Patents

Literature

39results about How to "Easy jacking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

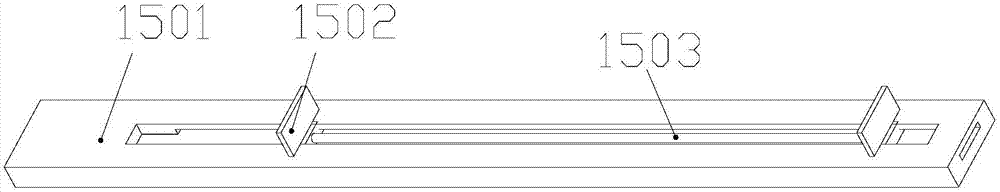

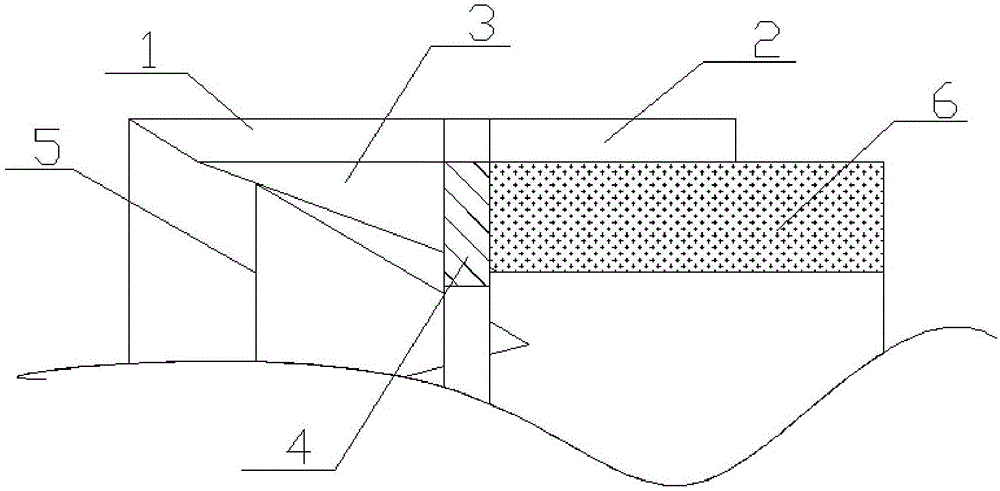

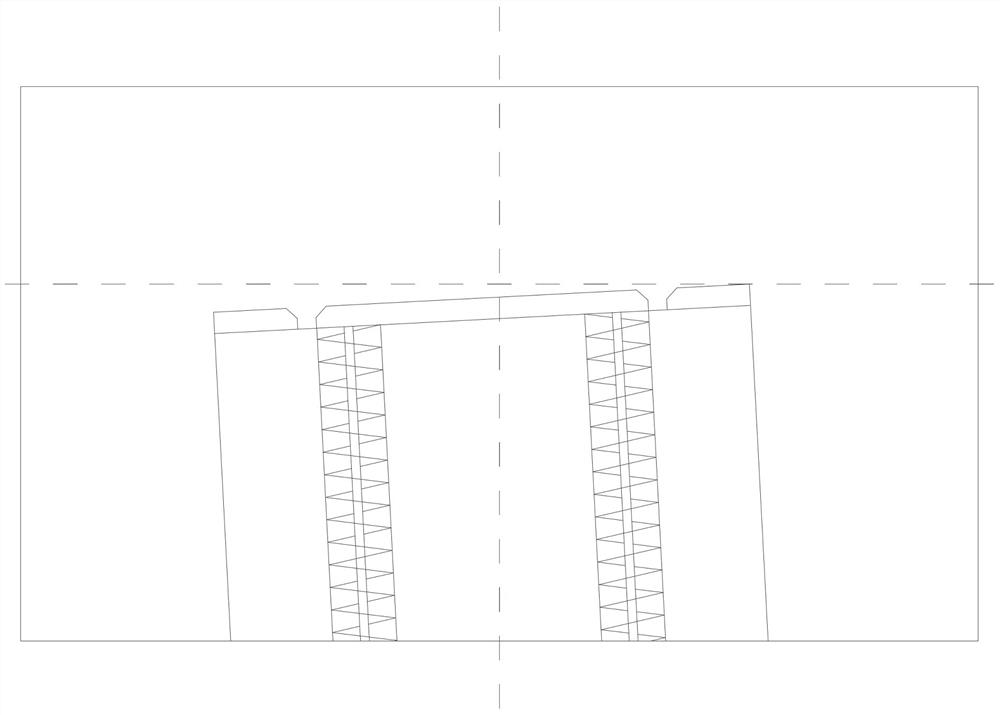

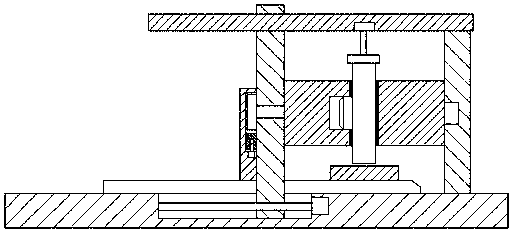

Cutting and forming device

The invention discloses a cutting and forming device comprising a chassis and a frame plate arranged on the chassis. The front and rear end faces of the chassis are fixedly provided with fixed plates in which fixing holes are formed, and the chassis is also provided with a sliding chute at the left side of the frame plate; the sliding chute is internally provided with a sliding carrier capable of sliding right and left, and the top of the sliding carrier is provided with an upper groove in which a top disc is slidably arranged; and the right end of the top disc is fixedly connected to the frame plate. The cutting and forming device has the advantages of simple structure, low production cost and easy operation, and the cutting efficiency of plates is improved greatly; the waste of human resources is reduced, and the cutting efficiency is good; and the cutting accuracy is high, and the requirements of the modern manufacturing are met.

Owner:JIANGSU DNCON LASER TECH

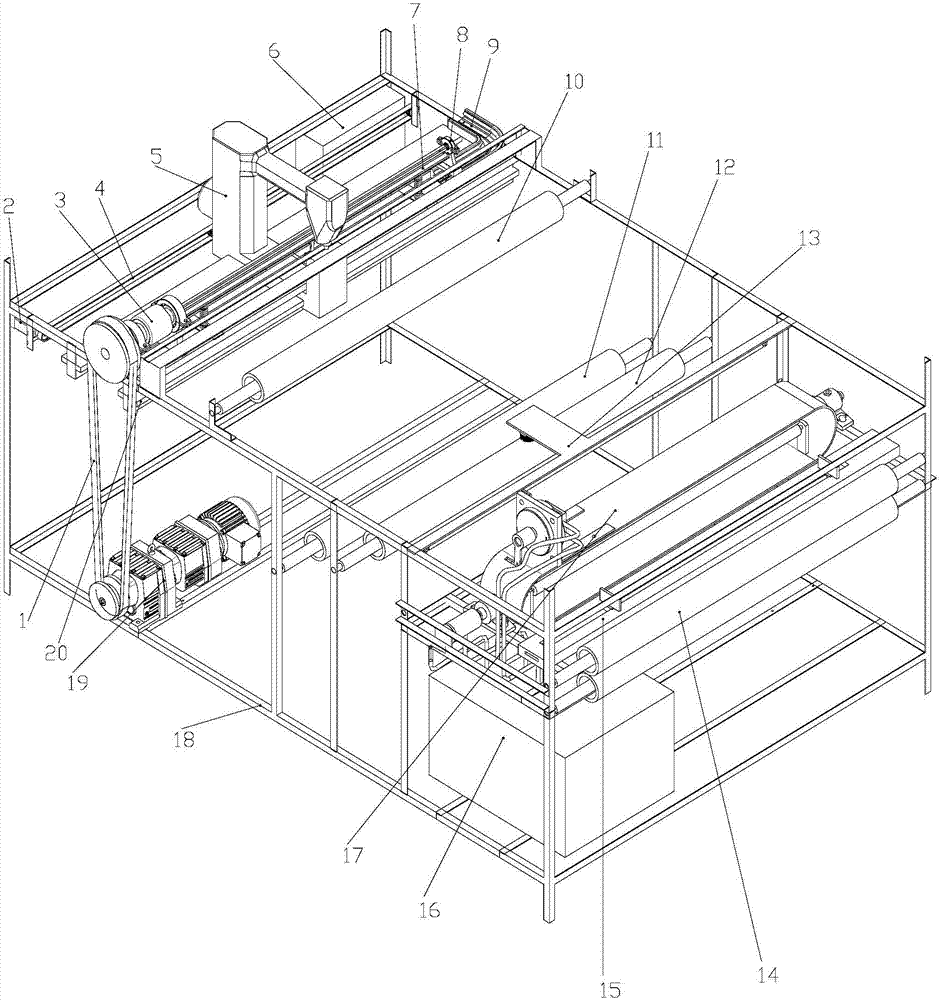

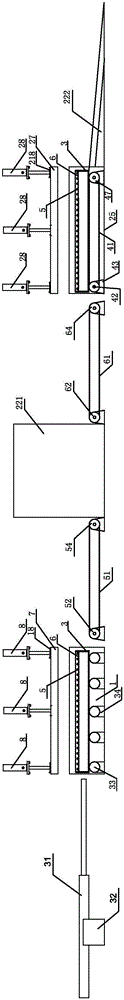

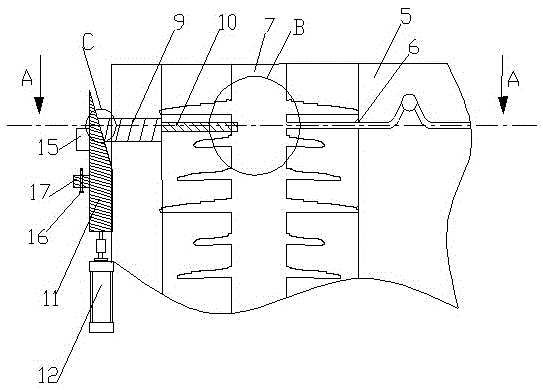

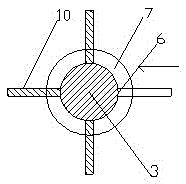

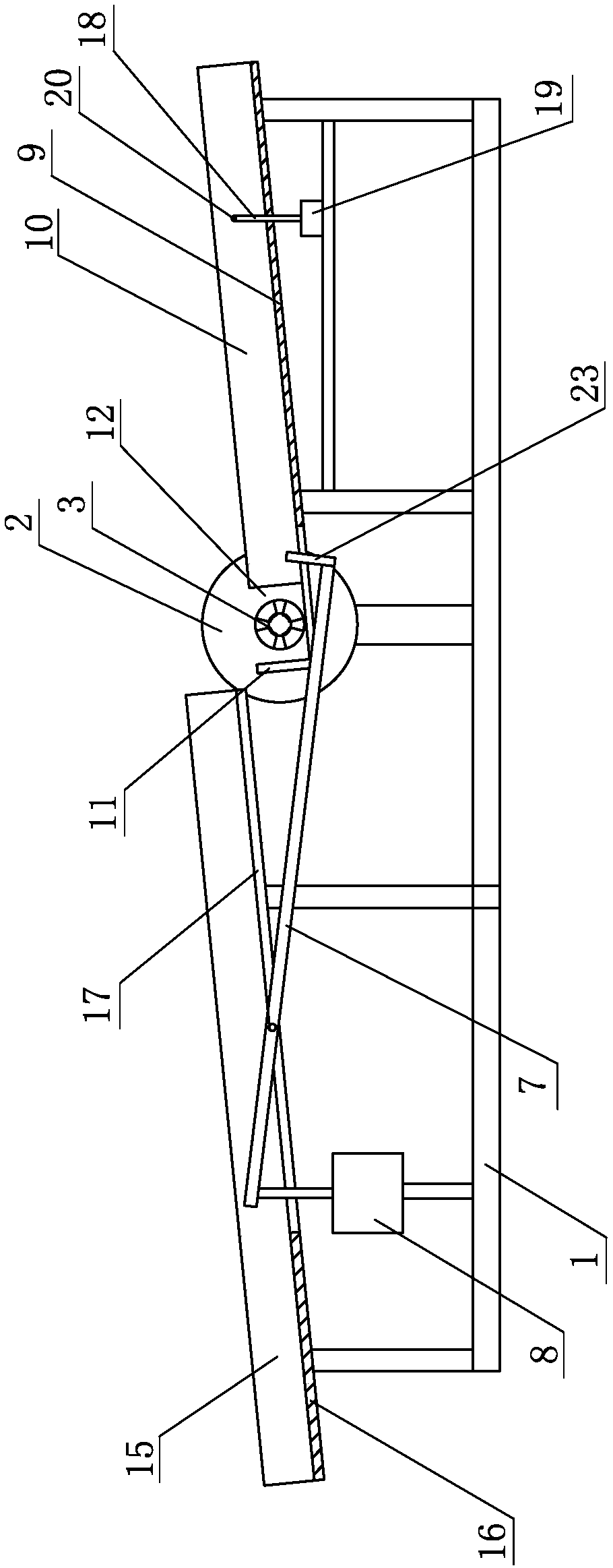

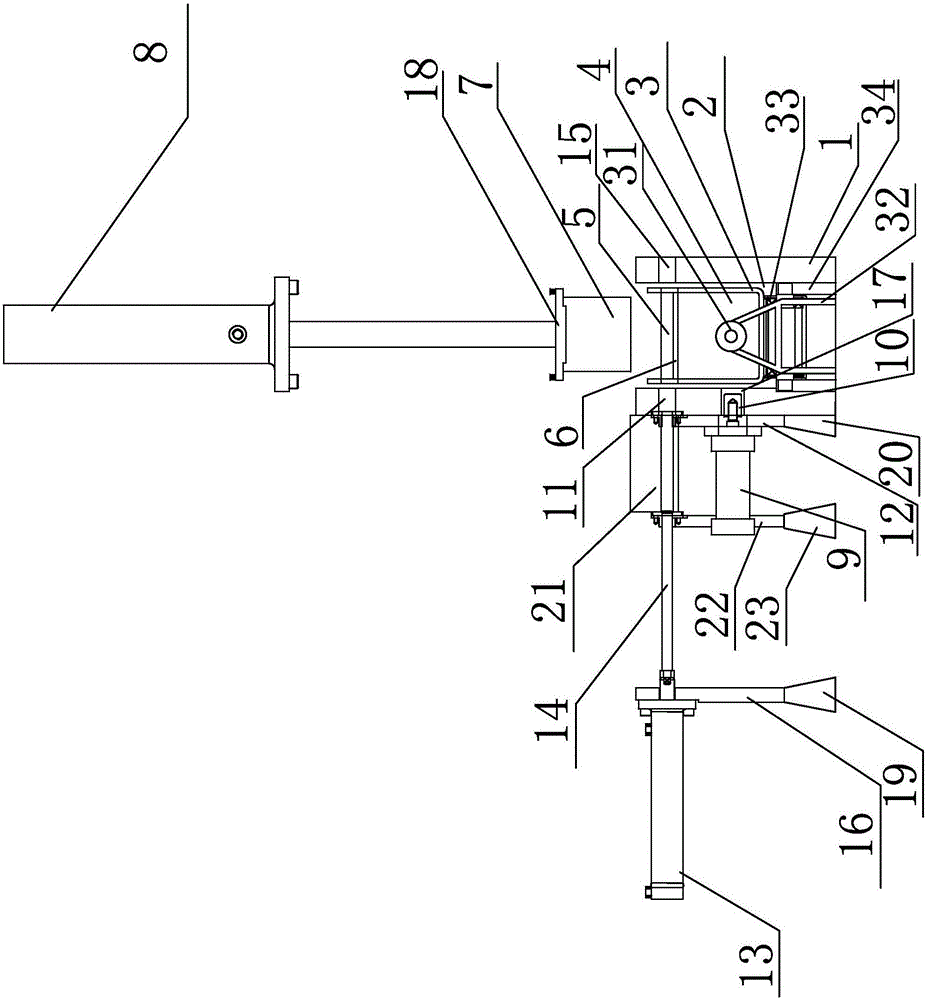

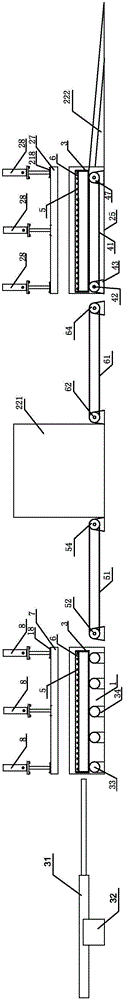

Banner rolling-up machine and working method

ActiveCN108002092AAchieve lateral movementEasy to control from a distanceOther printing apparatusArticle deliveryProduction rateEngineering

The invention relates to a banner rolling-up machine and a working method, and belongs to the technical field of printing equipment. The banner rolling-up machine comprises a supporting frame, the supporting frame is provided with a variable-section banner rolling-up device and an edge hemming device; when the variable-section banner rolling-up device collects banners, a wound roll of the variable-section banner rolling-up device can be enlarged, so that the banners are not slid under action of a pressing device, after collecting is completed, the sectional area is reduced, and the banners which are rolled into a cylinder shape can be easily taken down; the edge hemming device conducts hemming treatment on edges of the two ends of the banners, so that the banners have the cylinder-shaped edges, and hanging is convenient; and the supporting frame is further provided with a central controller which is used for reducing the size of whole equipment and improving the integration and automation degree so that the whole equipment can be easily controlled and operated. According to the banner rolling-up machine and the working method, subsequent processing and collecting and automatic edgehemming of the printed banners can be achieved, collecting, winding and easily unloading of the banners can be achieved, the cost is greatly saved, and the productivity of the banners is increased.

Owner:SHANDONG UNIV OF SCI & TECH

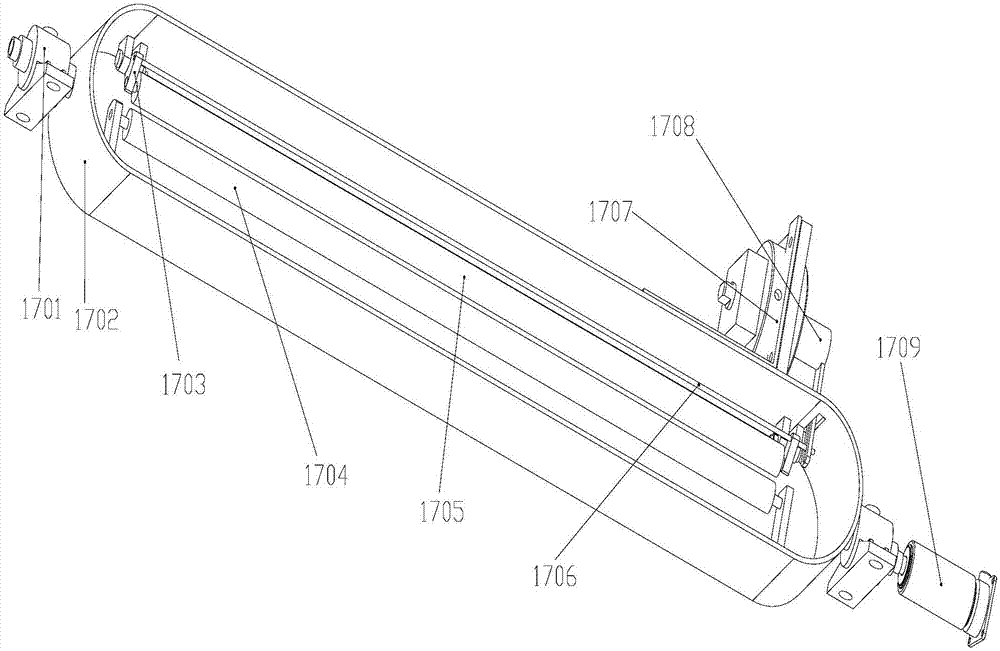

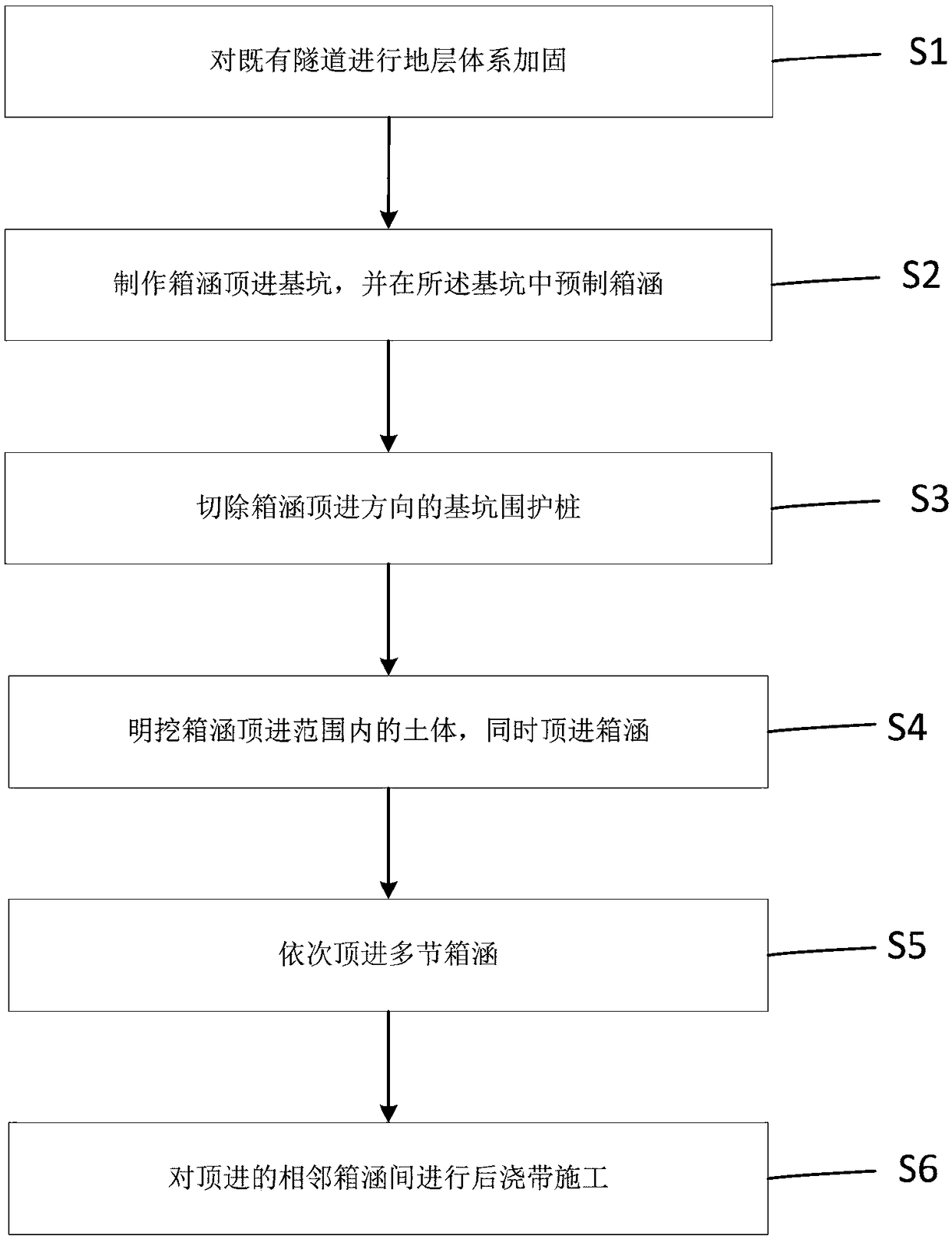

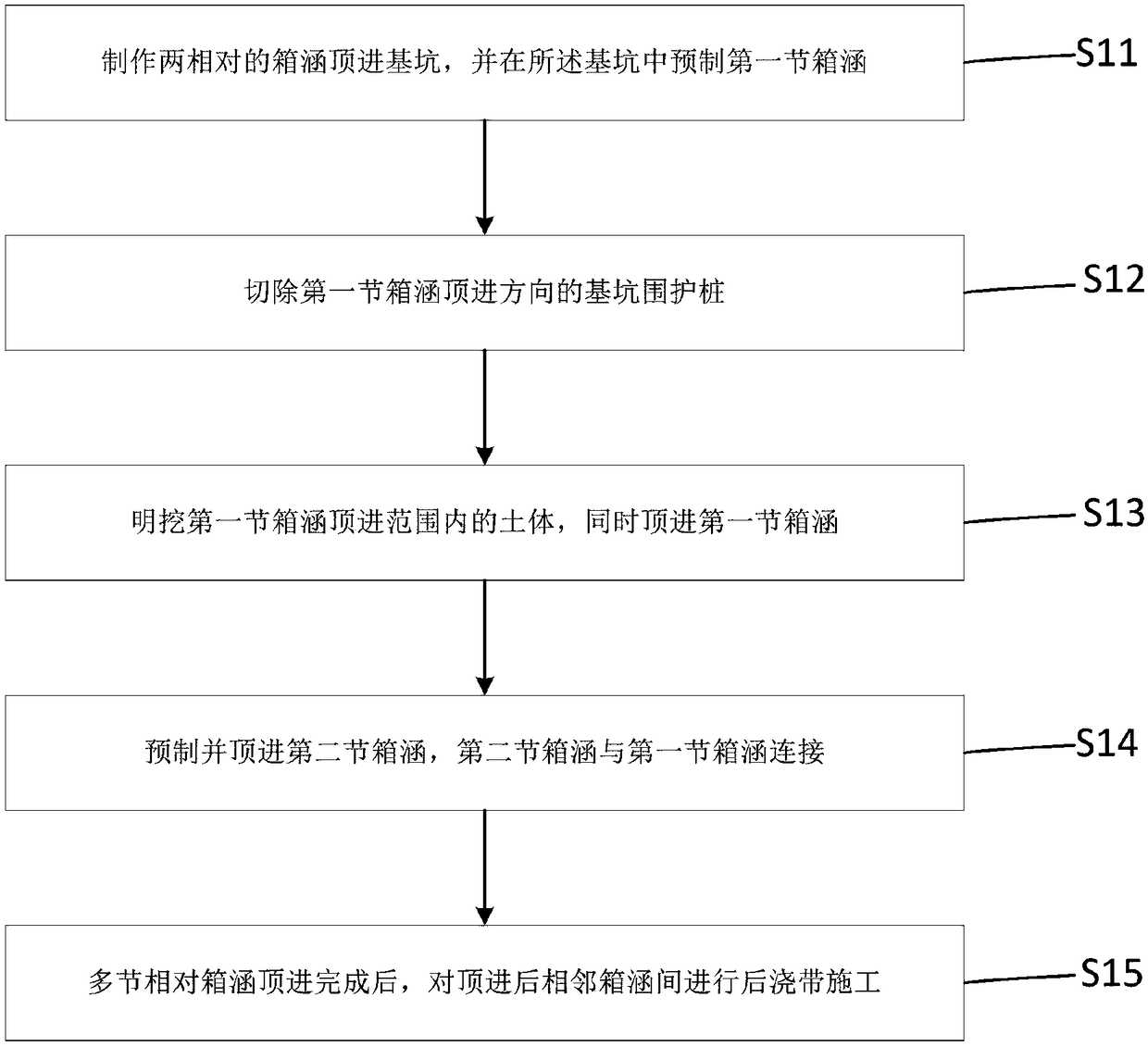

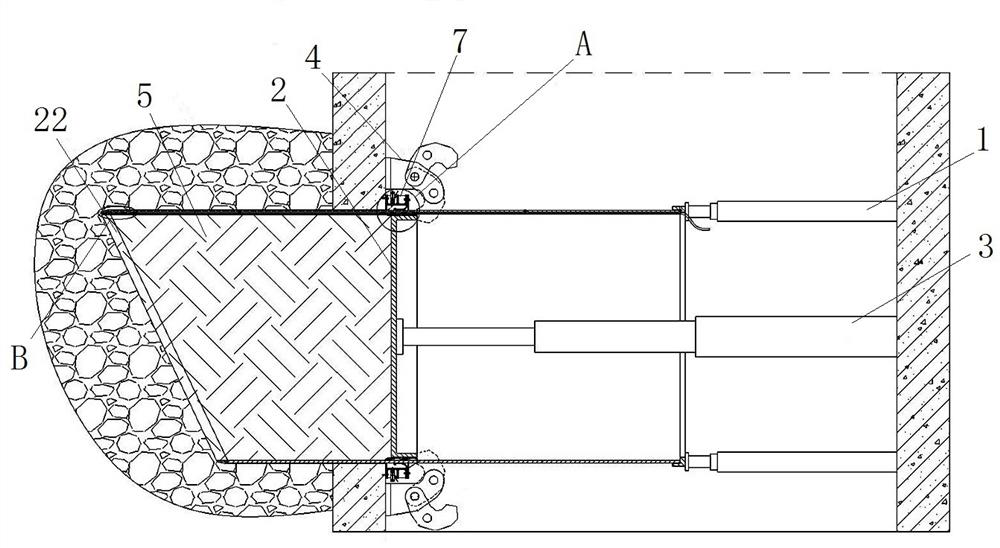

Method and system for jacking open-cut box culverts across operating subway interval

