Patents

Literature

35results about How to "Clamping and reliable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

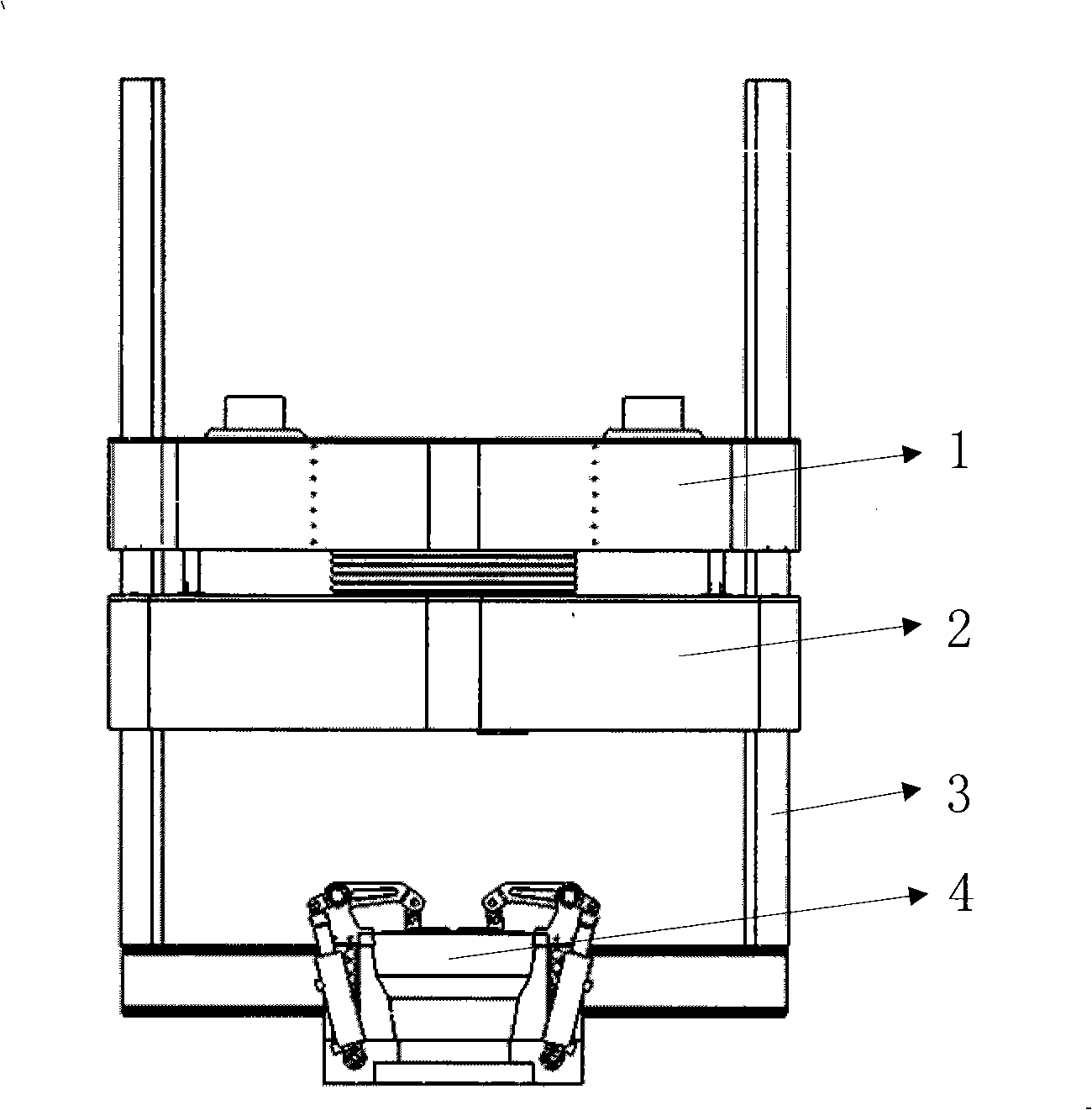

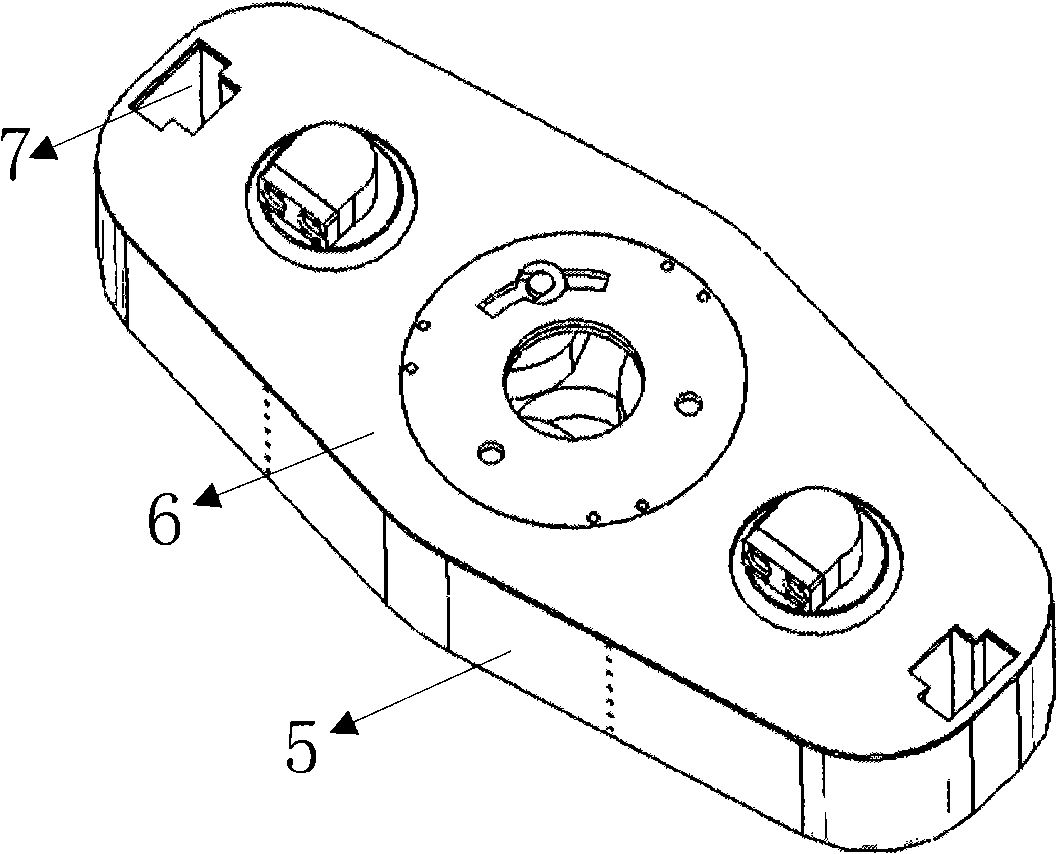

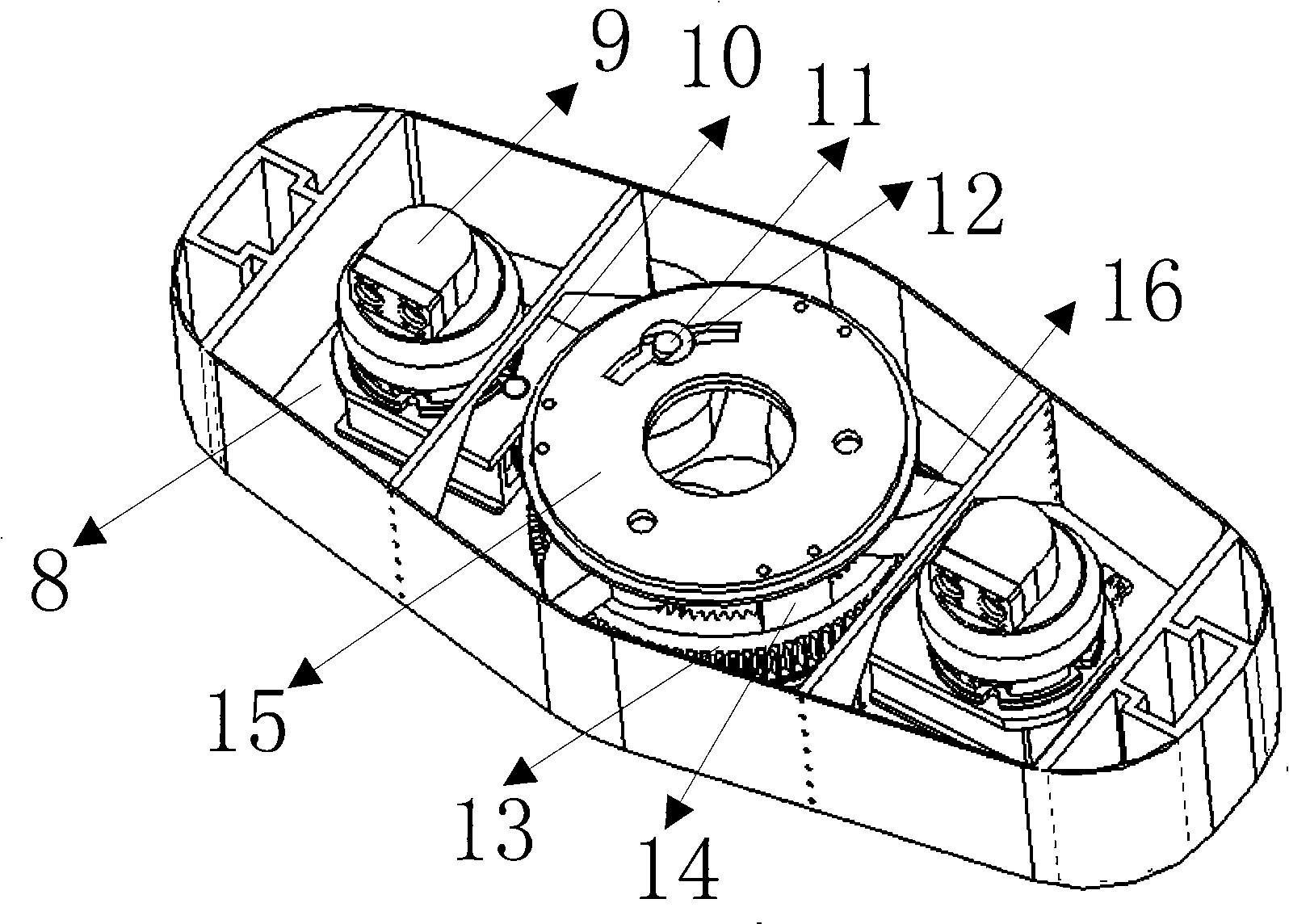

