Wet desulphurization slurry supply adjusting method

A wet desulfurization and slurry conditioning technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of fluctuating discharge of pollutants at the outlet, slow response of the slurry supply system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

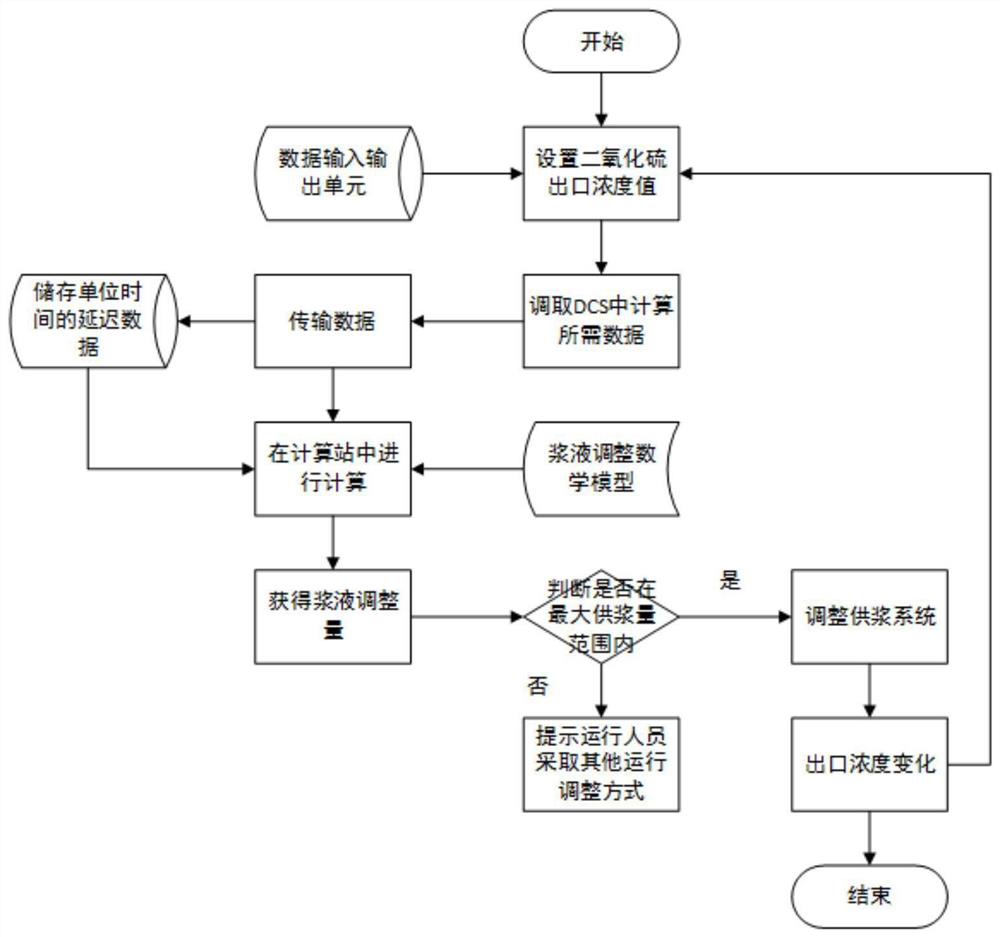

Method used

Image

Examples

Embodiment 1

[0047] Taking a domestic power plant as an example, a 330MW unit in this plant is a subcritical boiler produced by Harbin Boiler Factory, and a set of wet limestone-gypsum flue gas desulfurization system is built to support the removal of two boilers by limestone-gypsum wet flue gas desulfurization process Sulfur dioxide in the tail flue gas, under the design conditions, the flue gas volume at the inlet of the desulfurization system is 1211221m 3 / h (standard state, dry basis, 6% O 2 ).

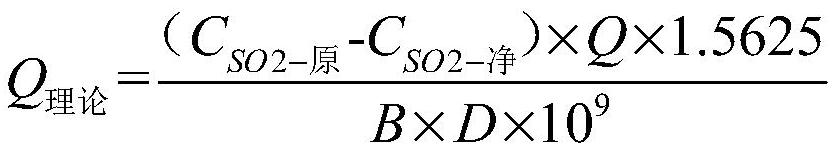

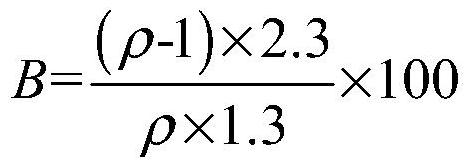

[0048] Firstly, according to the operation requirements, the operator sets the flue gas sulfur dioxide concentration C in the outlet flue of the wet desulfurization system SO2-设置 25mg / m 3 . The flue gas sulfur dioxide concentration C at the inlet flue of the wet desulfurization system is collected through the original DCS system data SO2-原 , flue gas sulfur dioxide concentration C in the outlet flue SO2-净 , The flue gas sulfur dioxide concentration C of the outlet flue before unit time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com