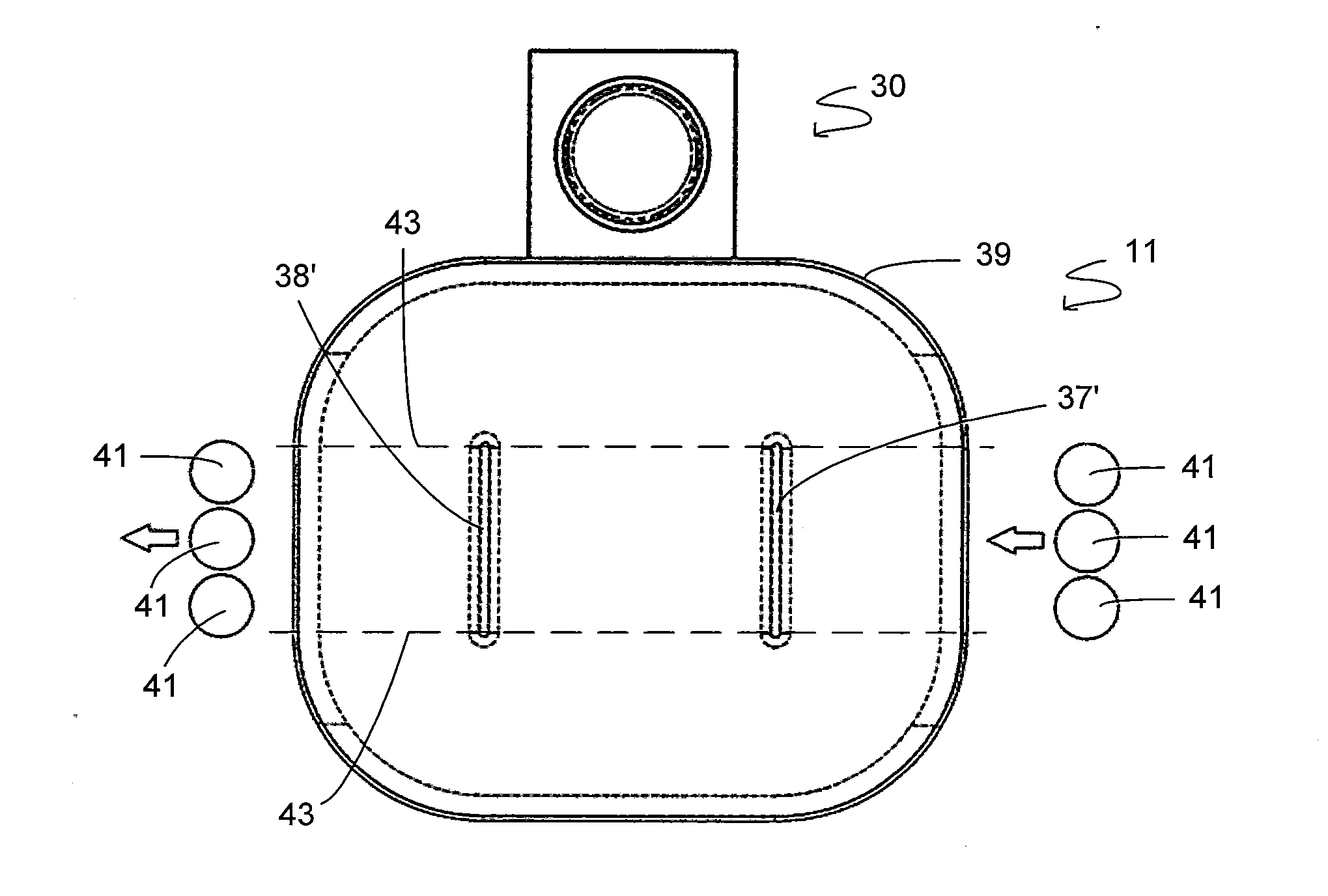

Apparatus for testing sample properties in a magnetic field

ActiveUS20160195591A1Polarisation-affecting propertiesMagnetic property measurementsMeasurement deviceMagnetic testing

A magnetic testing apparatus includes a magnet assembly with a sample path extending through the magnet assembly. The magnetic field produced by the magnet assembly defines a known, varying magnetic field profile along the sample path. A sample is moved along sample path such that the sample portion is subjected to a predetermined magnetic field ramp or magnetic field profile during a measurement period. A measurement arrangement is also provided to measure one or more properties of the sample during the measurement period, in order to test sample properties at a plurality of different magnetic fields. The apparatus may be particularly suited to magneto-optical measurements, including Magneto-Optical Kerr Effect measurements. The apparatus may be used for testing of hard disk platters.

Owner:HTS 110 LTD

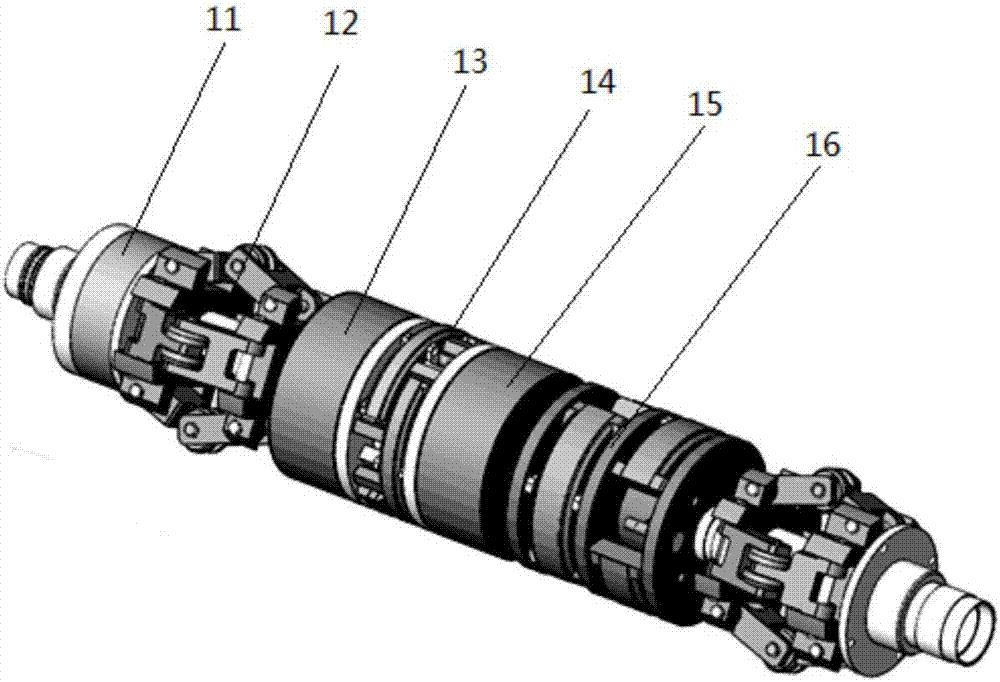

Testing device and testing method for magnetic flux leakage of petroleum gas storage well casing

InactiveCN107515245AHigh measurement accuracyImprove performanceUsing electrical meansElectrical/magnetic thickness measurementsPull forceHall element

The invention relates to a testing device and a testing method for magnetic flux leakage of a petroleum gas storage well casing. The testing device comprises a ground PC machine, a centering device and an underground instrument, wherein the ground PC machine is connected with the underground instrument through a cable; the underground instrument is connected with the centering device; the centering device and the underground instrument move up and down in the casing through the self weight of the underground instrument and the pull force of the cable; a signal acquisition unit of the underground instrument comprises a transverse magnetizer, a transverse detection unit, a wall thickness detection unit, a longitudinal magnetizer and a longitudinal detection unit, which are connected in sequence; the transverse detection unit comprises at least one transverse probe; the wall thickness detection unit comprises a 4*4 Hall element; the longitudinal detection unit comprises a plurality of longitudinal probes which are uniformly distributed on the circumference; each longitudinal probe comprises a longitudinal magnet and a plurality of groups of coils wound on the longitudinal magnet. According to the testing device and the testing method, provided by the invention, the problem that influences, caused by an underground environment, on a gas storage well casing damage detection method is solved; inner and outer damage conditions of the casing can be detected simultaneously by utilizing a magnetic flux leakage flaw detection technology and the detection is not influenced by an underground fluid environment.