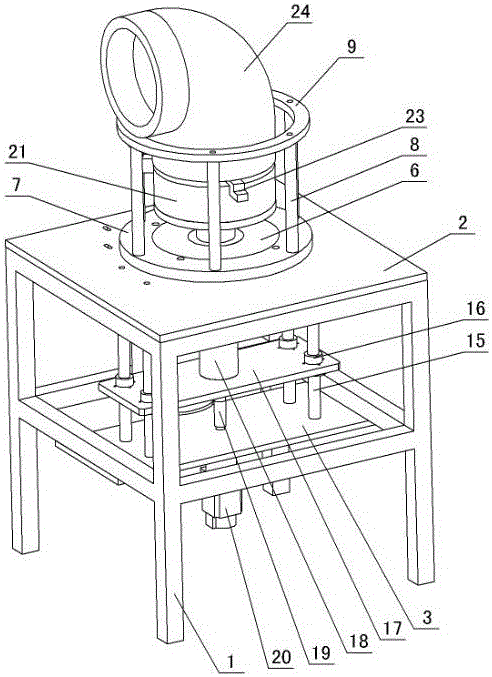

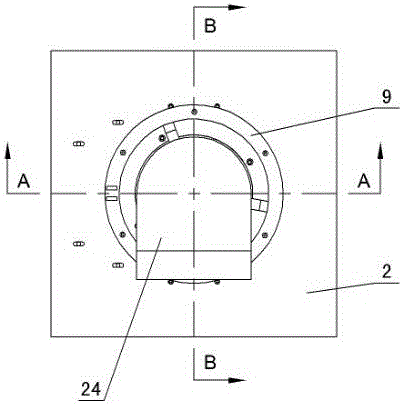

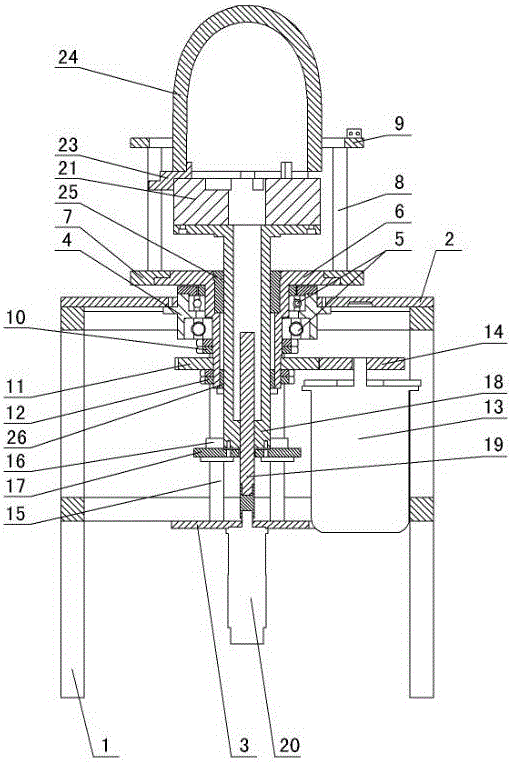

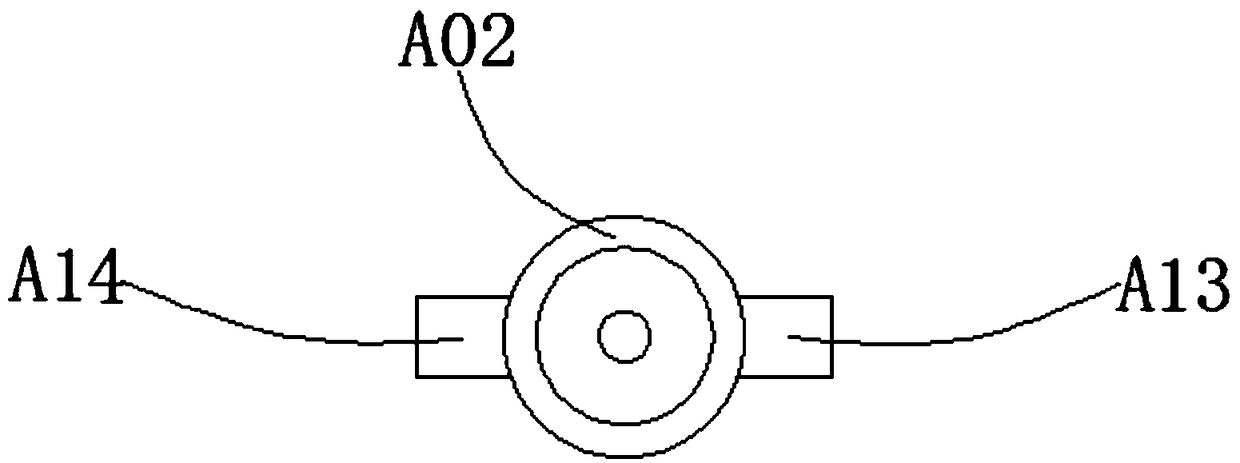

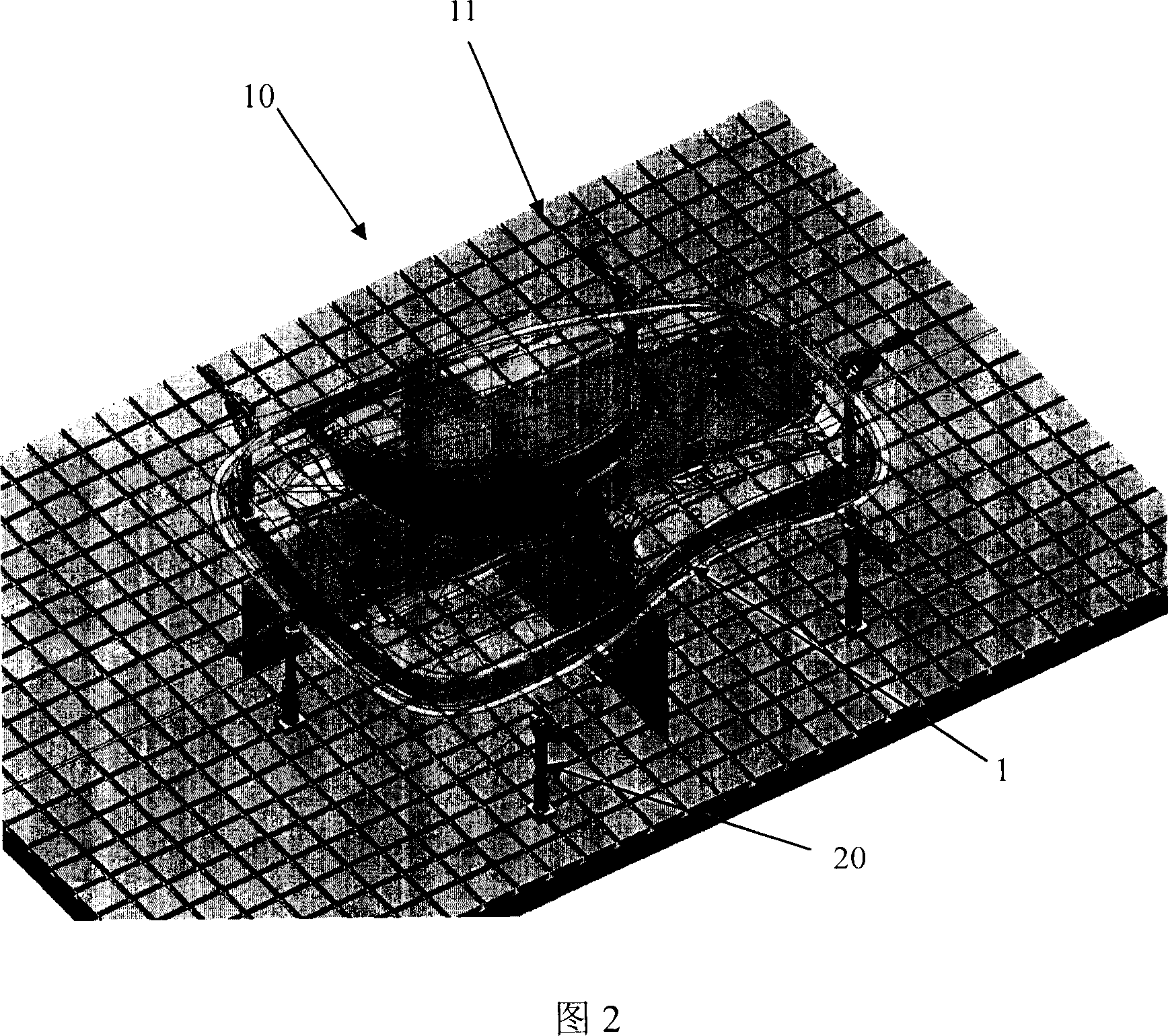

