Aluminum profile spraying system and aluminum profile spraying method

A technology for aluminum profiles and profiles, applied in coating, spraying device, device for coating liquid on the surface, etc., can solve the problem of uneven coating thickness on the surface of aluminum profiles, avoid the problem of uneven spraying, improve spraying quality and effect, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

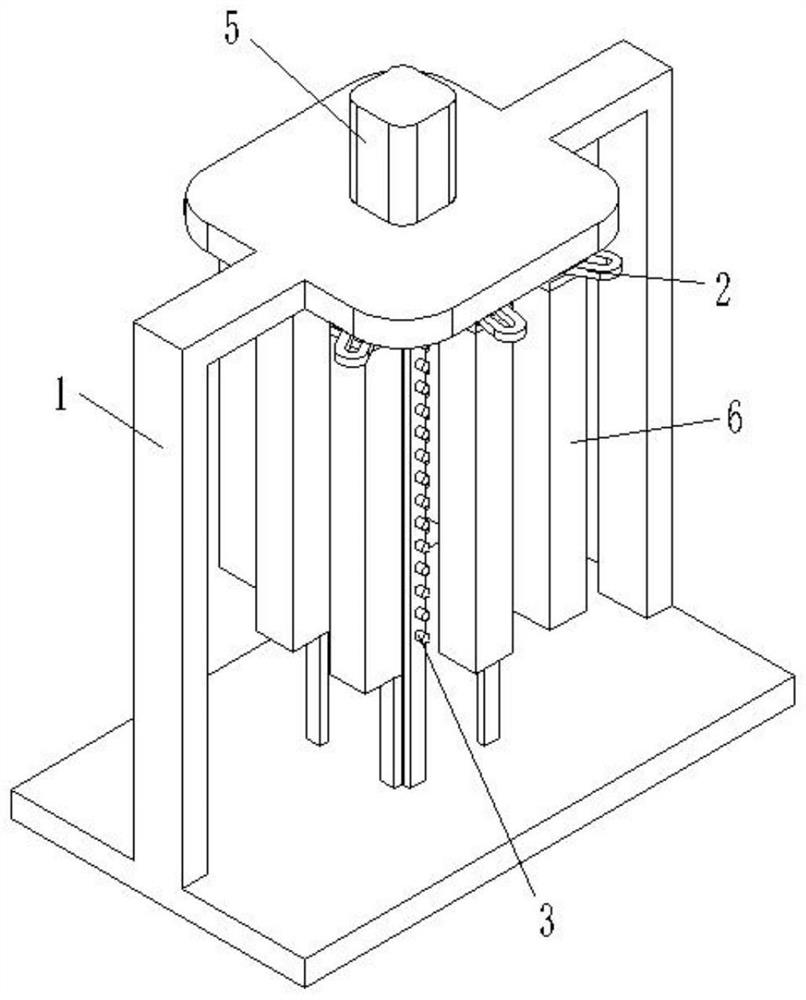

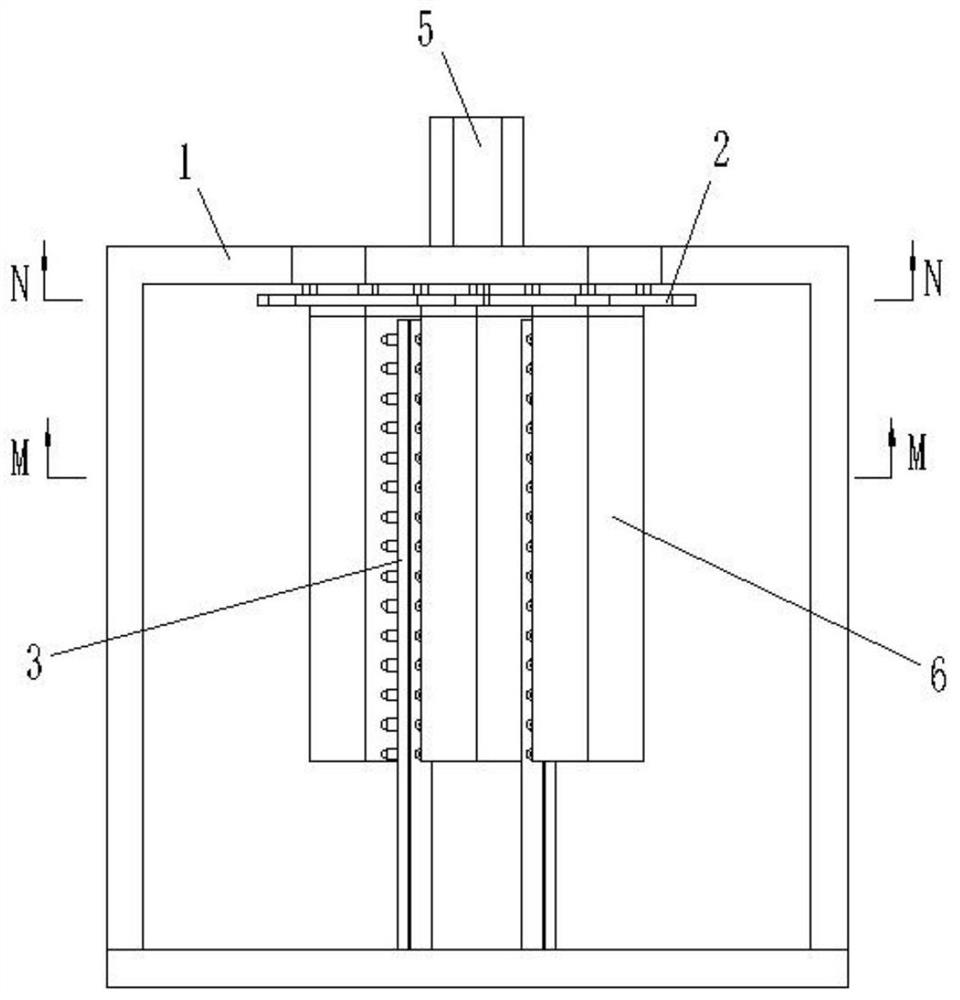

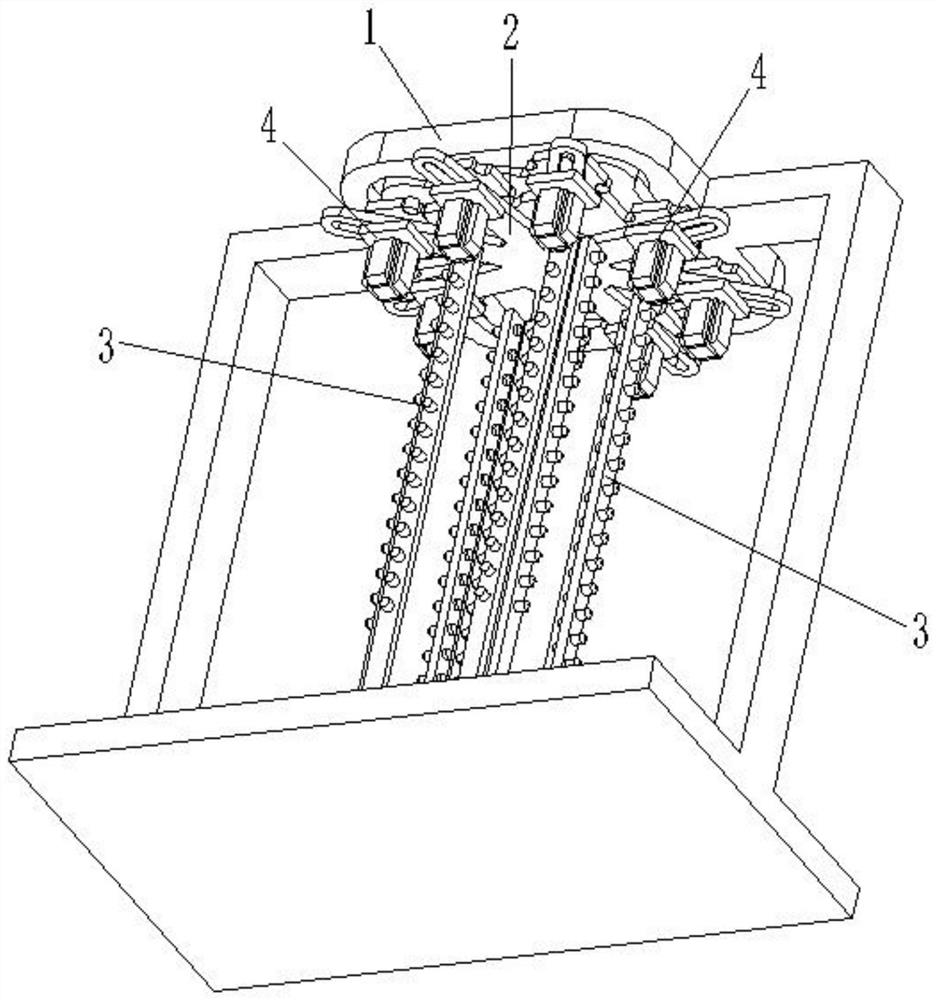

[0037] combine Figure 1 to Figure 12 As shown, the aluminum profile spraying system in this embodiment is used for surface spraying treatment of square hollow profiles, such as aluminum profiles. The aluminum profile spraying system includes a support frame 1 , a rotating disk 2 , a spray head assembly 3 , a connecting assembly 4 and a driving motor 5 .

[0038] The driving motor 5 is fixed on the supporting frame 1 , and the rotating disk 2 is coaxially fixedly connected with the output shaft of the driving motor 5 to form a connection relationship in which the driving motor 5 drives the rotating disk 2 to reciprocate relative to the supporting frame 1 . At the same time, eight branches uniformly distributed along the circumferential direction are provided on the rotating disk 2, and a radial chute 21 is provided ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com