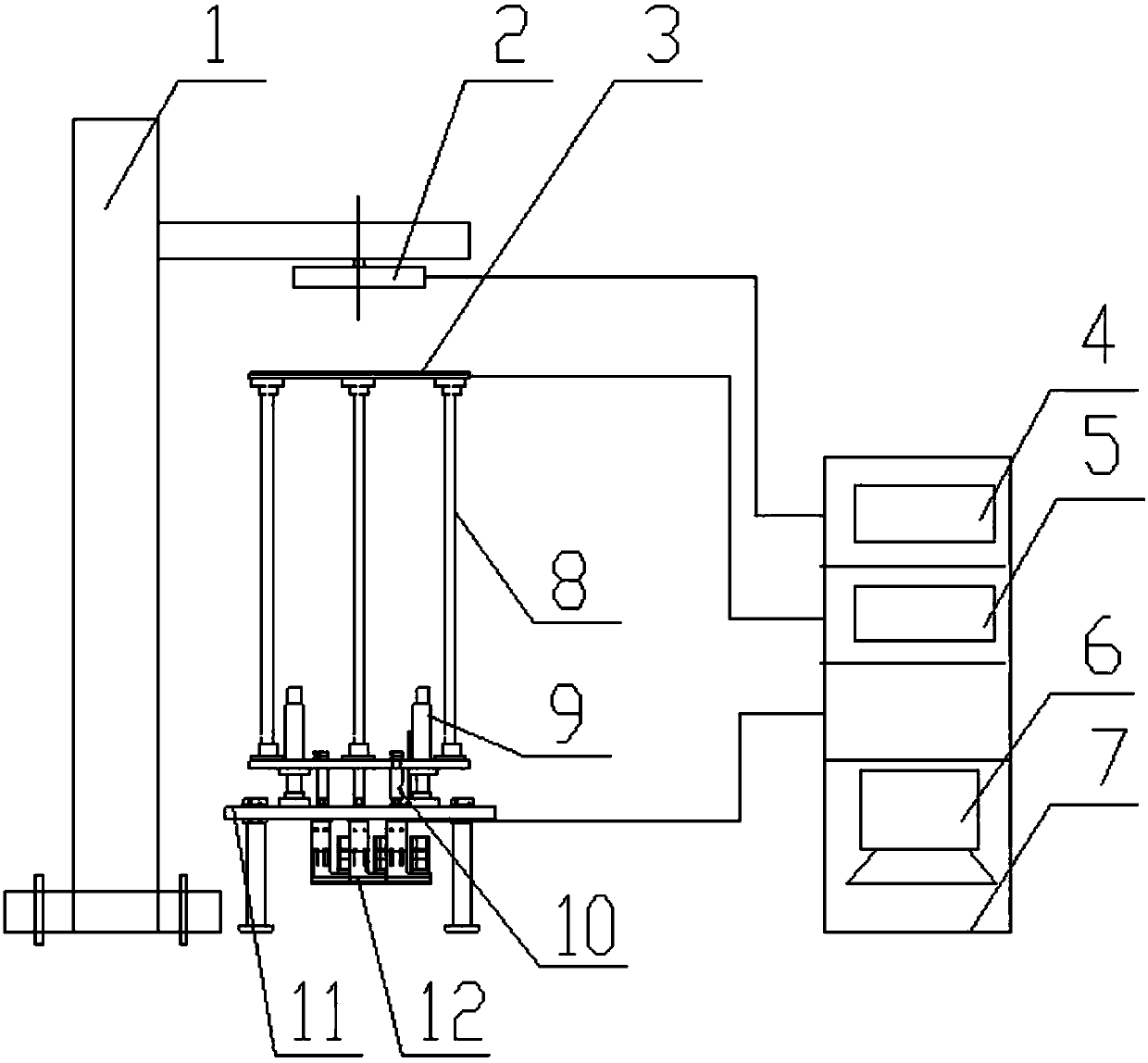

Electromagnetic induction-based calibrating device and method for cyclotron magnetic testing system

A cyclotron, electromagnetic induction technology, applied in measuring devices, instruments, measuring electrical variables, etc., can solve the problems of inaccurate test results, achieve the effect of compact structure, reduce test errors, and measure accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The present invention also provides a method for calibrating a cyclotron magnetic measurement system based on electromagnetic induction, the method comprising the following steps:

[0044] Step 1: Make preparations before the test: adjust the position of the test disc and the electrified wire disc to a suitable position, and the coil power supply loads a constant current for the electrified coil disc;

[0045] Step 2: Use the laser tracker to test the parallelism between the energized coil and the test disk. The accuracy requirement is 0.6mm. If the accuracy requirement is met, go to step 3. If the accuracy requirement is exceeded, adjust the parallelism to achieve the accuracy by padding Require;