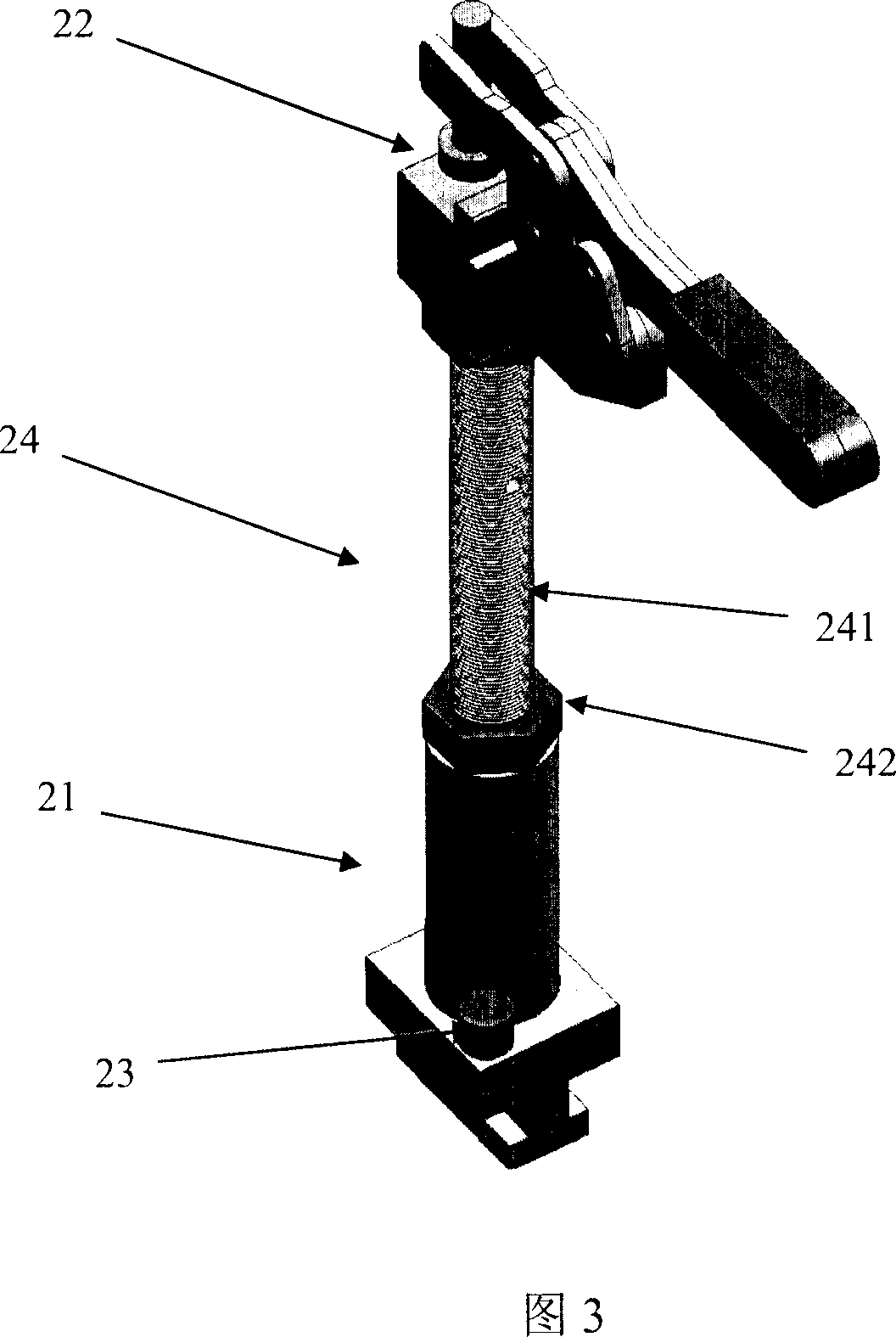

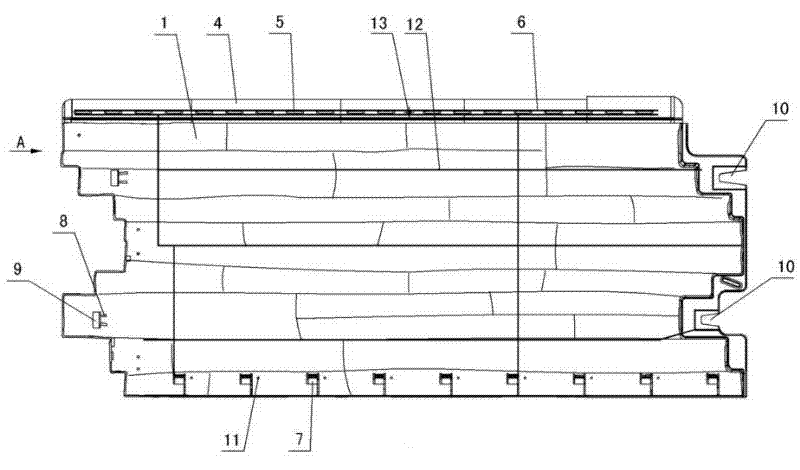

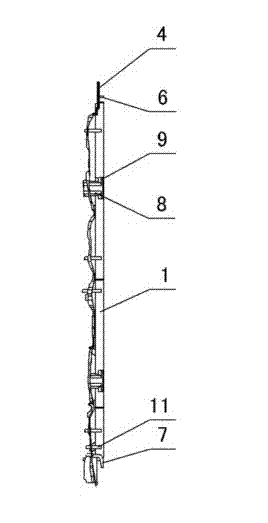

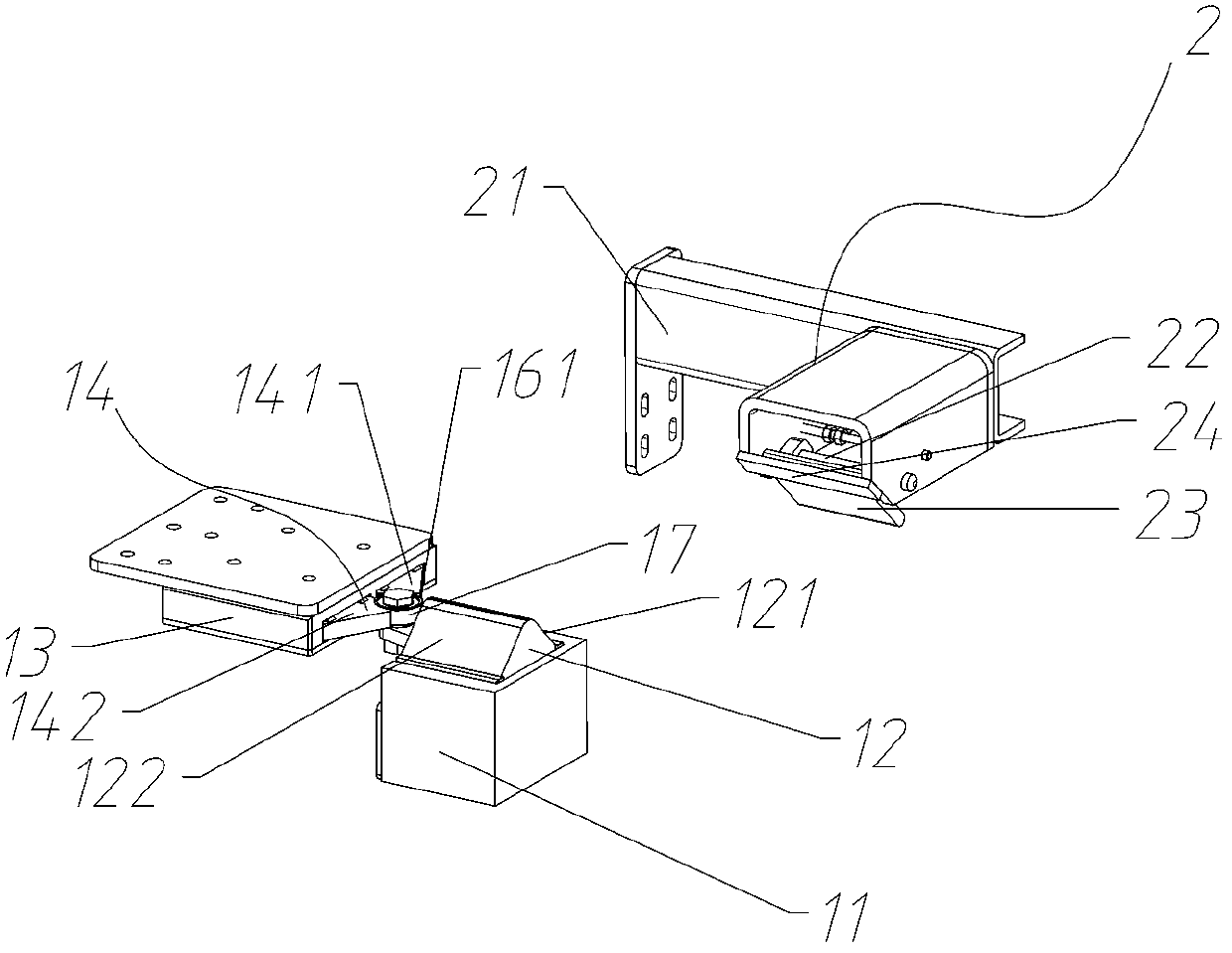

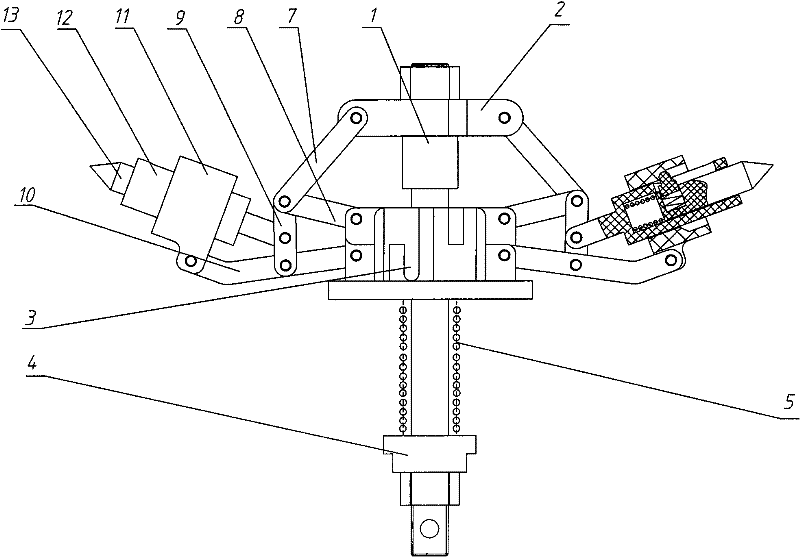

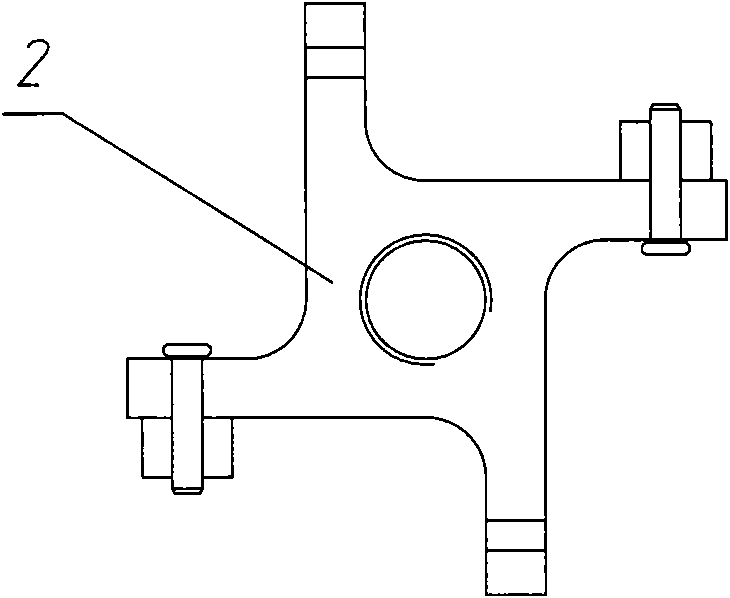

