Double-sensor molten steel liquid level measuring equipment

A dual sensor, liquid level measurement technology, applied in the direction of liquid level indicator for physical variable measurement, can solve the problem of inaccurate measurement of molten steel level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

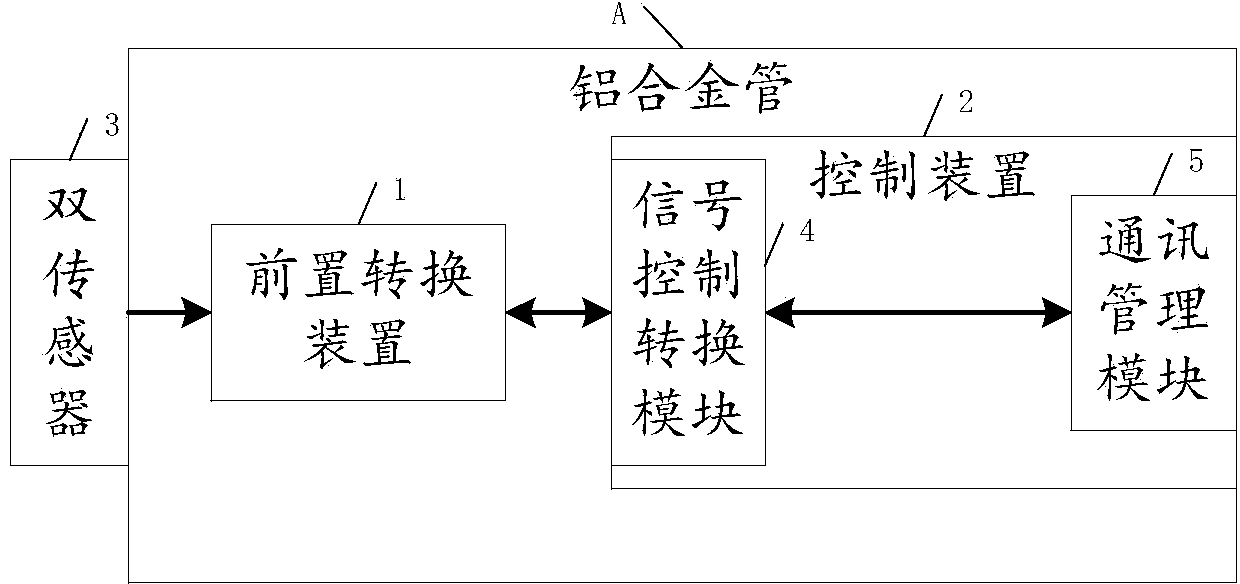

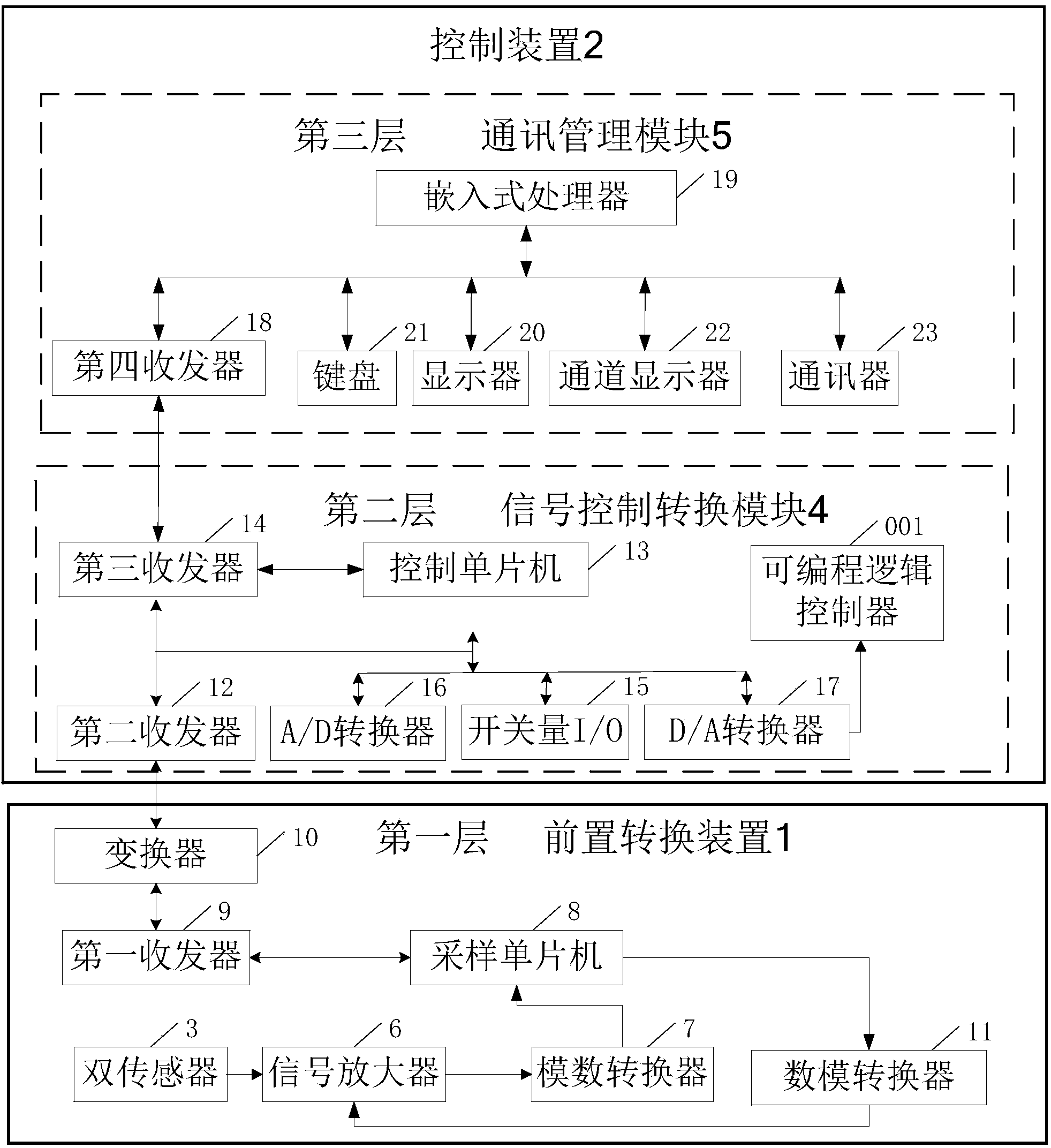

[0029] In the embodiment of the present invention, a dual-sensor molten steel level measuring device is described, including a pre-transfer device 1 and a control device 2 .

[0030] See below figure 1 , which describes the structural diagram of the dual-sensor molten steel level measuring device in the present invention.

[0031] exist figure 1 Among them, the pre-transfer device 1 includes double sensors 3, which are symmetrically installed at both ends of the nozzle of the crystallizer, and installed at one end of the aluminum alloy tube A; the aluminum alloy tube A is fixed on the crystallizer through a fixed bracket.

[0032] The front conversion device 1 is installed inside the aluminum alloy tube A and connected to the double sensor 3 through a signal line.

[0033] The control device 2 is installed inside the aluminum alloy pipe A and connected to the pre-conversion device 1 through a cable; wherein, the control device 2 includes a signal control conversion module 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com