InactiveCN109356195AEasy jackingQuality assuranceArtificial islandsUnderwater structuresEngineeringCulvert

The invention discloses a method and system for jacking open-cut box culverts across an operating subway interval. The method comprises the following steps that formation system reinforcement is performed on existing tunnels, the a box culvert jacking foundation pit is manufactured, and the box culverts are prefabricated in the foundation pit; foundation pit retaining piles in the jacking direction of the box culverts are cut, a soil mass within the jacking range of the box culverts is excavated by an open-cut method, and the box culverts are jacked in at the same time; the multi-section box culverts are sequentially jacked in, and post-casting belt construction is carried out between the adjacent jacked box culverts; and when the box culverts are jacked in, jacks are symmetrically arranged on both sides of the box culvert jacking direction, the two jacks are symmetrically jacked into the box culverts, and the thrust of the two jacks is corrected by a thrust control device. The impacton operating subways can be reduced, the jacking of the box culverts is facilitated, and the defect of deformation of an operating subway structure caused by foundation pit excavation is overcome.

Owner:THE FIRST ENG CO LTD OF CTCE GRP +1

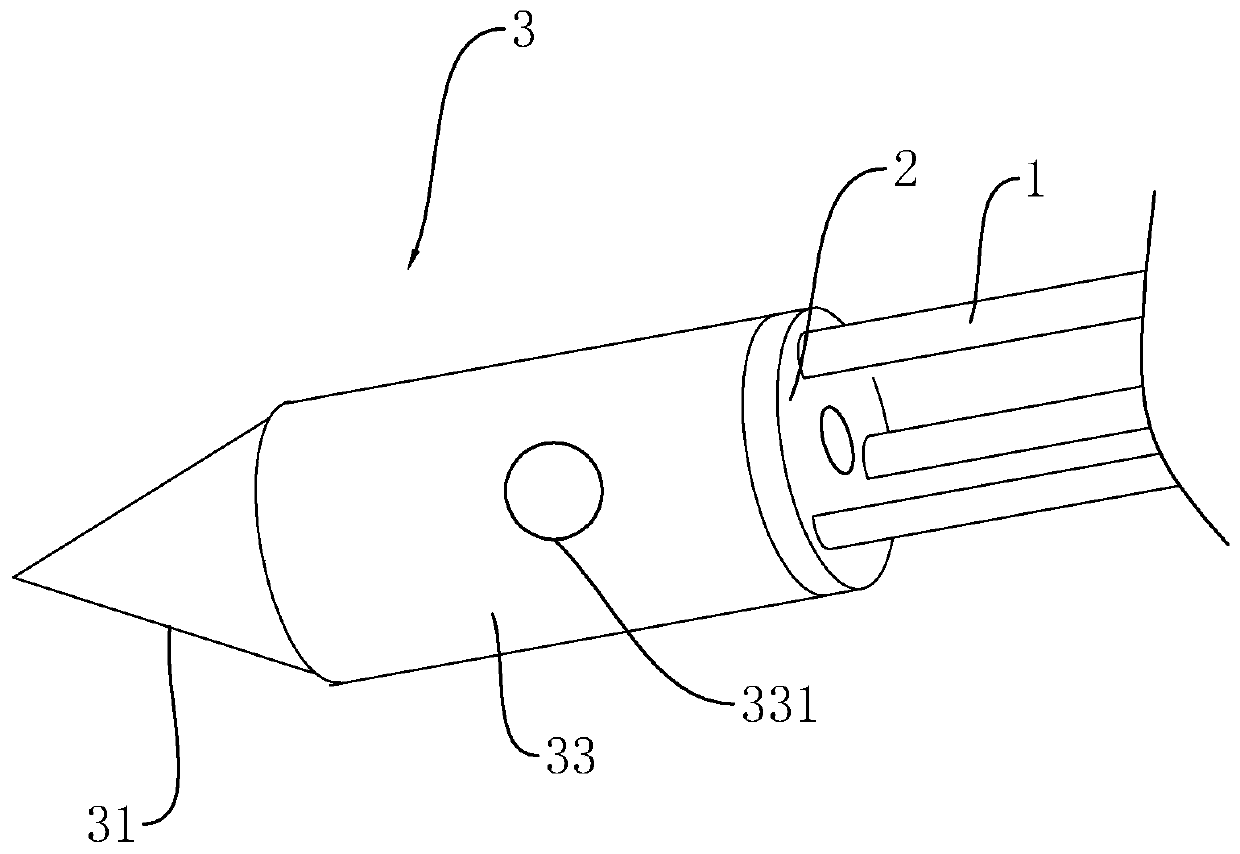

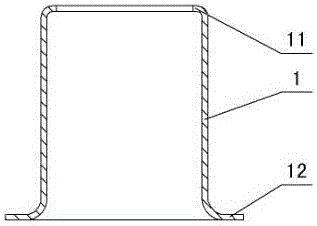

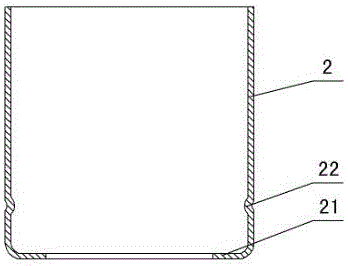

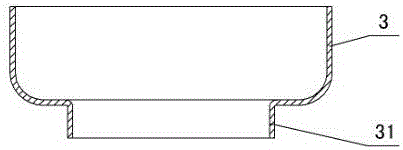

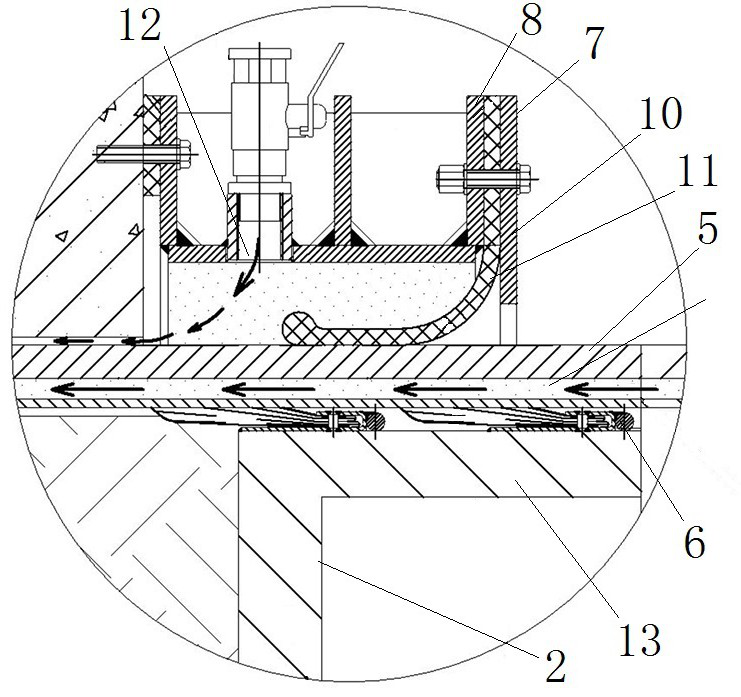

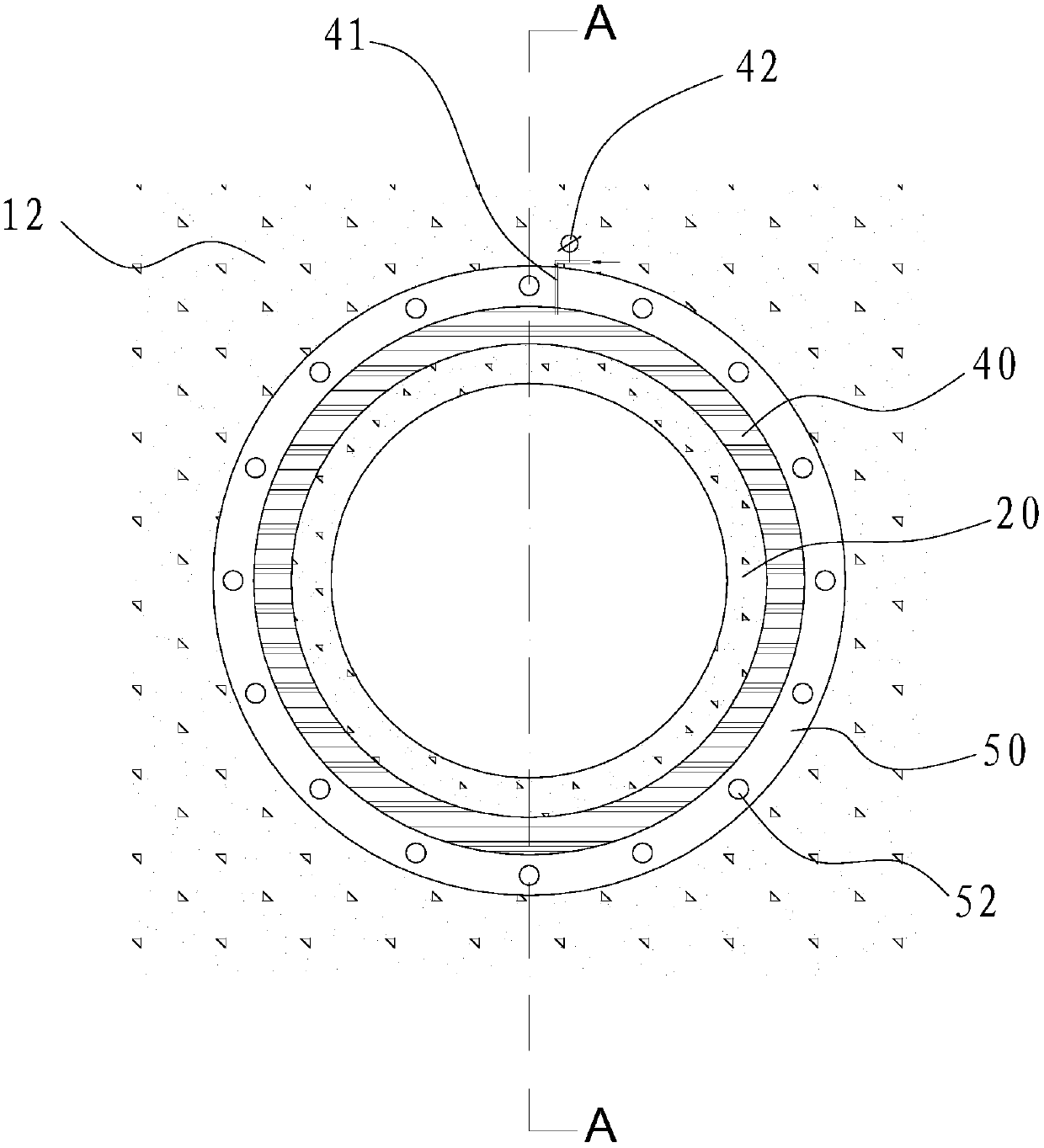

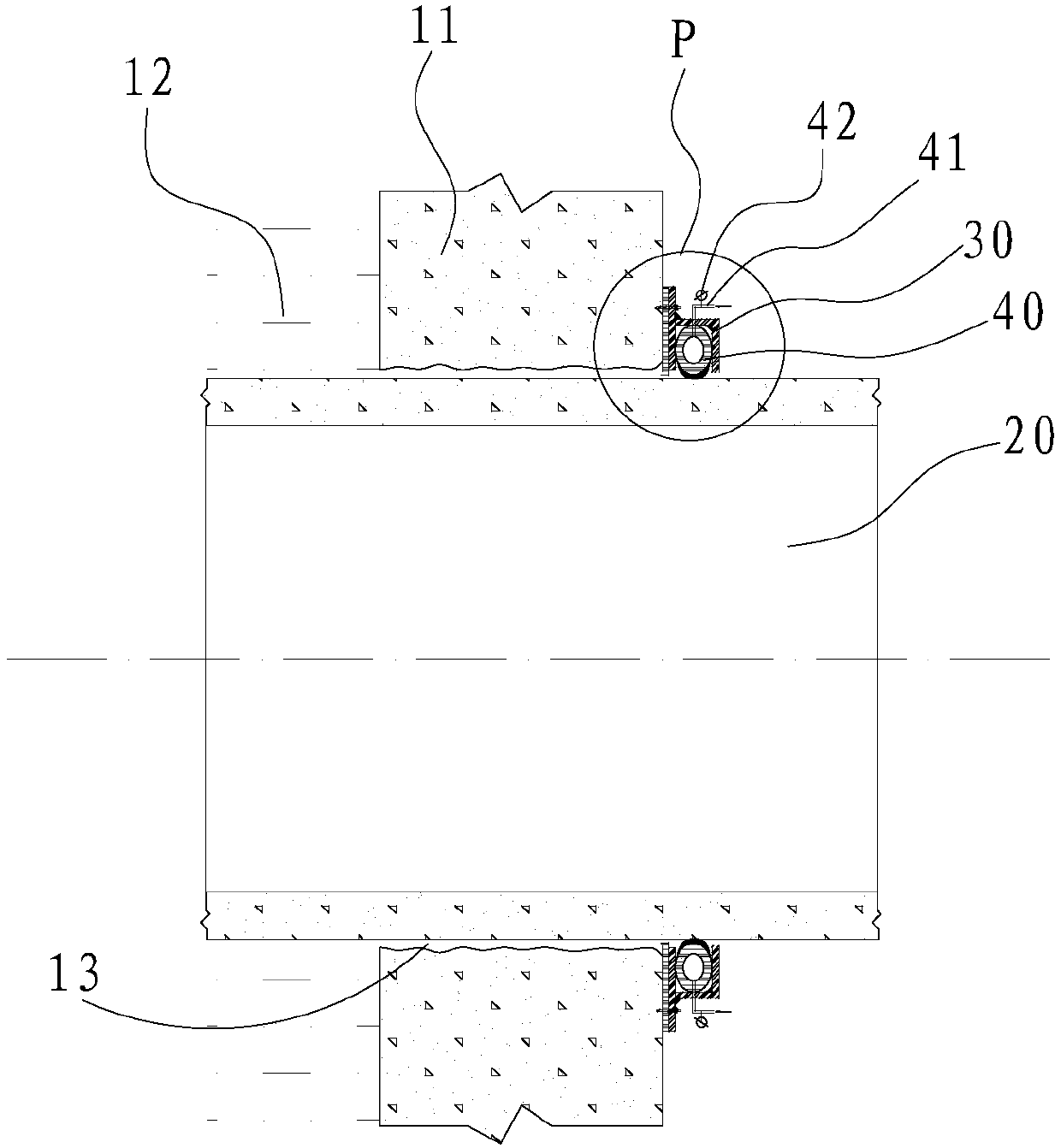

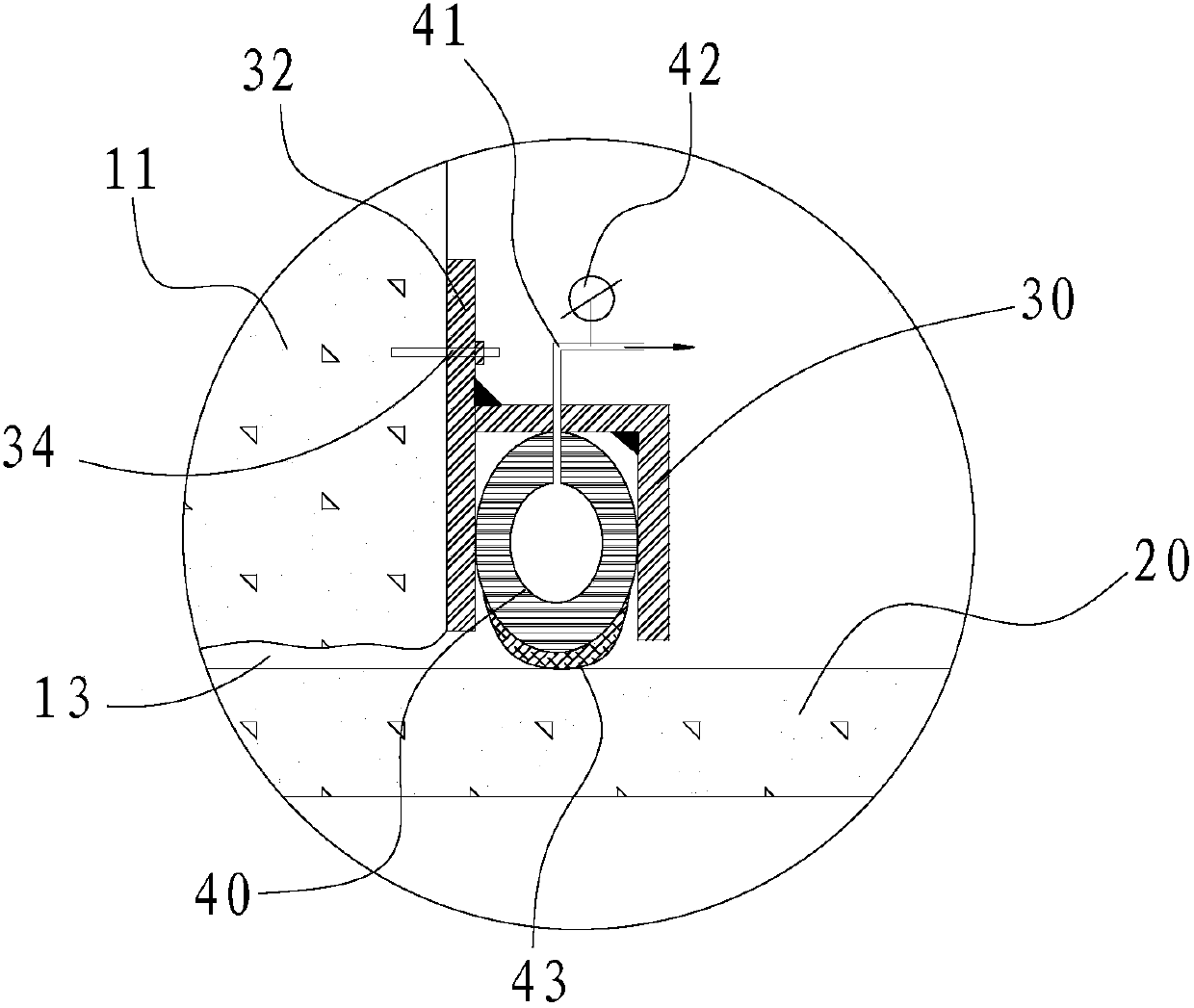

Sealing mounting structure of tunnel pipeline and mounting method of tunnel pipeline

The invention discloses a sealing mounting structure of a tunnel pipeline and a mounting method of the tunnel pipeline. The mounting structure comprises a working well, the tunnel pipeline, mounting groove bodies and annular bag bodies, wherein holes are formed in the wall of the working well; the tunnel pipeline is inserted into a soil layer through the holes; the mounting groove bodies are detachably mounted on the wall of the working well, and the sidewalls of the mounting groove bodies are clung to the wall of the working well; the mounting groove bodies which are provided with annular grooves sleeve the tunnel pipeline; the annular bag bodies are mounted in the corresponding annular grooves and sleeve the tunnel pipeline; the annular bag bodies are propped against the bottom parts of the corresponding annular grooves and the sidewall of the tunnel pipeline. According to the mounting structure, the error allowance value of the opening size of the holes in the wall of the working well can be extended, thus the radial deviation of the tunnel pipeline in the propping-in process can be reduced, and the abrasion between the holes and other mounting assemblies can be avoided; in addition, the sealing effect is realized in the mounting process of the tunnel pipeline, so that the loss of the drag reducing mud which is poured in the propping-in construction of the tunnel pipeline can be prevented; a complete and effective mud sleeve can be formed, and thus the lubricating can be performed to achieve drag reducing, and the holes can be prevented from water.

Owner:GUANGZHOU ELECTRIC POWER DESIGN INST +1

Pipe jacking construction method of municipal gas pipelines

InactiveCN106402489AEasy to useEasy jackingPipe laying and repairLine tubingArchitectural engineering

A pipe jacking construction method of municipal gas pipelines includes the steps that firstly, measurement and paying-off are conducted; secondly, an open caisson is constructed; thirdly, after the open caisson meets design requirements after maintenance, the open caisson evenly sinks and reaches designed elevation, and open caisson work stops; fourthly, installation of a jacking device and back wall treatment are conducted; fourthly, foot blades are installed, wherein the foot blades are symmetrically arranged at the top ends of sleeves, and each foot blade comprises a shielding plate, a tail plate, a ribbed plate, an annular beam and a fixing frame; sixthly, pipe jacking is conducted; seventhly, crossing pipe sections are welded, and then a reinforcing pipe is arranged on the butt joint of two gas pipelines, wherein the reinforcing pipe comprises an outer pipe and a polypropylene foaming material, the butt joint portion of the two gas pipelines is sleeved with the outer pipe, and the portion between the inner wall of the outer pipe and the outer walls of the gas pipelines in butt joint is filled with the polypropylene foaming material. By means of the foot blades, jacking of the sleeves are benefited, resistance is reduced, and the sleeves do not deviate during jacking and move along the pipelines; structural performance of the joint of the two adjacent gas pipelines in butt joint can be improved.