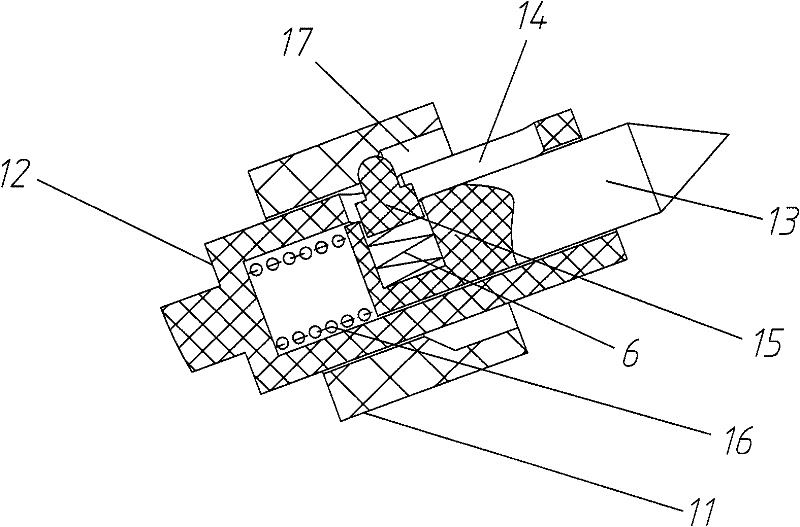

Automatized shaft mouth operation clamp for petroleum well workover

InactiveCN101343986AImprove reliabilityExtend the life cycleDrilling rodsDrilling casingsEconomic benefitsScrew thread

