River snail rice noodle soup blend production system and production technology thereof

A production system and technology of snail powder, applied in the production system of snail powder soup and its production process, can solve the problems of chili oil, such as a large number of human resources, inconsistency, and harsh production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with embodiment.

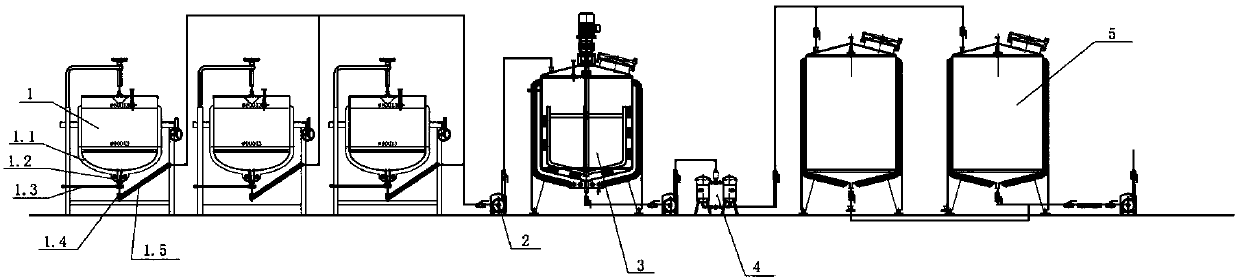

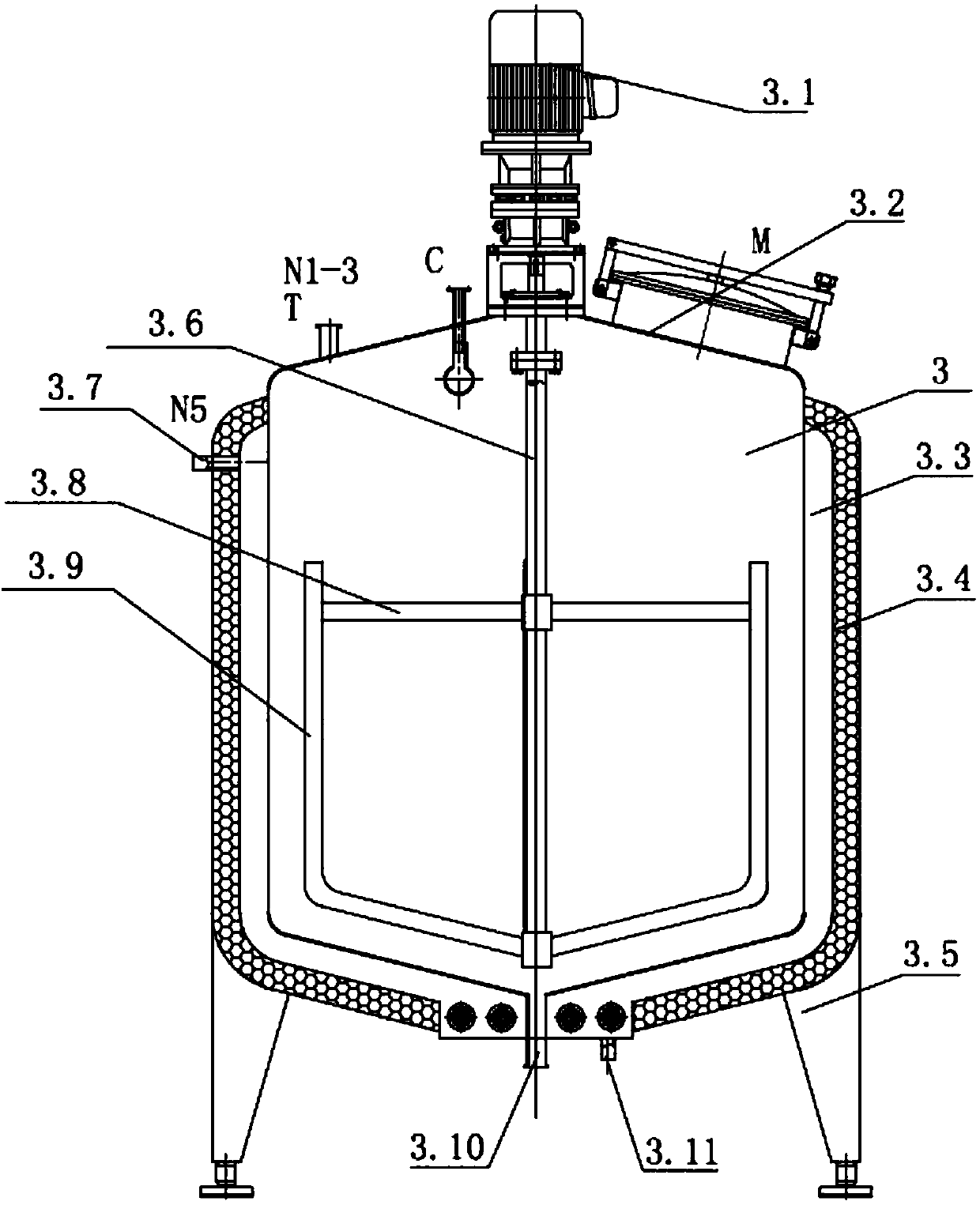

[0029] Such as Figure 1-2 As shown, a snail noodle soup production system includes a cooking pot 1, a pump 2, a blending tank 3, a filter 4 and a storage tank 5. This system uses a closed production environment to avoid secondary pollution. After the soup is boiled, until the finished product is produced, all are in the closed 316 food-grade pipeline, the product will not be polluted, and the original taste of the product will always be maintained.

[0030] The output end of boiling pot 1 is connected with the input end of pump 2. The cooking pot 1 is a stainless steel cooking pot, and the quantity is 3. According to the needs of users, the quantity of the cooking pot 1 can be increased according to the needs of the production amount. The cooking pot 1 preliminarily boils the soup to obtain preliminary soup. The outer wall of the boiling pot 1 is provided with an interlayer 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com