Device for improving magnetic testing sensitivity of aviation engine blade

An aero-engine and sensitivity technology, which is applied in the direction of material magnetic variables, can solve the problems of low longitudinal magnetization sensitivity, high magnetic field strength, and low magnetic detection efficiency, and achieve the effects of reducing the difficulty of demagnetization, low magnetic field strength, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

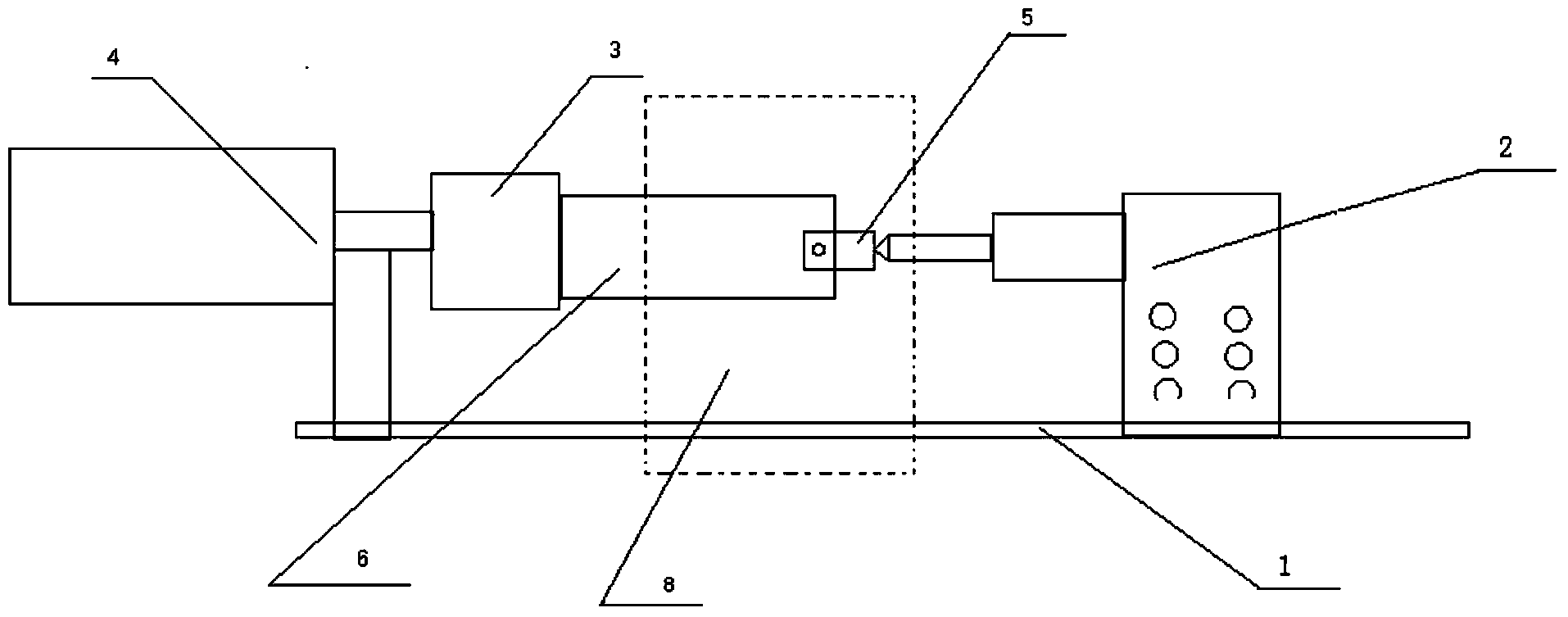

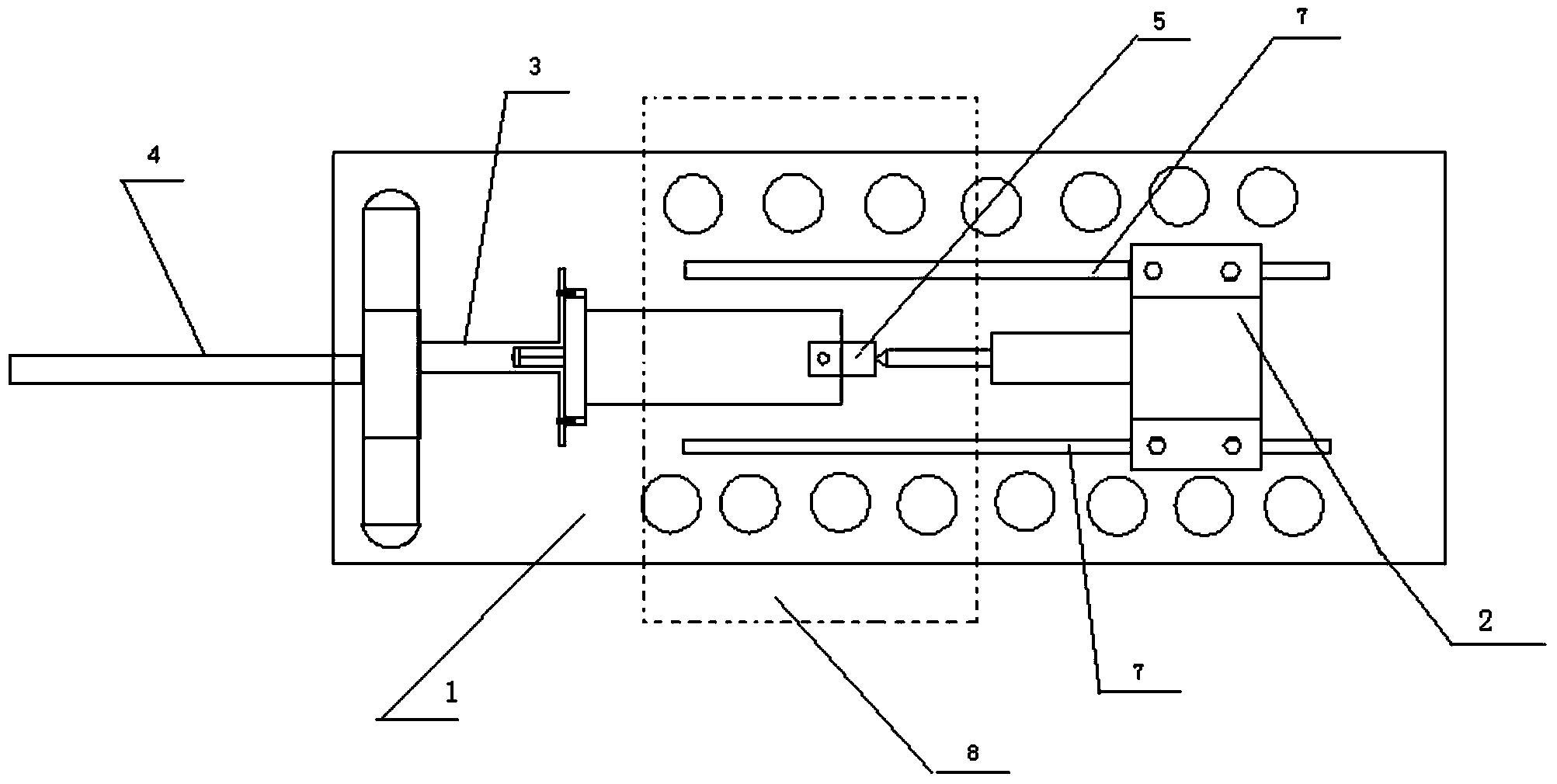

[0023] The device for improving the magnetic detection sensitivity of aeroengine blades in this embodiment has a structure such as figure 1 and figure 2 As shown, its composition is mainly composed of a fixed base plate 1 for placing the device on the bed body of the magnetic detection equipment, a tenon holding joint 3 placed on the fixed base plate for holding one end of the tenon of the blade under test, and a tenon holding joint 3 for holding the measured blade. The blade tip holding joint 2 at one end of the blade tip, and the extension plate 4 arranged on the tenon holding joint for increasing the magnetic detection aspect ratio of the measured blade is composed of the installation direction of the extension plate is opposite to the installation direction of the measured blade. The tenon holding joint and the blade tip holding joint are arranged oppositely. The tenon holding joint is a rotatable tenon holding joint, and its holding structure is a connection structure f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com