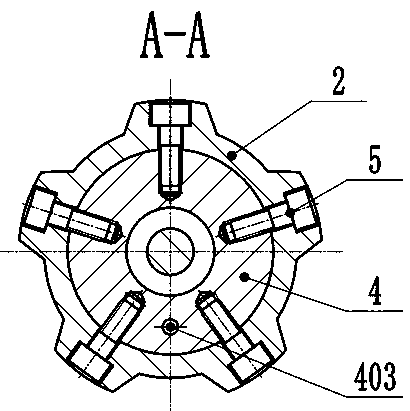

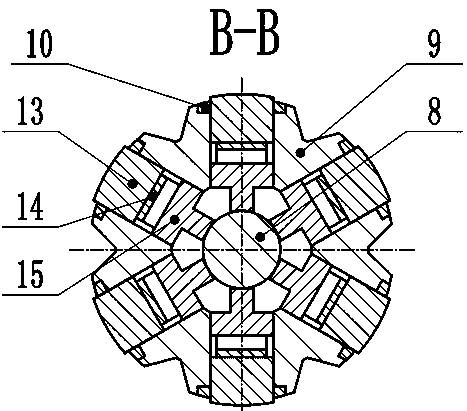

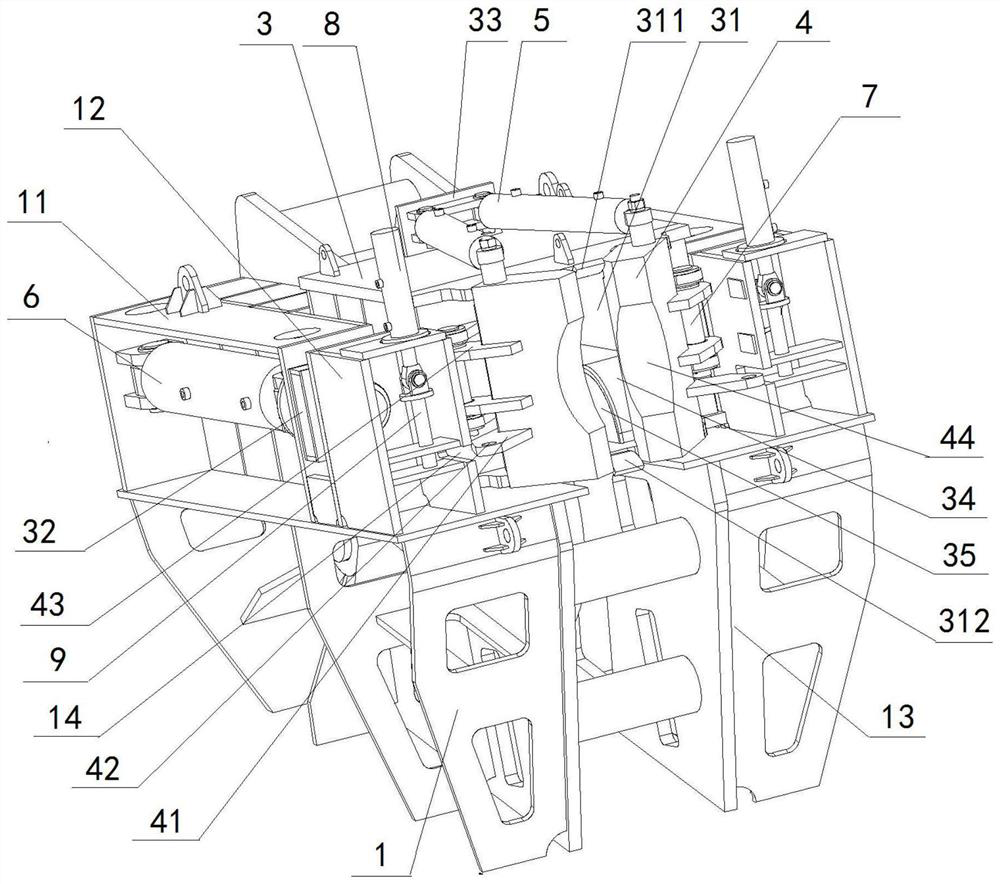

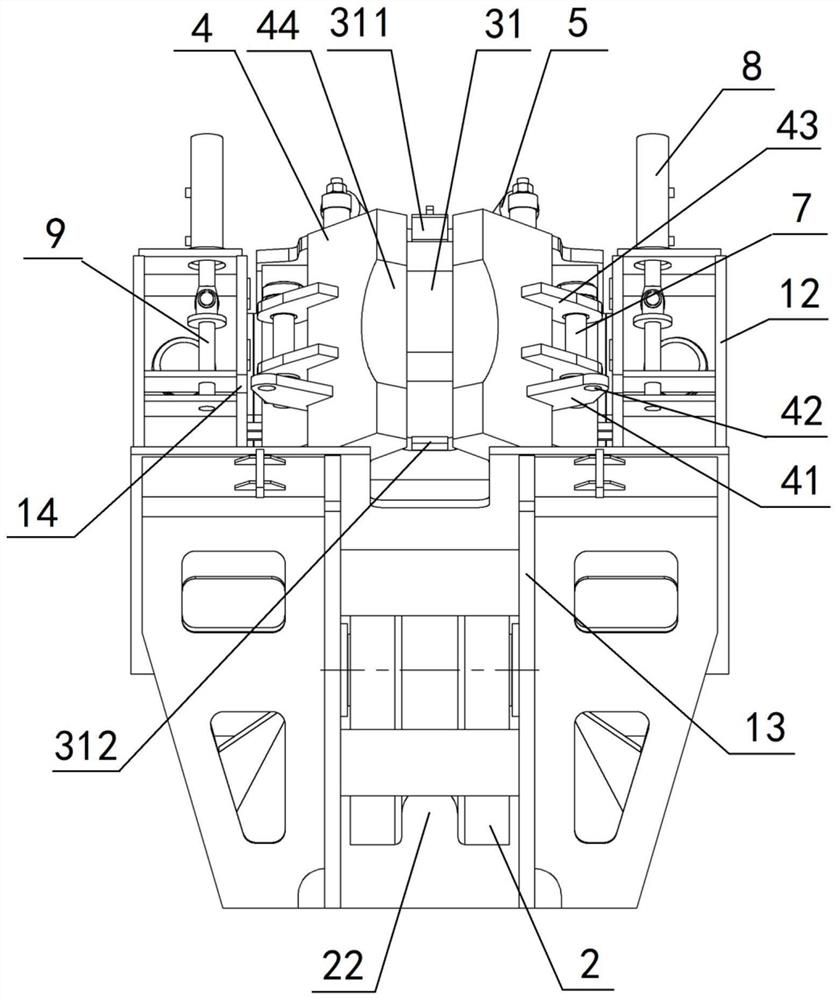

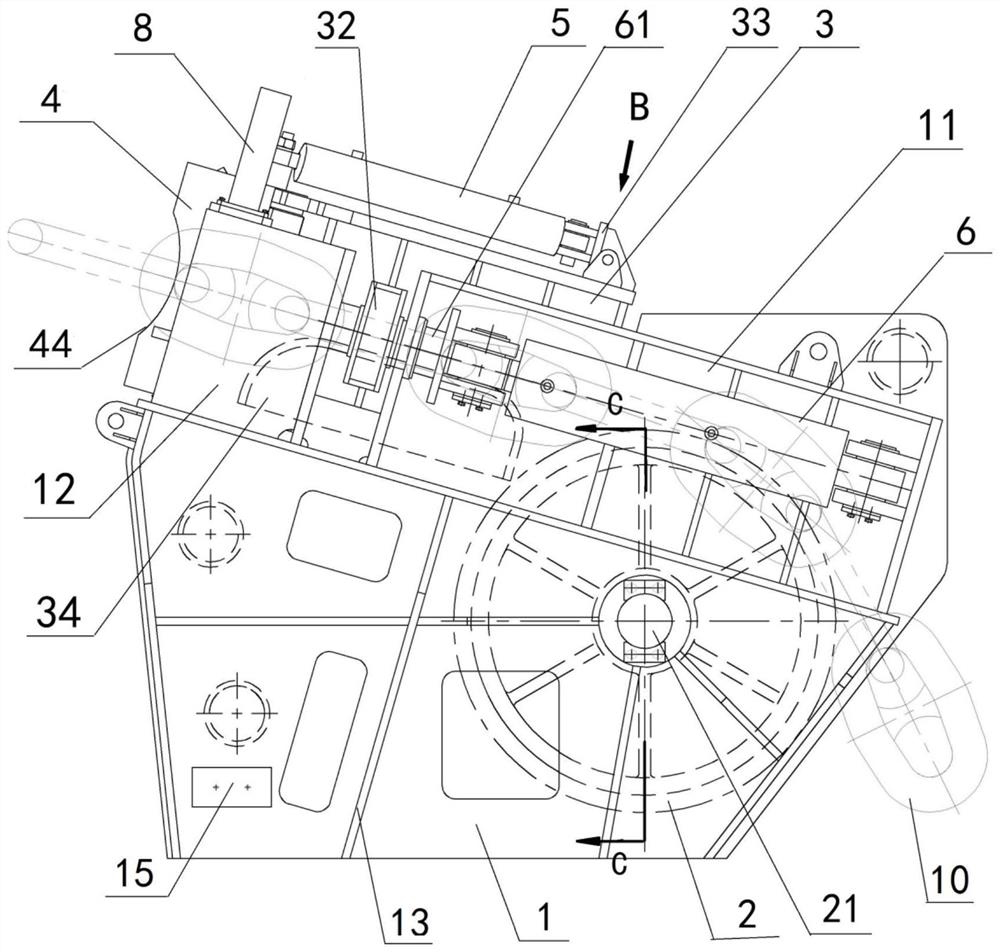

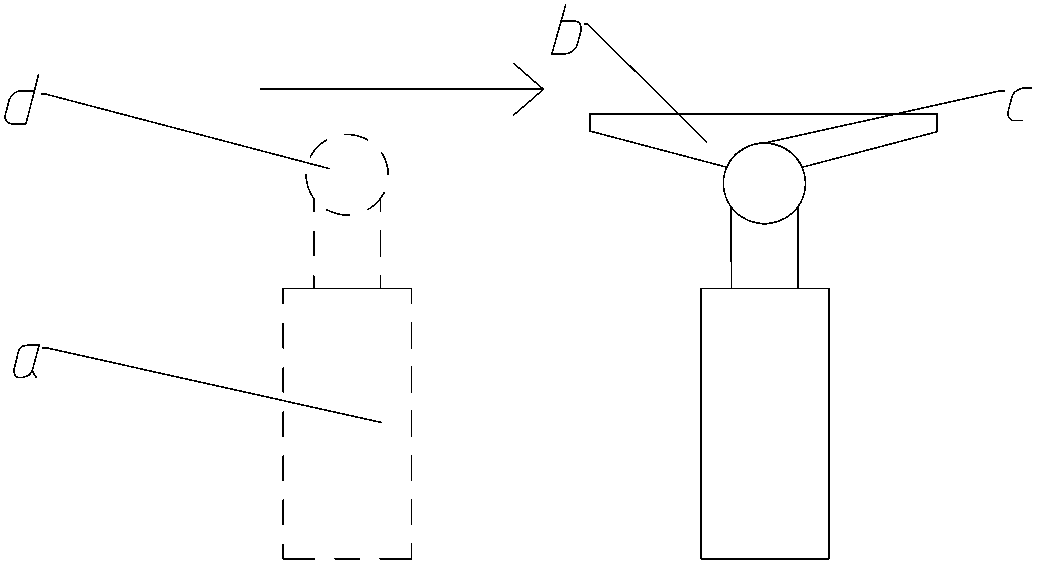

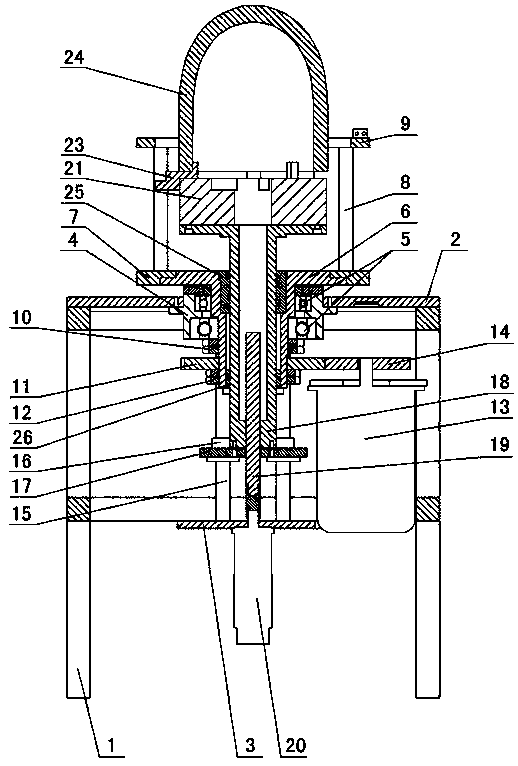

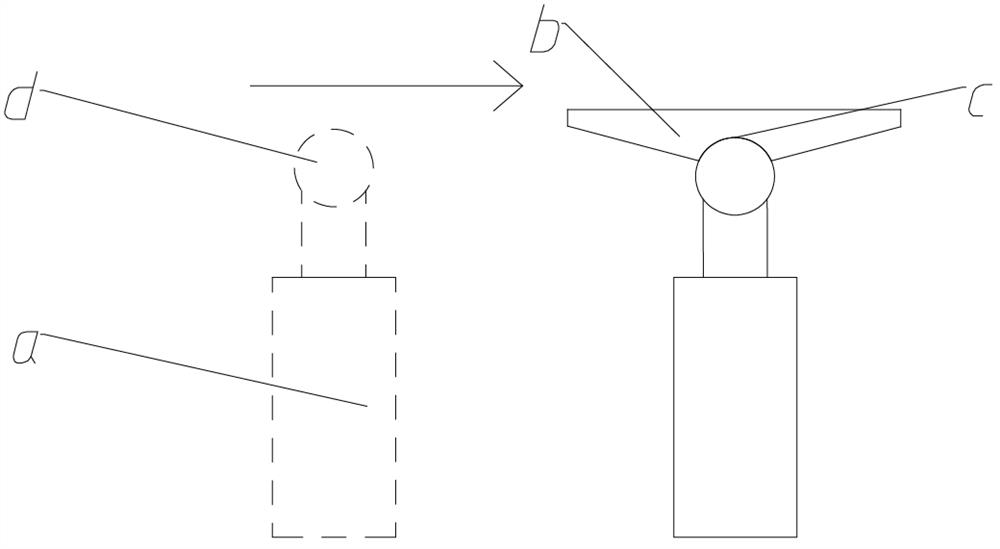

The invention discloses an automatic wellhead operation tong used for petroleum workover. The automatic wellhead operation tong mainly solves the problems that in prior petroleum workover field, low working efficiency, high labor intensity, the bad security, and serious environmental pollutions are caused because the operation for loading and unloading pipe