Owner:安顺集团建设有限公司

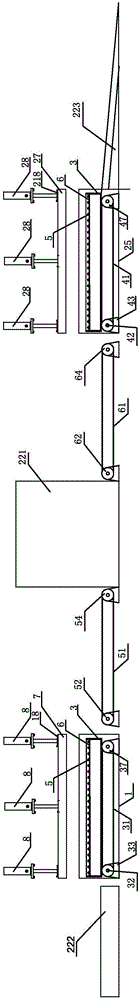

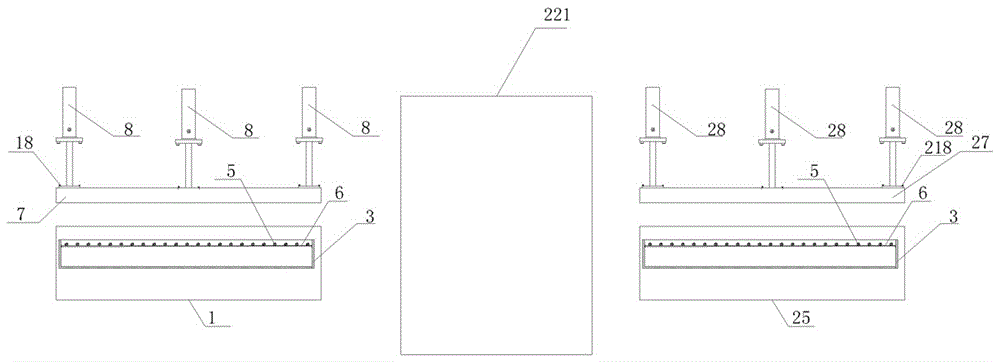

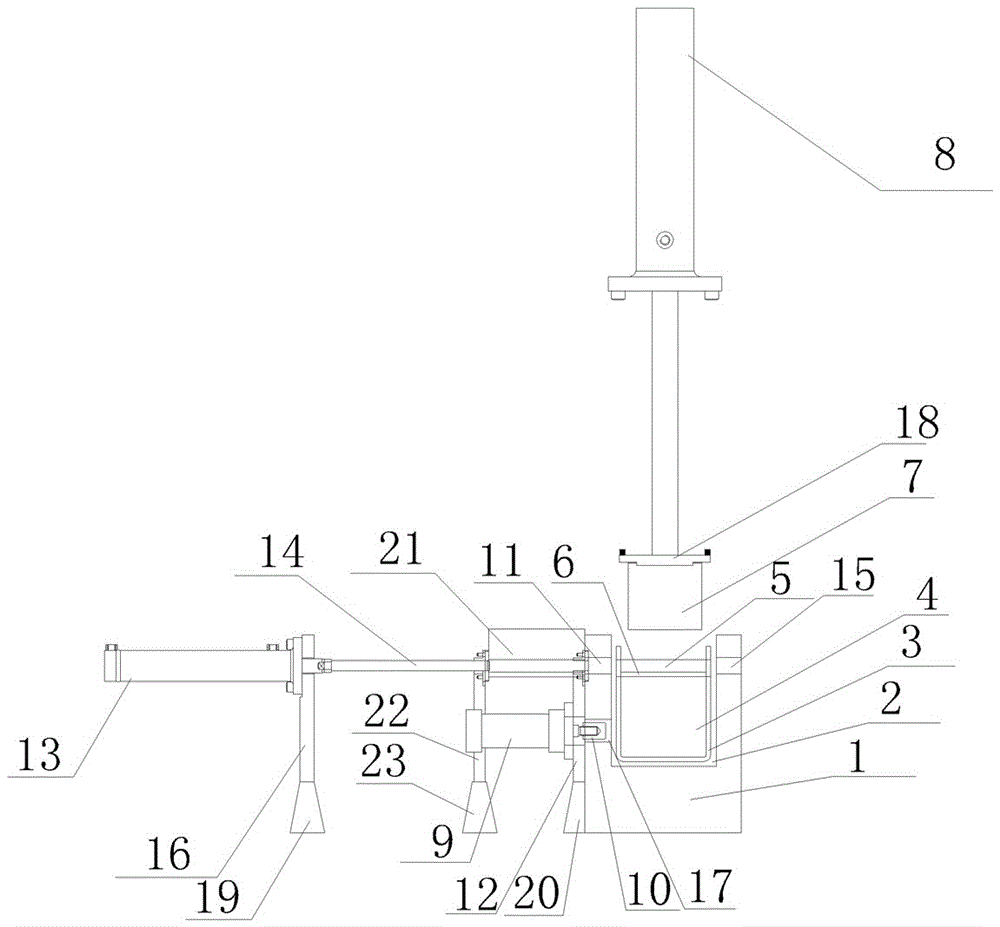

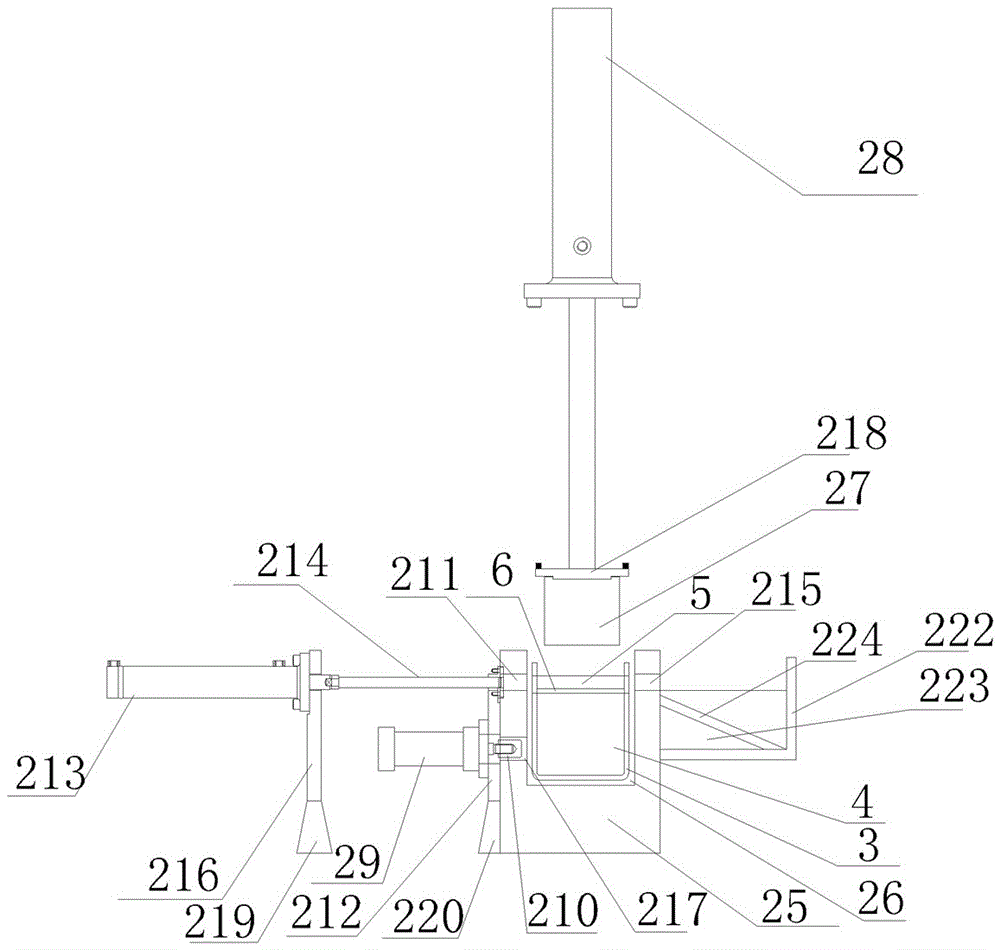

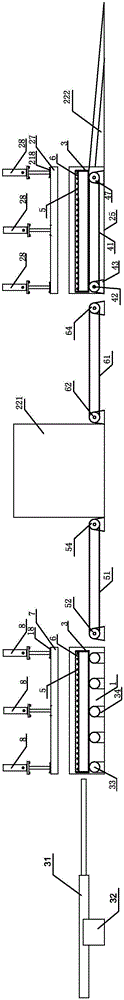

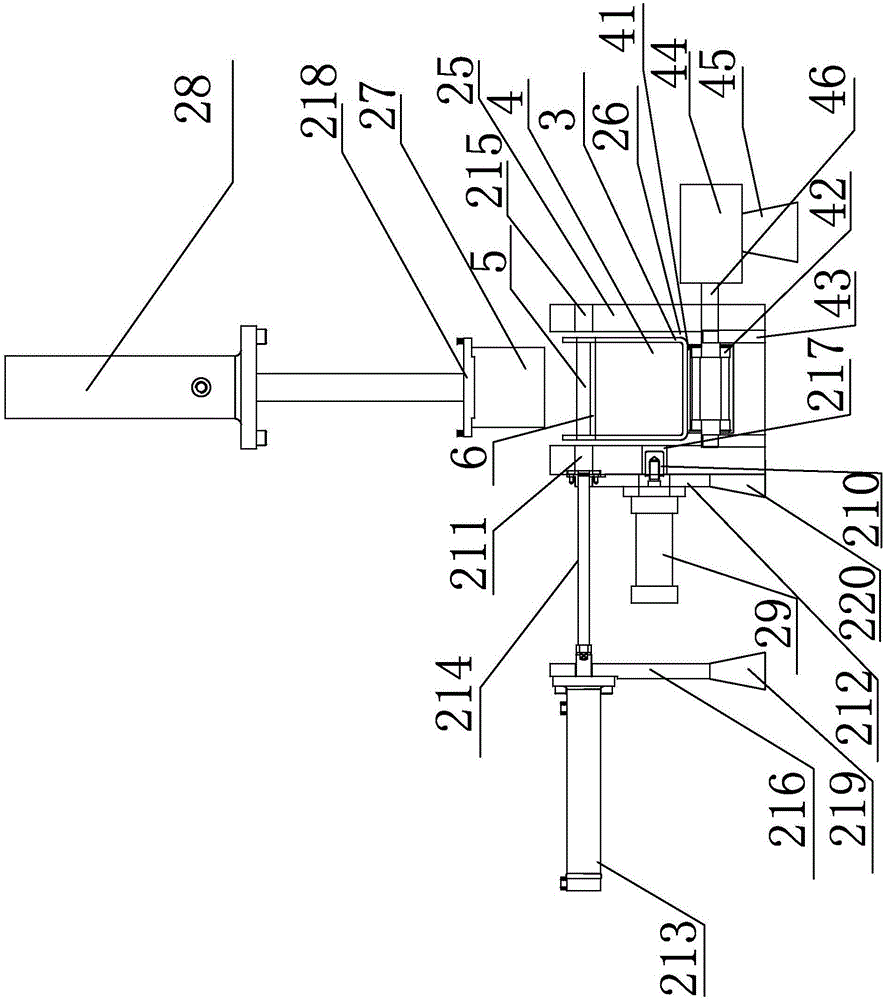

Novel reconsolidated bamboo square stock production line provided with durable dies and capable of moving in and out dies conveniently

InactiveCN105904567ASmooth penetrationIncrease contact areaWood working apparatusDomestic articlesProduction line

The invention discloses a novel reconsolidated bamboo square stock production line provided with durable dies and capable of moving in and out the dies conveniently. The production line comprises a forming device, a curing drying room and a die releasing device, wherein the forming device comprises a forming bracket, a forming die mounting slot and a die; the die releasing device comprises a die releasing bracket, a die releasing die mounting slot and the die; a forming pressing covering bar is arranged above the forming bracket; a plurality of forming pressing cover oil cylinders are connected to the forming pressing covering bar; forming positioning cylinders and forming ejector pin oil cylinders are arranged at one side of the forming bracket; pin storing boxes are arranged between the forming ejector pin oil cylinders and the forming bracket; a die releasing pressing covering bar is arranged above the die releasing bracket; a plurality of die releasing pressing cover oil cylinders are connected to the die releasing pressing covering bar; die releasing positioning cylinders and die releasing ejector pin oil cylinders are arranged at one side of the die releasing bracket; pin collecting slots are formed in the discharging side of the die releasing bracket; the die comprises a die body, a reconsolidated bamboo square stock chamber and a die top cover. With the adoption of the production line, the dies can be moved in and out conveniently, and pins can be collected conveniently, so that the working intensity of workers can be reduced; the forming efficiency and the die releasing efficiency are high; the dies are long in service lives.

Owner:ANJI YUKANG MACHINERY

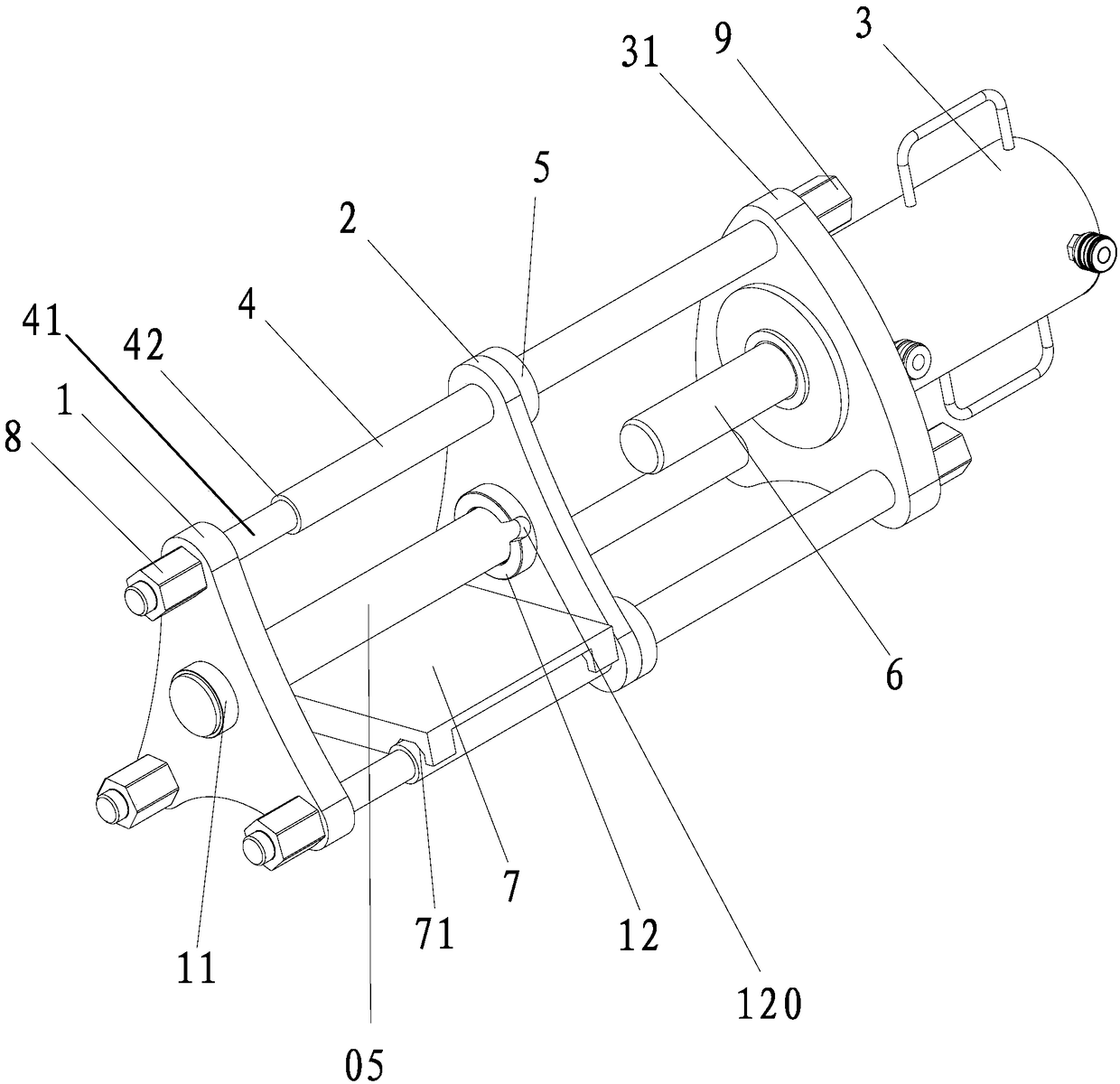

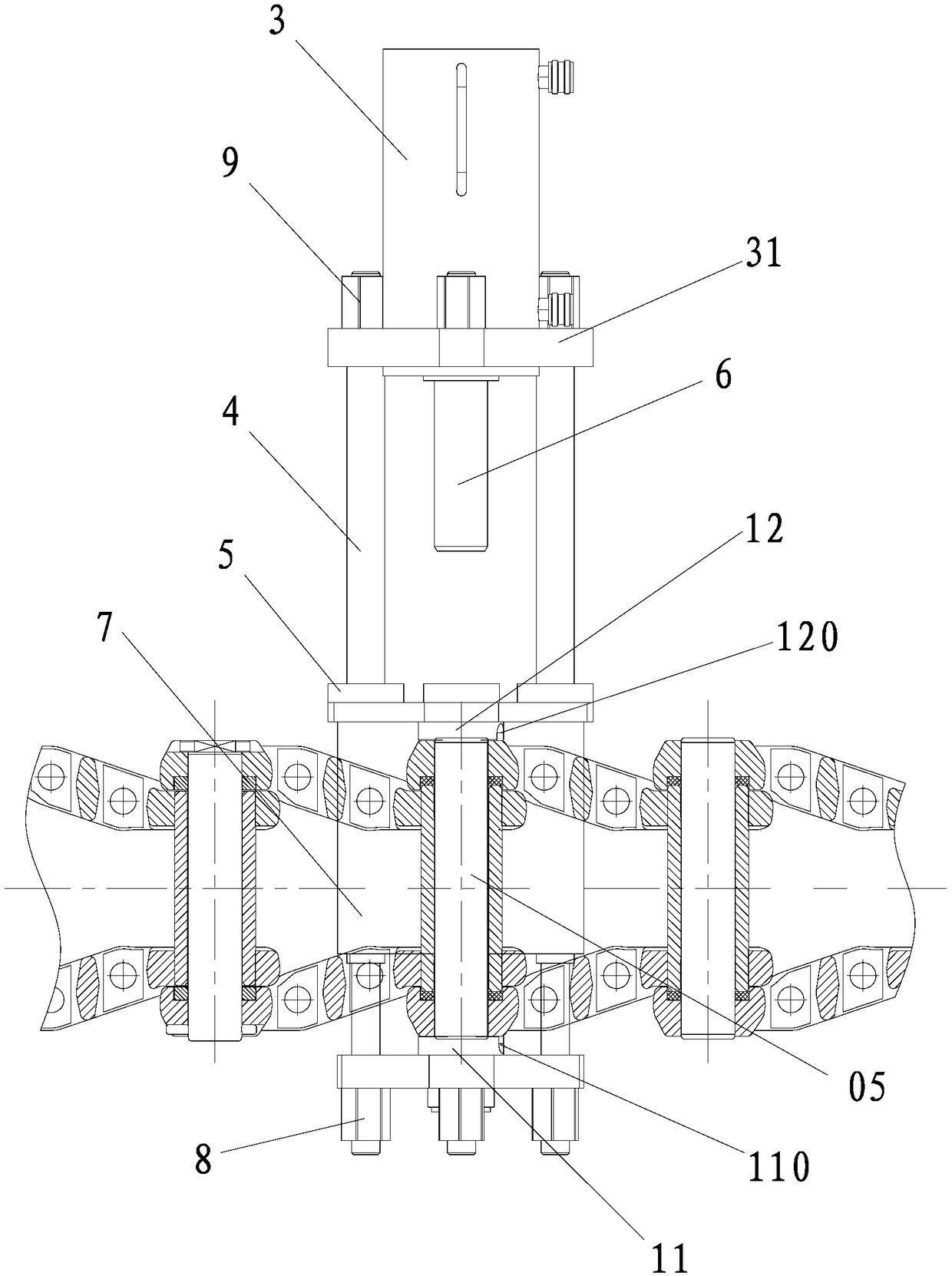

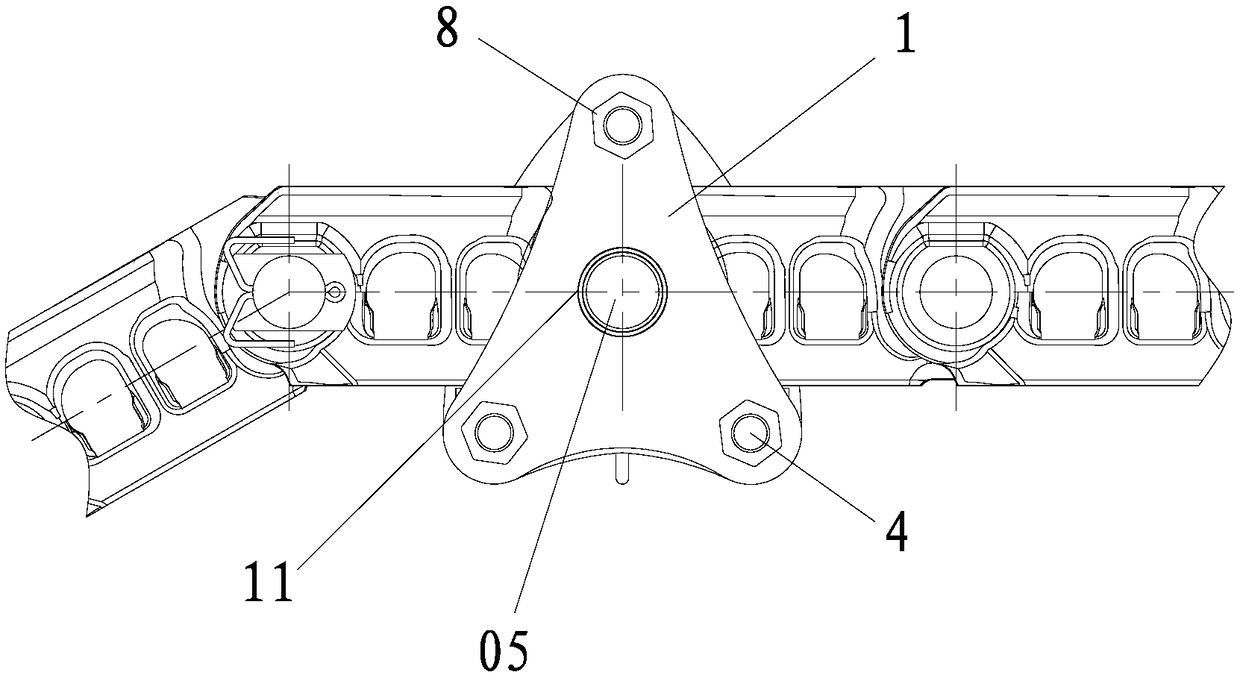

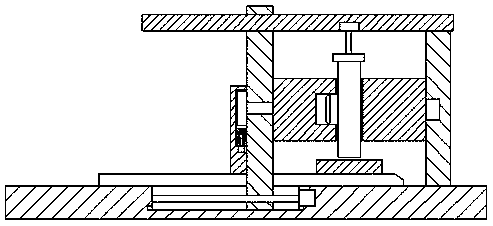

Floor type chain link disassembling and assembling machine

The invention discloses a floor type chain link disassembling and assembling machine. The floor type chain link disassembling and assembling machine comprises an adjusting plate, a supporting plate and an oil jack provided with a bottom plate. The supporting plate is located between the adjusting plate and the oil jack. The adjusting plate is connected with the bottom plate of the oil jack throughat least three parallel link rods. The adjusting plate is detachably connected with the link rods. The bottom plate of the oil jack is detachably connected with the link rods. The supporting plate isslidably arranged on the link rod in a sleeving mode. Each link rod is provided with a fixed ring. A plunger of the oil jack faces the supporting plate. A press-fitting pad rod is mounted on the plunger of the oil jack. The adjusting plate is provided with a first through hole. The supporting plate is provided with a second through hole. A working platform is arranged between the adjusting plateand the supporting plate. The floor type chain link disassembling and assembling machine provided by the invention is simple in structure, convenient to use, high in disassembling and assembling efficiency, capable of saving more time and labor, safer in use and also capable of effectively protecting chain links against deformation in the disassembling and assembling process.