Owner:SHAANXI HUACHEN GASOLINEEUM TECH +1

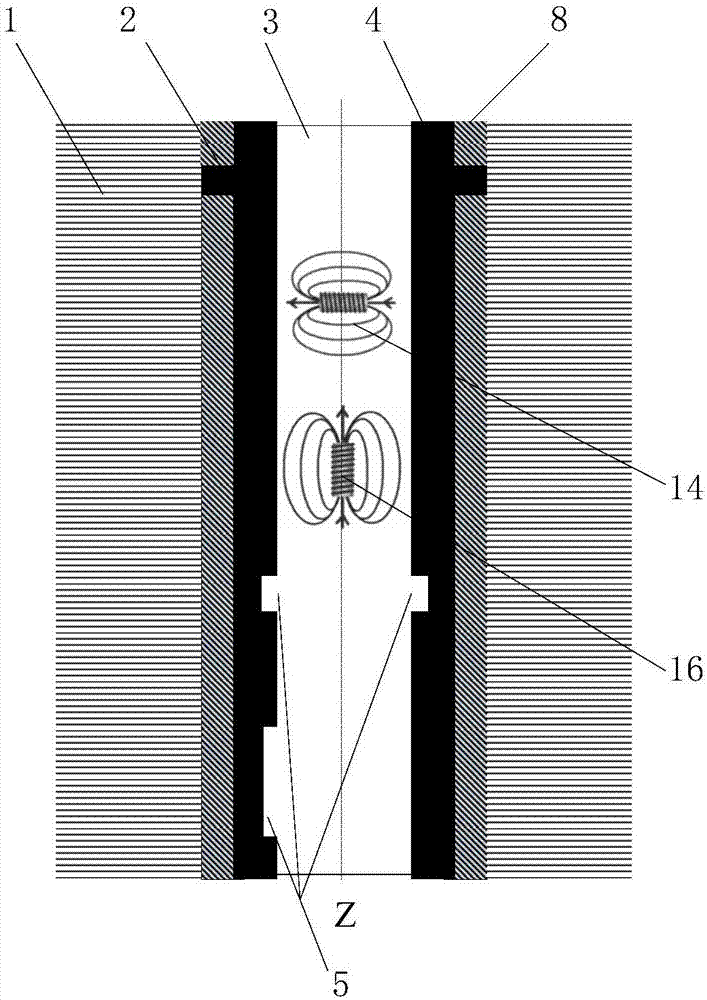

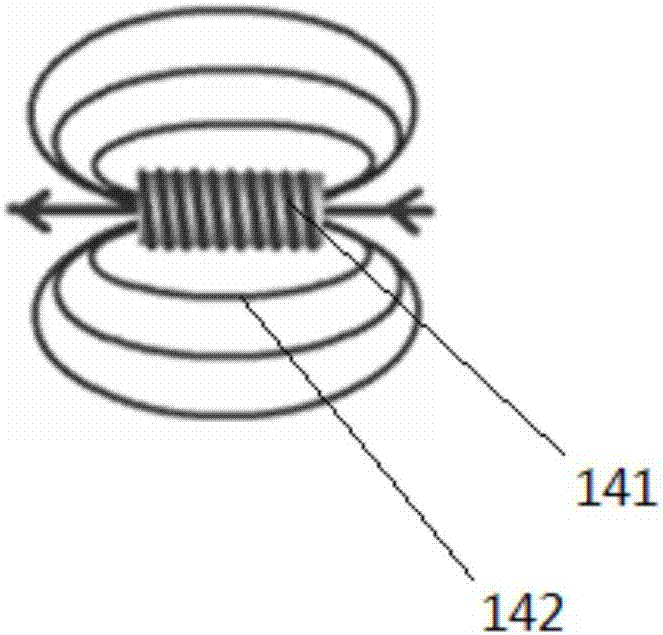

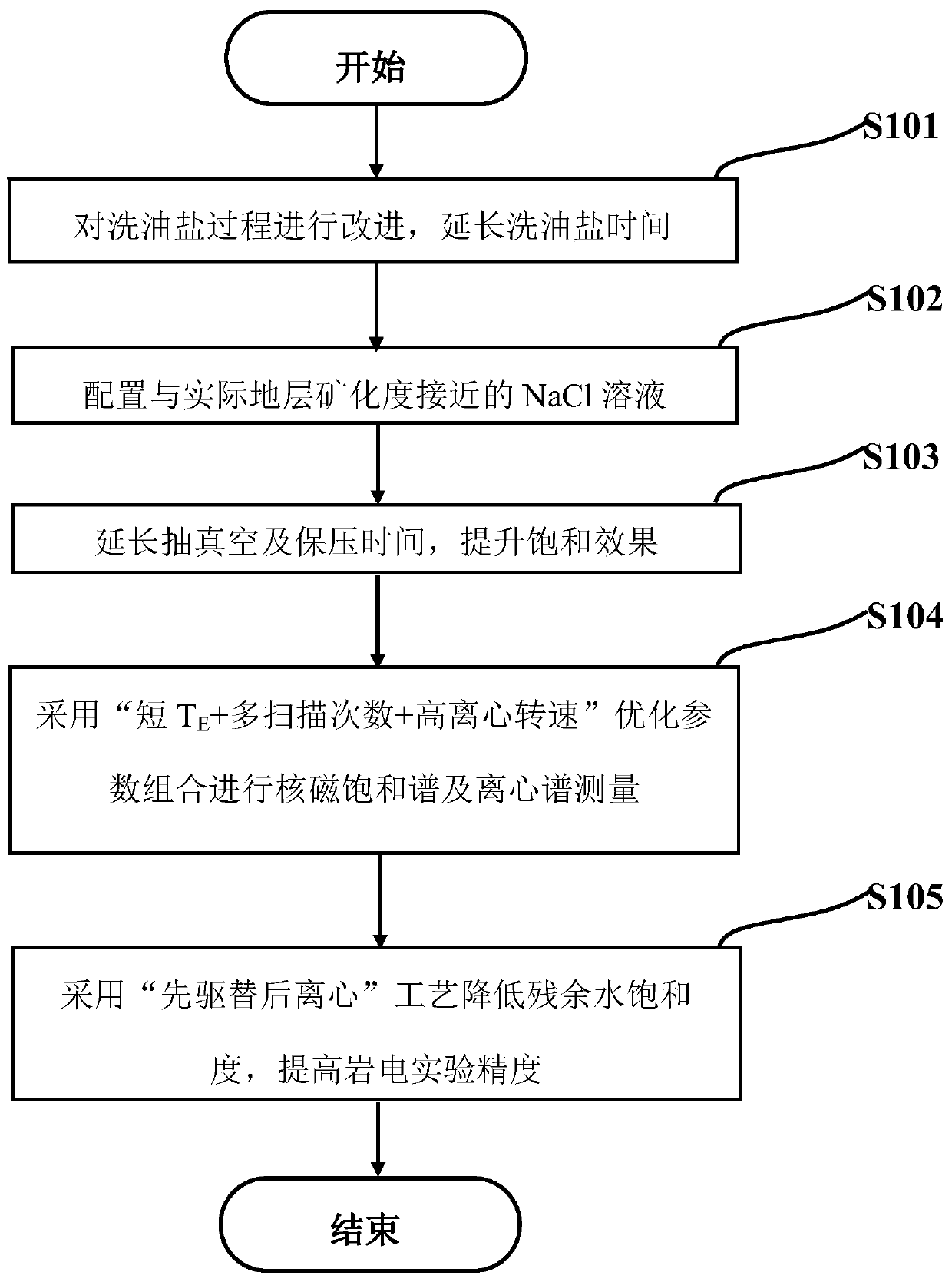

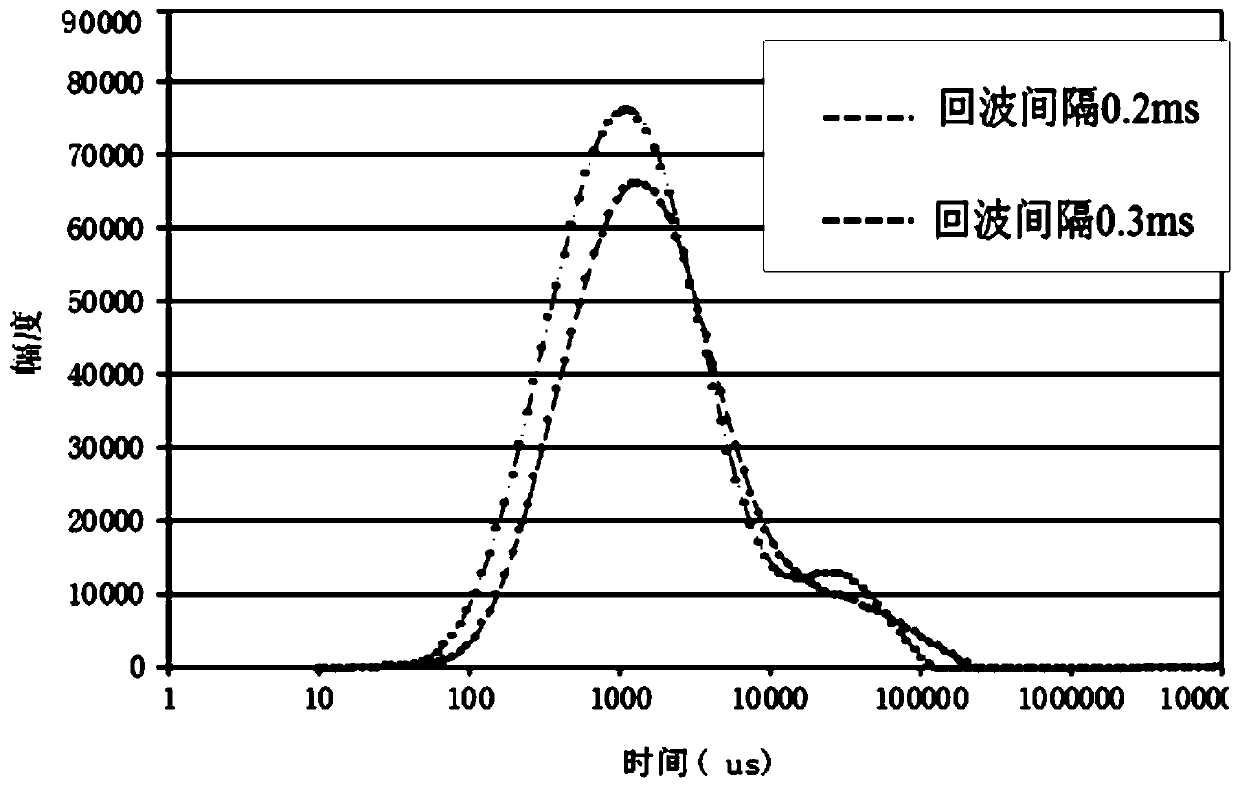

Nuclear magnetism and rock electricity experiment process of mixed rock

PendingCN111307852AGuaranteed cleanlinessImprove the effect of washing oil and saltMaterial analysis by electric/magnetic meansAnalysis using nuclear magnetic resonanceMagnetic testingPhysical chemistry

The invention provides a nuclear magnetism and rock electricity experiment process for mixed rock, which comprises the following steps: 1, placing a rock sample of the mixed rock in a closed container, and conducting vacuumizing treatment; then placing the rock sample in a solvent for pressurized cleaning; 2, after cleaning is completed, placing the rock sample in the closed container again, and conducting vacuumizing treatment; 3, preparing a NaCl saturated solution, and placing the rock sample treated in the step 2 in the NaCl saturated solution for impregnation saturation; 4, carrying out nuclear magnetic testing on the rock sample obtained in the step 3; and 5, carrying out rock electricity test on the rock sample obtained after the test in the step 4. According to a full oil salt washing principle, a traditional direct oil salt washing means is abandoned, and the rock sample is vacuumized and then cleaned, so that a cleaning solvent can enter nanoscale intercrystalline pores of the compact rock sample more easily, the rock sample washing degree is ensured as much as possible, the oil salt washing effect is improved, and the experimental measurement precision is effectively improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

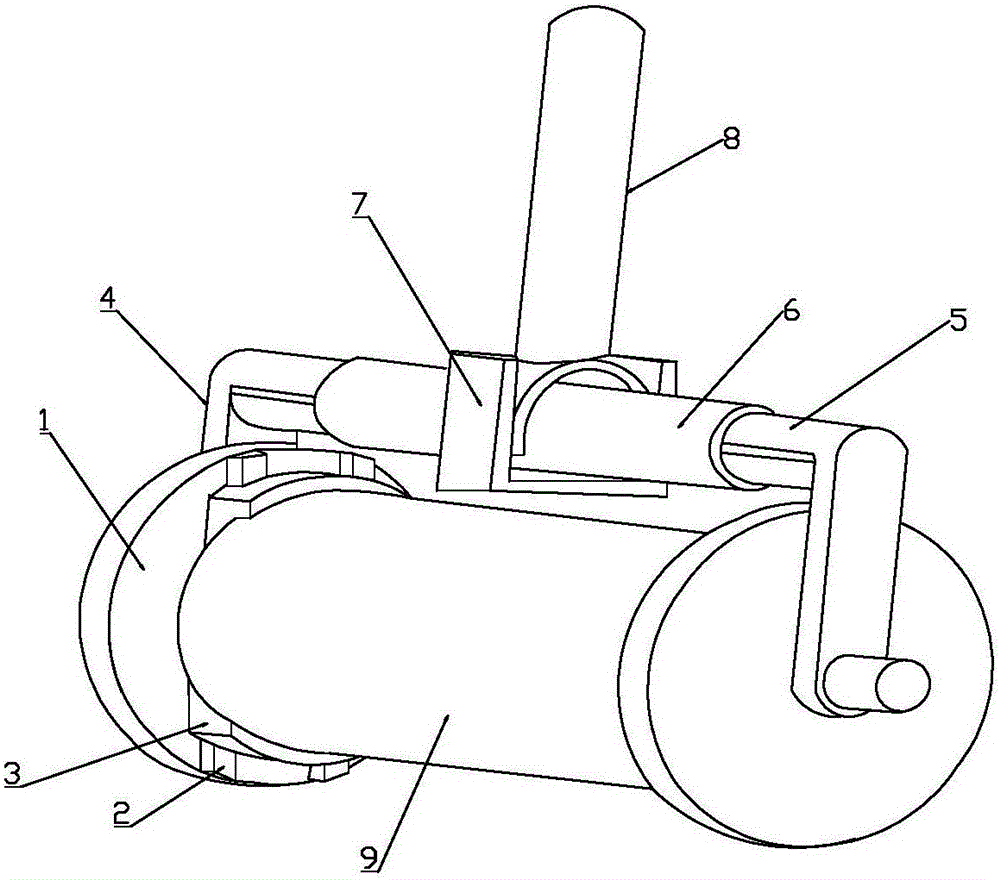

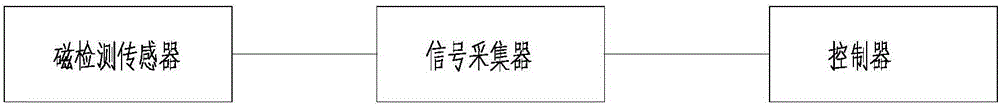

Bolt defect magnetic testing device

ActiveCN104950038AReduce jitterReduce noiseMaterial magnetic variablesMagnetic testingDisplay device

The invention provides a bolt defect magnetic testing device which comprises a magnetic testing mechanism, a signal acquiring device and a controller with a display; a magnetic testing sensor is arranged in the magnetic testing mechanism, and connected with the controller through the signal acquiring device; the magnetic testing mechanism comprises two supporting plates connected through a connecting rod; rotating plates rotationally connected with the corresponding supporting plates are arranged on the two corresponding supporting plates; the two rotating plates are arranged in parallel; grip slippers used for gripping two ends of a workpiece are respectively arranged on two opposite surfaces of the two rotating plates; a sliding seat sliding on the connecting rod is arranged on the connecting rod; the magnetic testing sensor is arranged on the sliding seat. The bolt defect magnetic testing device, provided by the invention, is used for nondestructive testing of the surface defect and the near surface defect of a high-strength bolt.

