Unequal-height tank whole jacking construction method

A construction method and box technology, applied in the direction of earth drilling, mining equipment, tunnels, etc., can solve the problems of high construction cost, heavy workload, large height difference, etc., and achieve low construction cost, high safety, and convenient construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

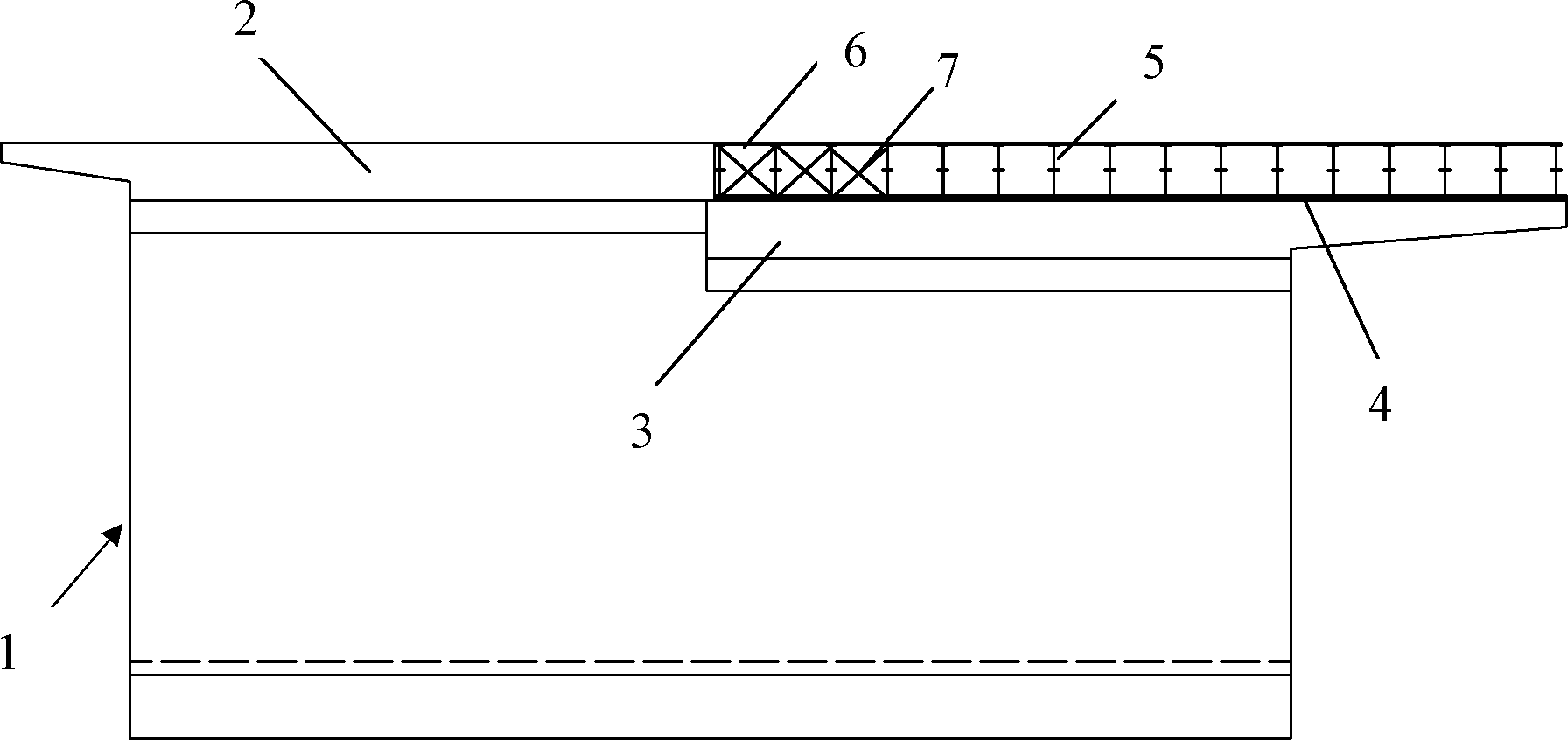

[0017] The construction method for integral jacking of boxes with different heights provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. Components that are the same as those in the prior art are given the same reference numerals, and their descriptions are omitted.