Owner:QUANZHOU HUAMAO MACHINERY EQUIP

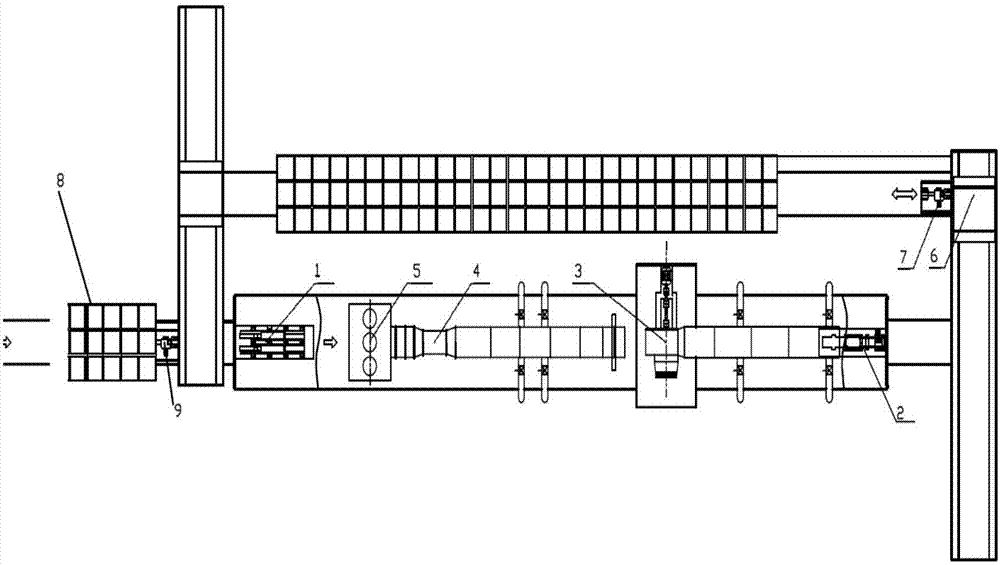

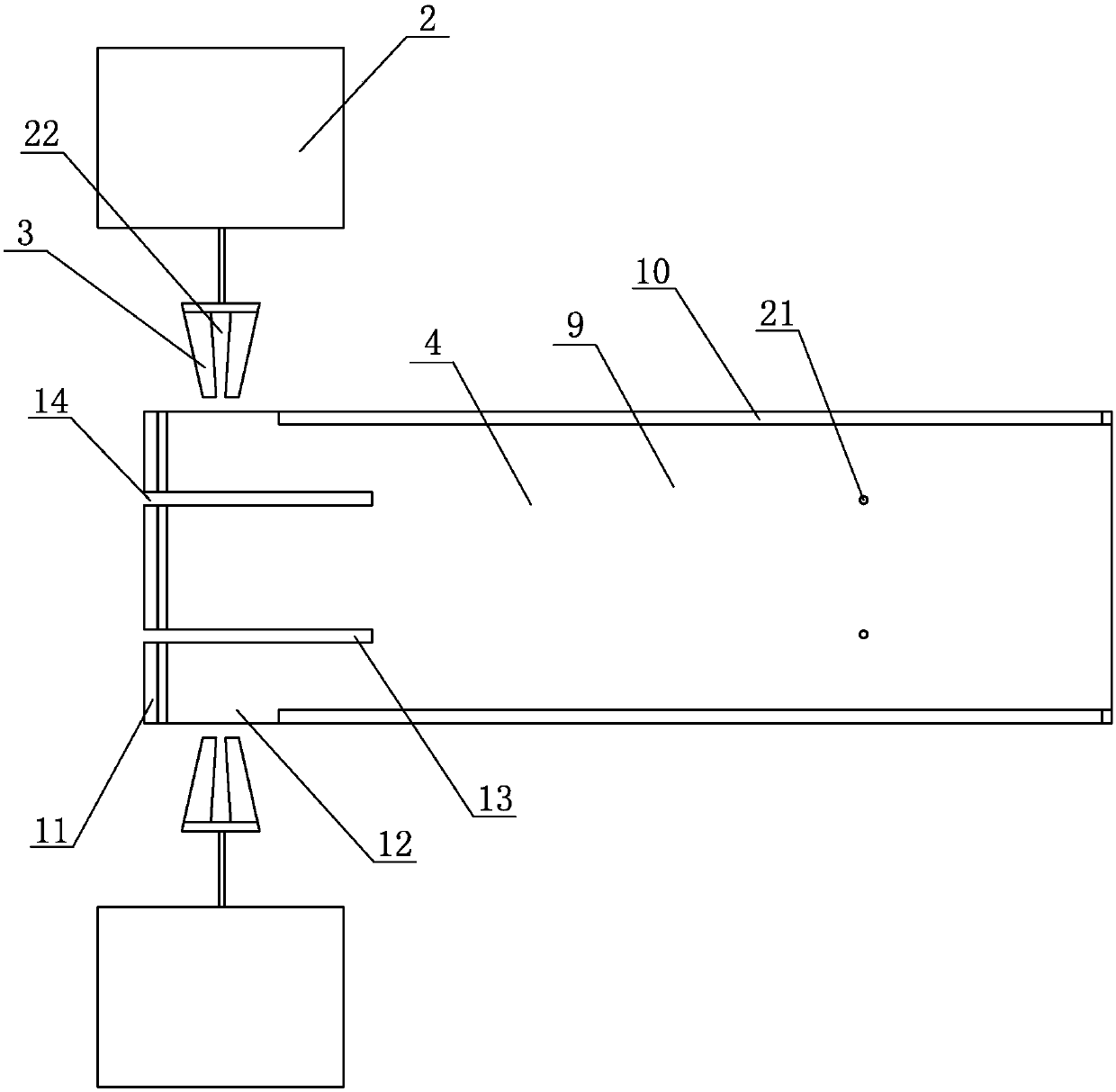

Sectional type advection smoke discharging drying device and drying method

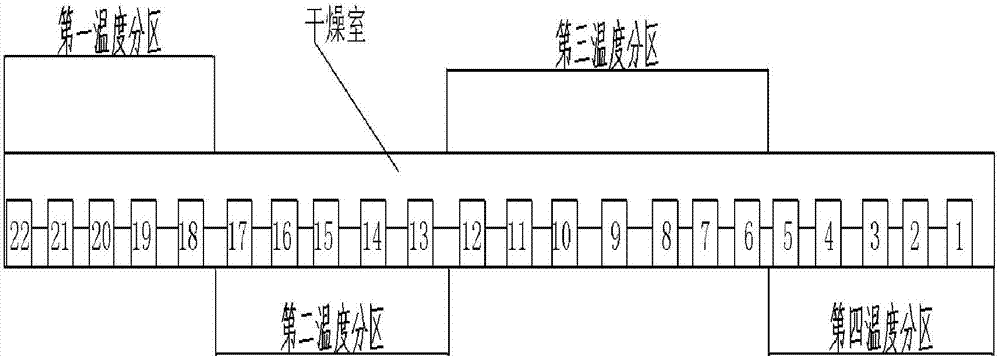

ActiveCN107449222APrevent spoilageShorten drying timeDrying solid materials with heatDrying gas arrangementsTunnel kilnBrick

The invention discloses a sectional type advection smoke discharging drying device. The drying device comprises a hydraulic kiln car pusher (1) and a drying chamber (10); the drying chamber comprises 22 kiln car position spaces and is divided into four sections; a drying chamber hot air blower (3) is arranged beside the side edge of the drying chamber (10); a hot air pipeline of the drying chamber hot air blower (3) leads to the interior of the drying chamber from the top of the drying chamber (10); a drying chamber dehumidifying fan (4) is arranged at the top of a kiln head of the drying chamber; an air draft pipe connected to the drying chamber dehumidifying fan (4) leads to the interior of the kiln head of the tunnel drying chamber from the top of the drying chamber; a drying chamber main moisture eliminating fan (5) is arranged at the top of the drying chamber; and an air draft pipeline connected to the drying chamber main moisture eliminating fan (5) is connected to an exhaust pipeline of the drying chamber dehumidifying fan (4). The drying device and the drying method have the advantage that the problems that the production efficiency is low and the drying effect is not obvious due to the facts that a traditional tunnel kiln adopts a multi-channel structure, the drying time is 22-28 hours per batch of green bricks, and the moisture content of the dried green bricks is more than 10% can be solved.

Owner:GUIZHOU UNIV

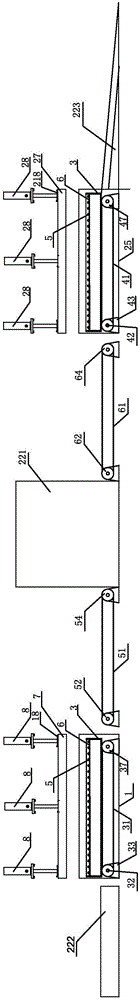

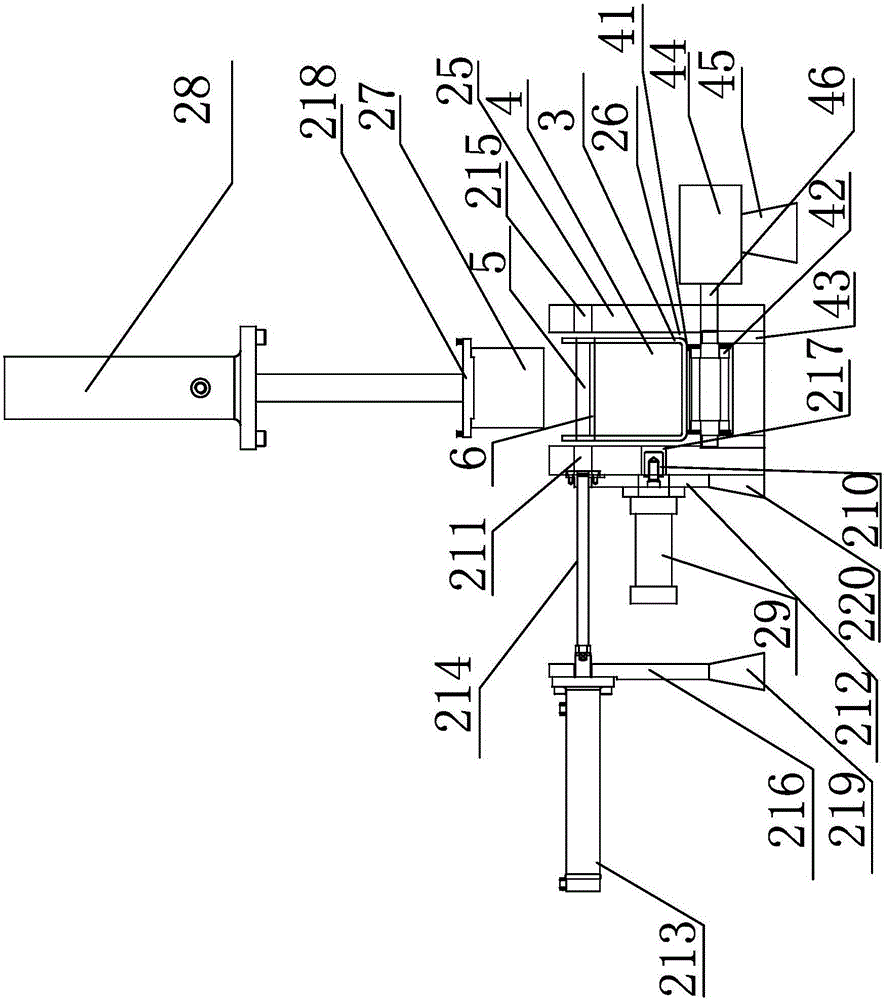

Heavy bamboo square stock production line provided with durable moulds and bringing convenience for mould to get in and out

InactiveCN105904571ASmooth penetrationIncrease contact areaWood working apparatusDomestic articlesProduction lineBiochemical engineering

The invention discloses a heavy bamboo square stock production line provided with durable moulds and bringing convenience for the moulds to get in and out. The heavy bamboo square stock production line comprises a forming device, a curing oast and a demoulding device, wherein the forming device comprises a forming support, a forming mould mounting tank and a mould; the demoulding device comprises a demoulding support, a demoulding mould mounting tank and a mould; a forming gland strip is arranged above the forming support and connected with a plurality of forming gland oil cylinders; forming positioning cylinders and forming pin jacking oil cylinders are arranged on one side of the forming support; a pin storage box is arranged between the forming pin jacking oil cylinders and the forming support; a first conveying mechanism is arranged at the bottom of the forming mould mounting tank; a demoulding gland strip is arranged above the demoulding support and connected with a plurality of demoulding gland oil cylinders; demoulding positioning cylinders and demoulding pin jacking oil cylinders are arranged on one side of the demoulding support; a second conveying mechanism is arranged at the bottom of the demoulding mould mounting tank; and each mould comprises a mould body, a heavy bamboo square stock chamber and a mould top cover. The heavy bamboo square stock production line is high in forming and demoulding efficiency and safe in operation, and the moulds are durable.

Owner:ANJI YUKANG MACHINERY

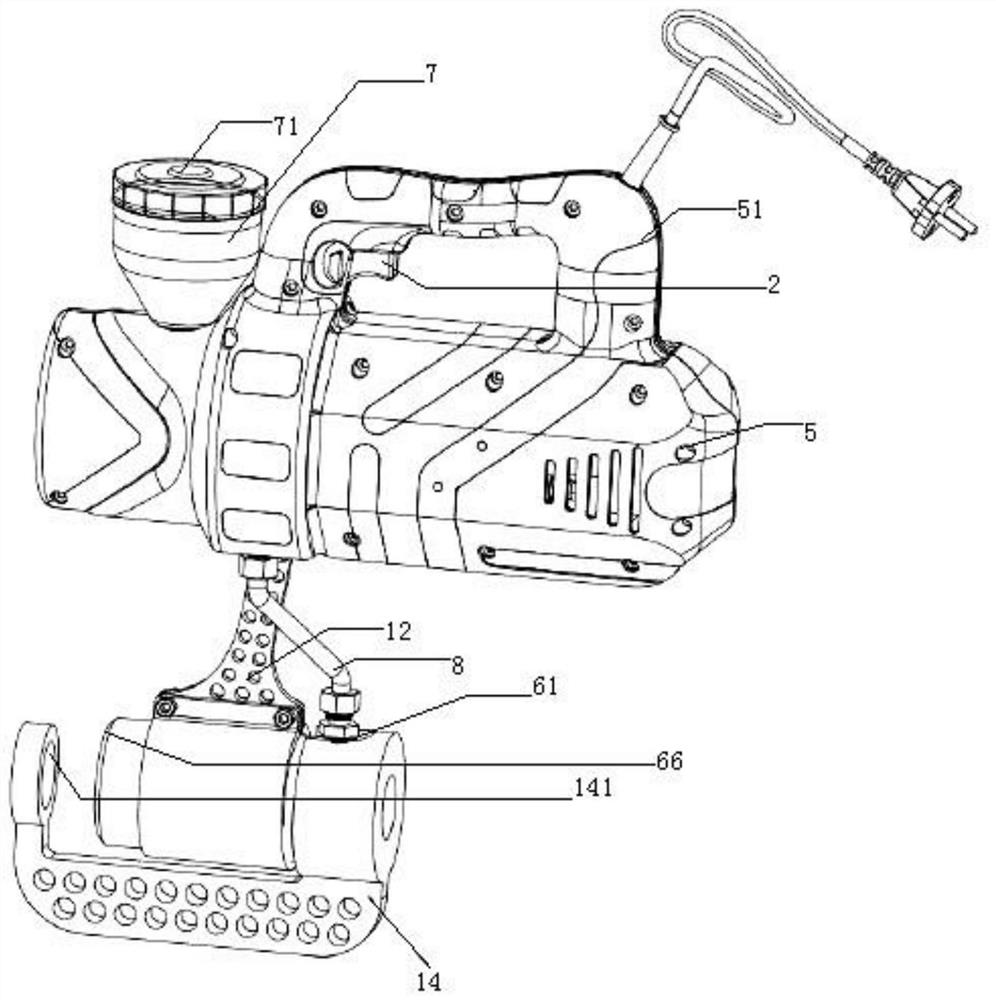

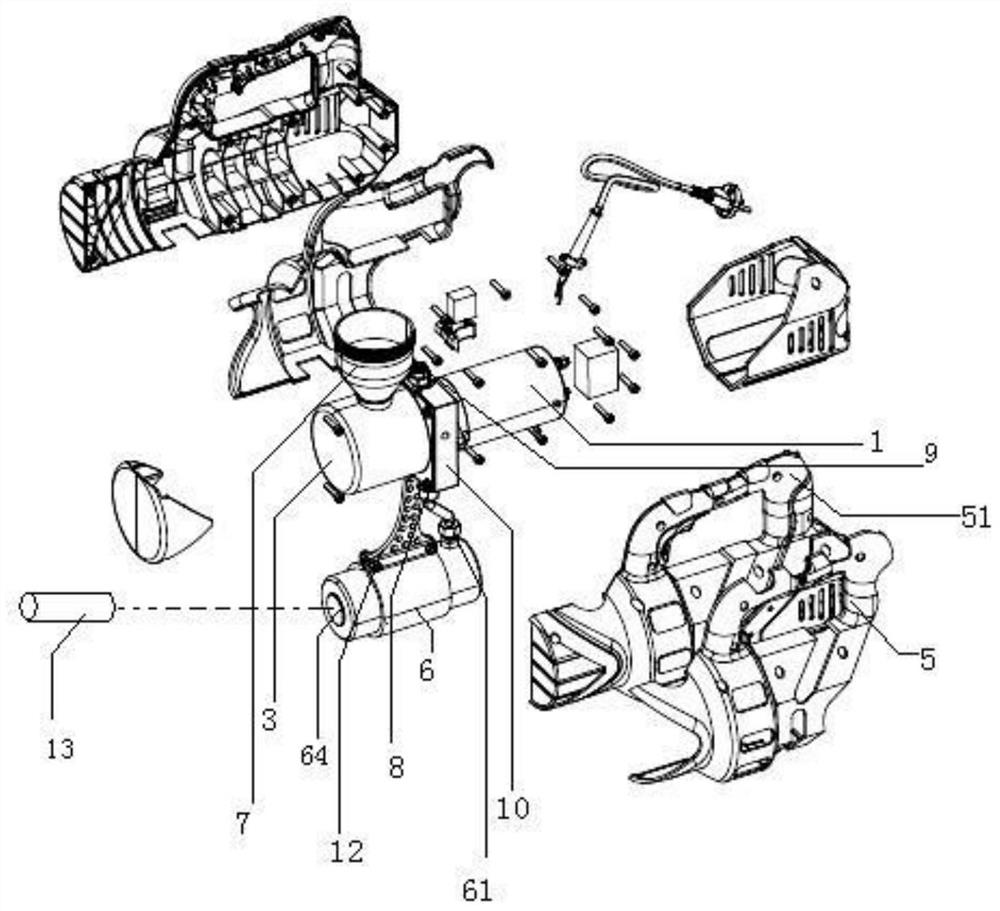

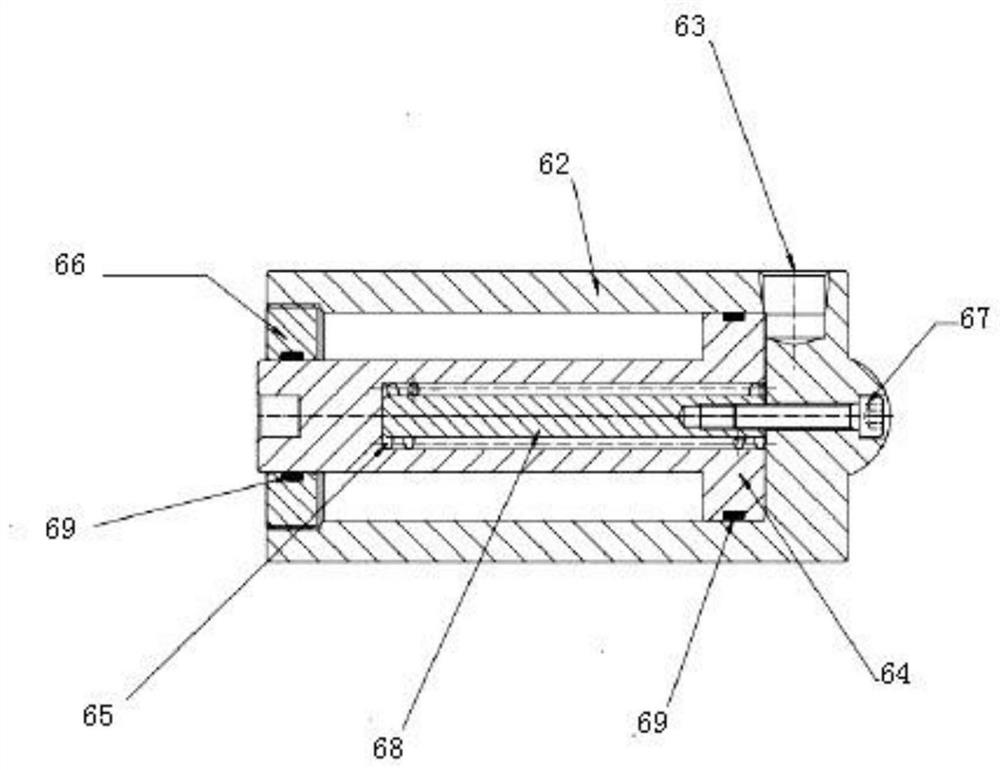

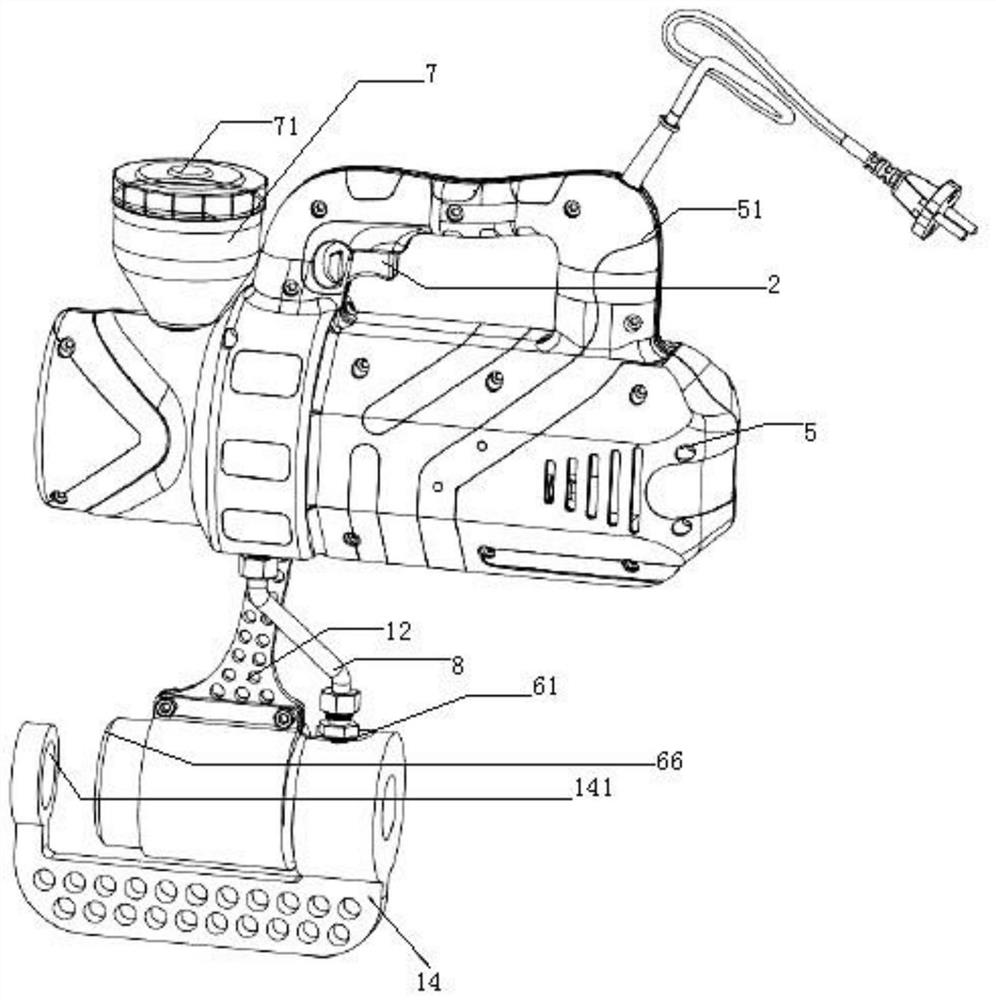

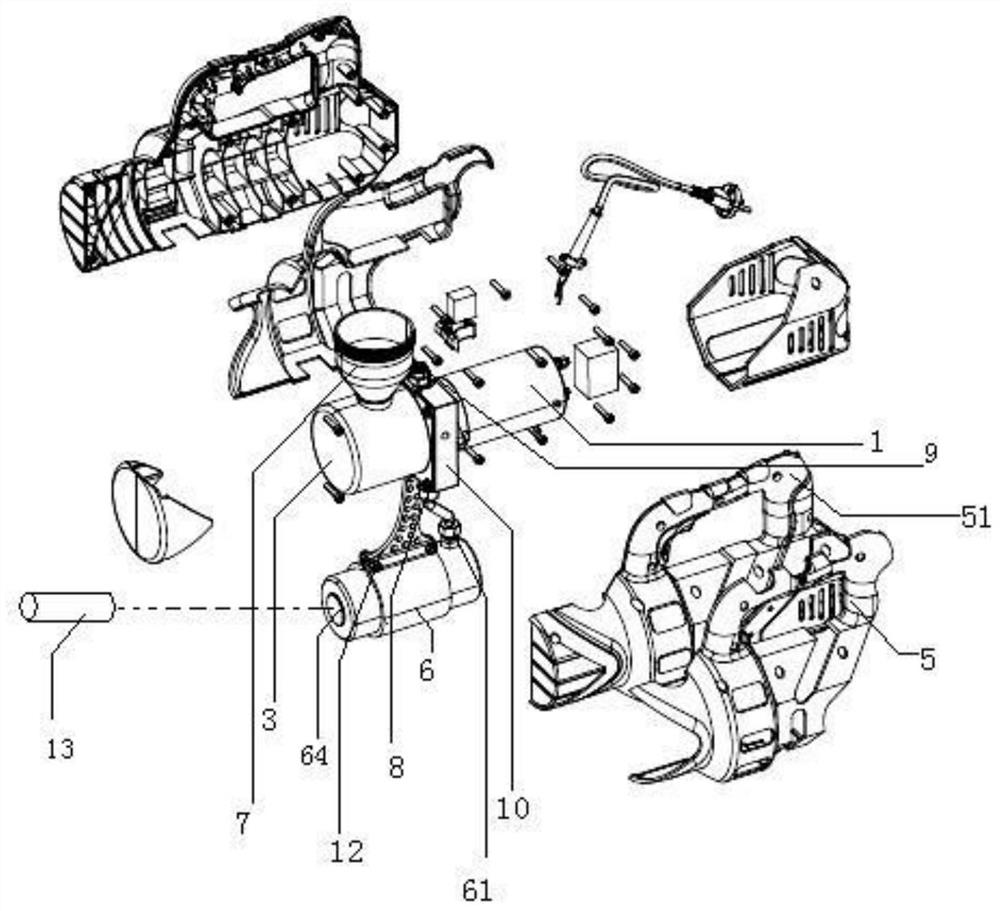

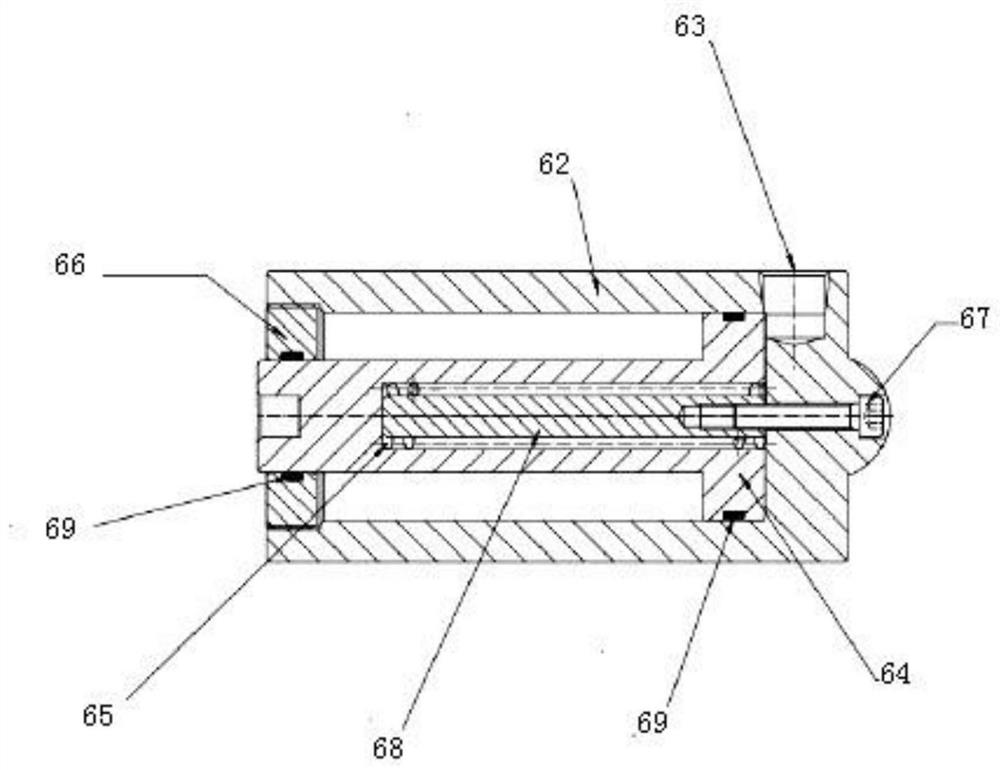

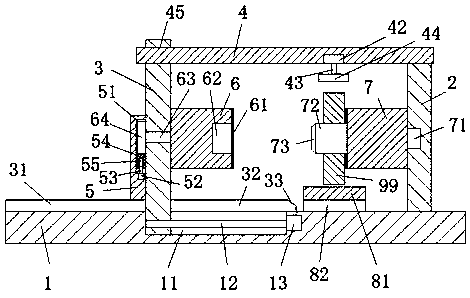

Hydraulic equipment for dismounting and mounting bucket tooth pin shaft

ActiveCN113293817ARealize forward and reverse controlCompact structureSoil-shifting machines/dredgersOil canGear pump

Hydraulic equipment for dismounting and mounting a bucket tooth pin shaft comprises a motor, a power switch, an oil drum, a bidirectional gear pump, a shell, an oil cylinder, an oil can, a high-pressure oil pipe, an overflow valve and an oil way integration distribution block. The oil can is mounted at the upper end of the oil drum; one side of the oil way integration distribution block is mounted on one side of the oil drum, and the motor is mounted on the other side of the oil way integration distribution block; the bidirectional gear pump is mounted on one side of the oil way integration distribution block, and a power input shaft of the bidirectional gear pump and a power output shaft of the motor are mounted together; the oil drum and the oil cylinder are mounted together; the overflow valve is mounted on the oil way integration distribution block; a lower oil pipe of the oil cylinder and a lower oil inlet and outlet pipe of the oil way integration distribution block are mounted together through an oil pipe; the shell is installed on the outer side of the motor, and the power switch is installed on the shell. The equipment is small and exquisite in structure and convenient to use, a piston of the oil cylinder can move forwards to eject out of or into the bucket tooth pin shaft and move backwards to return to the initial state only by controlling a power switch, so that the bucket tooth dismounting and mounting efficiency is improved.

