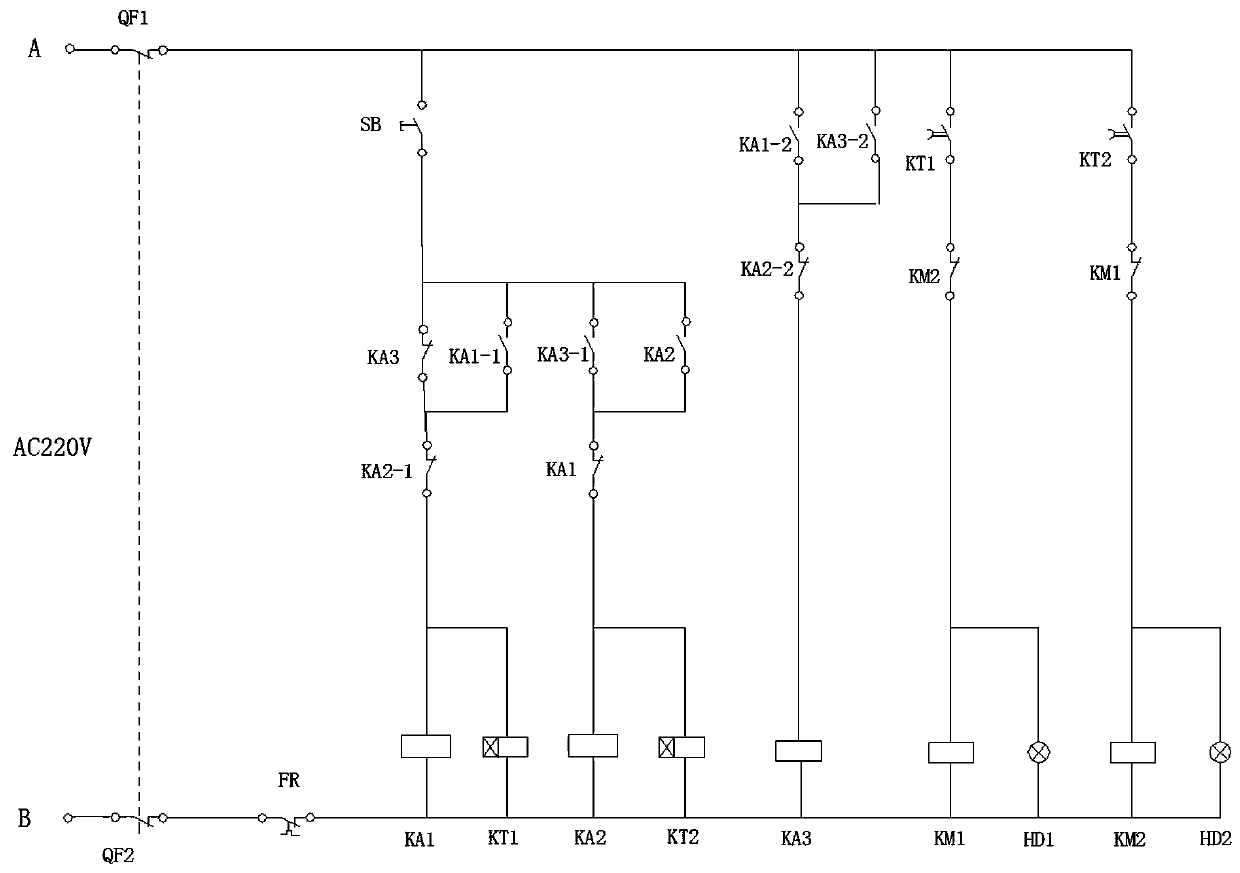

Single-button forward and reverse rotation automatic stop control circuit

A control circuit, forward rotation technology, applied in the control system, motor generator control, electrical components and other directions, can solve problems such as power supply short-circuit accident, easy operation error, mechanical accident, etc., to achieve reliable operation, ensure normal operation, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0017] Depend on figure 1 It can be seen that the single-button forward and reverse self-stop control circuit of this embodiment includes the secondary line power port A and power port B connected to an external 220V AC power supply, and also includes the forward rotation contactor KM1, the reverse rotation contactor KM2, and the forward rotation intermediate relay KA1, reverse intermediate relay KA2, reversing intermediate relay KA3, thermal relay FR, forward rotation time relay KT1, reverse rotation time relay KT2, double-pole circuit breakers QF1 and QF2, button SB, and forward rotation indicator HD1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com