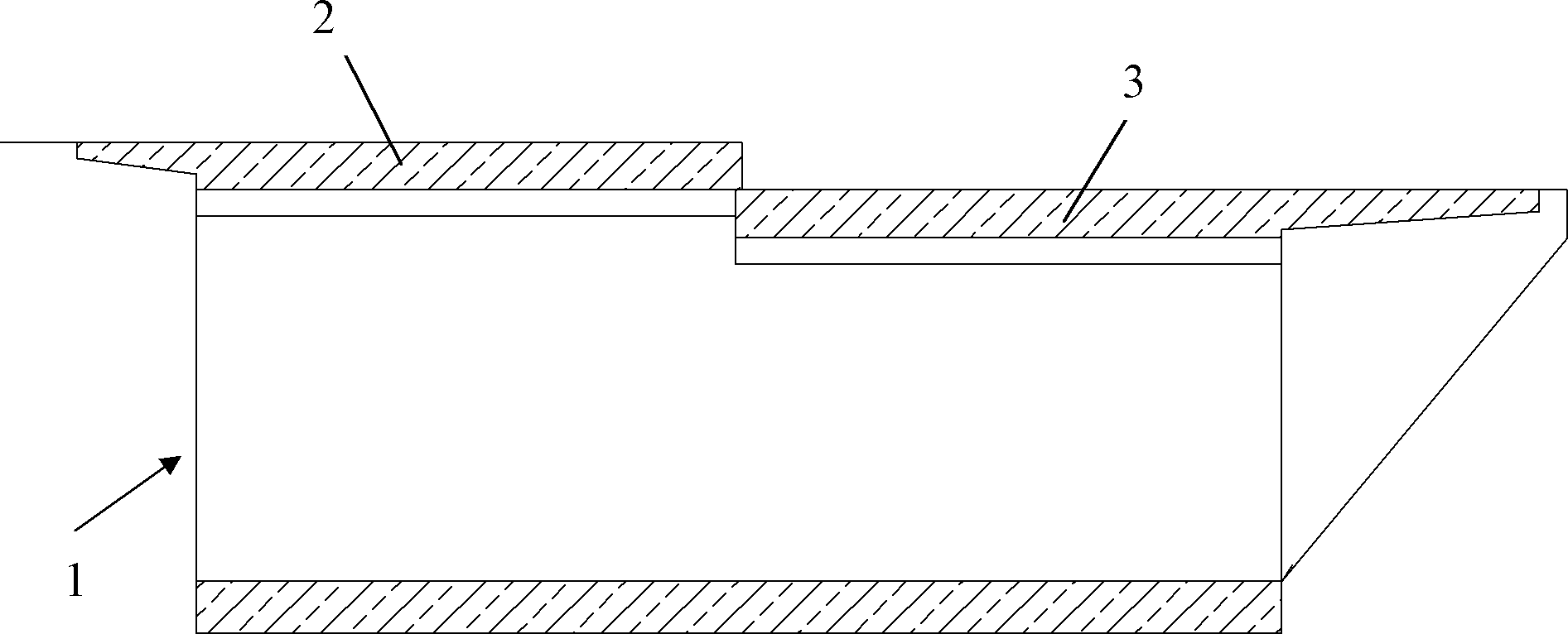

[0018] Now take a certain project as an example: the center distance between the high line and the low line of this project is 8.08 meters, and the top of the high line track is about 0.95 meters higher than the top of the line track, so the unequal height box 1 upper height box 2 and the height difference between the low cabinet 3 is designed to be 0.9 meters.

[0019] Such as figure 2 As shown, the overall jacking construction method for unequal height boxes provided in this embodiment includes the following steps in order:

[0020] 1) Firstly, adopt the traditional 3-5-3 buckle rail and longitudinal beam reinforcement met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com