Owner:漳州鑫山航机械有限公司

Heavy bamboo square material production line capable of conveniently collecting pins and conveniently demoulding

InactiveCN105922430AStable and reliable glandStable and reliable ejection processWood working apparatusDomestic articlesProduction lineEngineering

The invention discloses a heavy bamboo square material production line capable of conveniently collecting pins and conveniently demoulding. The heavy bamboo square material production line comprises a molding device, a solidifying drying room and a demoulding device, wherein the molding device comprises a molding bracket, a molding die mounting groove and a die, and the demoulding device comprises a demoulding bracket, a demoulding die mounting groove and a die; a molding press cover strip is arranged above the molding bracket, and a plurality of molding press cover oil cylinders are connected to the molding press cover strip; a molding positioning air cylinder and a molding ejector pin oil cylinder are arranged on one side of the molding bracket, a pin storage box is arranged between the molding ejector pin oil cylinder and the molding bracket, and a material pushing oil cylinder is arranged at one end of the molding bracket; a demoulding press cover strip is arranged above the demoulding bracket, and a plurality of demoulding press cover oil cylinders are connected to the demoulding press cover strip; a demoulding positioning air cylinder and a demoulding ejector pin oil cylinder are arranged on one side of the demoulding bracket, and a pin collecting hopper is arranged on the other side of the demoulding bracket; and a first conveying mechanism is arranged at the bottom of the demolding die mounting groove. The heavy bamboo square material production line improves the molding and demoulding efficiency, reduces the labor intensity of workers, is safe to operate and is low in manufacture cost.

Owner:ANJI YUKANG MACHINERY

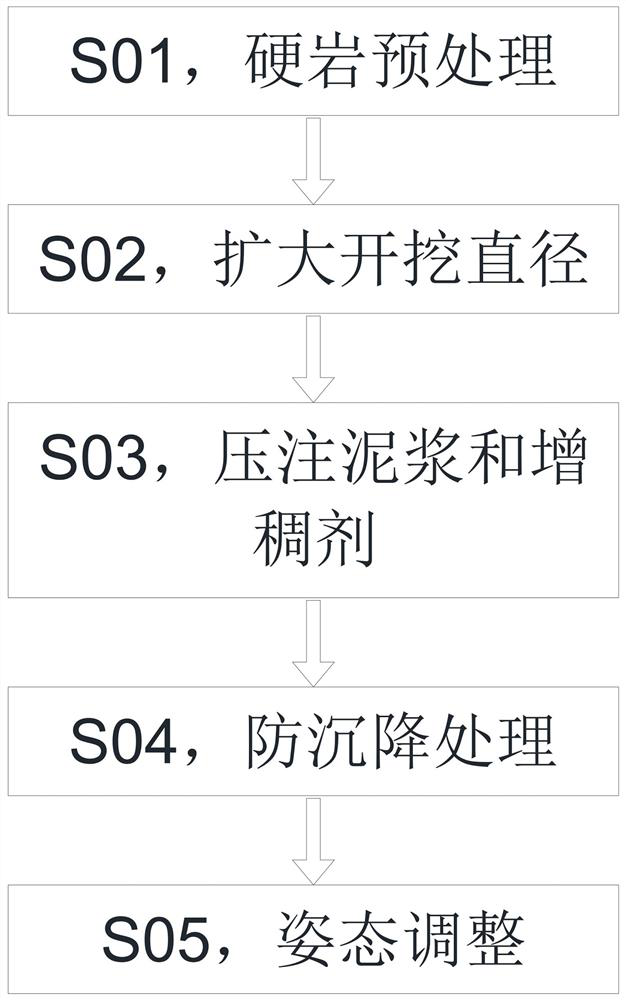

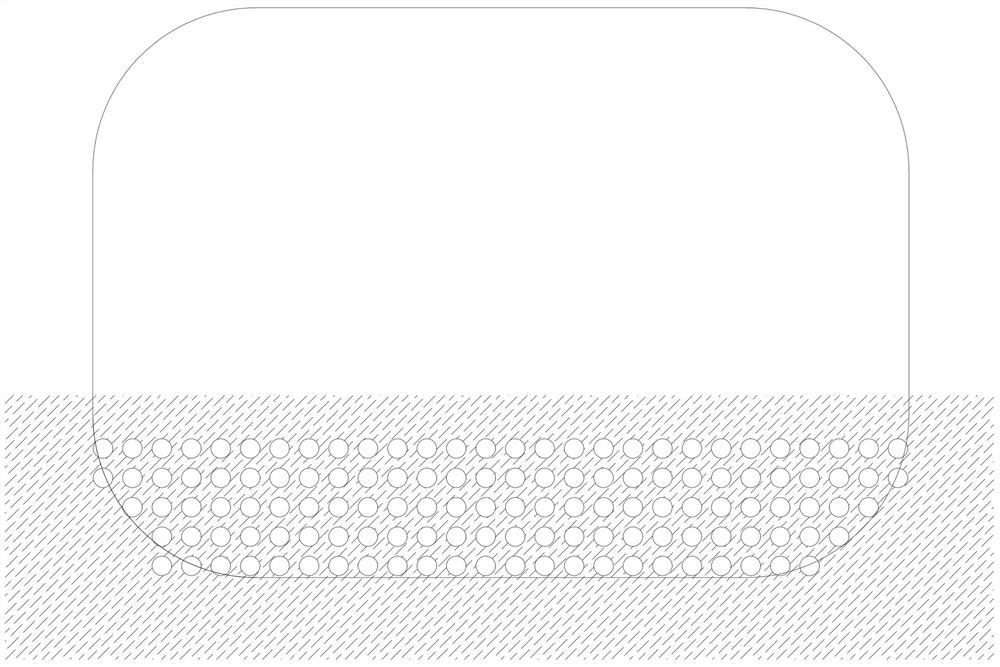

Large-size rectangular pipe jacking construction method for upper-soft lower-hard stratum

PendingCN113944475AImprove construction safetyReduce construction costsTunnelsPre treatmentPressure injection

The invention discloses a large-size rectangular pipe jacking construction method for an upper-soft lower-hard stratum, and belongs to the technical field of pipe jacking construction. The large-size rectangular pipe jacking construction method for the upper-soft lower-hard stratum comprises the following steps that S01, hard rock pretreatment is conducted, specifically, hard rock invading a pipe jacking tunnel is subjected to pre-crushing treatment; S02, the excavation diameter is enlarged, specifically, a cutter head is adjusted, and the excavation diameter of the bottom of a pipe jacking machine is enlarged; S03, pressure injection of slurry and a thickening agent is conducted, specifically, the slurry and the thickening agent are pressure-injected in front of the cutter head, so that the workability of a soil body is improved, the pressure of the soil body is balanced, and the excavation surface of a sand layer is kept stable; S04, anti-sedimentation treatment is conducted, specifically, high-consistency bentonite is injected into the periphery of the duct piece for filling; and S05, posture adjustment is conducted, in the jacking process, axis deviation correction and posture roll correction are conducted on the pipe jacking machine, and jacking accuracy is guaranteed. The technical problems that in upper-soft lower-hard complex geological large-size rectangular pipe jacking construction, the pipe jacking machine floats upwards and rolls left and right are effectively solved.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

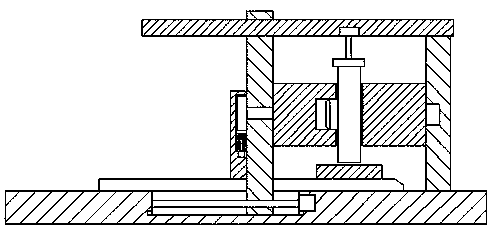

A High Concentricity Composite Insulator Injection Mold

Owner:JIANGSU XIANGYUAN ELECTRIC EQUIP

Heavy bamboo square stock production line provided with durable dies and bringing convenience for collection of pins

InactiveCN105904570AIncrease contact areaIncrease the bearing areaWood working apparatusDomestic articlesProduction lineBiochemical engineering

The invention discloses a heavy bamboo square stock production line provided with durable dies and bringing convenience for collection of pins. The heavy bamboo square stock production line comprises a forming device, a curing drying room and a die stripping device. The forming device comprises a forming support, a forming die installing groove and the die. The die stripping device comprises a die stripping support, a die stripping die installing groove and the die. A forming gland strip is arranged above the forming support and connected with a plurality of forming gland oil cylinders synchronously acting. Forming positioning air cylinders and forming pin ejecting oil cylinders are arranged on one side of the forming support. A pin storage box is arranged between each forming pin ejecting oil cylinder and the forming support. A die stripping gland strip is arranged above the die stripping support and connected with a plurality of die stripping gland oil cylinders synchronously acting. Die stripping positioning air cylinders and die stripping pin ejecting oil cylinders are arranged on one side of the die stripping support. Pin collecting hoppers are arranged on the other side of the die stripping support. Each die comprises a die body, a heavy bamboo square stock cavity and a die top cover. The heavy bamboo square stock production line is high in forming and die stripping efficiency, simple in structure, capable of preventing the pins from getting lost and low in production cost.

Owner:ANJI YUKANG MACHINERY

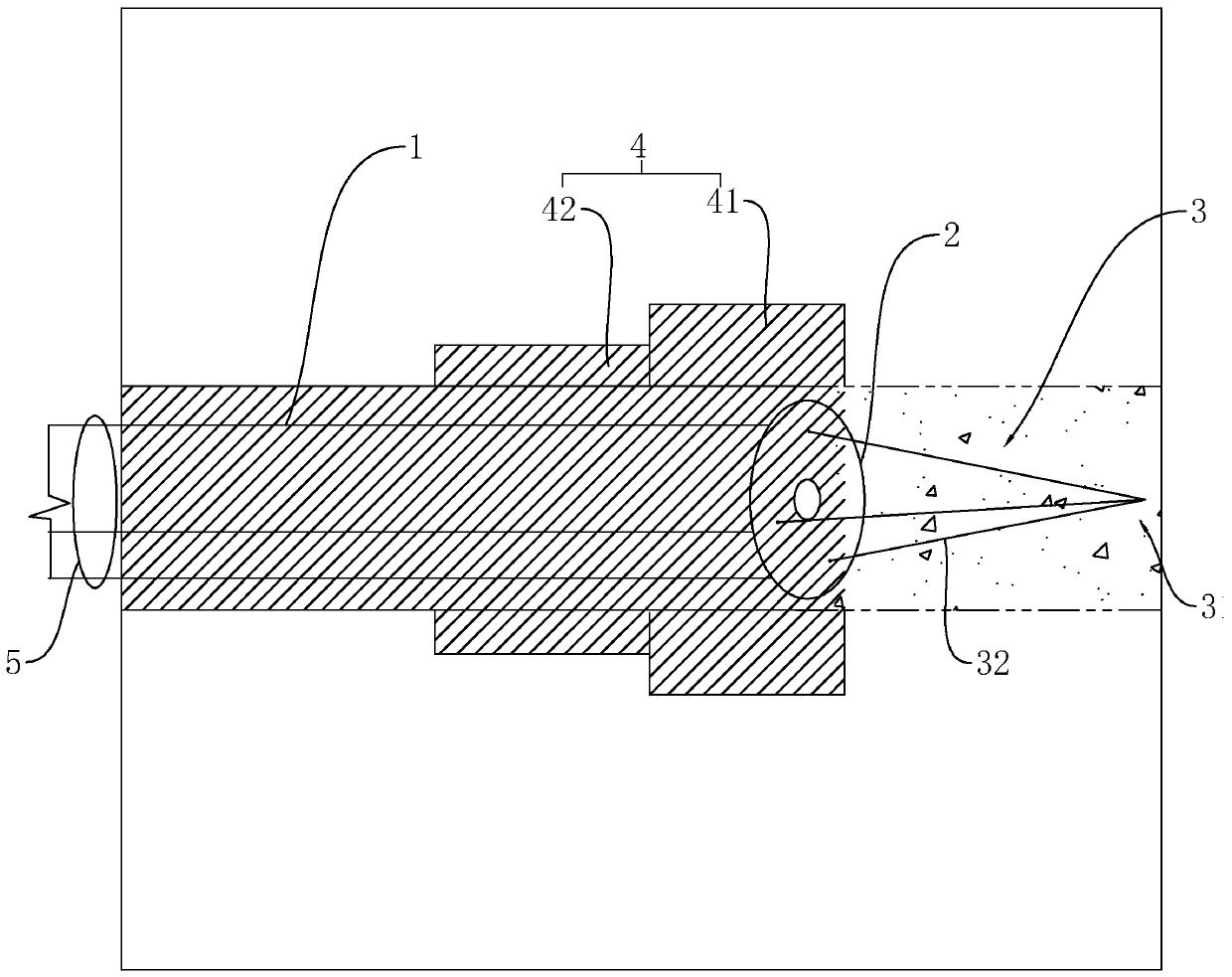

Anchor rod structure and construction method thereof

The invention relates to an anchor rod structure, and relates to the technical field of anchor rod construction. The anchor rod structure comprises an anchor cable and an anchor plate arranged at oneend of the anchor cable inserted into an anchor hole, an anti-sinking part used for preventing the anchor cable from sinking is arranged on one side, far away from the anchor cable, of the anchor plate, one end of the anti-sinking part is connected with the anchor plate, and the other end of the anti-sinking part is provided with a pointed cone part. Due to the fact that the anti-sinking part is arranged on the anchor plate, and the anchor plate is temporarily fixed through the anti-sinking part, the problem that the anchor plate is prone to sink before the rotary spraying grouting slurry is initially set is solved. The anchor rod structure has the advantages that the arrangement position of the anchor cable is guaranteed, and the supporting effect is good.

Owner:北京中润宝成工程技术有限公司

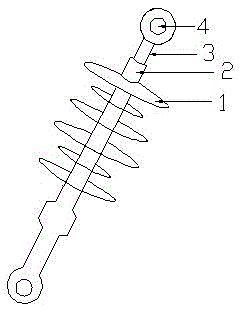

Composite molding process for electric vehicle chassis suspension assembly

The invention discloses a composite molding process for an electric vehicle chassis suspension assembly. The composite molding process for the electric vehicle chassis suspension assembly is characterized by comprising the following steps of 1, drawing molding; 2, upper sealing sleeve rolling; 3, injection molding; 4, fixing base fixing; 5, lower sealing sleeve jacking; 6, fixing box jacking; 7, composite flanging and molding; 8, primary composite molding part plastic spraying; 9, primary composite molding part fixing; 10, shock-proof buffering ring jacking; 11, upper sealing sleeve jacking; 12, fixing ring jacking; and 13, fixing box rolling. After all parts are drawn and molded through a drawing mold, a fixing base serves as a main assembly part; all the parts are sequentially clamped into the fixing base through a hydraulic cylinder, and then flanging is conducted through the hydraulic cylinder, so that all the parts are tightly clamped; and compared with existing welding connecting, the drawing cost is low, assembly is reliable, the fastness is good, the overall strength is high, the service life is long, welded joints are avoided, the appearance is attractive, the machining period is short, and the production efficiency is high.

Owner:李志联

Hydraulic equipment for removing and installing bucket tooth pins

ActiveCN113293817BRealize forward and reverse controlCompact structureSoil-shifting machines/dredgersGear pumpPower switching

Hydraulic equipment for removing and installing bucket tooth pins, including motors, power switches, oil drums, bidirectional gear pumps, housings, oil cylinders, oiling pots, high-pressure oil pipes, overflow valves, and oil circuit integrated distribution blocks; the oiling pots are installed in the oil The upper end of the barrel; one side of the oil circuit integrated distribution block is installed on one side of the oil barrel, and the motor is installed on the other side of the oil circuit integrated distribution block; the bidirectional gear pump is installed on one side of the oil circuit integrated distribution block, and the power input of the bidirectional gear pump The shaft and the power output shaft of the motor are installed together; the oil drum and the oil cylinder are installed together; the relief valve is installed on the oil circuit integrated distribution block; the lower oil pipe of the oil cylinder and the lower inlet and outlet pipes of the oil circuit integrated distribution block are installed together through the oil pipe; The housing is mounted on the outside of the motor, and the power switch is mounted on the housing. The invention is compact in structure and convenient to use. Only by controlling the power switch, the piston of the oil cylinder can move forward to push out or push the bucket tooth pin shaft, and move backward to return to the initial state, thereby improving the efficiency of disassembling and installing bucket teeth.

Owner:漳州鑫山航机械有限公司

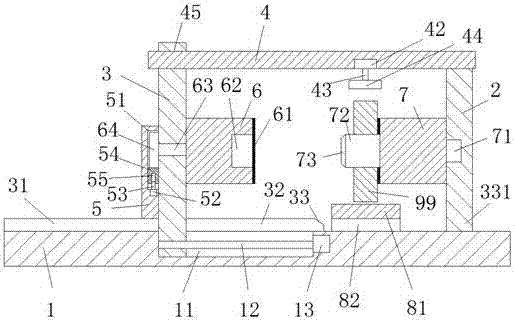

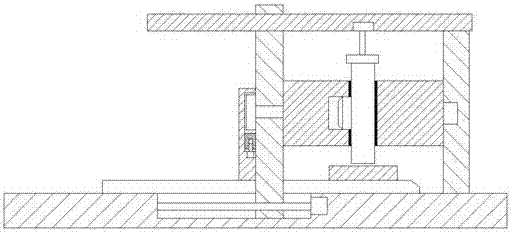

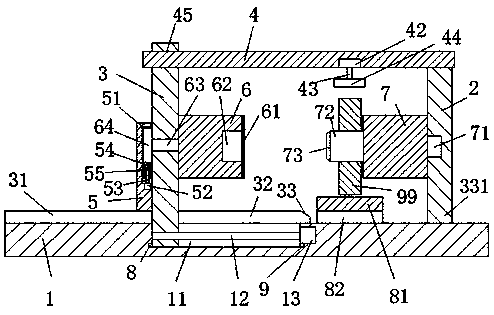

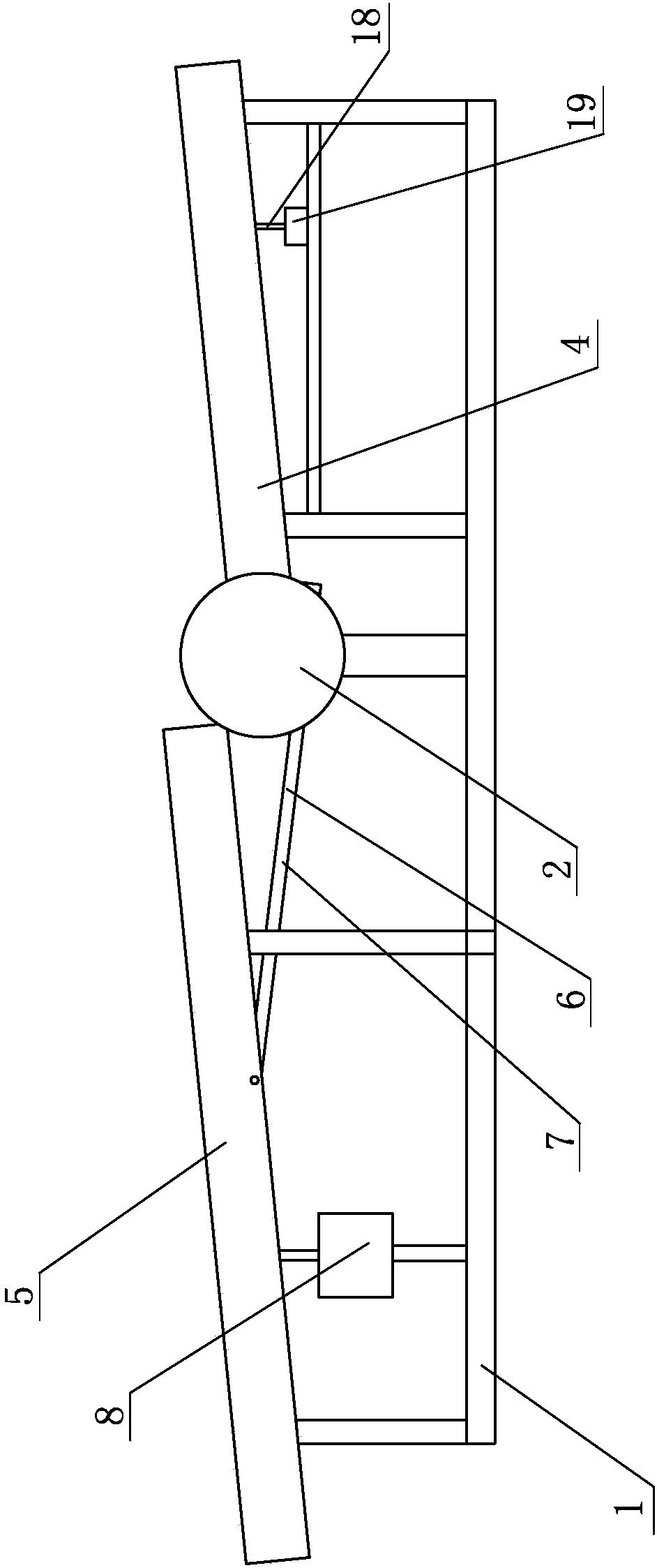

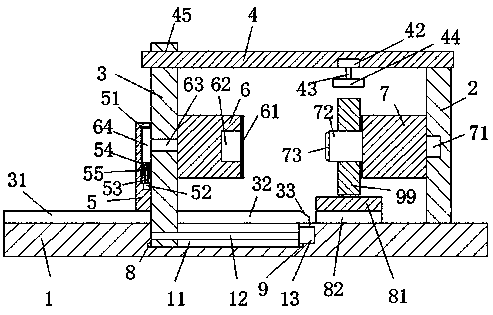

Plate cutting and forming equipment

InactiveCN107696129AClamp firmlyEasy jackingMetal working apparatusEngineeringMechanical engineering

The invention discloses plate cutting and forming equipment. The equipment comprises a bottom disc and a support plate arranged on the bottom disc. Fixing plates are fixedly mounted on the front end surface and the rear end surface of the bottom disc correspondingly. Fixing holes are formed in the fixing plates. A slide groove is further formed in a position, located on the left side of the support plate, in the bottom disc. A slide support is arranged in the slide groove in a left-right horizontal sliding mode. An upper opening groove is formed in the top of the slide support. A top disc is arranged in the opening groove in a horizontal sliding mode. The right end of the top disc is fixedly connected with the support plate. The plate cutting and forming equipment is simple in structure, low in production cost and easy to operate, the plate cutting efficiency is greatly improved, wasting of human resources is reduced, the cutting effect is good, the cutting precision is high, and modern production demands are met.

Owner:安徽省宣城市永健机械有限公司

Unequal-height tank whole jacking construction method

ActiveCN102619523BSmall height differenceEnsure stabilityTunnelsWork periodArchitectural engineering

Disclosed is an unequal-height tank whole jacking construction method. A waterproof protecting layer is laid at the top of a low tank; an I-beam layer is arranged on the surface of the protecting layer, and adjacent I-beams are connected to form a support; a steel plate layer is laid on the surface of the support, the edges of a steel plate are welded with the tops of the I-beams; the edges of the steel plate are welded with an embedded steel plate at the top of a high tank; and the unequal-height tanks are jacked to the direction of a low line from the outer side of a high line, and after the I-beams at the front end of a steel platform pass through the high line, the I-beams and the steel plates are detached while jacking, and the like. The I-beams and the steel plate are arranged on the low tank of the unequal-height tanks to form the steel platform, so that the steel platform is level with the top of the high tank, height difference between the low tank and the high line is reduced, stability of the high line is guaranteed when the low tank passes through the high line in a jacking process, and the purpose of wholly jacking a frame bridge on the promise of guaranteeing safety of traveling of an existing line is achieved. Besides, construction is convenient, safety is high, work period is short, and construction cost is low.

