A kind of modification method of iron-based material

An iron-based material and modification technology, applied in the field of materials, can solve the problems of changing the properties of iron-based materials, and achieve the effect of improving the magnetic properties of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

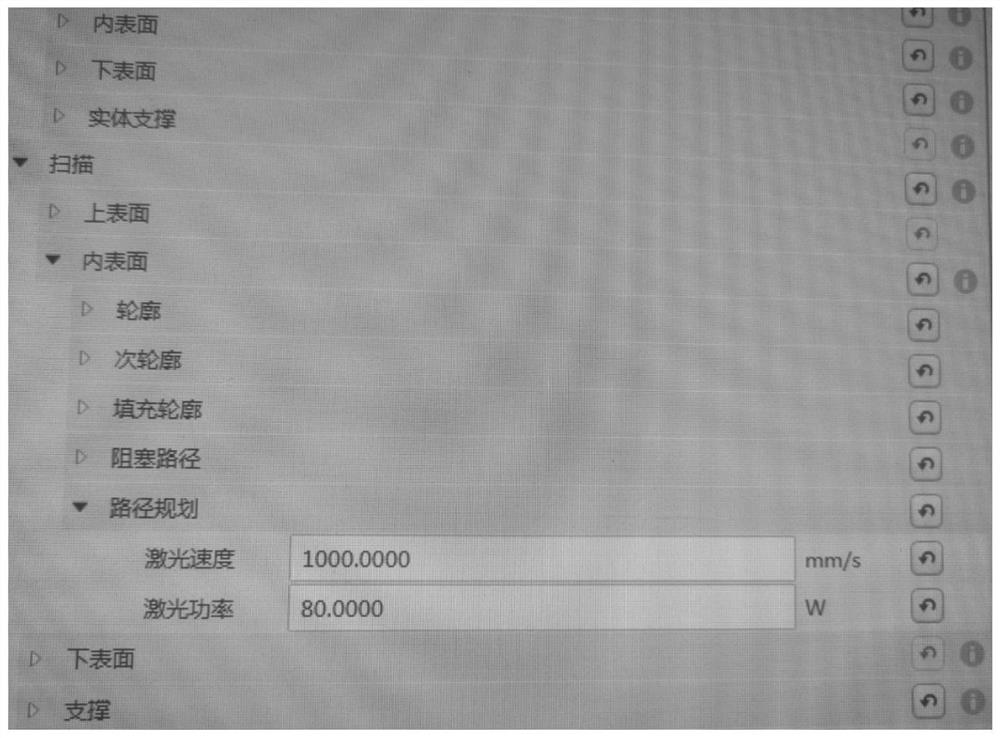

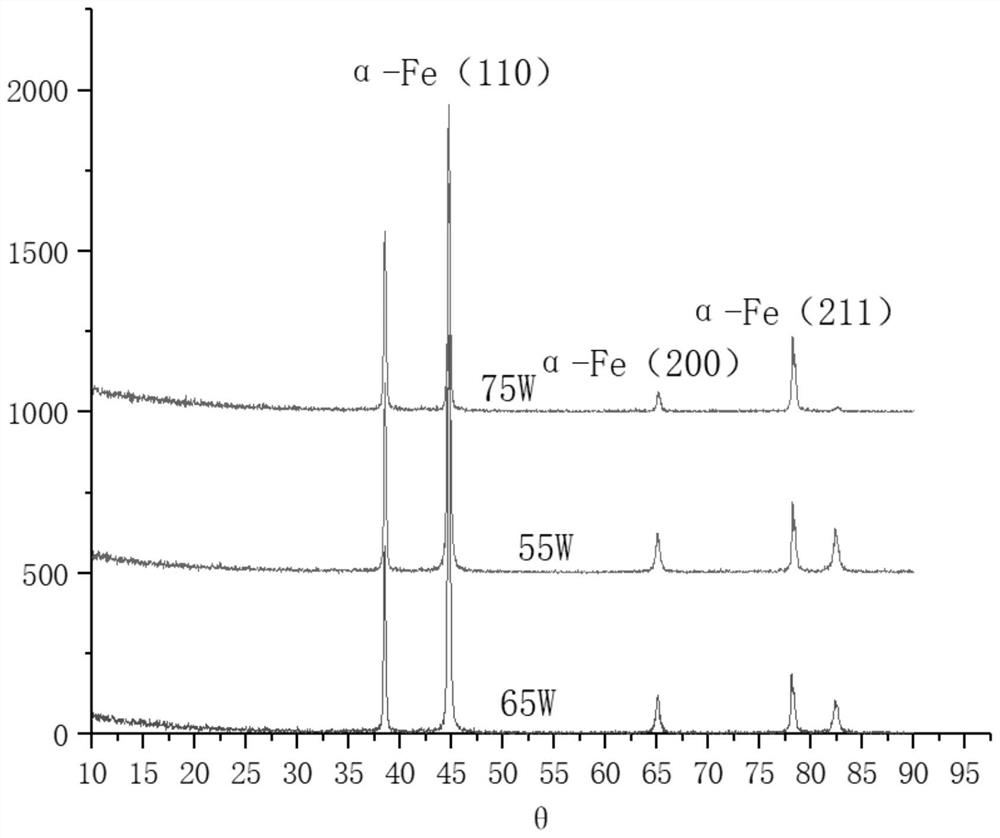

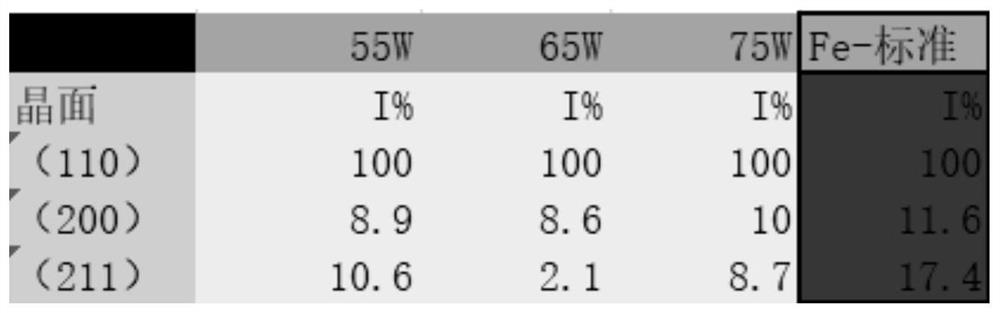

[0024] In the previous experiment, the printing direction was set to be 45° for the square circle and the structural twins respectively. The laser power was unchanged during each printing process, but the laser power was set to increase from 30W to 190W each time. Therefore, different batches The laser power is different in the sample 3D printing. During the printing process, the interface for setting parameters is as follows: figure 1 shown.

[0025] For each printing process, the laser scanning speed is 500mm / s.

[0026] Through the analysis of multiple printings, it is found that the DC soft magnetic test results of the square circle are the best when the laser power is 75W (the initial rotation angle is 45°, and the rotation increment is 0°), and the square circle μi with the printing direction of 45° reaches Compared with other conditions (referring to different printing laser powers), the printing direction of the square circle μi of 45° fluctuates around 0.1mH / m.

[...

Embodiment 2

[0033] In the experiment, the printing direction is set to be the square circle in the direction of 45° and 90° respectively. The laser scanning speed is unchanged during each printing process, but the laser scanning speed is set to increase from 300mm / s to 800mm / s by 25mm / s for each printing. s, therefore, the laser scanning speed is different in different batches of sample 3D printing.

[0034] For each printing process, the laser power is 75W.

[0035] Through the analysis of multiple printings, it is found that the DC soft magnetic test results of the square circle are the best when the laser scanning speed is 550mm / s (the initial rotation angle is 90°, and the rotation increment is 0°), and its Bs reaches all batches of samples Highest value: 2.2055T

[0036] Wherein, the printing direction is the 45° direction (90° direction), which refers to the initial rotation angle. In this embodiment, the initial rotation angle is 45° (90°), and the rotation increment is 0° as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com