Nondestructive testing method and system for internal cracks of thermal barrier coating

A technology for thermal barrier coatings and internal cracks, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of low accuracy of ultrasonic detection of coating cracks, failure to meet the detection conditions, and undetectable state of coating cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

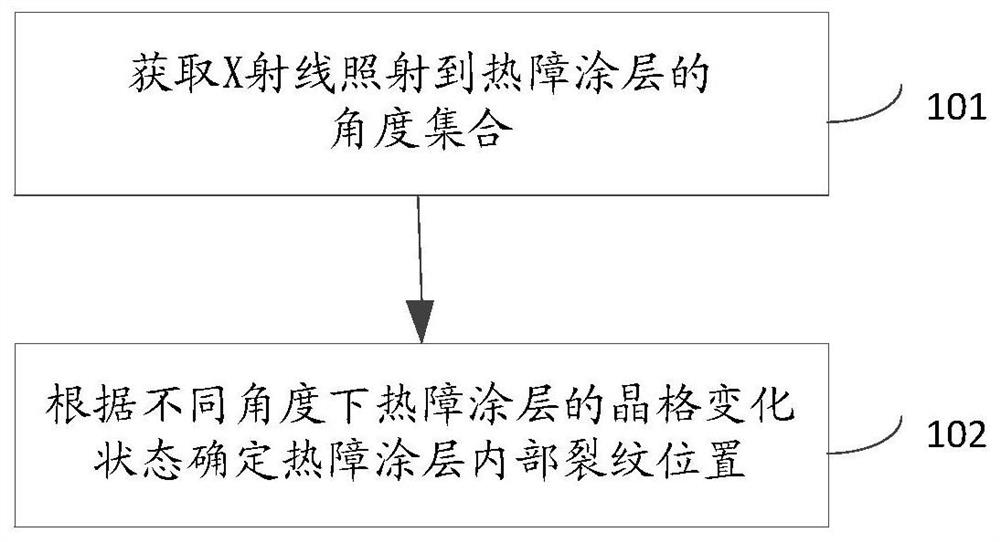

[0044] figure 1 It is a flow chart of the non-destructive detection method for internal cracks in the thermal barrier coating in the embodiment of the present invention, such as figure 1 As shown, the non-destructive detection method for internal cracks in a thermal barrier coating provided by the present invention includes:

[0045] Step 101: Obtain a set of angles at which X-rays irradiate the thermal barrier coating; the set of angles includes multiple angles, and the angles are the angles between the X-rays and the surface of the thermal barrier coating. In this embodiment, X-ray irradiation is carried out from 0-90°.

[0046] Step 102: Determine the internal crack position of the thermal barrier coating according to the lattice change state of the thermal barrier coating at different angles.

[0047] In the present invention, the thermal barrier coating sample to be tested is placed on the sample stage, the surface of the thermal barrier coating sample to be tested shou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com