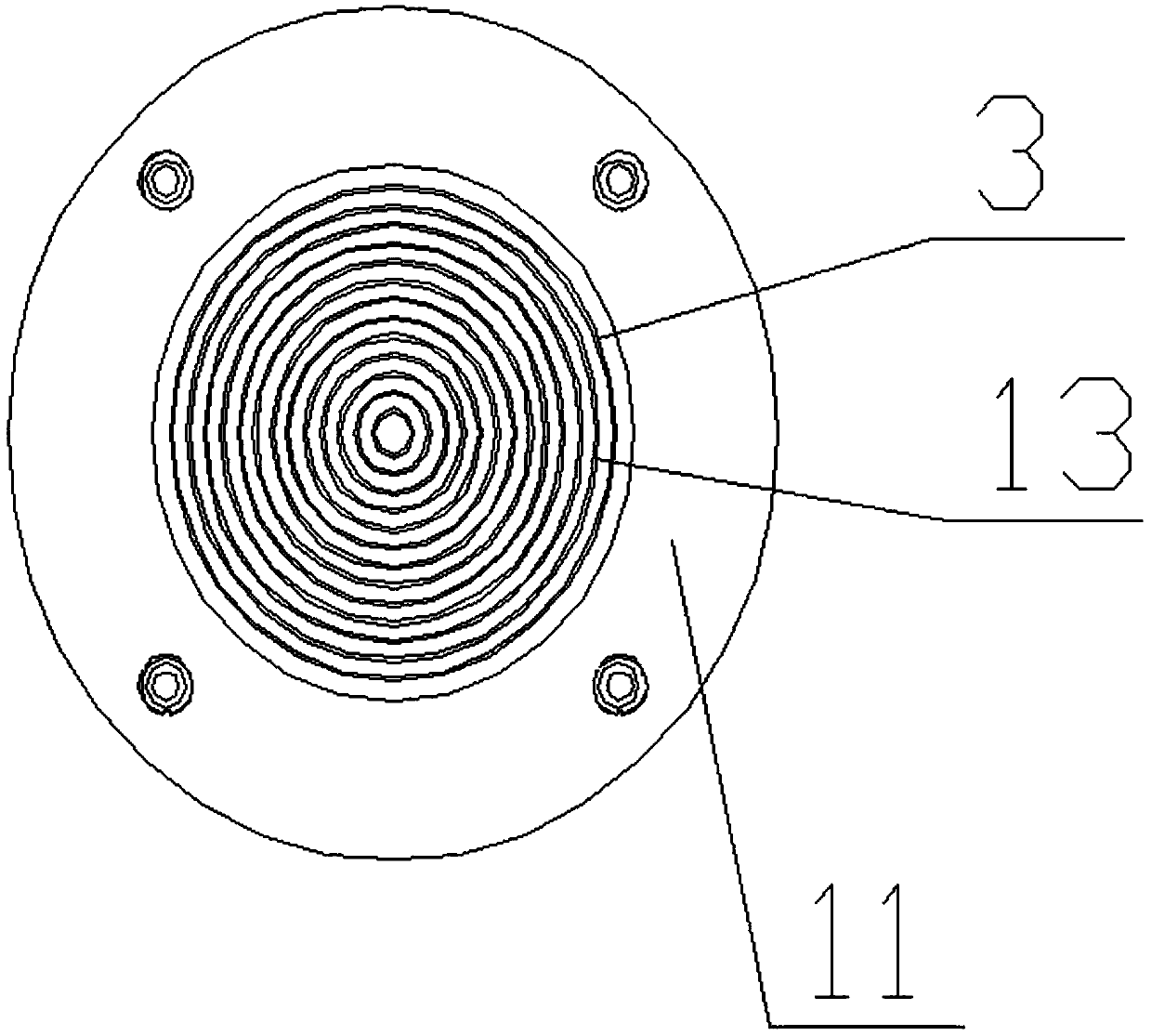

[0046] Step 3: Number the detection coils from inside to outside, sequentially N1, N2, N3, ..., N20;

[0047] Step 4: Connect the detection coil N1 to the fluxmeter, and perform preheating, zero adjustment and drift adjustment on the fluxmeter;

[0048] Step 5: Control the...

Embodiment 2

[0053] The present invention also provides a method for calibrating a cyclotron magnetic measurement system based on electromagnetic induction, the method comprising the following steps:

[0054] Step 1: Make preparations before the test: adjust the position of the test disc and the electrified wire disc to a suitable position, and the coil power supply loads a constant current for the electrified coil disc;

[0055] Step 2: Use the laser tracker to test the parallelism between the energized coil and the test disk. The accuracy requirement is 0.6mm. If the accuracy requirement is met, go to step 3. If the accuracy requirement is exceeded, adjust the parallelism to achieve the accuracy by padding Require;

[0056] Step 3: Number the detection coils from inside to outside, sequentially N1, N2, N3, ..., N20;

[0057] Step 4: Connect 20 detection coils to 20 fluxmeters respectively, and perform preheating, zero adjustment and drift adjustment on all 20 fluxmeters;

[0058] Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com