column is accomplished by a manually-operated opening type hydraulic tong and a replacing elevator. The automatic wellhead operation tong is characterized in that the operation tong integrates a close type power tong and a power slip into a whole, and the operation tong is composed of a main tong, a back tong, a slip and vertical guide rails, supporting frames extending from the both sides of the slip are used for installing the two vertical guide rails, the main tong and the back tong can be moved vertically along the guide rails, and the enclosed space between the main tong and the back tong can be used for collecting residual liquid of the pipe column. The automatic wellhead operation tong has the advantages that automatic wellhead operation tong can realize the automatic screwing and unscrewing of the screw threads from the tube and the environment-friendly operation; the tong can be firmly clipped at the tong mouth, thus components are not needed to be replaced in a wide range, and the working efficiency is improved greatly. The clipping performance is good, the working is reliable, and the social and economic benefits are quite remarkable.

Owner:DAQING GASOLINEEUM INST

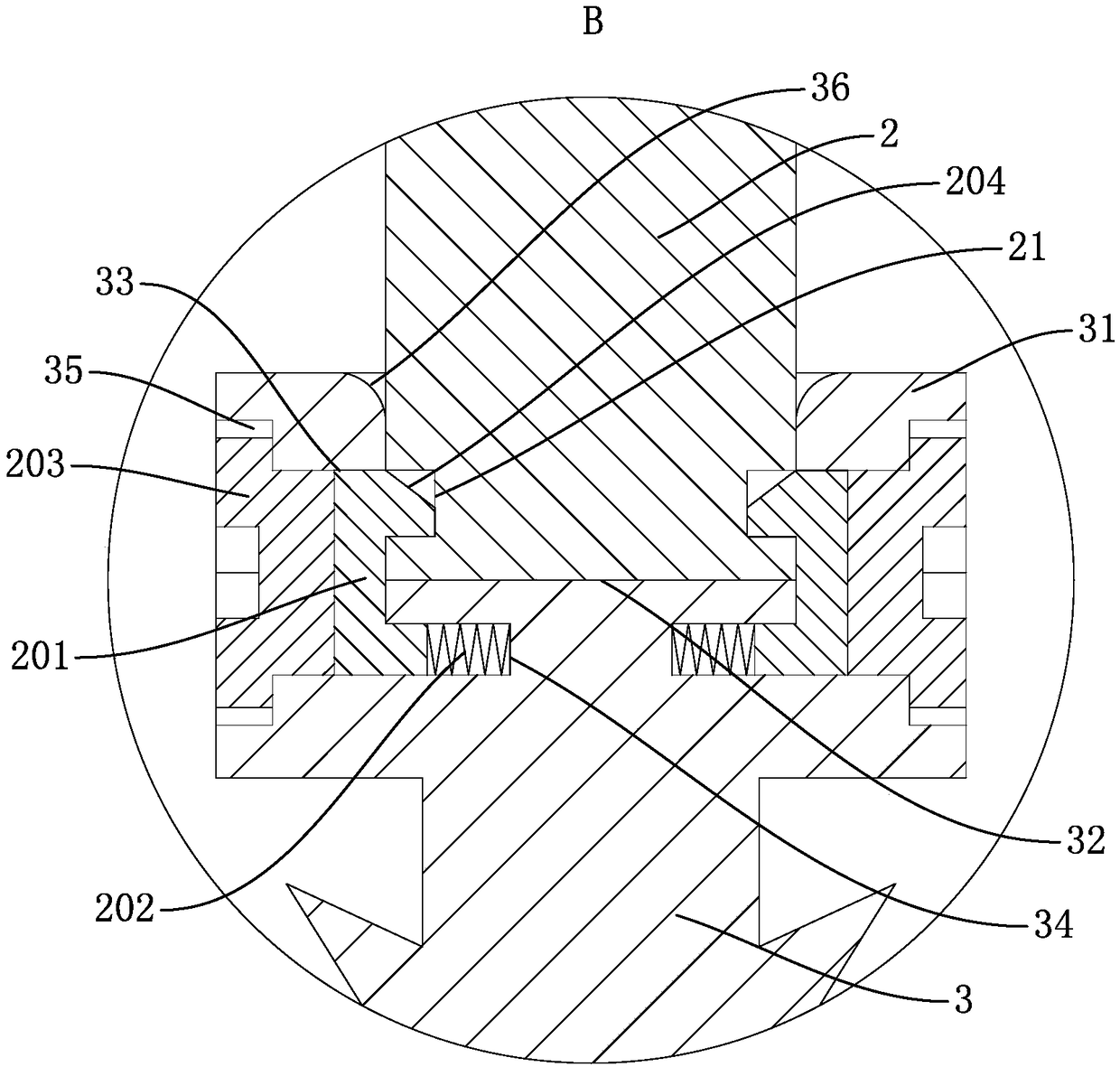

Linkage self-locking type car hub fixing device

ActiveCN107214537ANo looseningCompact structurePositioning apparatusMetal-working holdersSelf lockingScrew thread