Owner:NINGBO YINZHOU CITAI ELECTRONICS TECH CO LTD

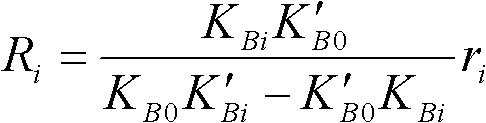

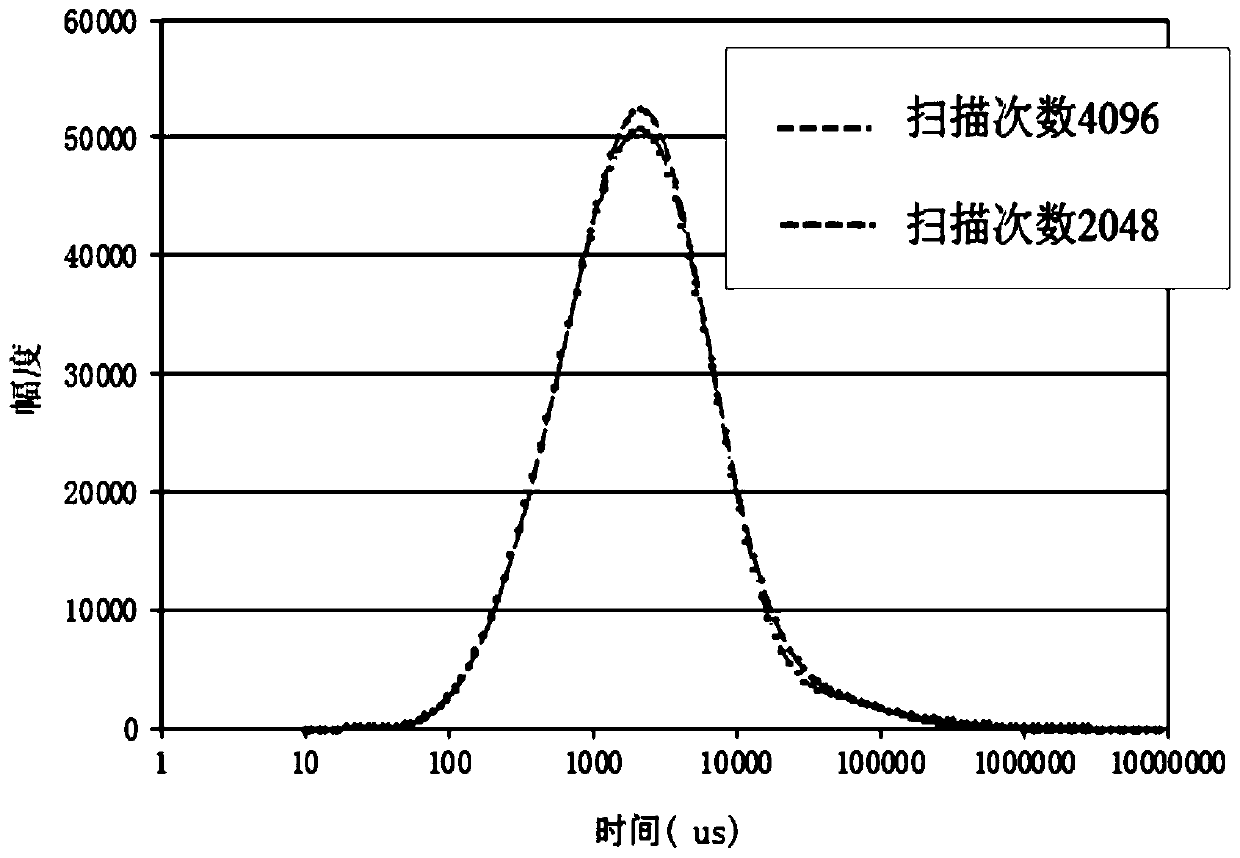

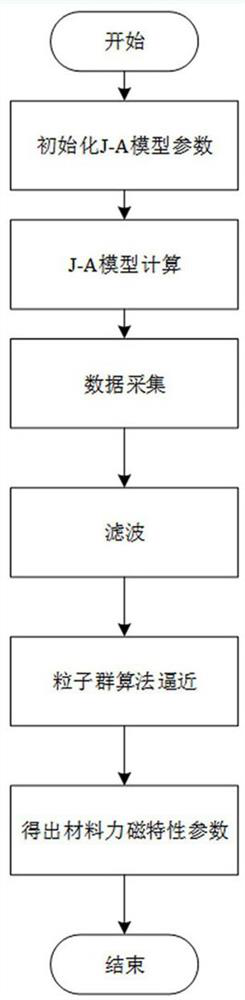

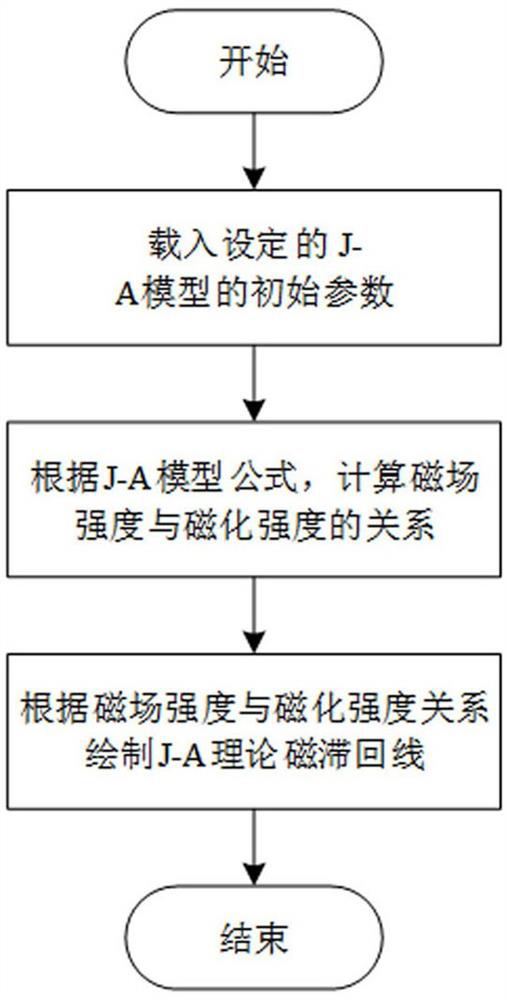

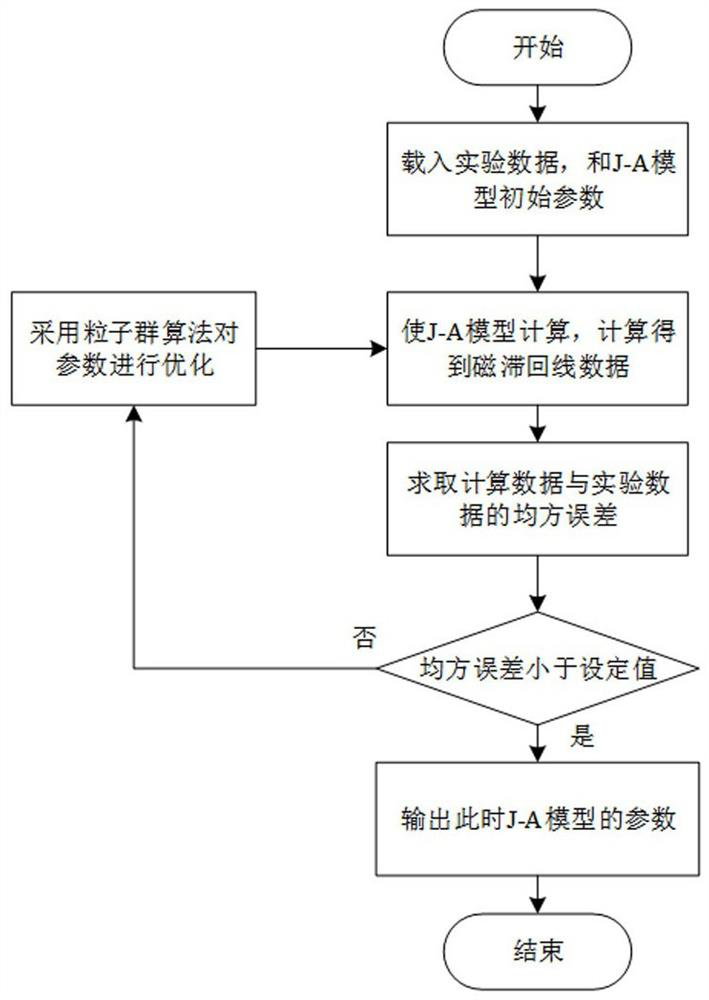

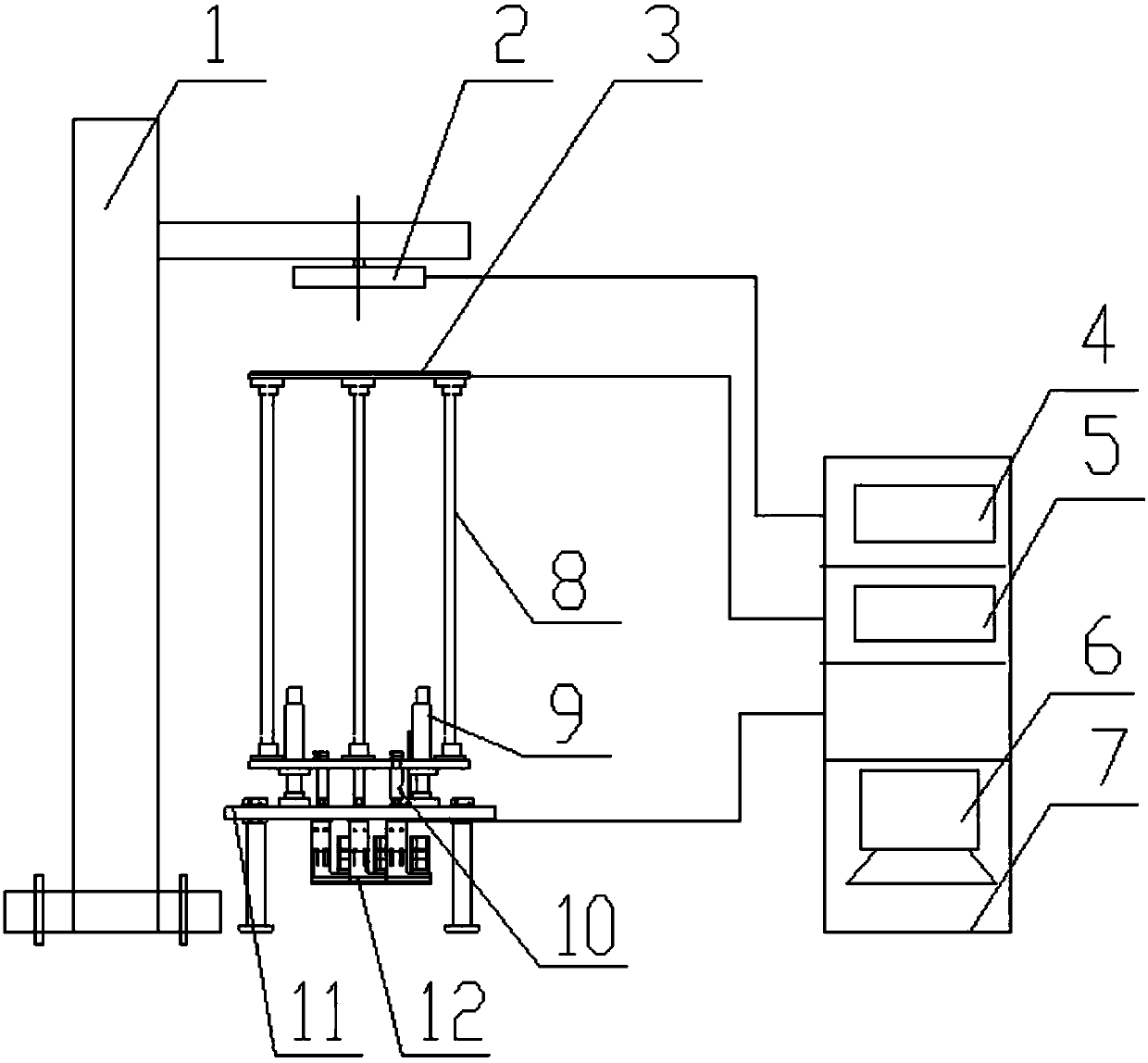

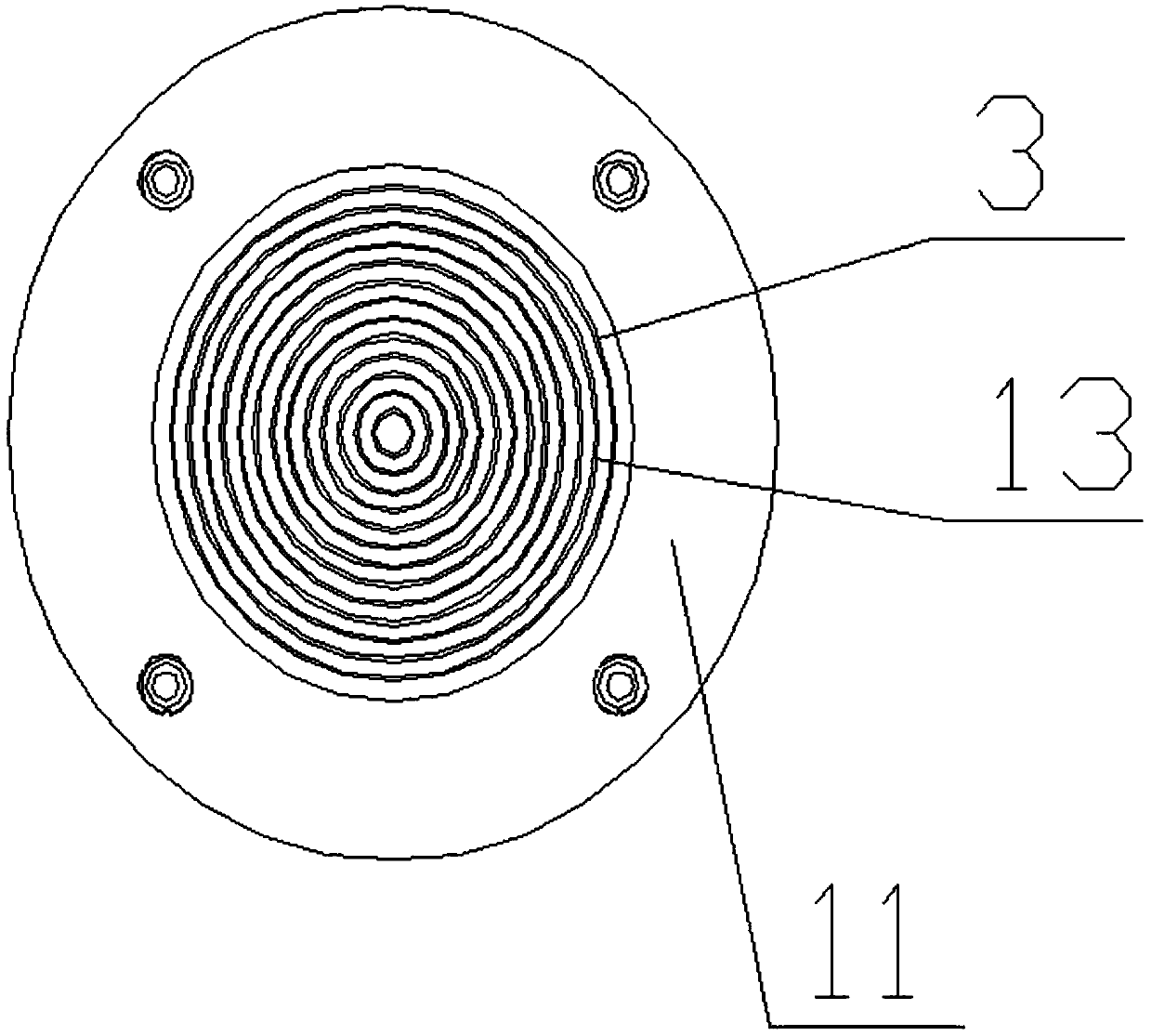

Method for determining force-magnetic characteristic parameters of material for strong and weak magnetic detection

The invention relates to the technical field of nondestructive testing, in particular to a method for determining force-magnetic characteristic parameters of a material for strong and weak magnetic testing, which comprises the following steps of: approaching a hysteresis loop I under different stresses and a hysteresis loop II of a sample in an unstressed state by adopting a particle swarm algorithm; the J-A model parameter when the mean square error of the data on the two curves is smaller than a set value or minimum is the force-magnetic characteristic parameter of the material. According to the method for determining the force-magnetic characteristic parameters of the material for strong and weak magnetic detection, the force-magnetic characteristic parameters of the material in strong and weak magnetic detection can be determined, and accurate hysteresis loops of the material under different stresses can be determined by applying the force-magnetic characteristic parameters calculated by the method to a J-A model; the stress in strong and weak magnetic detection can be identified by using the relationship between the stress and the hysteresis loop, so that the method for determining the force-magnetic characteristic parameters of the material for strong and weak magnetic detection has a very wide engineering application prospect.