Owner:CHINA RAILWAY SIXTH GRP CO LTD +1

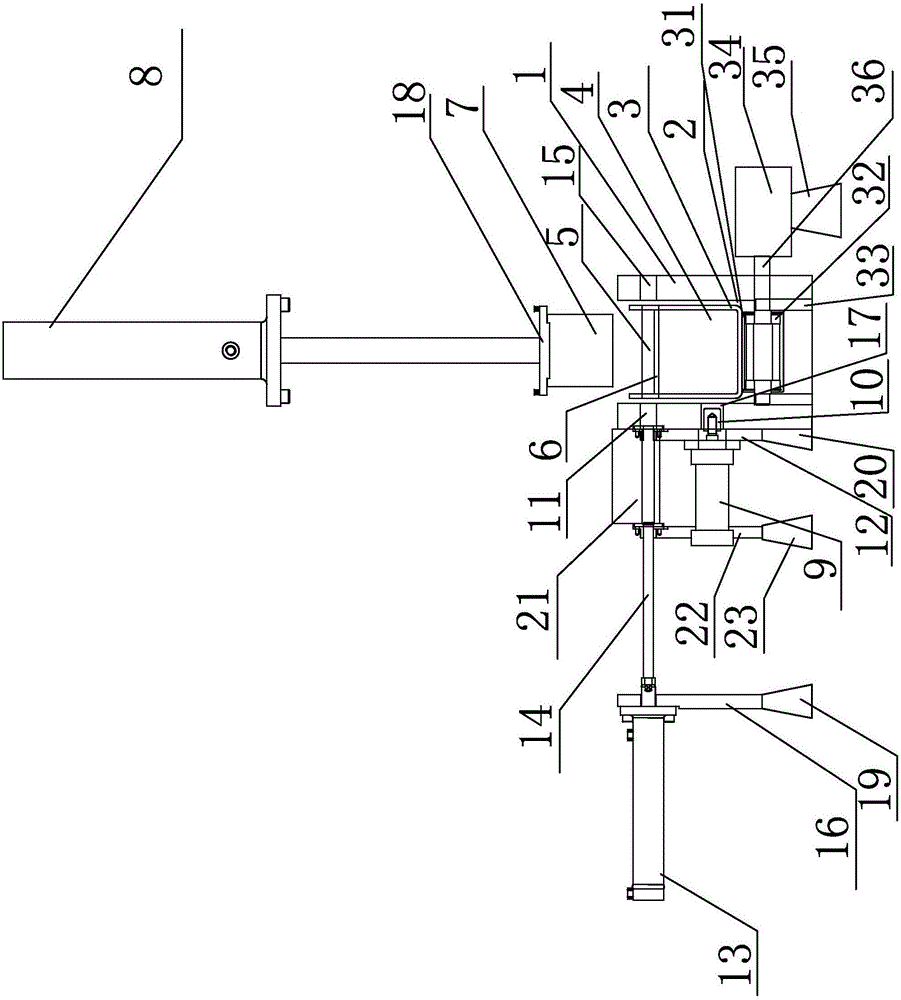

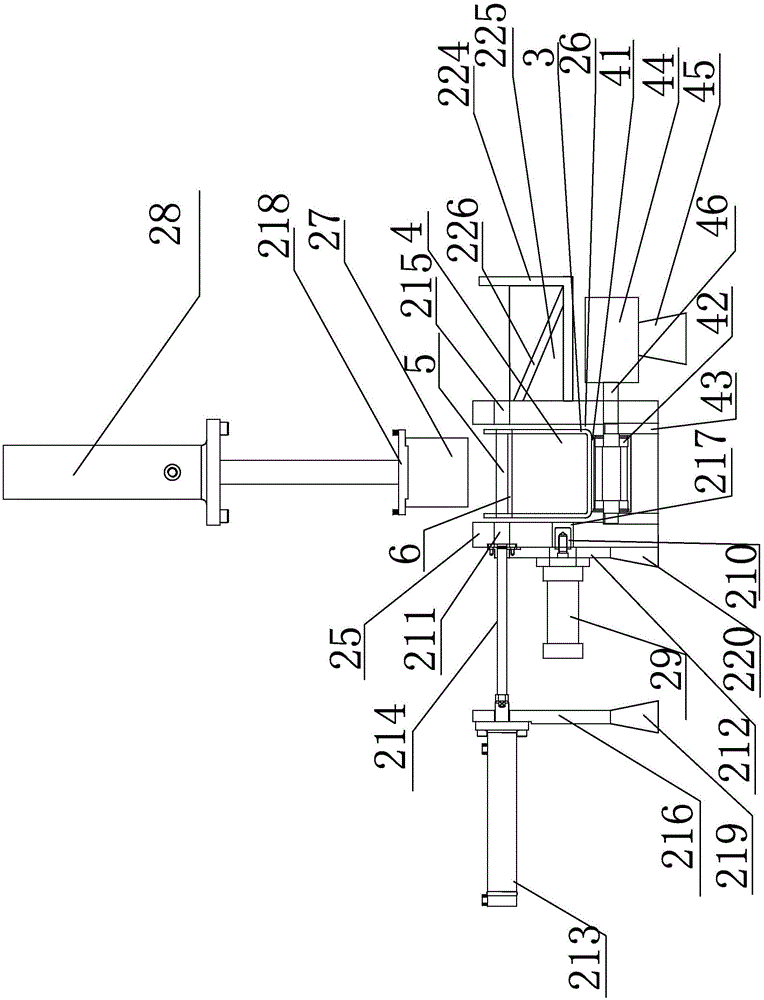

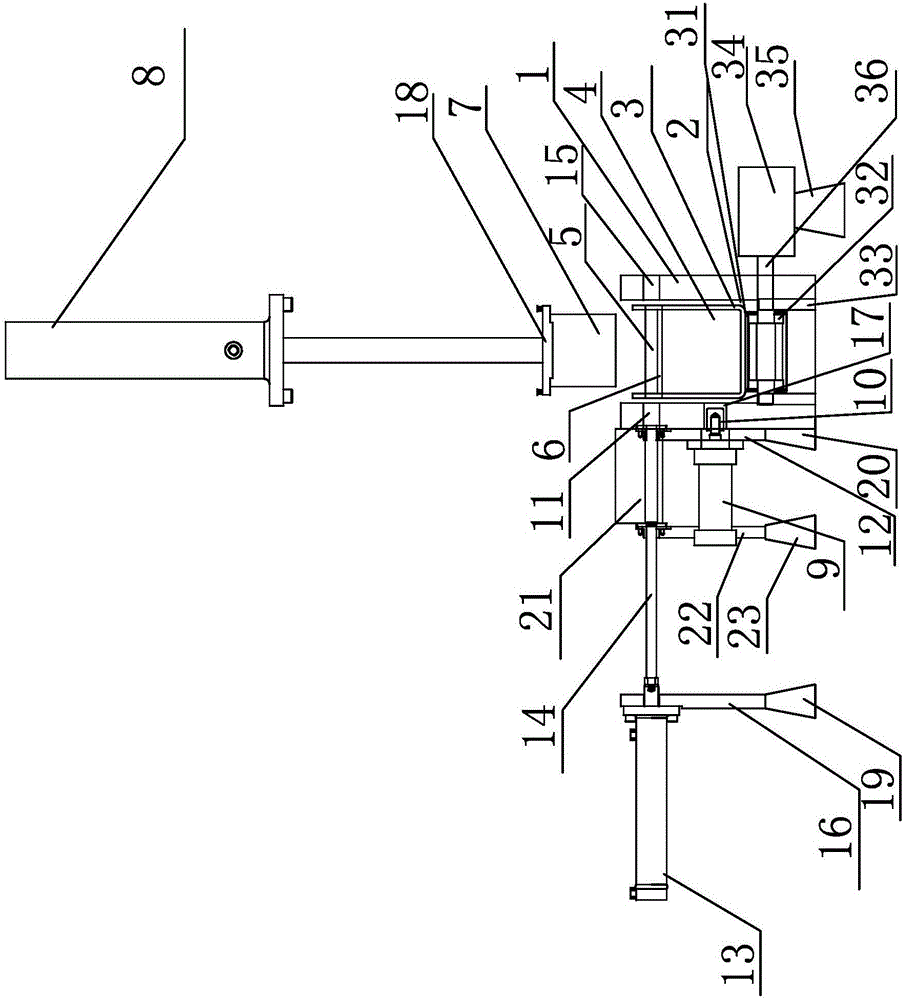

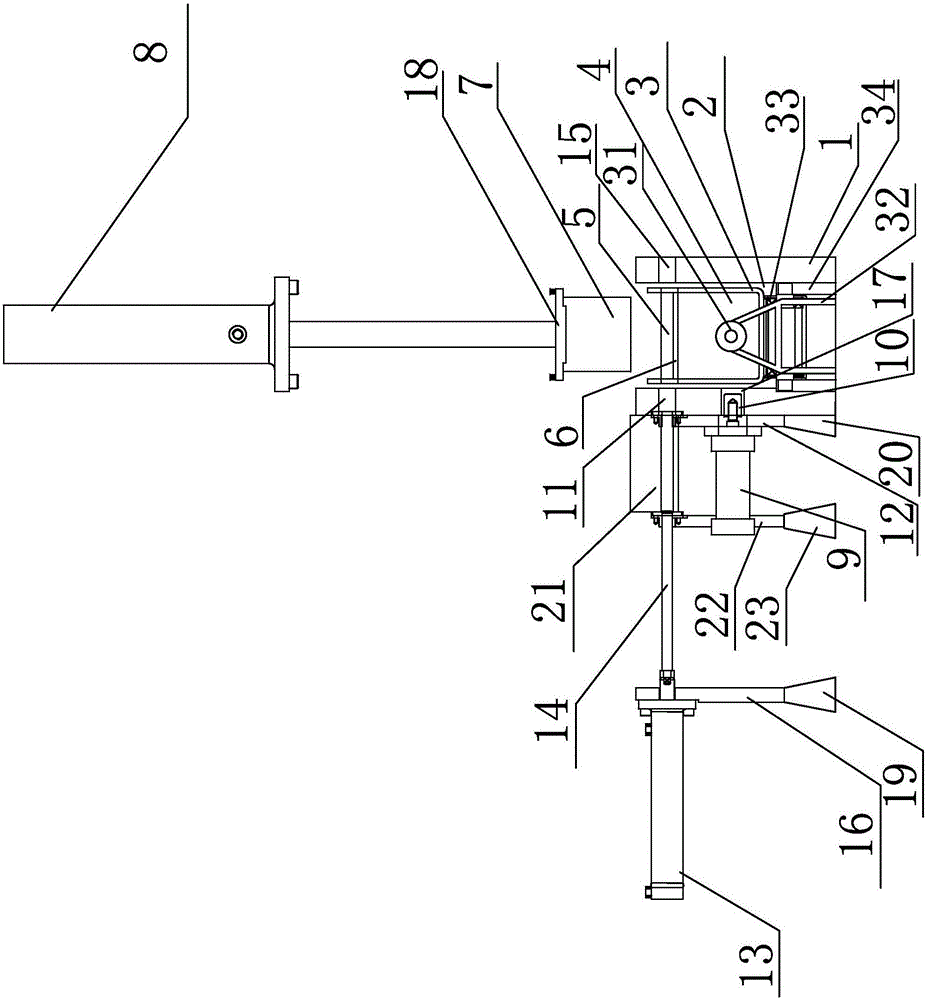

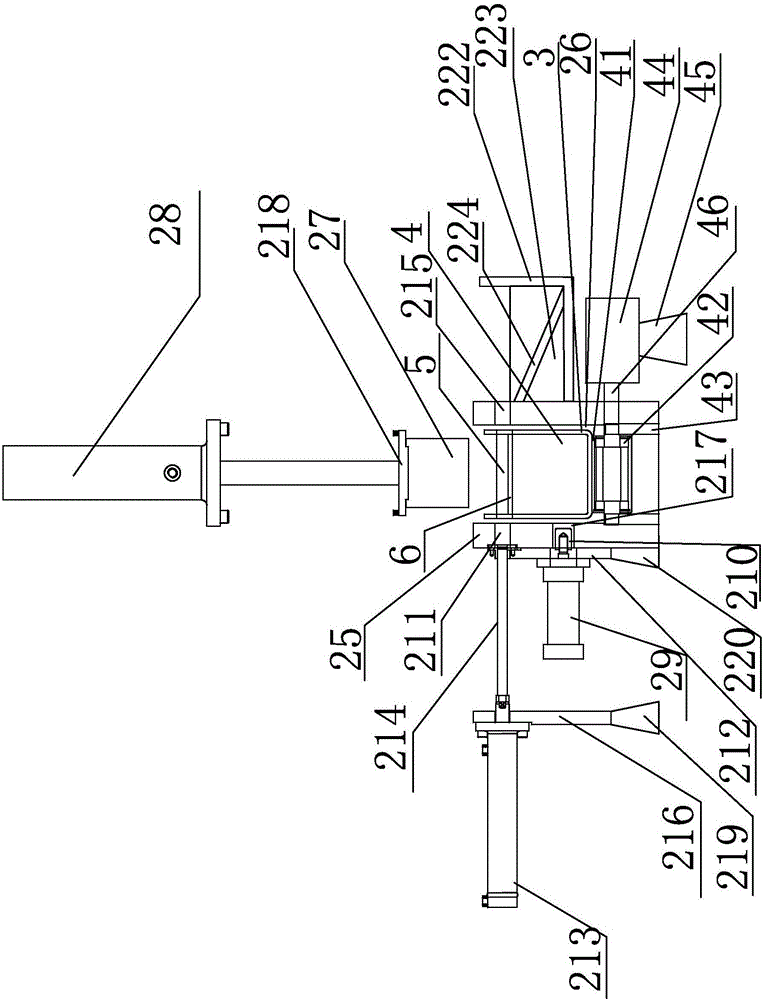

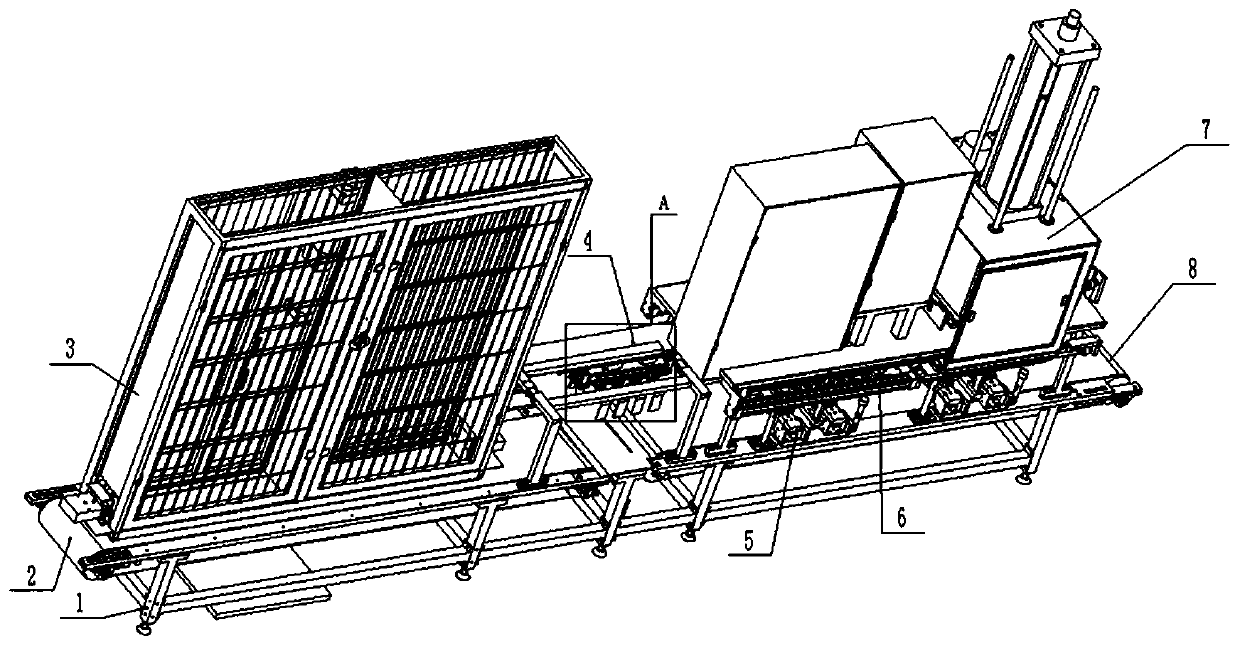

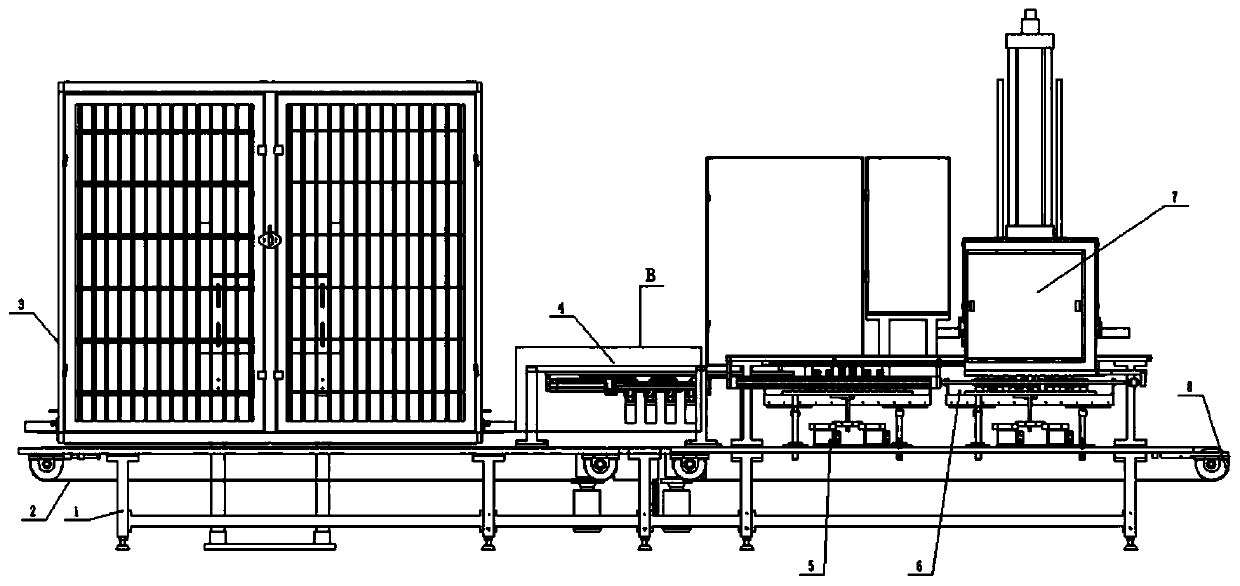

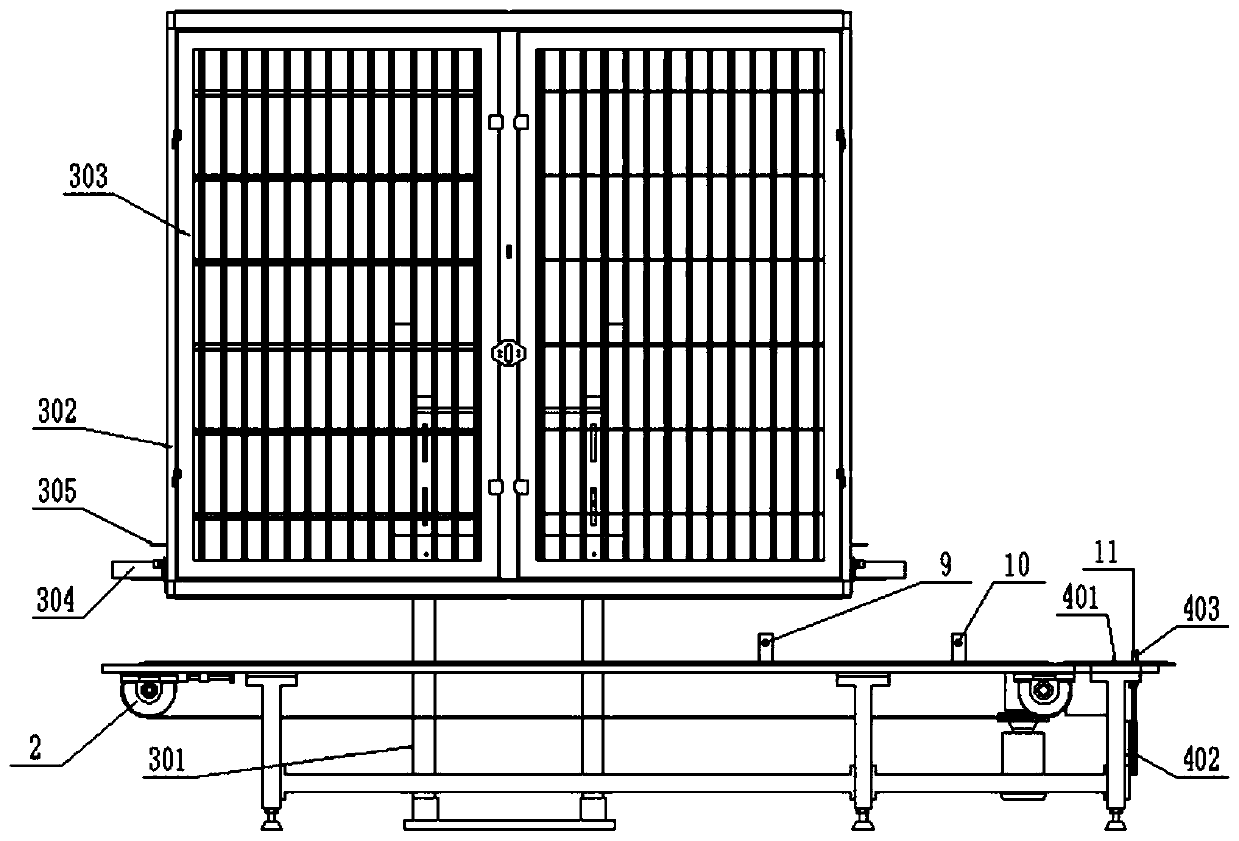

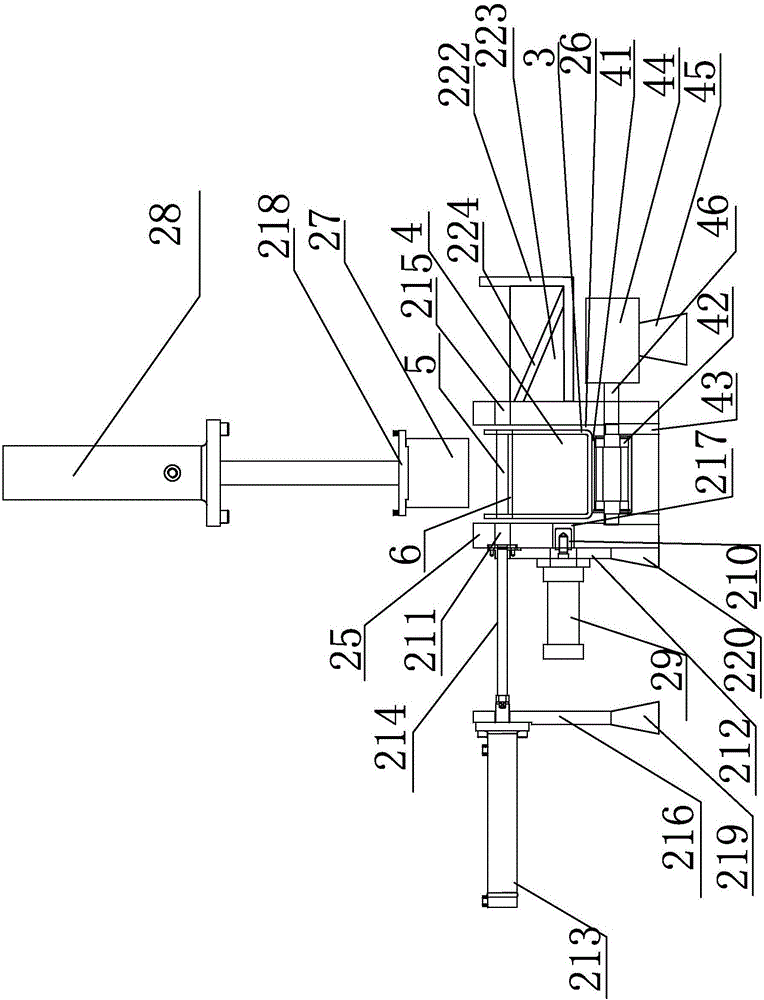

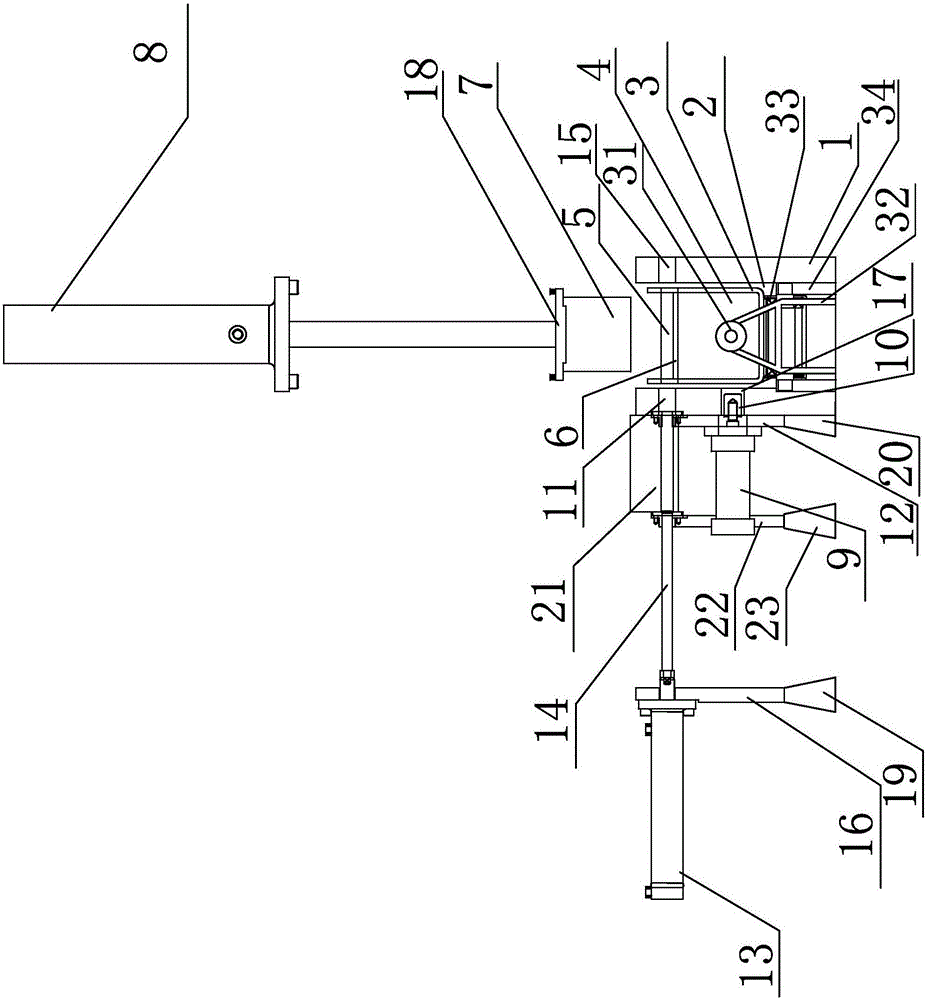

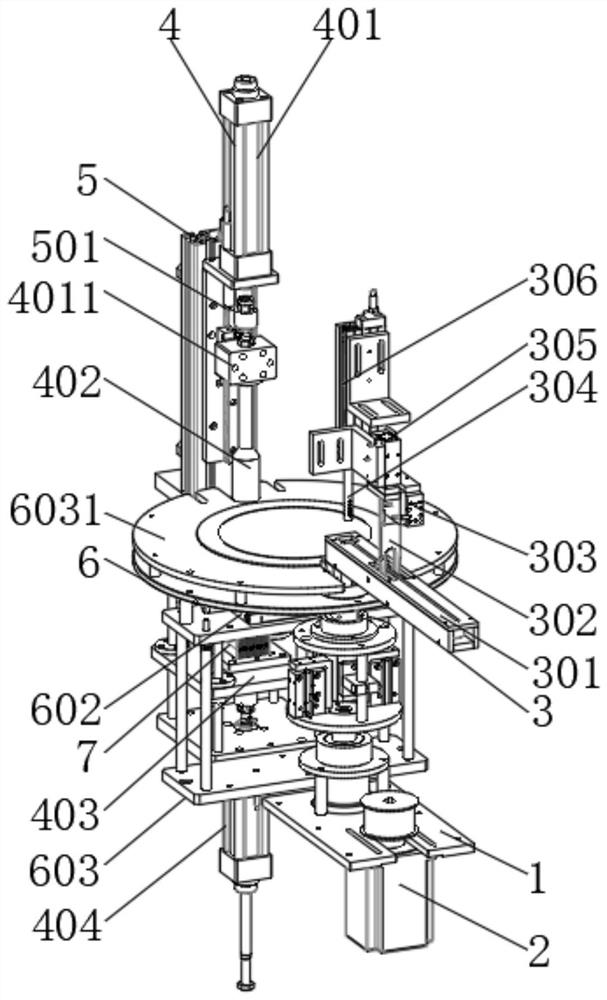

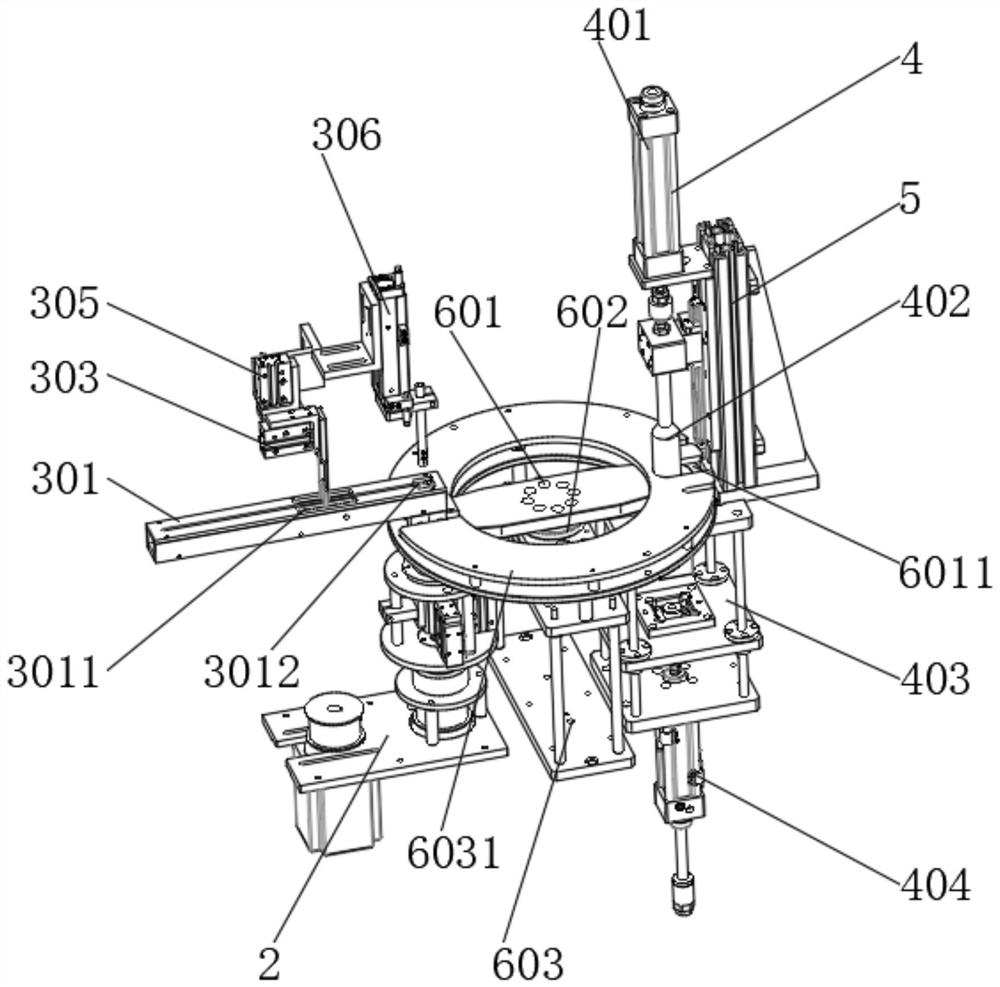

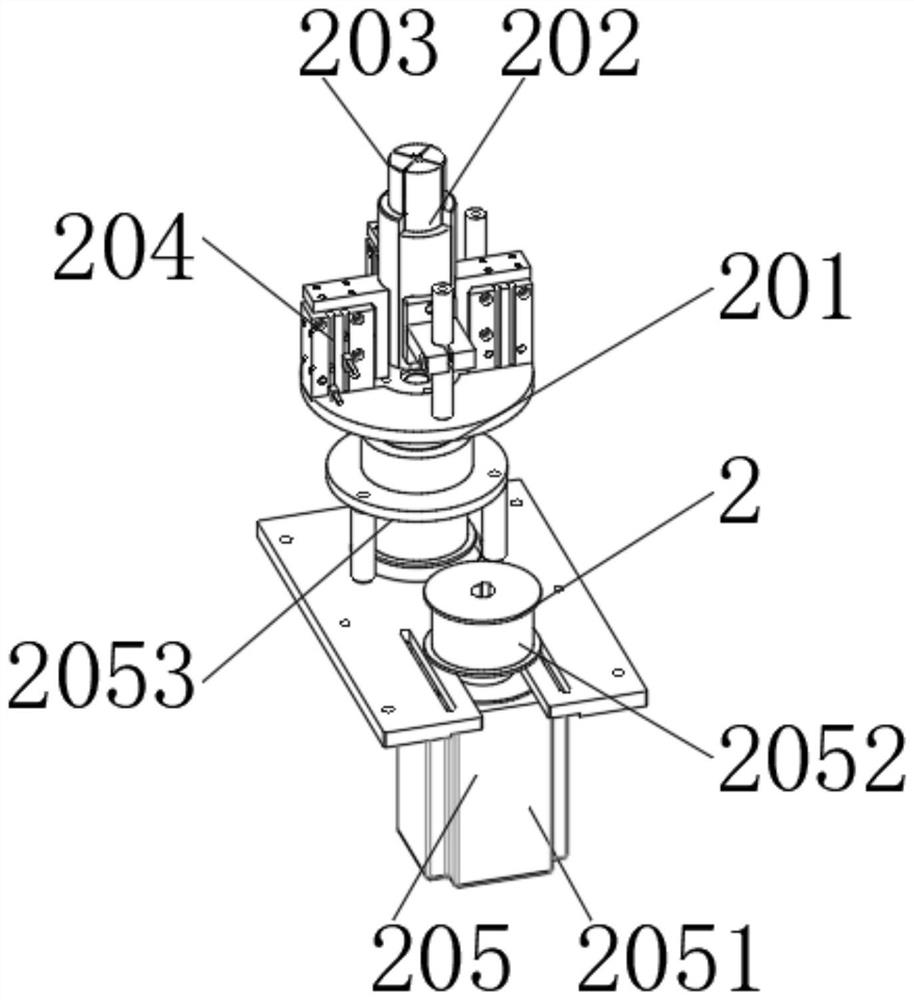

Pole group inserting machine and use method thereof

ActiveCN110085924APrecise positioningEasy jackingFinal product manufactureLead-acid accumulators constructionEngineeringTransfer mechanism

The invention relates to the technical field of battery production equipment, and particularly relates to a pole group inserting machine and a use method thereof. The pole group inserting machine comprises a rack. A supplying mechanism for supplying a battery case to a first conveyor belt is arranged on the rack above the first conveyor belt. A transfer mechanism is arranged on the rack between the first conveyor belt and a second conveyor belt. A plurality of stabilization mechanisms for stabilizing the battery case on the second conveyor belt are arranged on the rack above the second conveyor belt. A pole group positioning mechanism is fixed on a movable plate. A pole group jacking mechanism is arranged above the pole group positioning mechanism. The pole group jacking mechanism is usedfor jacking the pole group in the pole group positioning mechanism into the battery case stabilized by the stabilization mechanisms, and the pole group jacking mechanism is slidably arranged on the rack. An anti-pole prevention device is arranged in the pole group jacking mechanism so that an alarm can be given when the pole group is placed upside down, the pole group lug of the pole group placedupside down is ensured not to be damaged by the jacking block, and the labor cost can be greatly saved and the production efficiency can be enhanced.

Owner:TIANNENG GRP HENAN ENERGY TECH

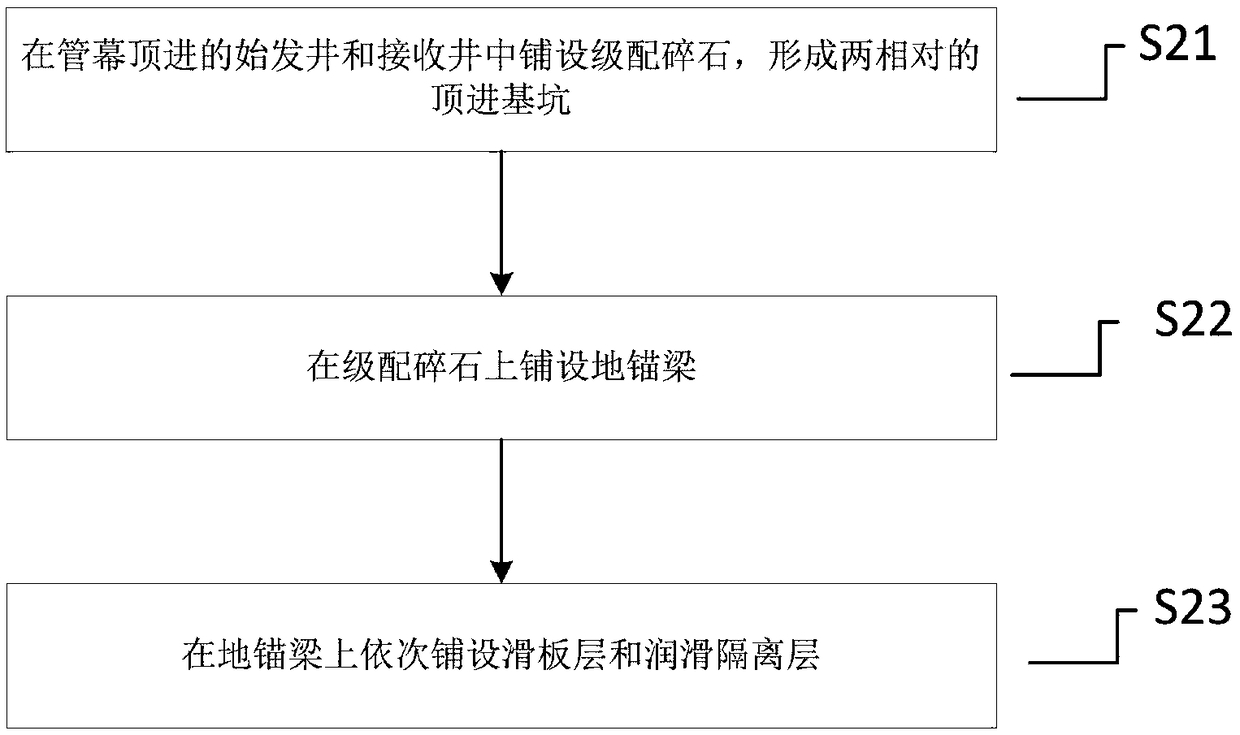

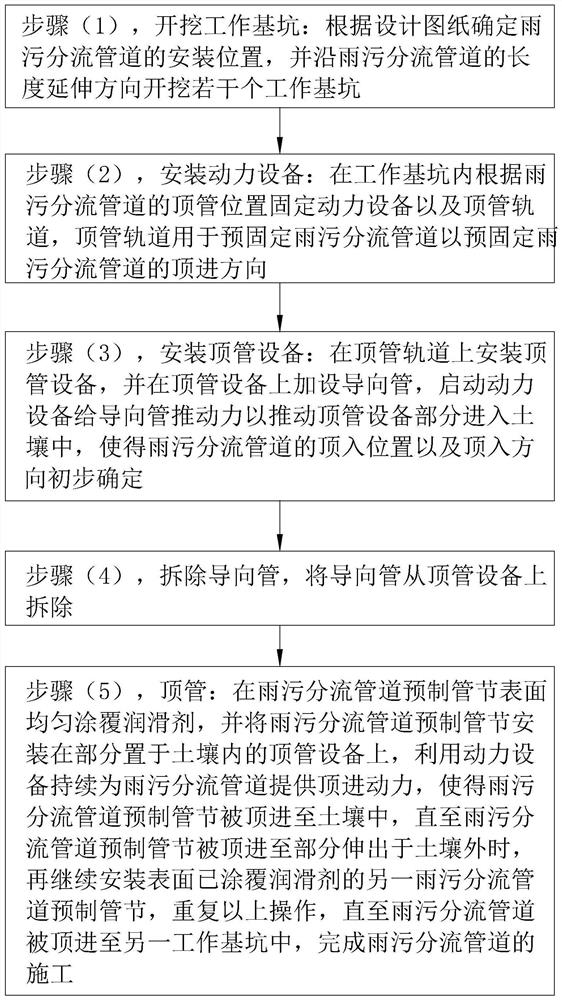

Construction method of municipal rain and sewage diversion pipeline

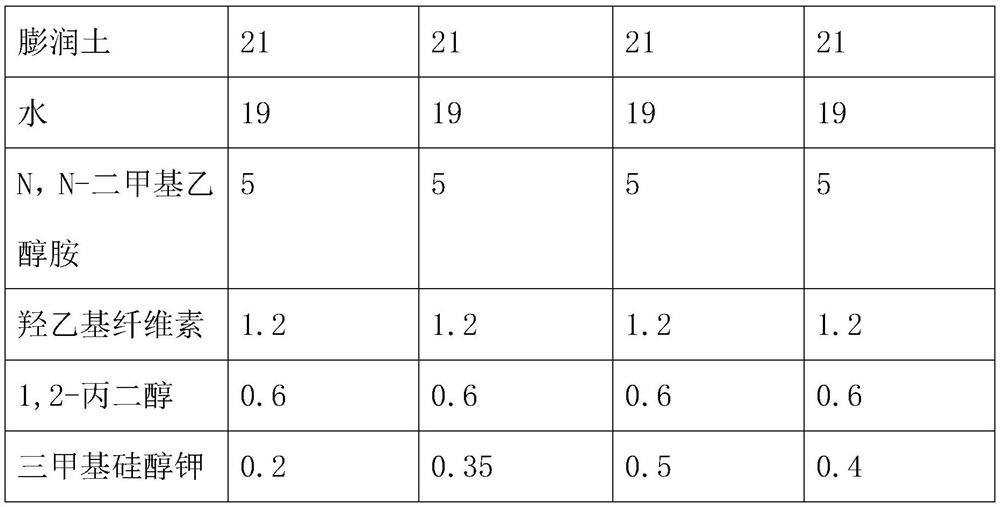

The invention relates to the technical field of municipal construction, in particular to a construction method of a municipal rain sewage diversion pipeline. The construction method comprises the following steps of S1, excavating a working foundation pit; S2, installing power equipment; S3, installing pipe jacking equipment; S4, dismantling a guide tube; and S5, pipe jacking. A lubricant comprisesthe following components in parts by weight of 30-40 parts of sodium stearate; 20-25 parts of acrylic emulsion; 15-25 parts of packing; 15-20 parts of water; 3-6 parts of N, N-dimethyl ethanolamine;1-2 parts of hydroxyethyl cellulose and 0.5-1 part of 1,2-propylene glycol. The construction method has the effect of enabling the rain sewage diversion pipeline to be pushed into soil more easily.

