Weft yarn clamping mechanism

A technology of clamping mechanism and weft yarn, which is applied in the field of weaving, can solve the problems that the production efficiency cannot be effectively improved, and achieve the effect of shortening the reciprocating time and improving the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

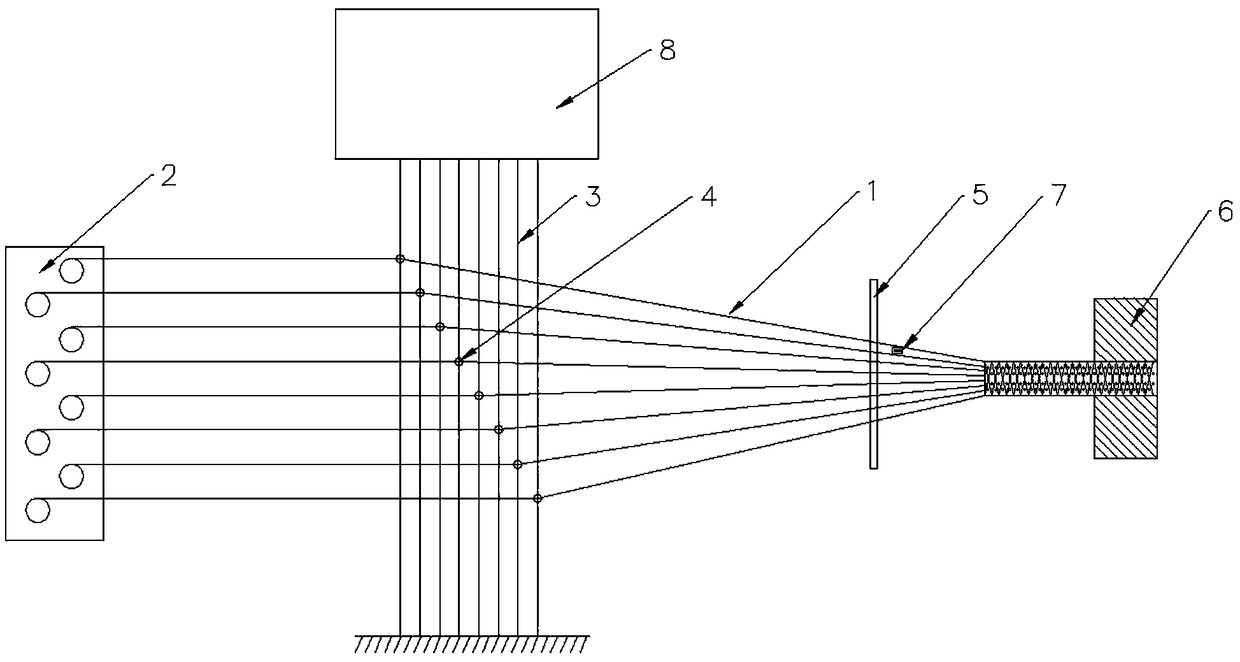

[0047] see Image 6 , a weft yarn clamping mechanism 100, which is used to clamp and pull the weft yarn, and is installed on the weft insertion mechanism of a 2.5D knitting machine. Weft mechanism 110, the weft yarn clamping mechanism 100 includes a belt conveyor 20, a clamping rod 10 and a pressing block 30, and the belt conveyor is fixedly installed on the support of the weft insertion mechanism.

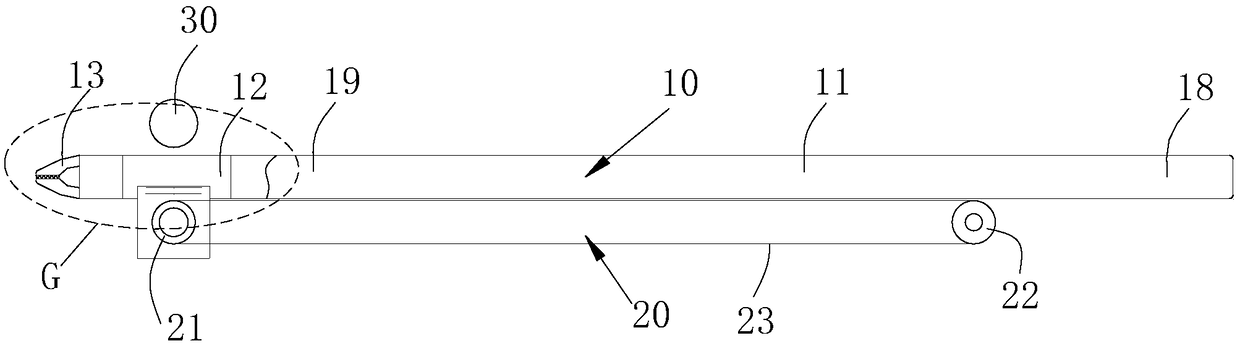

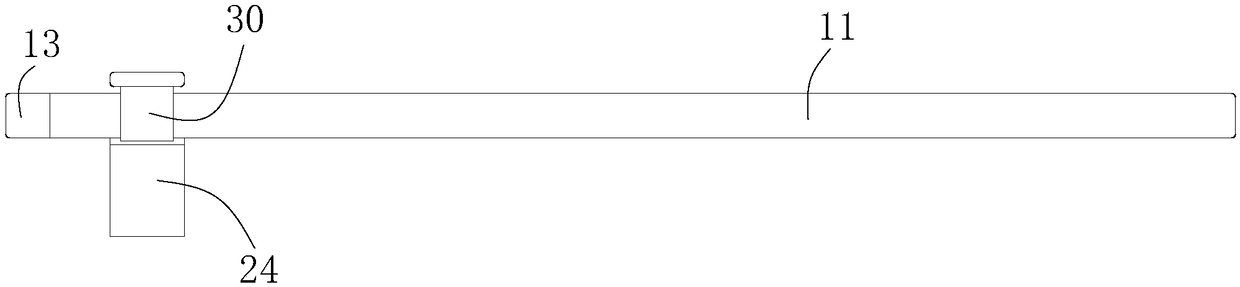

[0048] see Figure 2-Figure 5 The belt conveyor 20 includes a driving wheel 21, a driven wheel 22, and a servo motor 24 that drives the driving wheel to rotate. Wherein the driving wheel 21 and the driven wheel 22 are all installed on the support through the rotating shaft, and the servo motor 21 is also installed on the support.

[0049] The clamping rod 10 is arranged on the belt 23 of the belt conveyor, and the pressing block 30 is rotatably installed on the support, and the pressing block 30 compresses the clamping rod 10 on the belt; when the belt rotates, it can drive the ...

Embodiment 2

[0069] The mechanical structure of this embodiment is the same as that of Embodiment 1, and the difference is that when pulling the weft yarn, the operation mode of the chuck is different, and the specific description is as follows:

[0070] Such as Figure 7 As shown, in this embodiment, between the belt conveyor 820 and the weft selection mechanism 120, a chuck starting point A2 position 821, a chuck retraction point B2 position 822, an intermediate stop point E position 825, and a middle stop point E position 825 are arranged sequentially. Retraction point F position 826, chuck opening point C2 position 823 and chuck closing point D2 position 824; the weft selection mechanism has a second pressure plate 182 for pressing the weft yarn;

[0071] Before the work starts, the chuck is on standby at position 821 of the starting point A2 of the chuck. When working, driven by the belt conveyor 820, the clamping rod 810 starts to move, firstly the chuck moves from the starting point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com