Owner:PIPECHINA SOUTH CHINA CO +2

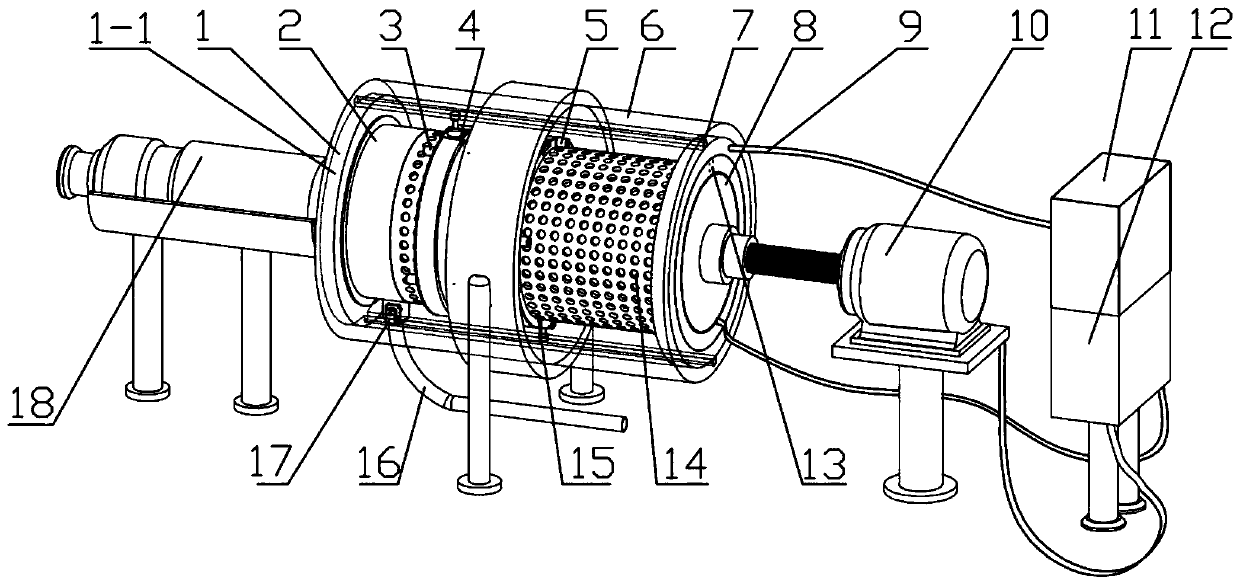

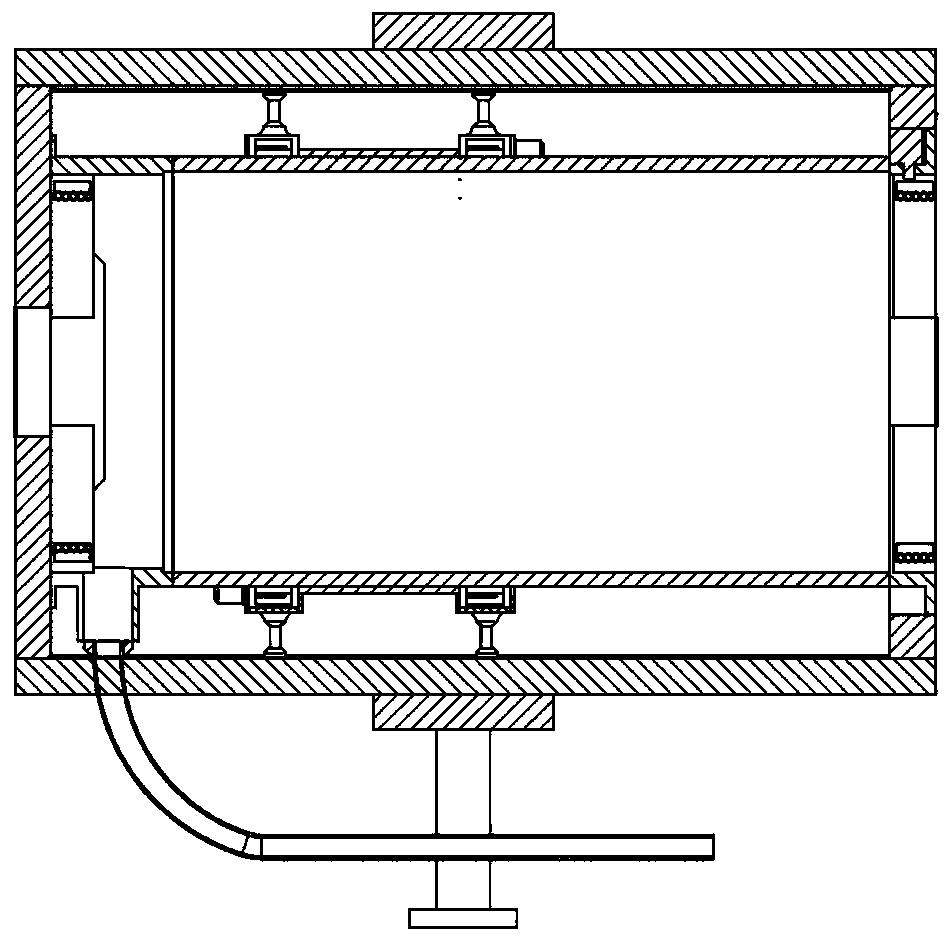

Electromagnetic induction-based calibrating device and method for cyclotron magnetic testing system

PendingCN107843865AHigh measurement accuracyCompact structureMagnetic measurementsElectrical measurementsMagnetic testingEngineering

The invention discloses an electromagnetic induction-based calibrating device for a cyclotron magnetic testing system. The calibrating device comprises a driving mechanism and a detection mechanism mounted above the driving mechanism; the detection mechanism comprises a detection rack and a detection wire coil arranged above the detection rack, an electrified wire coil panel is arranged above thedetection wire coil and is connected with a wire coil power source, and the detection wire coil is connected with a fluxmeter. The invention also provides an electromagnetic induction-based calibrating method for the cyclotron magnetic testing system. The method comprises the following steps: a step of doing preparation work, a step of obtaining testing parallelism, a step of obtaining a serial number, and a step of collecting a magnetic induction intensity value; calibration results are analyzed and processed. The electromagnetic induction-based calibrating device and method are advantaged bycompact structure, simple operation, precise measurement, automatic collection of data and the like; measuring precision of the detection wire coil can be improved via calibration, testing errors canbe reduced, and the electromagnetic induction-based calibrating device and method are of vital importance in the field of nuclear medicine.

Owner:HEFEI CAS ION MEDICAL & TECHNICAL DEVICES CO LTD

Magnetic testing method and magnetic testing apparatus

ActiveUS8466674B2Accurate detectionInhibition effectMaterial magnetic variablesMagnetic testingGray level

A magnetic testing apparatus has a magnetizing device applying a rotating magnetic field to a material to be tested, a testing signal detecting device, and a signal processing device applying signal processing to the testing signal. The signal processing device has a first synchronous detecting device detecting a testing signal by using the first current as a reference signal, a second synchronous detecting device detecting an output signal of the first synchronous detecting device by using the second current as a reference signal to extract a candidate flaw signal, and a testing image display device displaying a testing image in which each of pixels has a gray level corresponding to an intensity of the candidate flaw signal at each of positions of the material to be tested, and a phase of the candidate flaw signal at each of the positions is capable of being identified.