Owner:广东中立建设有限公司

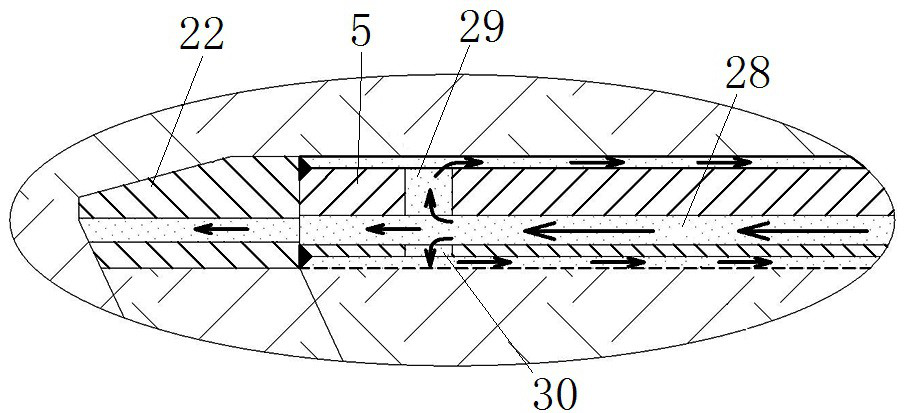

Pipe jacking device, construction device and construction method of subsurface tunnel

The invention relates to a pipe jacking device, a construction device and a construction method of a subsurface tunnel. The construction device of the subsurface tunnel comprises a pipe jacking device and a working pipe, the pipe jacking device comprises a pipe jacking pushing device, a sealing plate, a sealing plate pushing device and a sealing plate limiting device, and the sealing plate keeps a sealing state for a soil body in the working pipe under the pushing action of the sealing plate pushing device; the sealing plate limiting device limits the position of the sealing plate when the jacking pipe pushing device and the sealing plate pushing device retract backwards, so that the position of the sealing plate is not changed; according to the construction method, in the process of jacking the working pipe into the soil layer and the process of connecting the next section of working pipe, the sealing plate is kept in a sealing state until the working pipe penetrates through the soil layer, the sealing plate is dismantled, and a soil body is excavated. By means of the construction device and the construction method, soil in the working pipe can be effectively prevented from gushing out of the tunnel portal, the function of stabilizing the tunnel face is achieved, and the adaptability of the construction device and the construction method to unstable stratums or stratums with the high settlement requirement can be improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Packing device for dry powder extinguishing agent

PendingCN107745843AReduce labor intensityImprove packaging efficiencyWrapper twisting/gatheringEngineeringStructural engineering

The invention discloses a packing device for dry powder extinguishing agent. The packing device is characterized in that the packing device includes a rack, a feeding mechanism, a catching mechanism and a packing mechanism. The catching mechanism is installed on the left side of the feeding mechanism. The packing mechanism includes a telescopic cylinder and a packing piece installed on an output shaft of the telescopic cylinder. The feeding mechanism includes a feeding slot. The angle between the feeding slot and the horizontal plane is 5-15 degrees. The catching mechanism includes a catchingslot and two sets of catching pieces installed on the two sides of the middle part of the catching slot separately. The catching pieces include a catching rod and a top lifting air cylinder. The middle of the catching rod is connected with the catching slot in a rotation mode. The top lifting air cylinder is installed on the left side of the catching rod. The output shaft of the top lifting air cylinder is connected with the bottom of the left side of the catching rod. The right side of the catching rod is installed above or below the left end of the catching slot. According to the packing device, packing efficiency is improved and the labor intensity of an operator is reduced.

