Hydraulic equipment for removing and installing bucket tooth pins

A technology of hydraulic equipment and pin shafts, which is applied in the field of self-electric disassembly equipment, can solve the problems of low work efficiency, inconvenience, time-consuming and laborious, etc., and achieve the effects of improving efficiency, convenient use, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

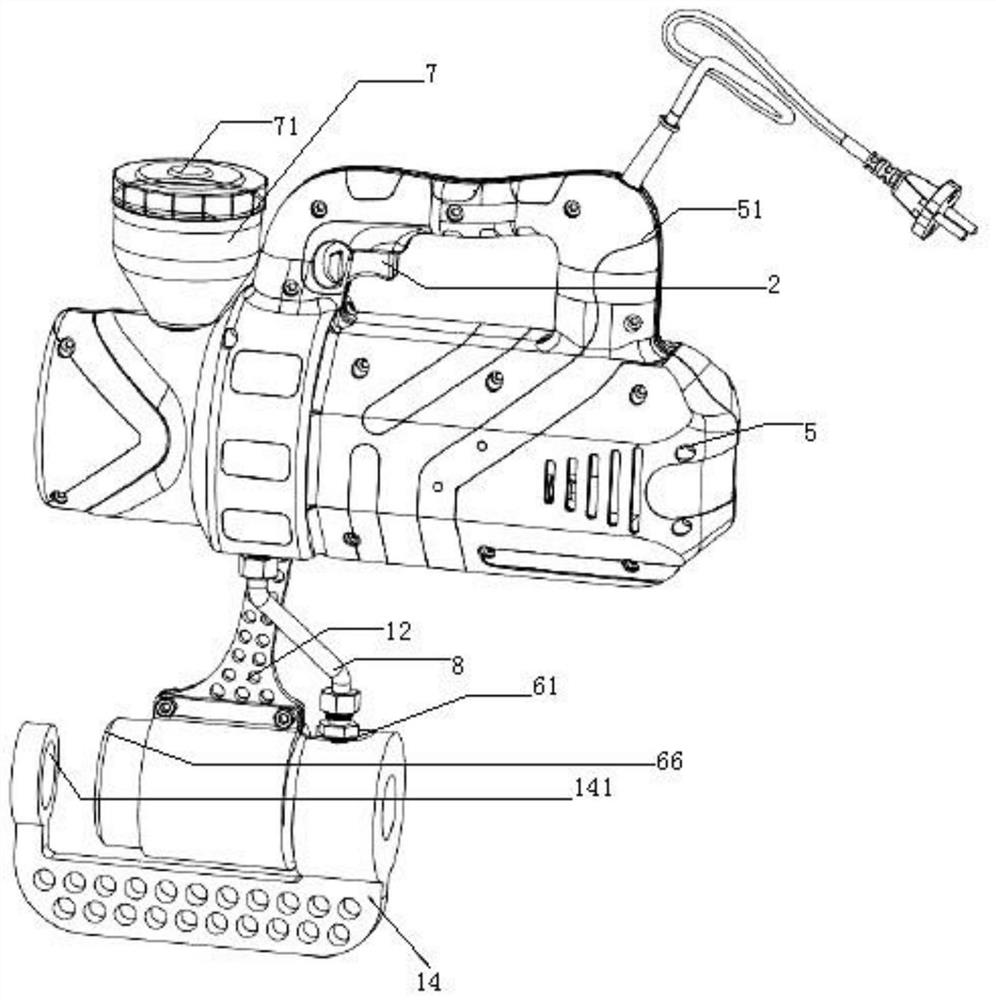

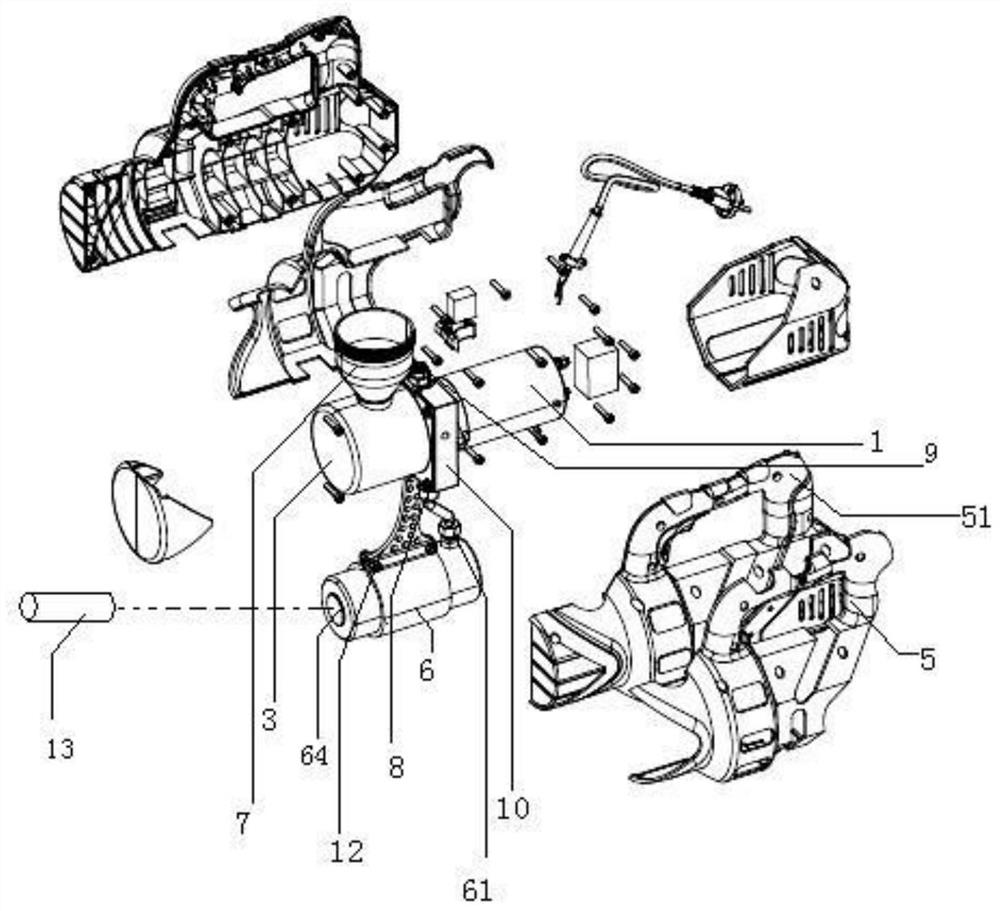

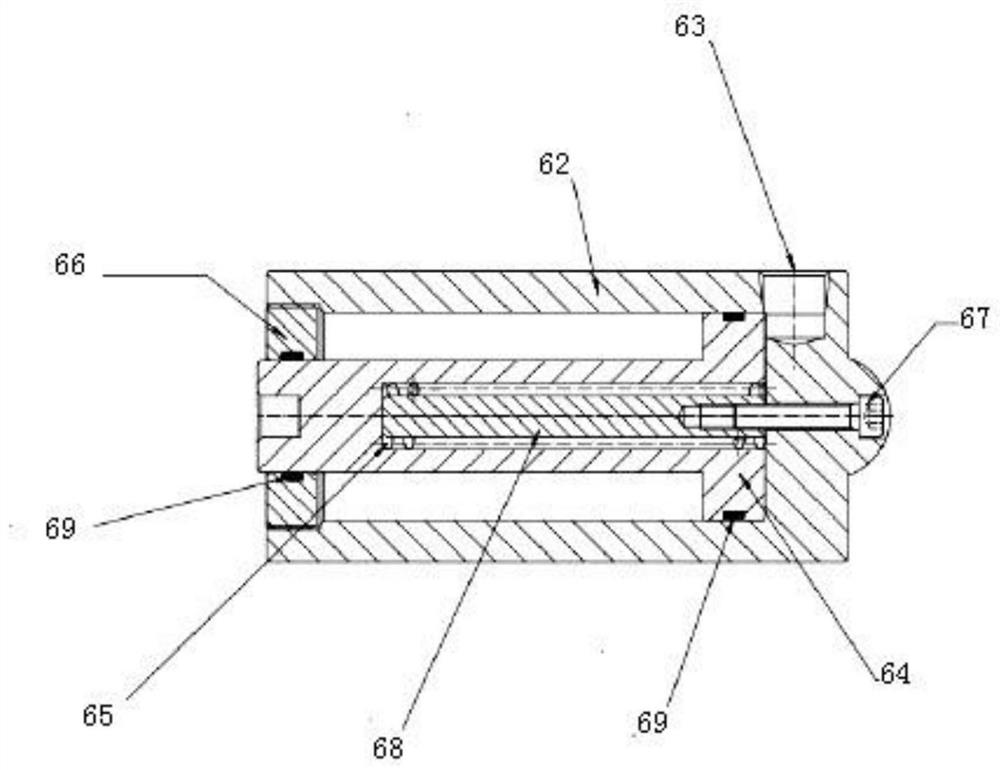

[0021] figure 1 , 2 , 3, 4, 5, 6, 7, remove and install the hydraulic equipment of the bucket tooth pin shaft, including DC24V / 800W DC motor 1, dual-position power switch 2, oil drum 3, small bidirectional gear pump 4 , shell 5, oil cylinder 6, conical oiling pot 7, high-pressure oil pipe 8, high-pressure relief valve 9, oil circuit integrated distribution block 10; the middle of the upper end of the oil barrel 3 has an oil filling hole with an inner thread, and the oiling pot is 7. It is screwed into the inner thread of the oil injection hole through the outer thread of the oil pipe in the lower end and installed on the outer upper end of the oil drum 3; the left end of the cylindrical hollow oil drum 3 is a closed structure, the right end is an open structure, and the oil circuit is integrated The left part of the distribution block 10 is installed on the right outer end of the oil drum 3 through the screw nut, the motor 1 is horizontally installed on the right outer end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com