Owner:NIPPON STEEL CORP

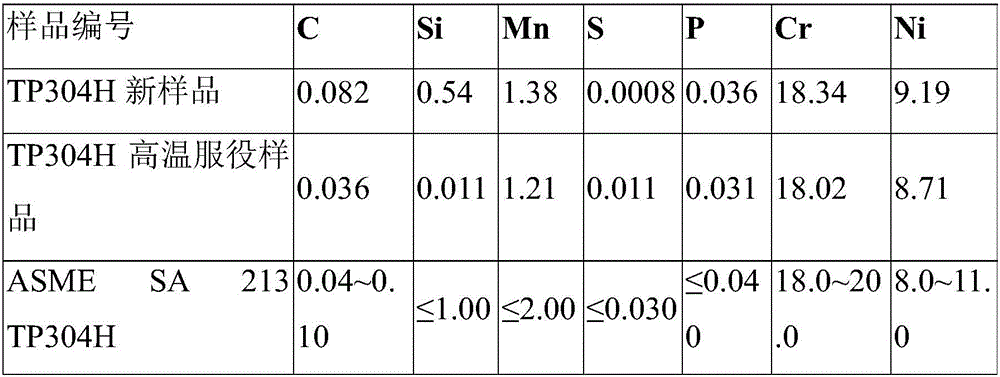

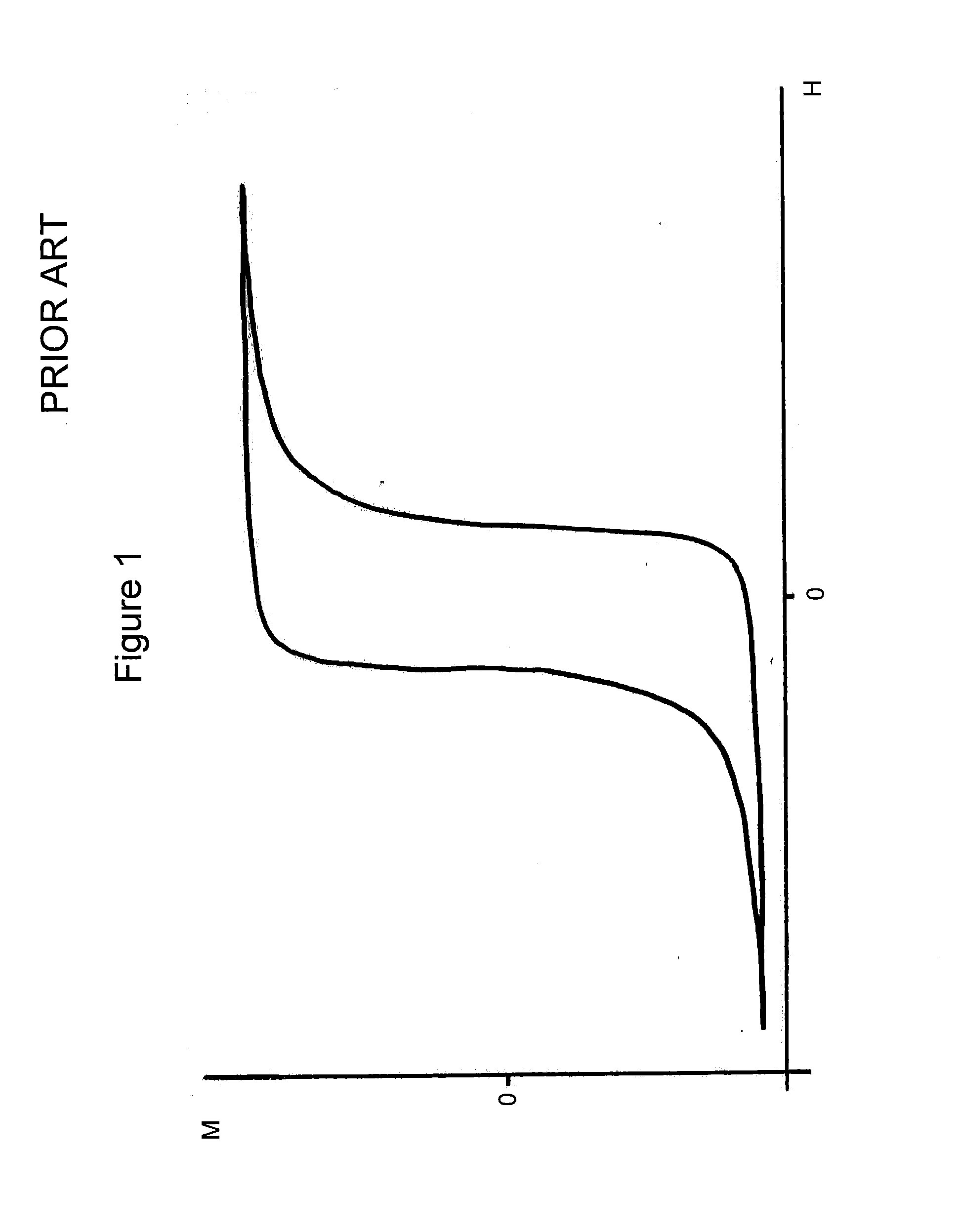

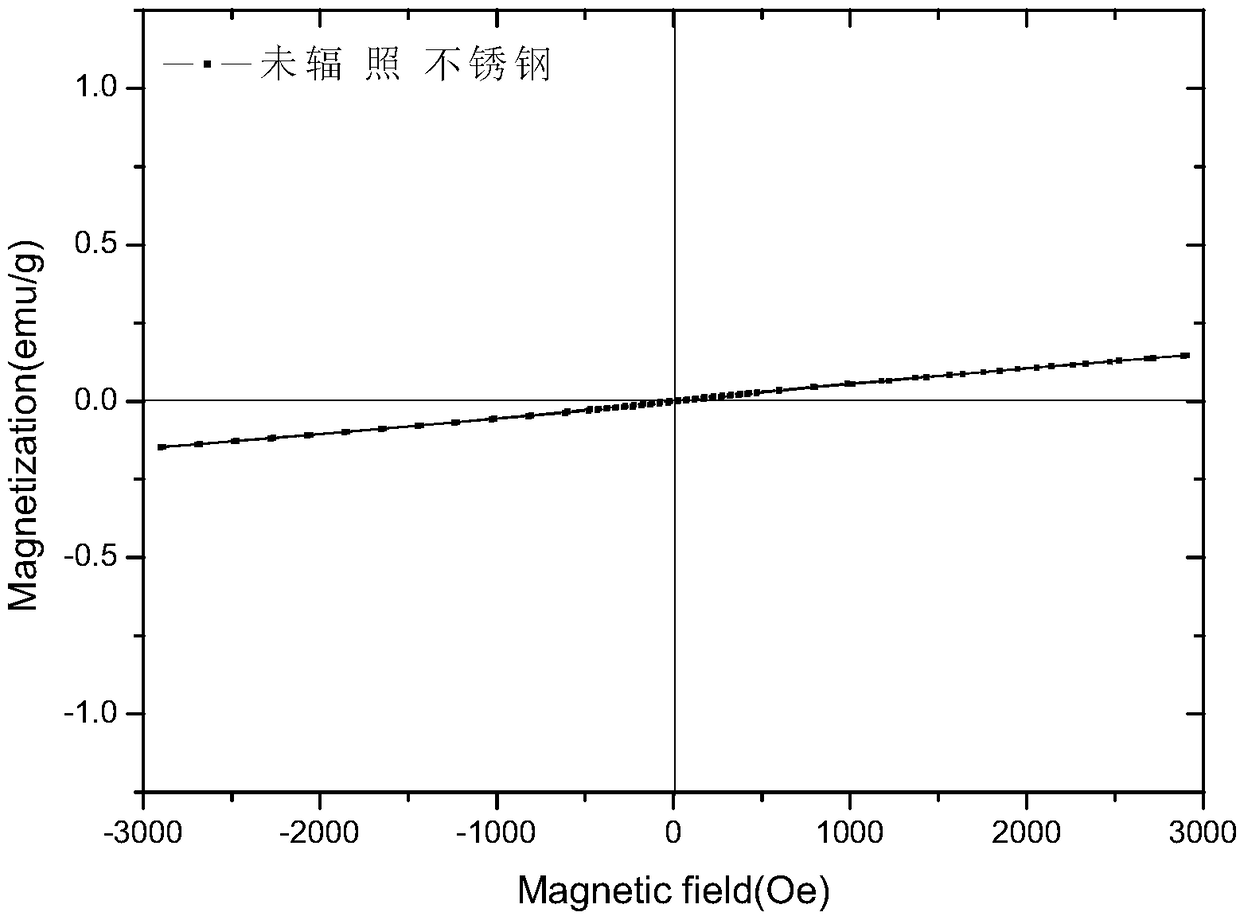

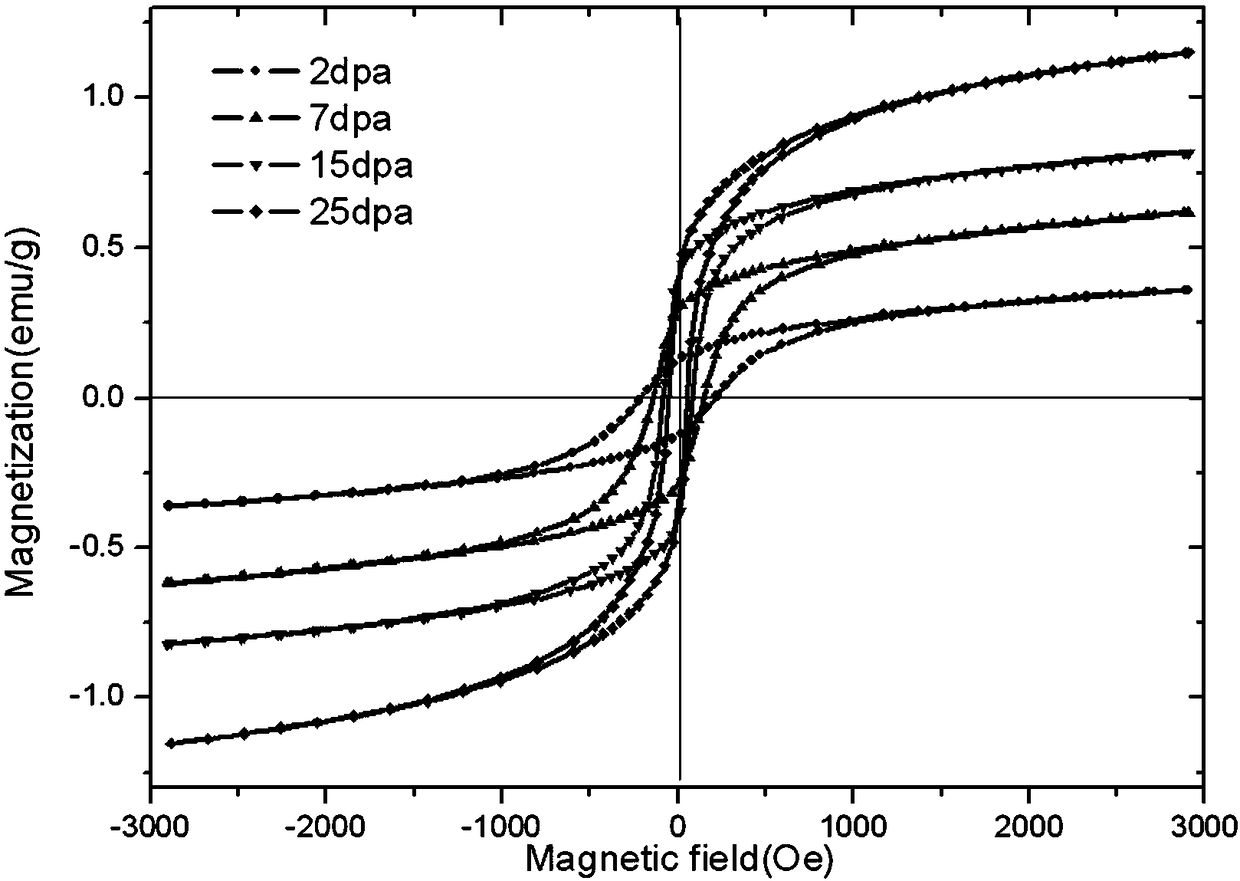

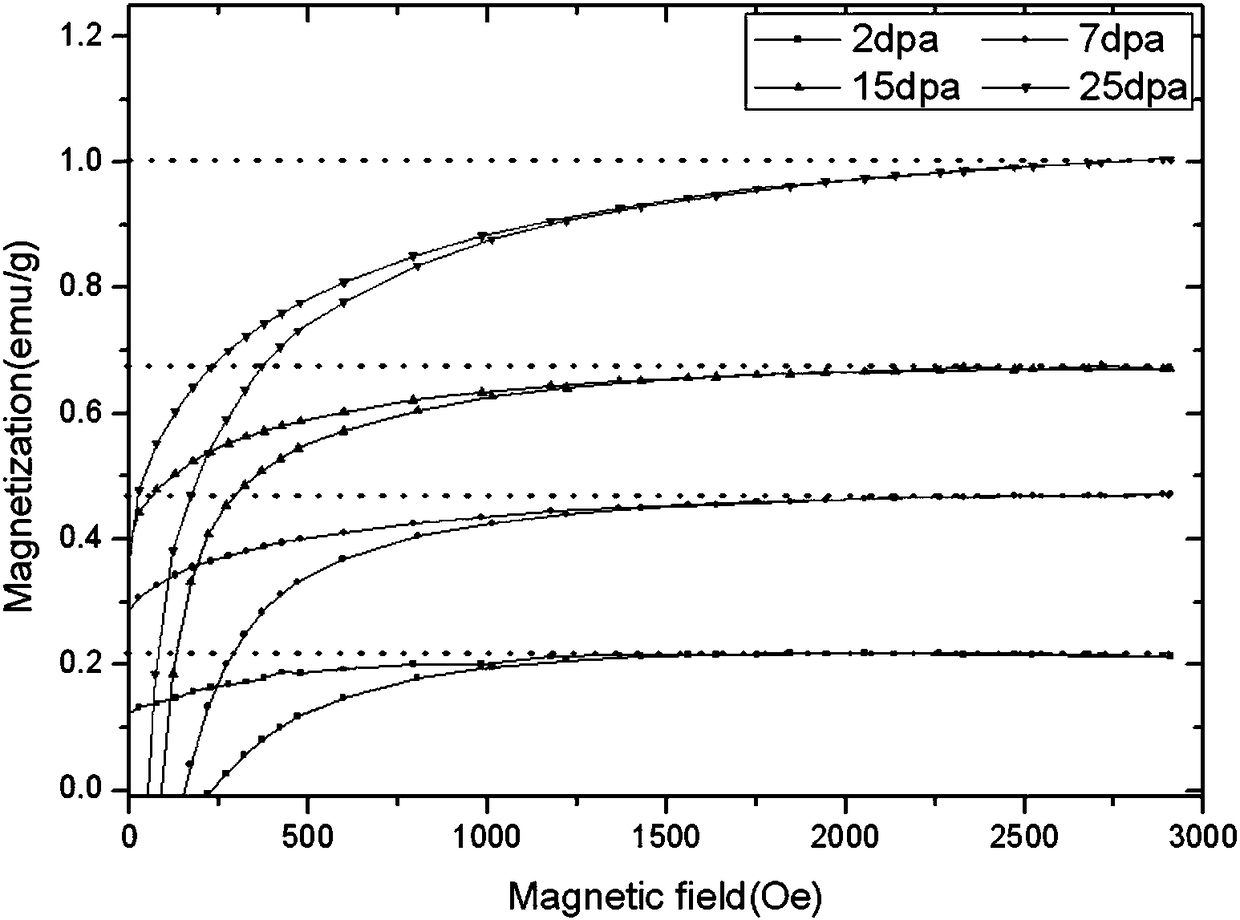

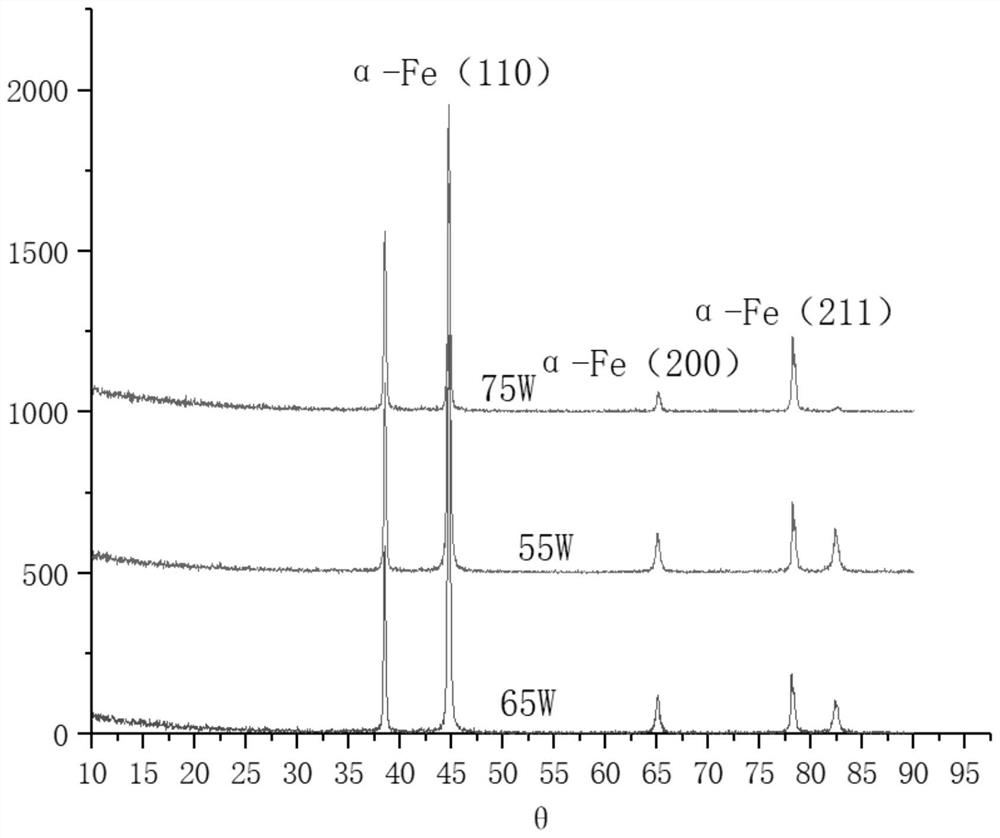

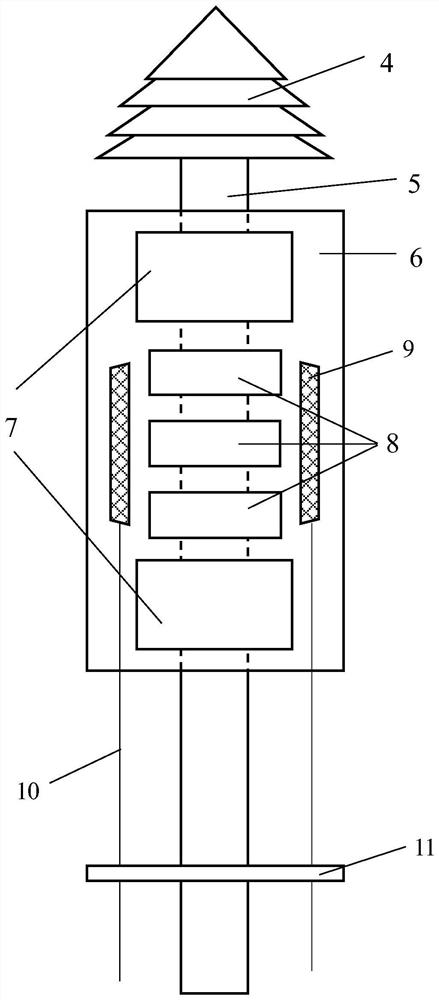

Magnetic nondestructive testing method for testing ferritic transformation quantity of austenitic stainless steel after being subjected to ion irradiation

ActiveCN108333032ASmall sizeThe test data is validPreparing sample for investigationMaterial magnetic variablesHysteresisSolution treatment

The invention discloses a magnetic nondestructive testing method for testing the ferritic transformation quantity of austenitic stainless steel after being subjected to ion irradiation. The method comprises the following steps that (1) austenitic stainless steel is subjected to solution treatment after being processed to be round sheets; (2) the round sheets are subjected to magnetic testing, anda hysteresis loop first M-H curve of non-irradiated austenitic stainless steel is obtained; (3) the round sheets are subjected to ion irradiation, and the equivalent thickness L1 in an ion irradiationdestructive area is obtained; (4) the irradiated austenitic stainless steel is subjected to magnetic testing, and a hysteresis loop second M-H curve of the irradiated austenitic stainless steel is obtained; (5) the contribution of the non-irradiated austenitic stainless steel on the first M-H curve is deducted from the second M-H curve, and the specific saturation magnetization Ms of the irradiated austenitic stainless steel is obtained; (6) the specific saturation magnetization Mst of the irradiation destructive part is calculated by adopting the formula I (detailed description is shown in the original text); and (7) the ferritic transformation quantity of austenitic stainless steel after obtaining ion irradiation is calculated by adopting the formula II (detailed description is shown inthe original text). The method is convenient to test, the sample size is small, the data accuracy is high, and the repeatability is good.