Owner:SUZHOU WUYUE SYNTHETIC FIRE SCI TECH

A cutting and forming equipment

Owner:JIANGSU DNCON LASER TECH

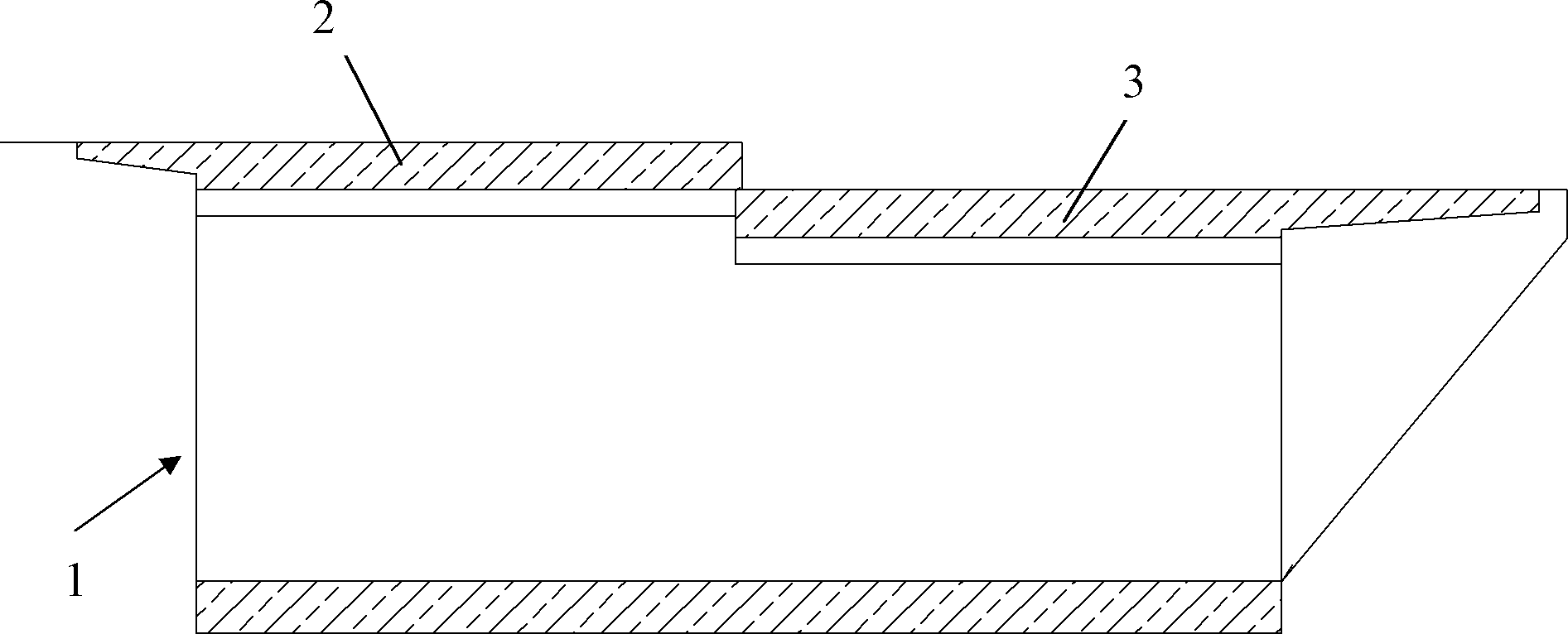

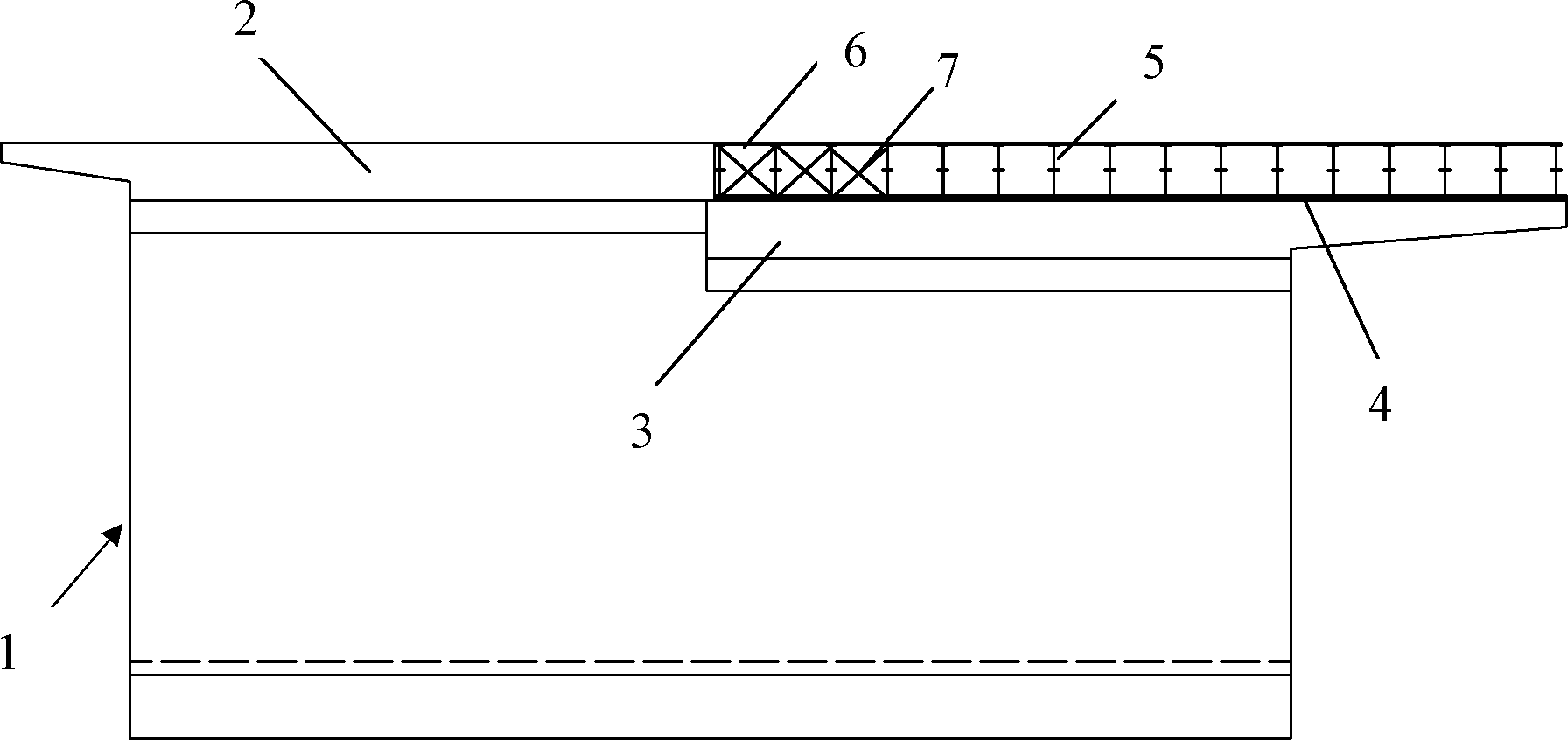

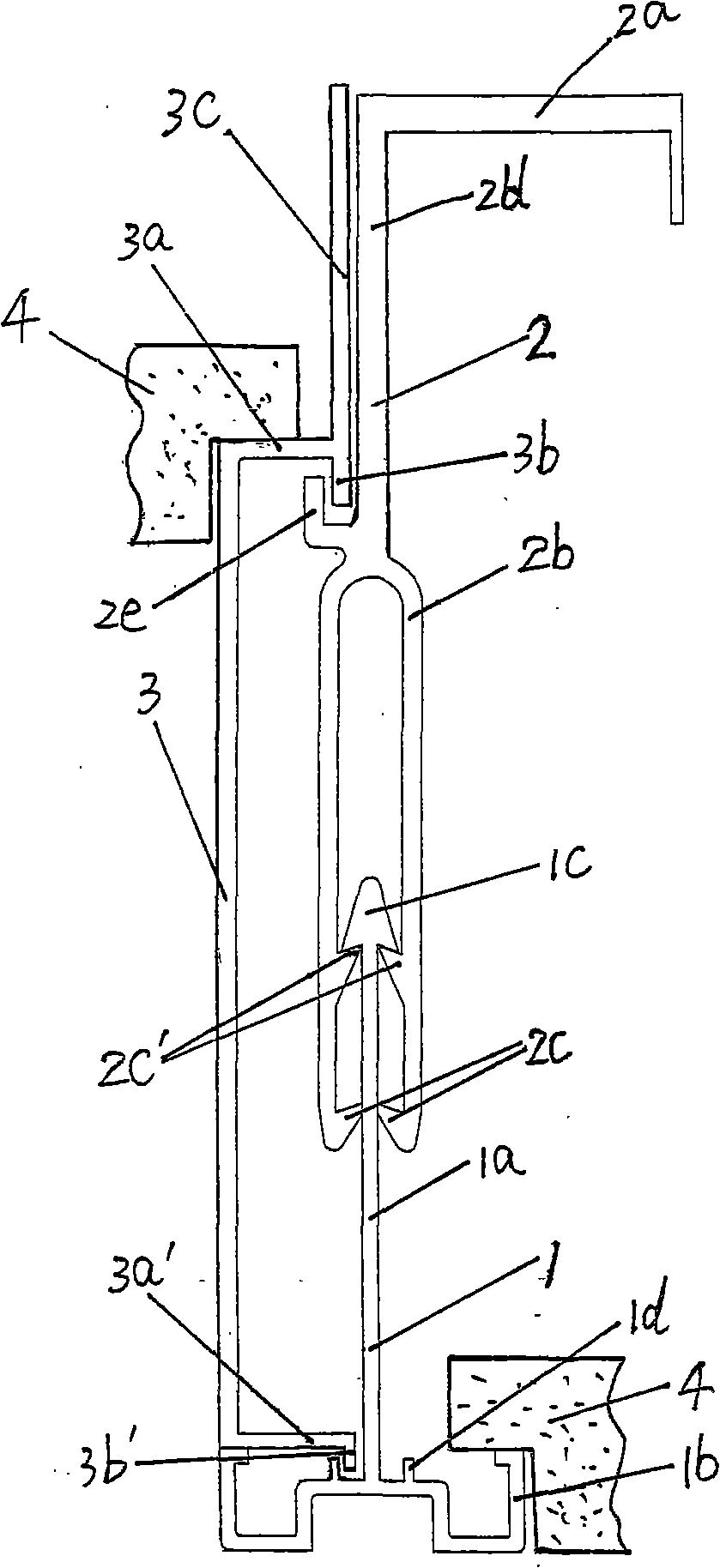

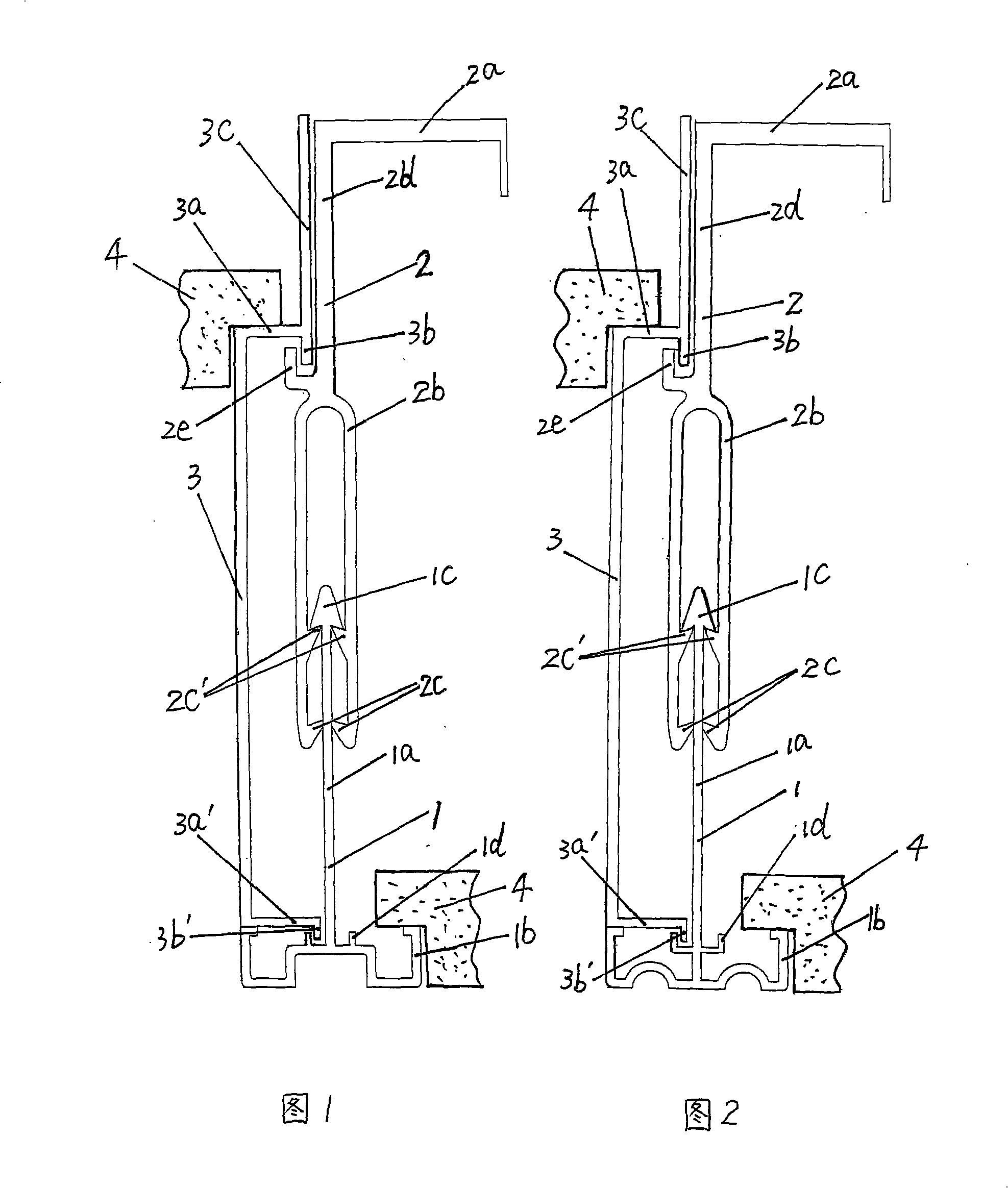

Stacking keel installation method

The invention provided an overlapped keel mounting method. The overlapped keel comprises a block mounted hanging hook (2), a key keel (1) and a false keel (3); the mounting method is: firstly mounting the hanging hook at the decorated top surface, then clamping the wedge-shaped hook (1c) at the top of key keel into a U-shaped clip from bottom to be hung on a barb, and finally inserting an upper hanging lug (3a) on the upper wallboard of the rider keel into an upper supporting lug (2e) at the lower part of the footboard of the hanging hook, and inserting a lower hanging lug (3a') on the lower wallboard of the rider keel into a lower supporting lug (1d) at the lower part of the hanging steel bar of the key keel or at the back of a supporting board. The method is easy in mounting, maintenance, and replacing, steady in mounting and good in decorative effect.

Owner:湖南安雅达建材科技有限公司

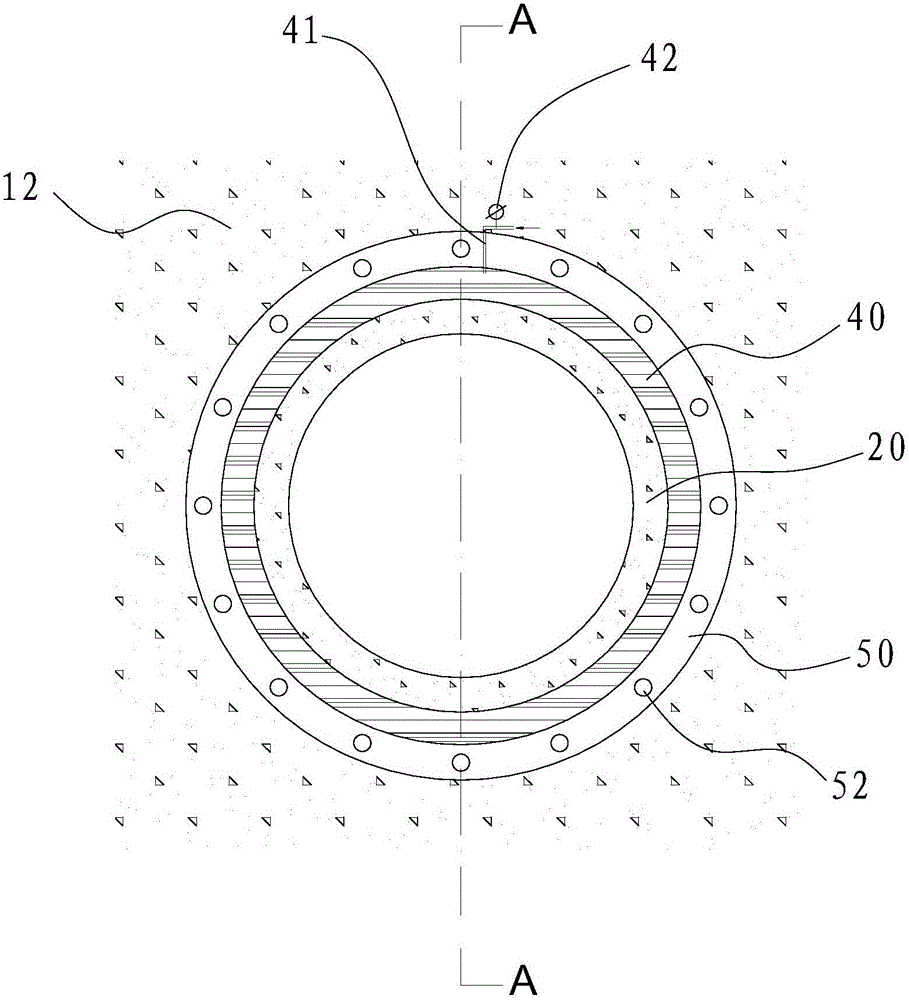

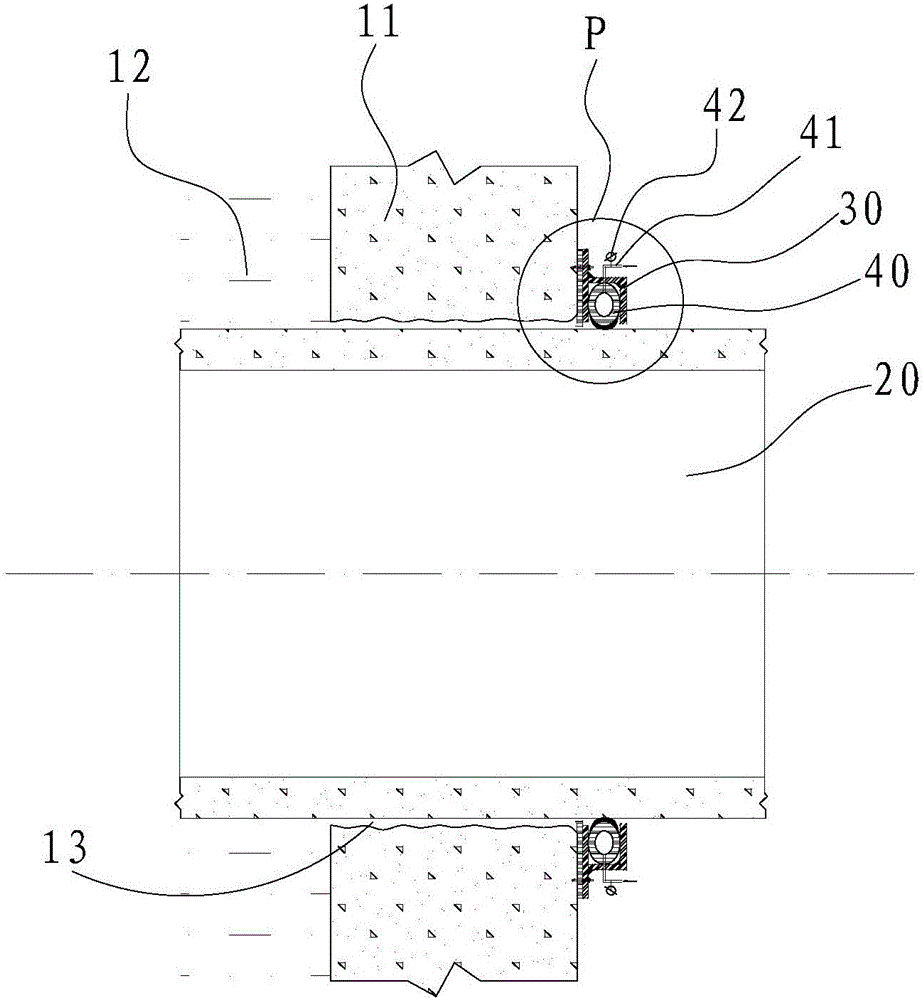

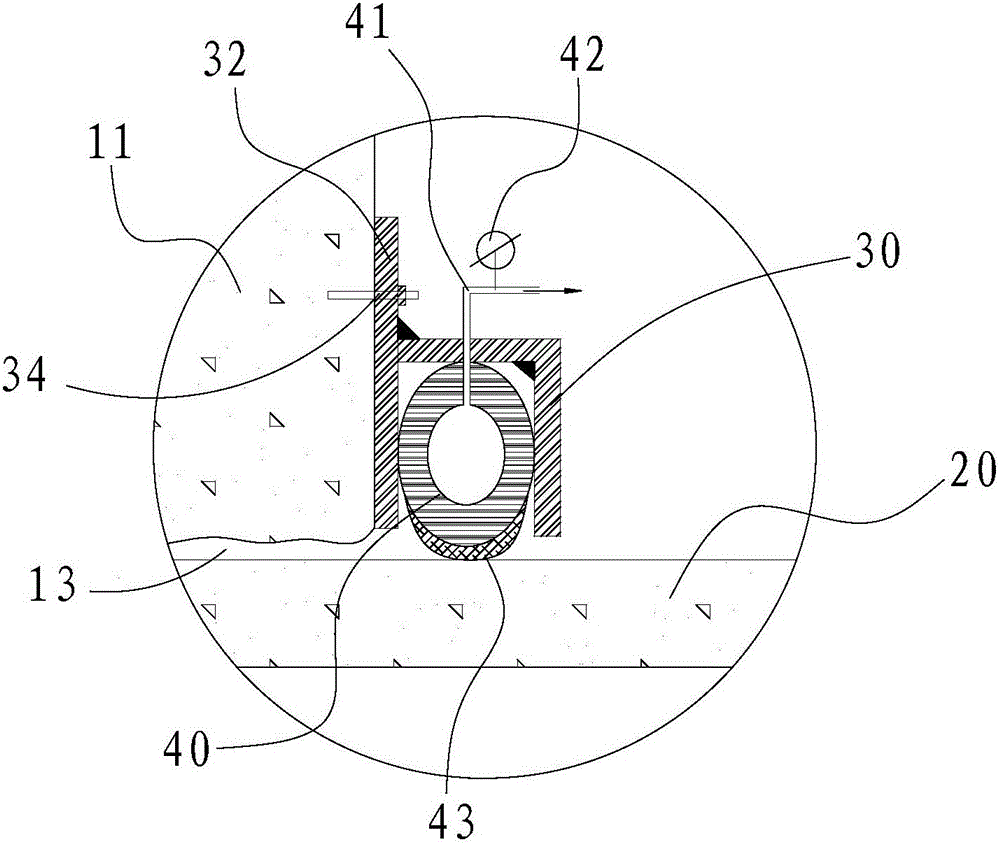

Sealing installation structure of tunnel pipeline and installation method of tunnel pipeline

The invention discloses a sealing mounting structure of a tunnel pipeline and a mounting method of the tunnel pipeline. The mounting structure comprises a working well, the tunnel pipeline, mounting groove bodies and annular bag bodies, wherein holes are formed in the wall of the working well; the tunnel pipeline is inserted into a soil layer through the holes; the mounting groove bodies are detachably mounted on the wall of the working well, and the sidewalls of the mounting groove bodies are clung to the wall of the working well; the mounting groove bodies which are provided with annular grooves sleeve the tunnel pipeline; the annular bag bodies are mounted in the corresponding annular grooves and sleeve the tunnel pipeline; the annular bag bodies are propped against the bottom parts of the corresponding annular grooves and the sidewall of the tunnel pipeline. According to the mounting structure, the error allowance value of the opening size of the holes in the wall of the working well can be extended, thus the radial deviation of the tunnel pipeline in the propping-in process can be reduced, and the abrasion between the holes and other mounting assemblies can be avoided; in addition, the sealing effect is realized in the mounting process of the tunnel pipeline, so that the loss of the drag reducing mud which is poured in the propping-in construction of the tunnel pipeline can be prevented; a complete and effective mud sleeve can be formed, and thus the lubricating can be performed to achieve drag reducing, and the holes can be prevented from water.

Owner:GUANGZHOU ELECTRIC POWER DESIGN INST +1

Reconsolidated bamboo square stock production line with durable molds easy to take and dowels convenient to collect

InactiveCN105922431ASmooth penetrationIncrease contact areaWood working apparatusFlat articlesProduction lineBiochemical engineering

The invention discloses a reconsolidated bamboo square stock production line with durable molds easy to take and dowels convenient to collect. The production line comprises a forming device, a solidifying drying room and a mold releasing device; the forming device comprises a forming support, a forming mold installation groove and one mold; the mold releasing device comprises a mold releasing support, a mold releasing mold installation groove and one mold; a forming press cover strip is arranged above the forming support and is connected to a plurality of forming press cover oil cylinders, a forming location air cylinder and a forming ejection pin oil cylinder are arranged on one side of the forming support, a pin storage box is arranged between the forming ejection pin oil cylinder and the forming support, and a pushing oil cylinder is arranged at one end of the forming support; a mold releasing press cover strip is arranged above the mold releasing support and is connected to a plurality of mold releasing press cover oil cylinders, a mold releasing location air cylinder and a mold releasing ejection pin oil cylinder are arranged on one side of the mold releasing support, and a dowel collection hopper is arranged on the other side of the mold releasing support; the molds comprise mold bodies, reconsolidated bamboo square stock cavities and mold top covers. The production line has the advantages that the forming efficiency and the mold releasing efficiency are high, the operation is safe, the molds are durable and the manufacturing cost is low.

Owner:ANJI YUKANG MACHINERY

A kind of cutting and forming equipment for plate

InactiveCN107696129BClamp firmlyEasy jackingMetal working apparatusMechanical engineeringEngineering

The invention discloses plate cutting and forming equipment. The equipment comprises a bottom disc and a support plate arranged on the bottom disc. Fixing plates are fixedly mounted on the front end surface and the rear end surface of the bottom disc correspondingly. Fixing holes are formed in the fixing plates. A slide groove is further formed in a position, located on the left side of the support plate, in the bottom disc. A slide support is arranged in the slide groove in a left-right horizontal sliding mode. An upper opening groove is formed in the top of the slide support. A top disc is arranged in the opening groove in a horizontal sliding mode. The right end of the top disc is fixedly connected with the support plate. The plate cutting and forming equipment is simple in structure, low in production cost and easy to operate, the plate cutting efficiency is greatly improved, wasting of human resources is reduced, the cutting effect is good, the cutting precision is high, and modern production demands are met.

Owner:安徽省宣城市永健机械有限公司

Heavy bamboo square stock production line with mold which is durable and easy to take

InactiveCN105904572ASmooth penetrationIncrease contact areaWood working apparatusFlat articlesBiochemical engineeringOperation safety

The invention discloses a heavy bamboo square stock production line with a mold which is durable and easy to take. The heavy bamboo square stock production line comprises a forming device, a curing drying house and a demolding device. The forming device comprises a forming supporting frame, a forming mold installation groove and the mold. The demolding device comprises a demolding supporting frame, a demolding mold installation groove and the mold. A forming pressing cover strip is arranged above the forming supporting frame. The forming pressing cover strip is connected with a plurality of forming pressing cover oil cylinders. Forming positioning air cylinders and forming pin pushing oil cylinders are arranged on one side of the forming supporting frame. A pin storage box is arranged between the forming pin pushing oil cylinders and the forming supporting frame. A material pushing oil cylinder is arranged at one end of the forming supporting frame. A demolding pressing cover strip is arranged above the demolding supporting frame and connected with a plurality of demolding pressing cover oil cylinders. Demolding positioning air cylinders and demolding pin pushing oil cylinders are arranged on one side of the demolding supporting frame. A first conveying mechanism is arranged at the bottom of the demolding mold installation groove. The mold comprises a mold body, a heavy bamboo square stock cavity and a mold top cover. The heavy bamboo square stock production line is high in forming and demolding efficiency, safe to operate and simple in structure, and the mold is long in service life.

Owner:ANJI YUKANG MACHINERY

Automatic material taking split type magnet assembling equipment

PendingCN112775640AEasy to assembleEasy jackingInductances/transformers/magnets manufactureMetal working apparatusEngineeringAssembly machine

The invention relates to the technical field of magnet assembling equipment, in particular to automatic material taking split type magnet assembling equipment. The automatic material taking split type magnet assembling equipment overcomes the defects of slow manual assembling and and low working efficiency in the prior art; the automatic material taking split type magnet assembling equipment comprises a bottom plate; an assembling mechanism and a feeding mechanism are arranged on the two sides of the top end of the bottom plate correspondingly; a position adjusting mechanism is arranged between the assembling mechanism and the feeding mechanism; a discharging mechanism is arranged above the assembling mechanism; multiple magnets are pushed to the top end of the assembling mechanism through the discharging mechanism; the multiple magnets are combined into a whole through the assembling mechanism; and then through the position adjusting mechanism and the feeding mechanism, the combined magnets are pushed into an outer sleeve barrel to realize automatic assembling of the multiple magnets; and therefore, the working efficiency is high.

Owner:常州科恩威尔自动化科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com