Owner:SUZHOU NUCLEAR POWER RES INST +3

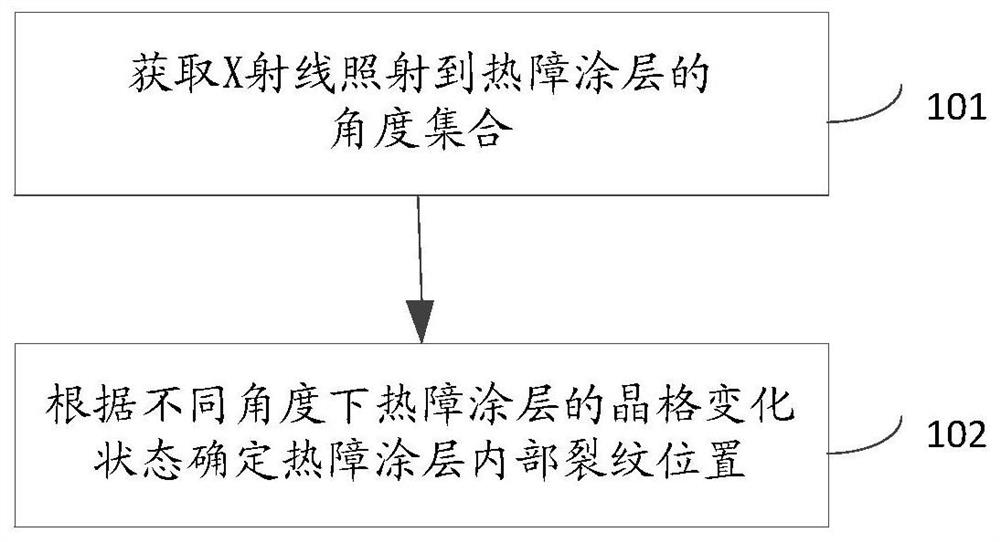

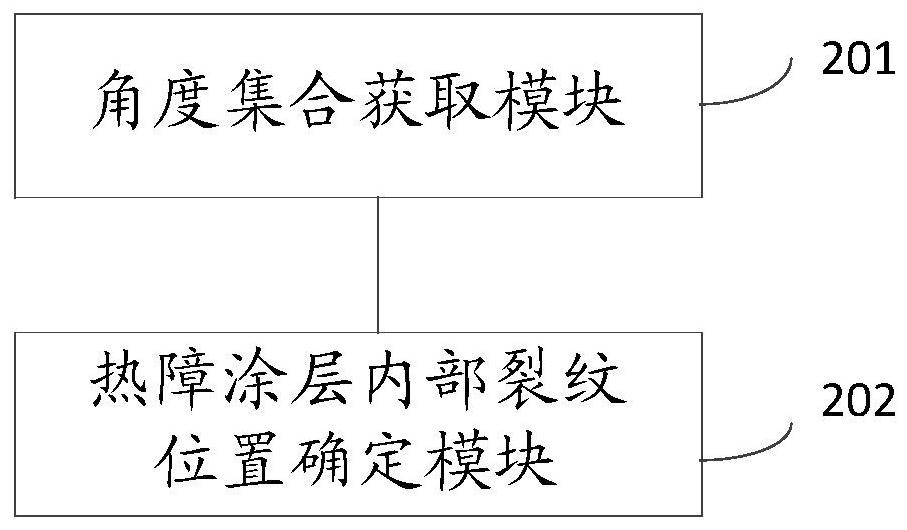

Nondestructive testing method and system for internal cracks of thermal barrier coating

PendingCN113049616ASolve the problem that the crack state cannot be detectedCalculate the crack lengthMaterial analysis using wave/particle radiationUsing wave/particle radiation meansMagnetic testingUltrasonic testing

The invention discloses a nondestructive testing method and system for internal cracks of a thermal barrier coating. The nondestructive testing method comprises the following steps of: acquiring an angle set of X-rays irradiated to the thermal barrier coating; and determining internal crack positions of the thermal barrier coating according to a lattice change state of the thermal barrier coating at different angles. According to the nondestructive testing method and the system for the internal cracks of the thermal barrier coating, the internal cracks of the thermal barrier coating are subjected to nondestructive testing by adopting an X-ray method, and the problems that the ultrasonic testing accuracy is not high, a magnetic testing method is limited by a thermal barrier coating material, and a penetration testing method cannot detect the crack state in the coating are solved.

Owner:BEIHANG (SICHUAN) WESTERN INT INNOVATION PORT TECH CO LTD

Device for improving magnetic testing sensitivity of aviation engine blade

ActiveCN103529119AImprove the sensitivity of magnetic detectionIncrease the magnetic detection lengthMaterial magnetic variablesAviationMagnetic testing

The invention discloses a device for improving magnetic testing sensitivity of an aviation engine blade. The device mainly comprises a fixing bottom plate for arranging a tool device on a magnetic testing equipment bed, a tenon holding head which is arranged on the fixing bottom plate and which is used for holding one end of a tenon of the tested blade, a blade tip holding head for holding one end of the tested blade, and an extended plate which is arranged on the tenon holding head and which is used for increasing the length-diameter ratio of the tested blade, wherein the mounting direction of the extended plate is opposite to the mounting direction of the tested blade; the tenon holding head and the blade tip holding head are arranged oppositely; at least one of the tenon holding head and the blade tip holding head is a rotary holding head which can hold the tested blade to rotate; and at least one of the tenon holding head and the blade tip holding head is a movable holding head which can move and adjust the mounting position relative to the other one. The device has the characteristics that the longitudinal magnetization sensitivity is high, the length-diameter ratio is smaller than blade magnetic testing magnetic field intensity, demagnetization can be easily achieved without using large-size demagnetization equipment to carry out repeated demagnetization, the magnetic testing efficiency is high, and the device is applicable to various blades.

Owner:CHENGDU ENGINE GROUP

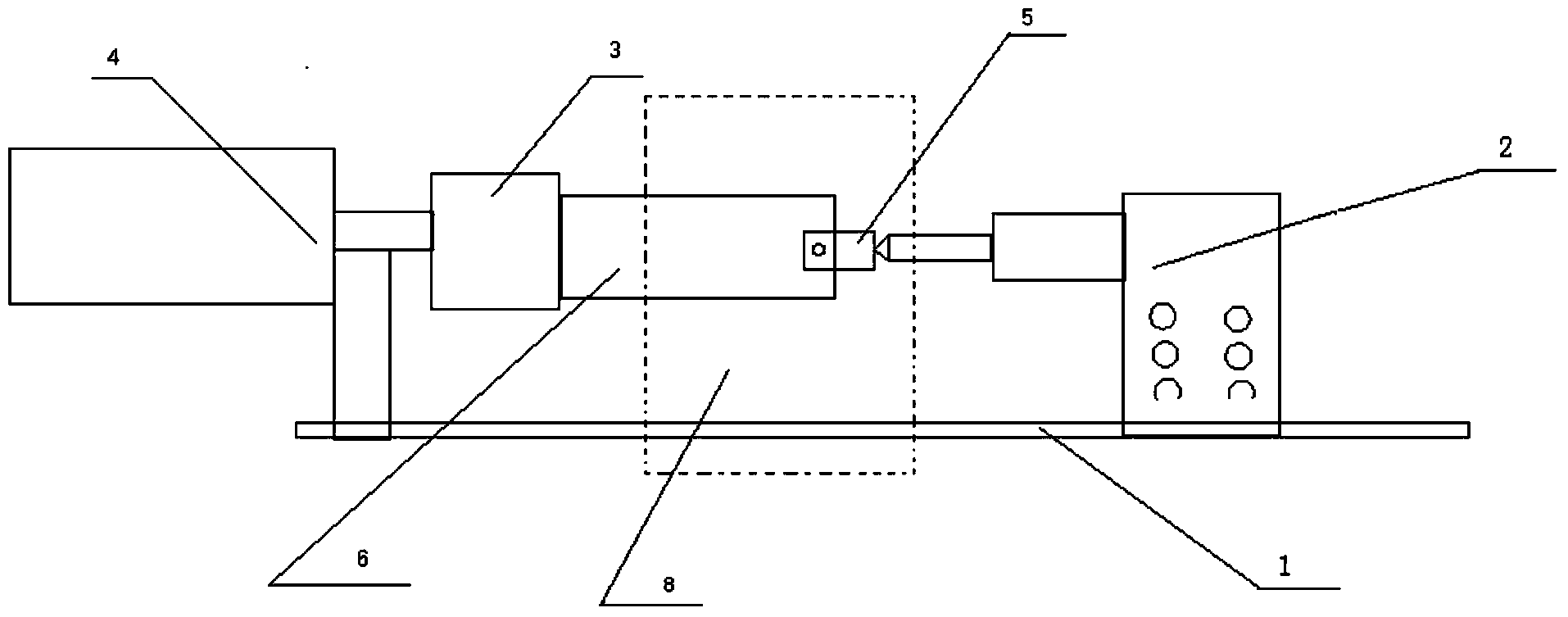

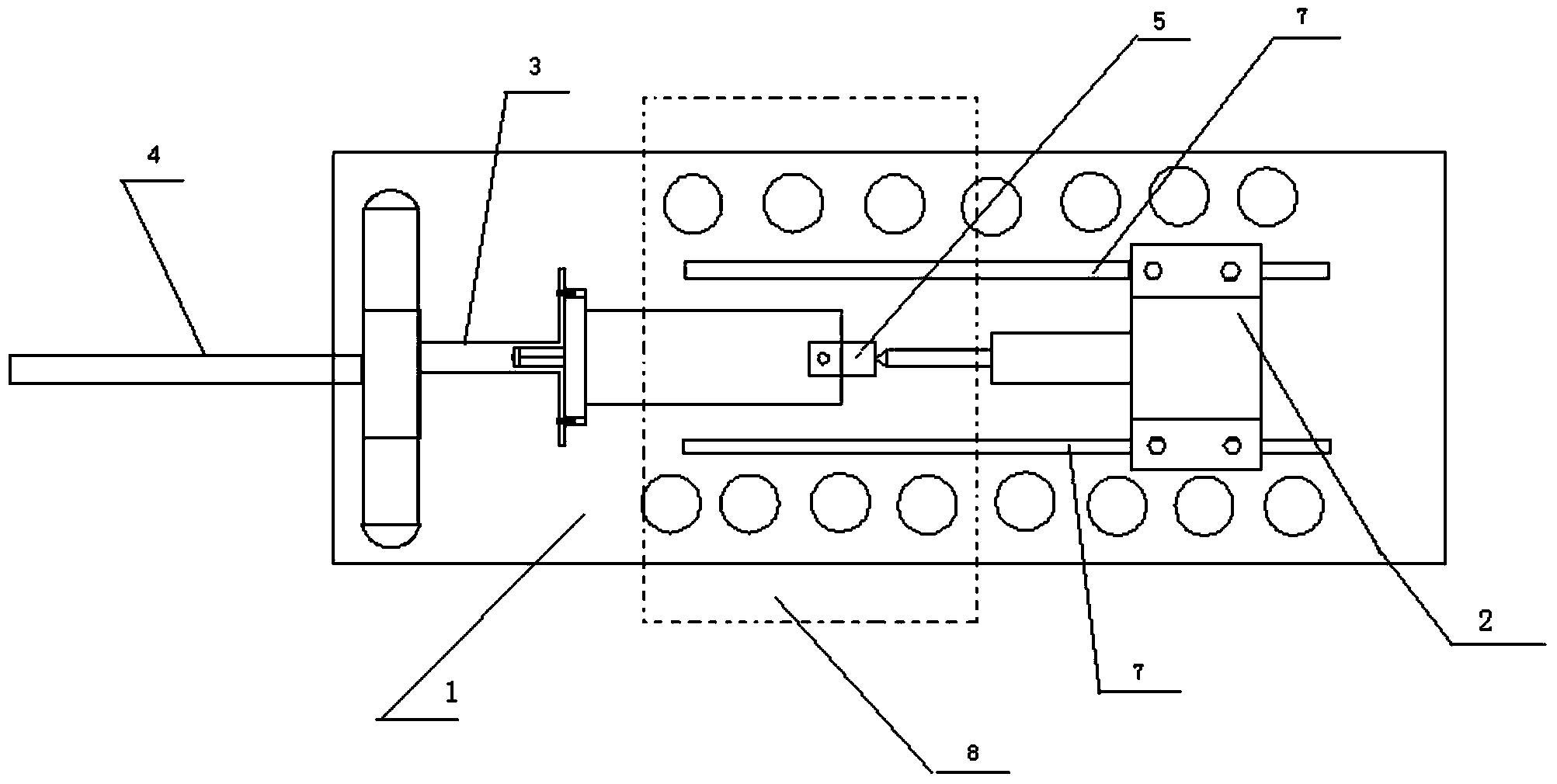

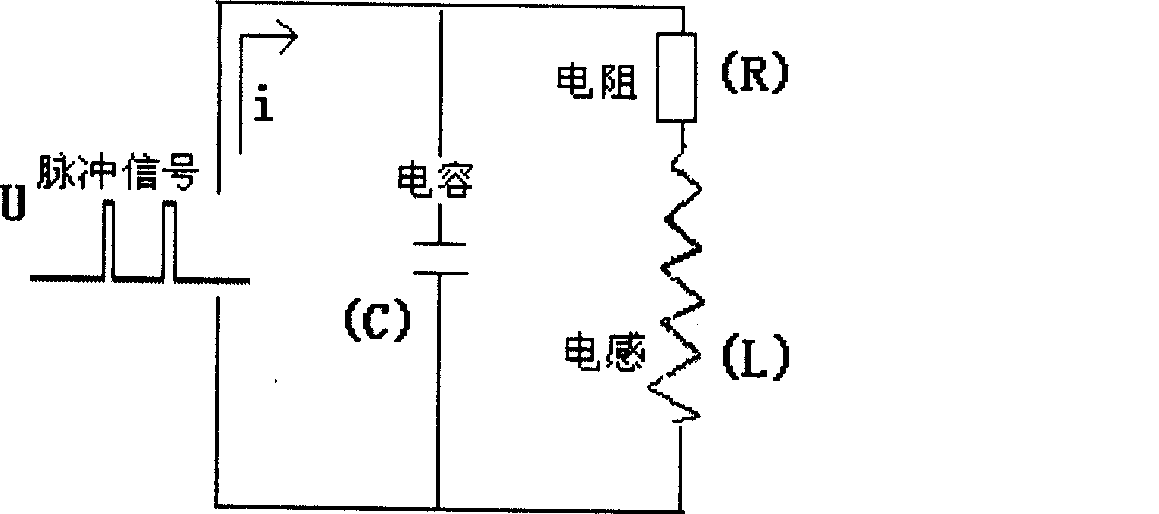

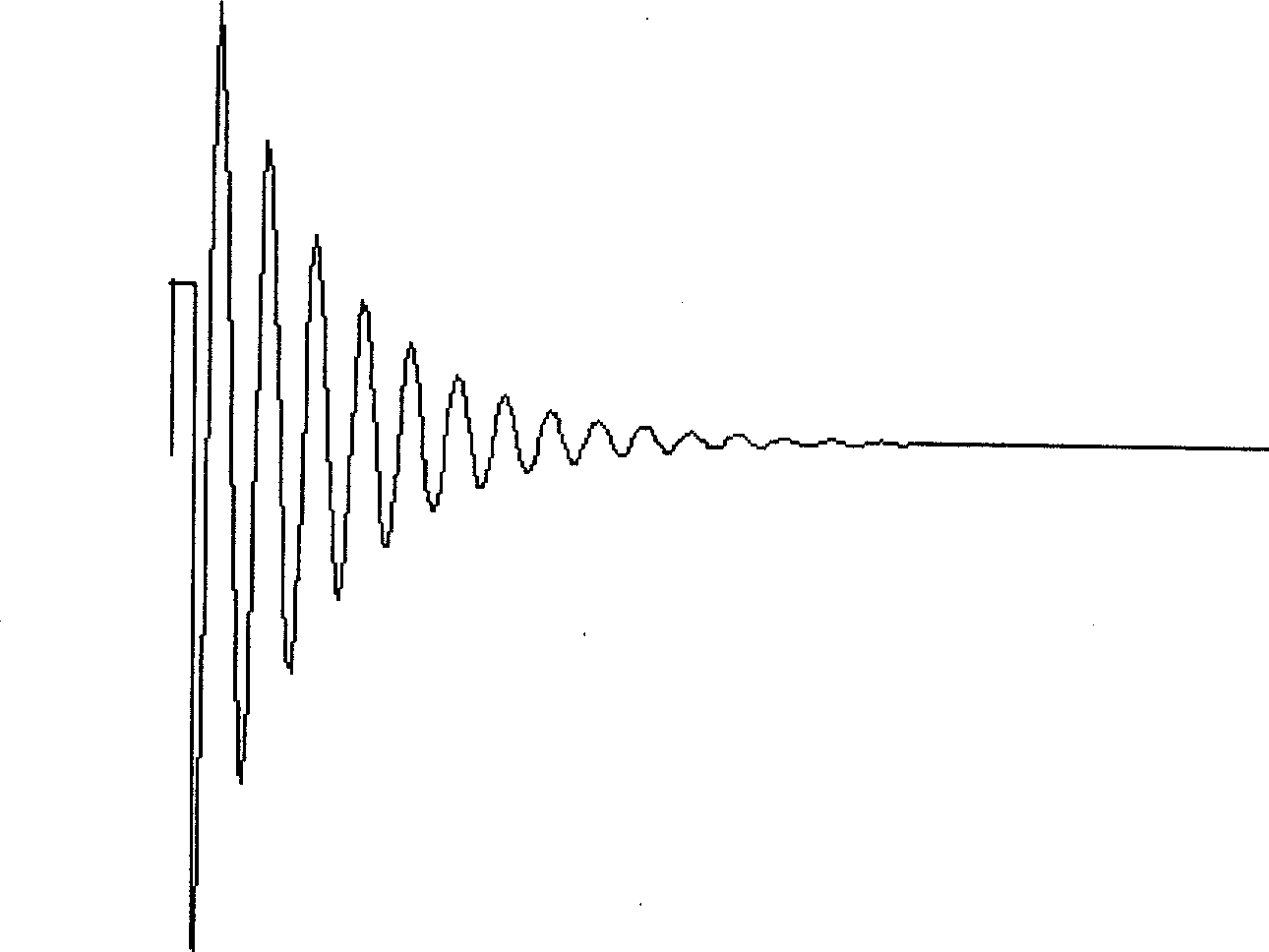

Resonance eddy detection method for surface crack

InactiveCN100470245CEasy to manufactureNon-destructiveMaterial magnetic variablesRough surfaceMagnetic testing

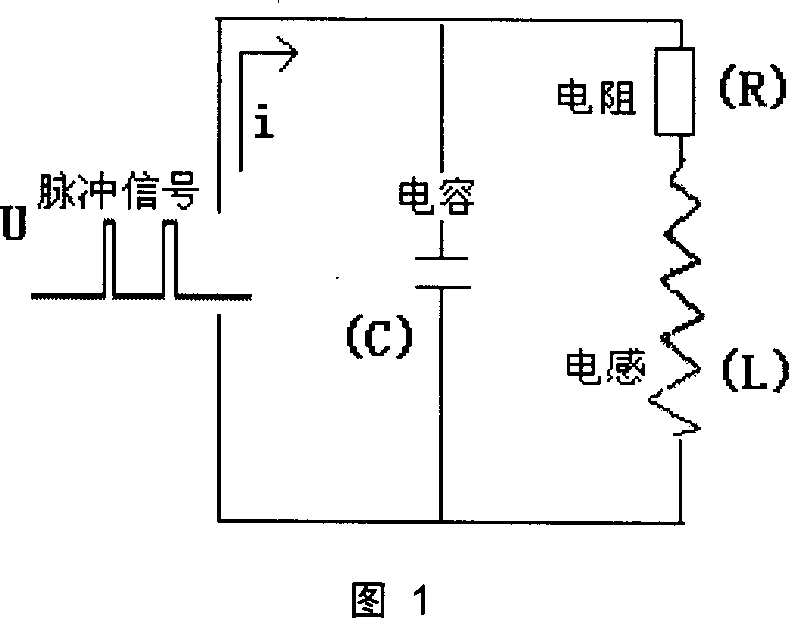

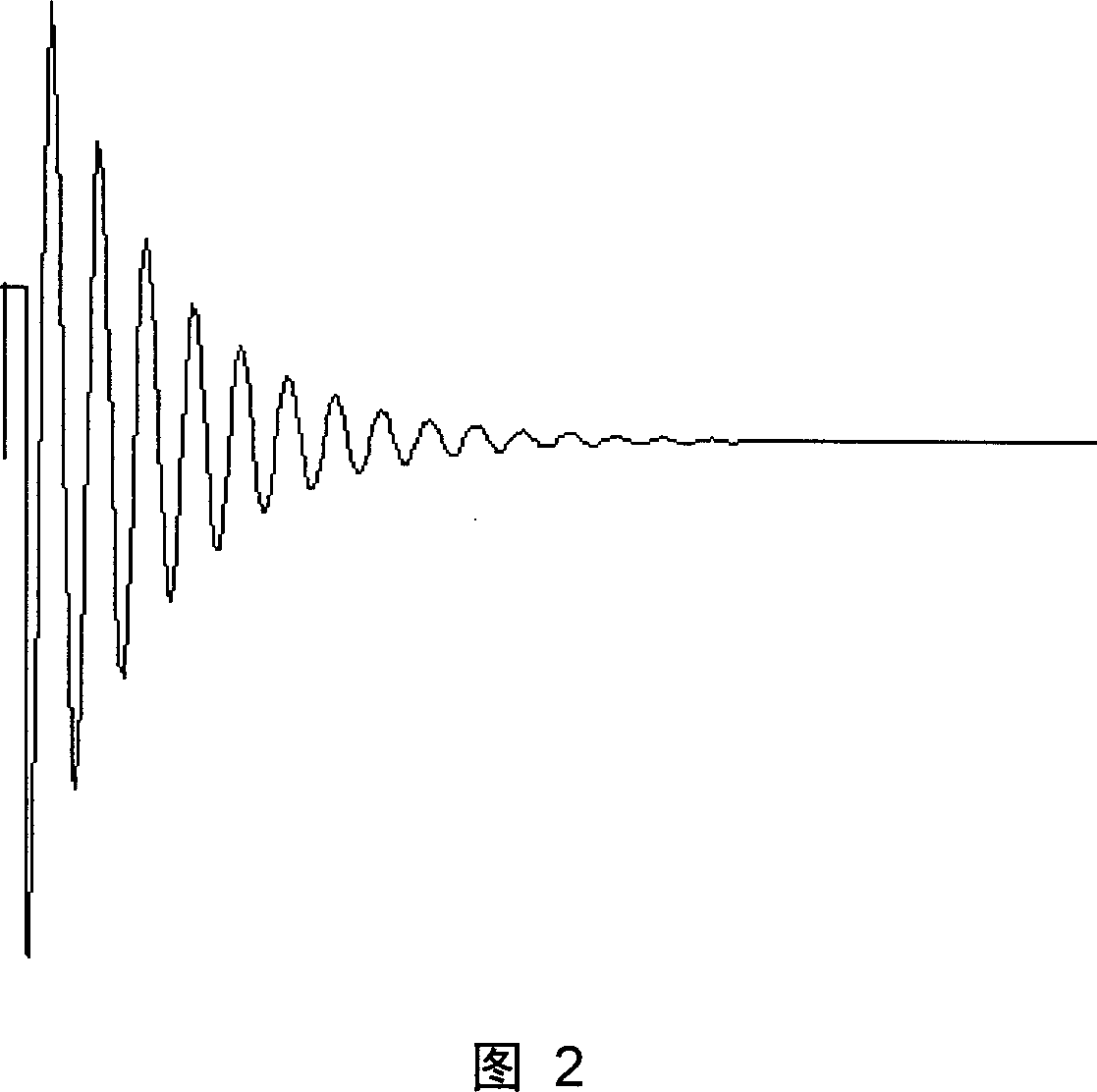

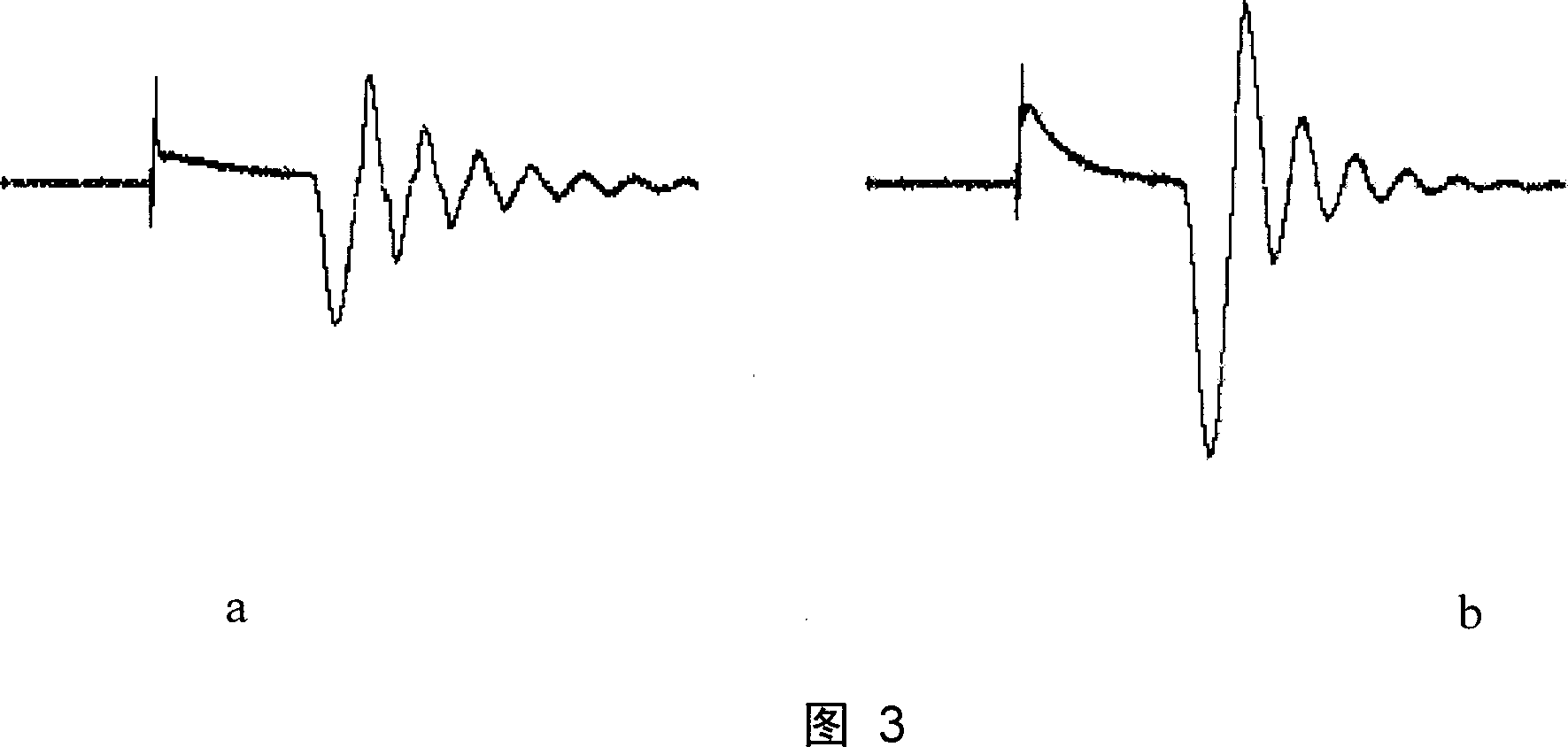

This invention relates to crack resonance whorl testing method, which belongs to iron magnetic material lossless electro-magnetic testing field. This invention uses resonance circuit to generate pulse resonance signals to excite sensor ring to get whorl field to judge the crack existence through test ring. The advantage lies in improving extracting highness and overcomes the rough surface impact to realize spot test to fulfill traditional testing rough crack.

Owner:TSINGHUA UNIV

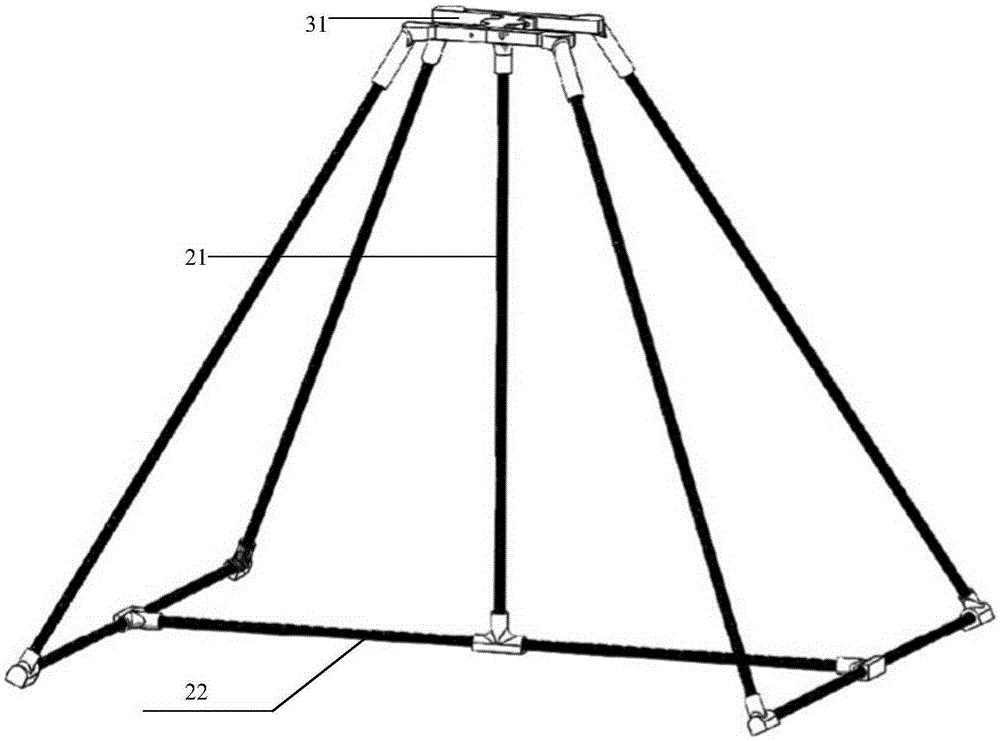

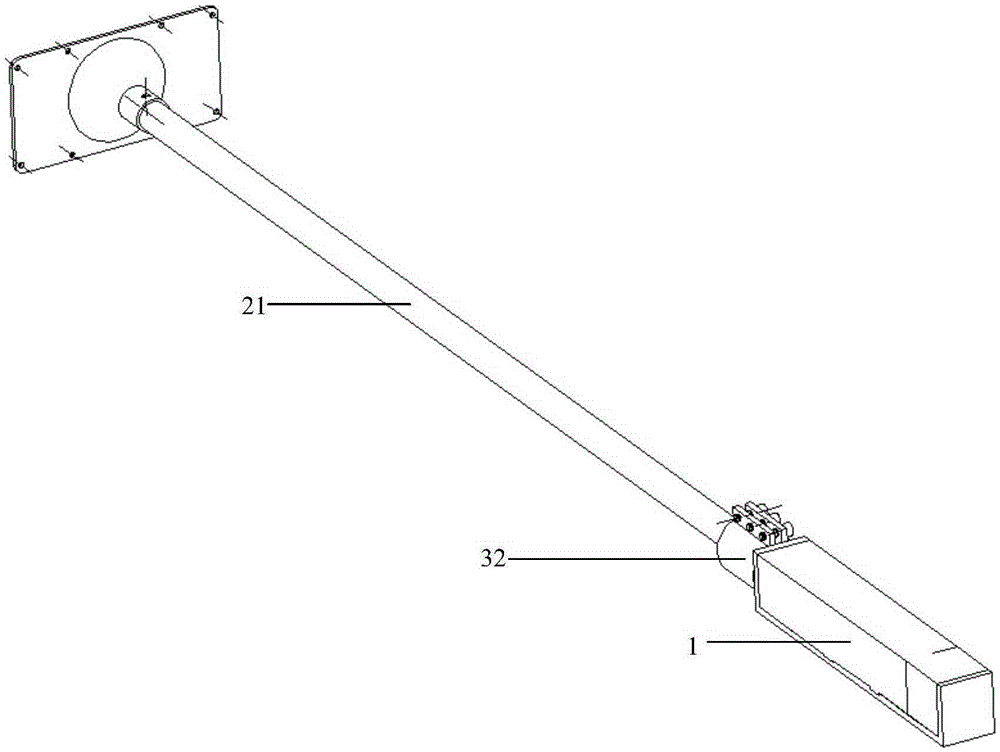

Hard suspension type magnetic flux door magnetic testing system on unmanned gyroplane

ActiveCN105353416ACause a crash hazardEasy post-processingElectric/magnetic detectionAcoustic wave reradiationMagnetic disturbanceMagnetic testing

The invention discloses a hard suspension type magnetic flux door magnetic testing system on an unmanned gyroplane, and the system comprises an undercarriage, a magnetic flux door sensor and a magnetic flux door gatherer; the magnetic flux door gatherer is set on the unmanned gyroplane for exploration; the magnetic flux door sensor is set on the undercarriage; the magnetic flux door sensor and the magnetic flux door gatherer are connected by wireless signals; the undercarriage comprises multiple connecting pieces and connecting rods; the connecting rods form a framework structure through the connecting pieces. Compared with traditional material, material adopted by the system enables the weight of the system to be reduced; the magnetic interference problem in a data acquisition system is solved; the relative position of the gatherer and the sensor is made to be unique; the flight safety is guaranteed; the sensor extends out of the gyroplane to the maximum extent and is not influenced from outside wind power; the sensor won't be blown onto the rotors of the gyroplane and then will not cause a crash danger; the check and maintenance workload is little; influence by artificial factors is reduced in the most possible way; and the system can work long and stably.

Owner:BEIJING ORANGELAMP NAVIGATION TECH DEV

Method for dewatering sludge and detecting water content

InactiveCN110104925AEasy to detect onlineSludge treatmentAnalysis using nuclear magnetic resonanceHelmholtz coilMagnetic testing

The invention discloses a method for dewatering sludge and detecting the water content. The method comprises the following steps that 1, a calibration curve is built, wherein by using a Helmholtz coiland a detection coil, a standard sample with the known water content is obtained and subjected to low-field nuclear magnetic testing, the standard sample and the nuclear magnetic resonance semaphoreare subjected to primary linear fitting, and the calibration curve is built; 2, feeding, wherein sludge is introduced into a filter-press chamber so as to achieve feeding; 3, filter pressing for dewatering, wherein by using thrust of an oil cylinder and electromagnetic force between a left push plate and a right push plate, the filter-press chamber is subjected to filter pressing; 4, detection ofthe water content, wherein by using the electromagnetic force, a detection unit is pushed to move rightwards to the detection position, an echo attenuation curve is obtained, and a transverse relaxation time T2 curve of samples is obtained; 5, calculation of the water content of a sample, wherein the transverse relaxation time T2 curve, obtained in the step 4, of the samples is subjected to area integral and calculated to be substituted into the calibration curve in the step 1, and the water content is obtained. In the method, the water content of the sludge can be conveniently and quickly detected on line in the dewatering process without sampling.

Owner:饶宾期

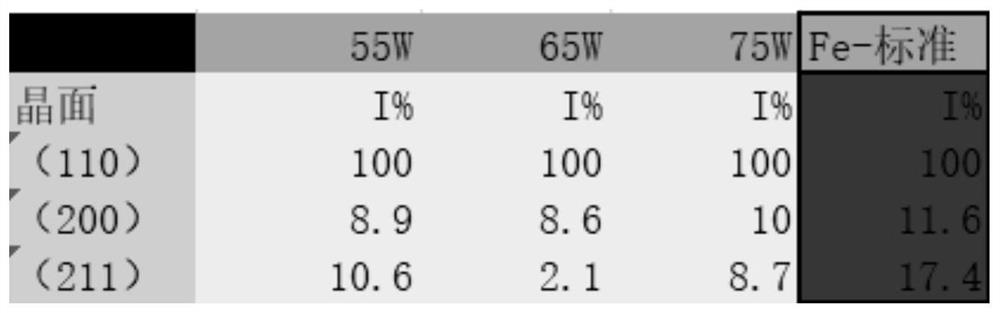

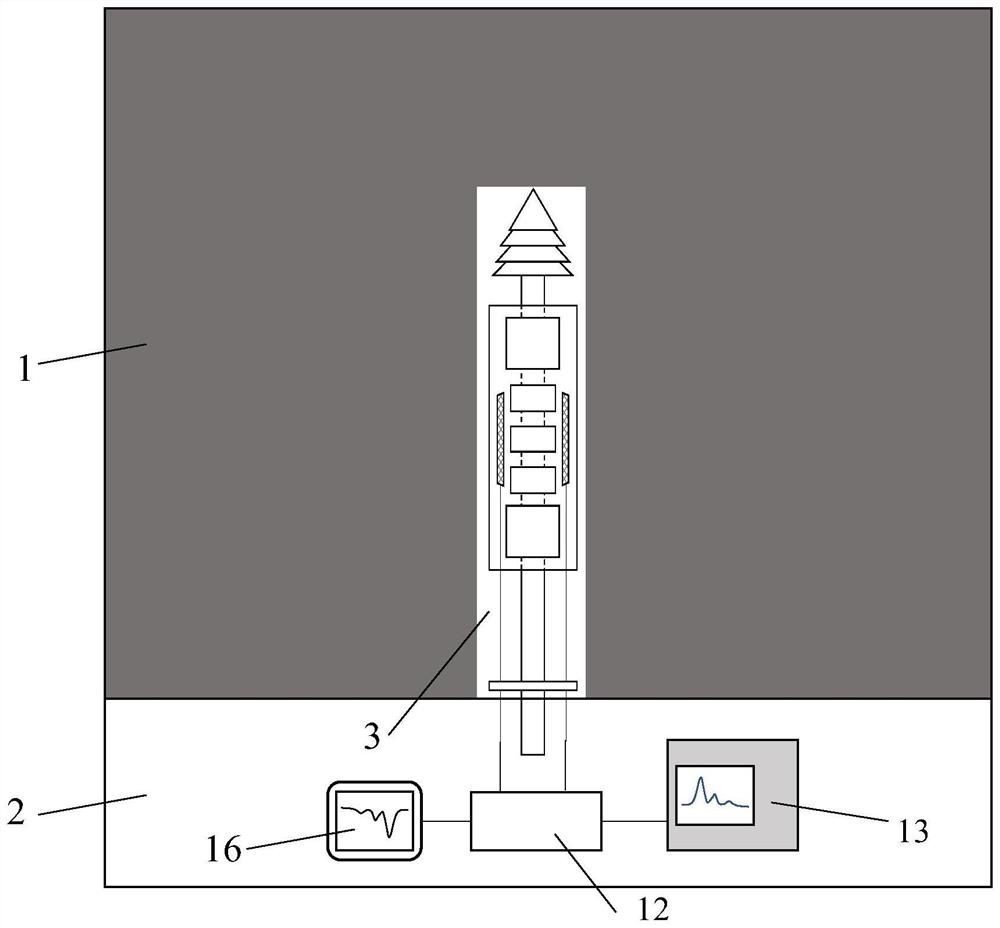

A kind of modification method of iron-based material

ActiveCN111151745BImprove magnetic propertiesAdditive manufacturing apparatusIncreasing energy efficiencyMagnetic testingCondensed matter physics

Owner:TONGJI UNIV

Coal reservoir structure testing while-drilling bit based on nuclear magnetic resonance and testing method

PendingCN114412448AReal-time non-destructive monitoringRealize non-destructive monitoringSurveyMining devicesNMR - Nuclear magnetic resonanceNuclear engineering

The invention discloses a coal reservoir structure testing while-drilling bit based on nuclear magnetic resonance and a testing method, nuclear magnetic detection is carried out on coal around a drilled hole in real time through a nuclear magnetic probe in the drilling process, a nuclear magnetic detection process is achieved after drilling construction is completed, then the drilled hole can be used for subsequent gas extraction, and the drilling efficiency is improved. According to the mode that one-time drilling has multiple functions, on one hand, additional drilling of a plurality of drill holes is reduced; on the other hand, nuclear magnetic detection can be conducted in the drilling process and the drilling retreating process through a nuclear magnetic testing means, real-time in-situ coal seam nondestructive monitoring is achieved, and data validity and credibility are greatly improved; and finally, a plurality of pieces of nuclear magnetic relaxation information obtained during drilling and a plurality of pieces of nuclear magnetic relaxation information obtained during drilling retreating form a set, judgment is carried out according to a set standard, whether the coal seam pore structure around the drill hole changes due to drill hole pressure relief or not can be finally determined, and then corresponding measures are taken in time according to the change conditions. And the safety of subsequent coal seam mining is ensured.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com