Owner:ANHUI JIANGHUAI WHEEL CO LTD

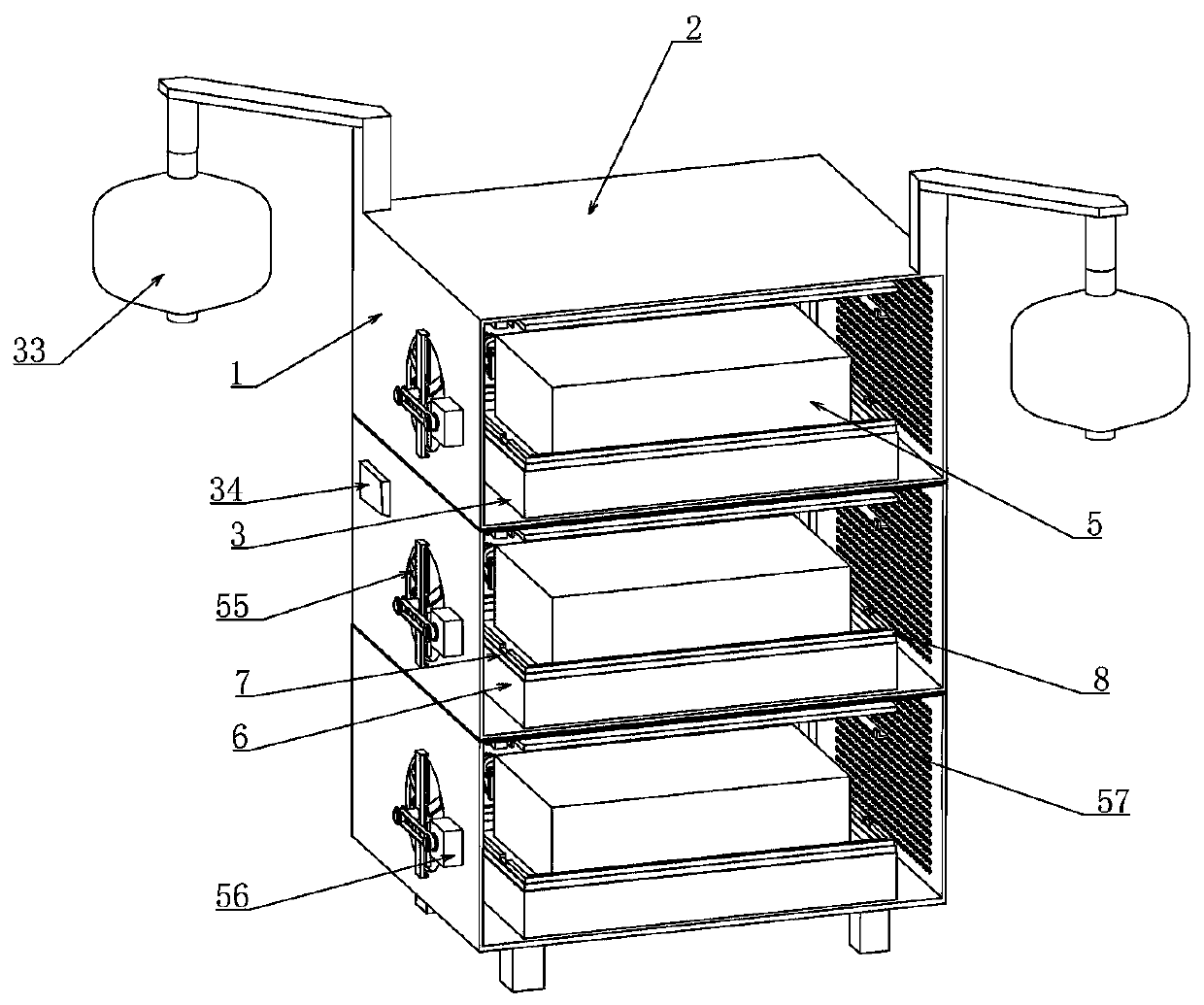

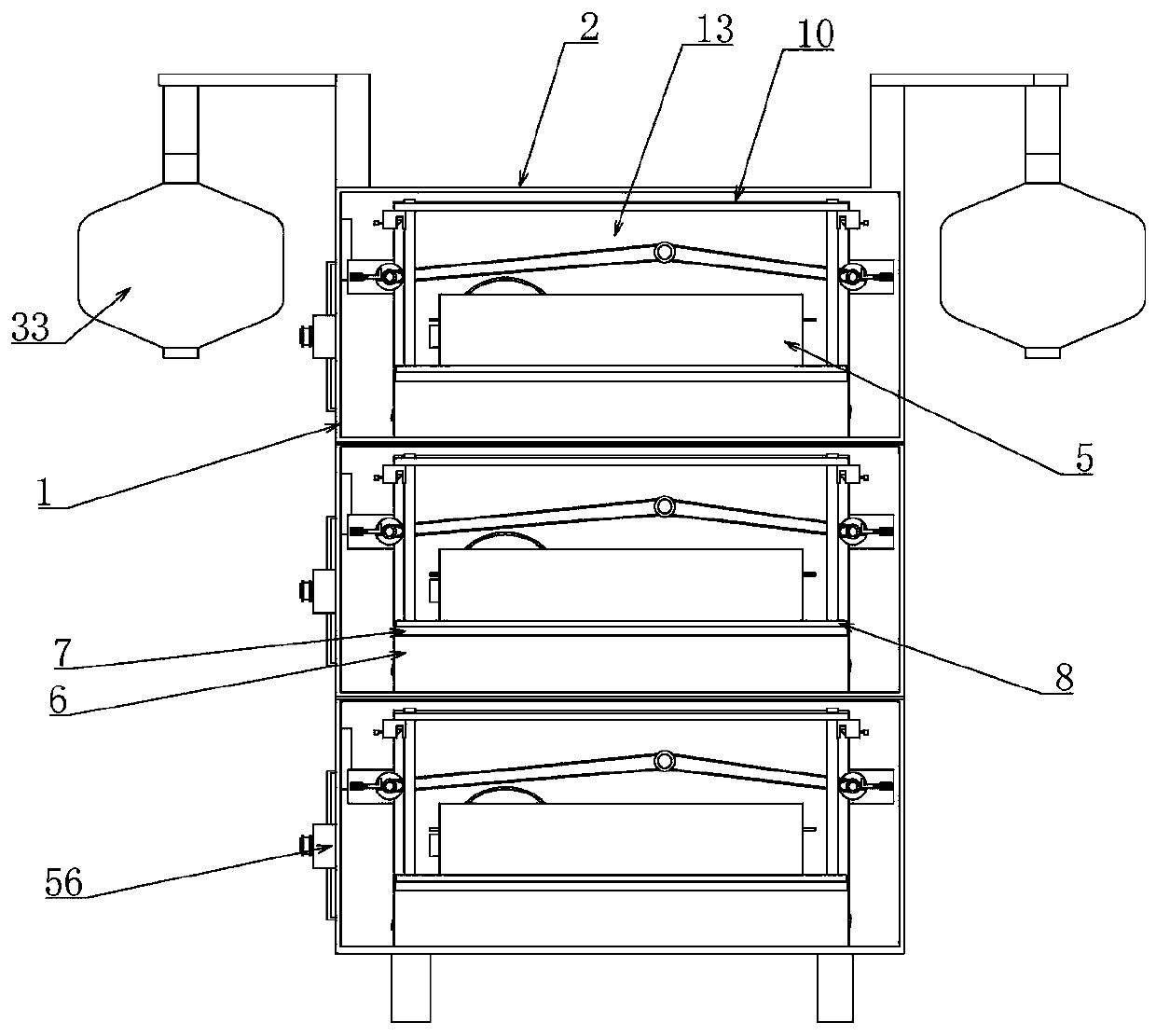

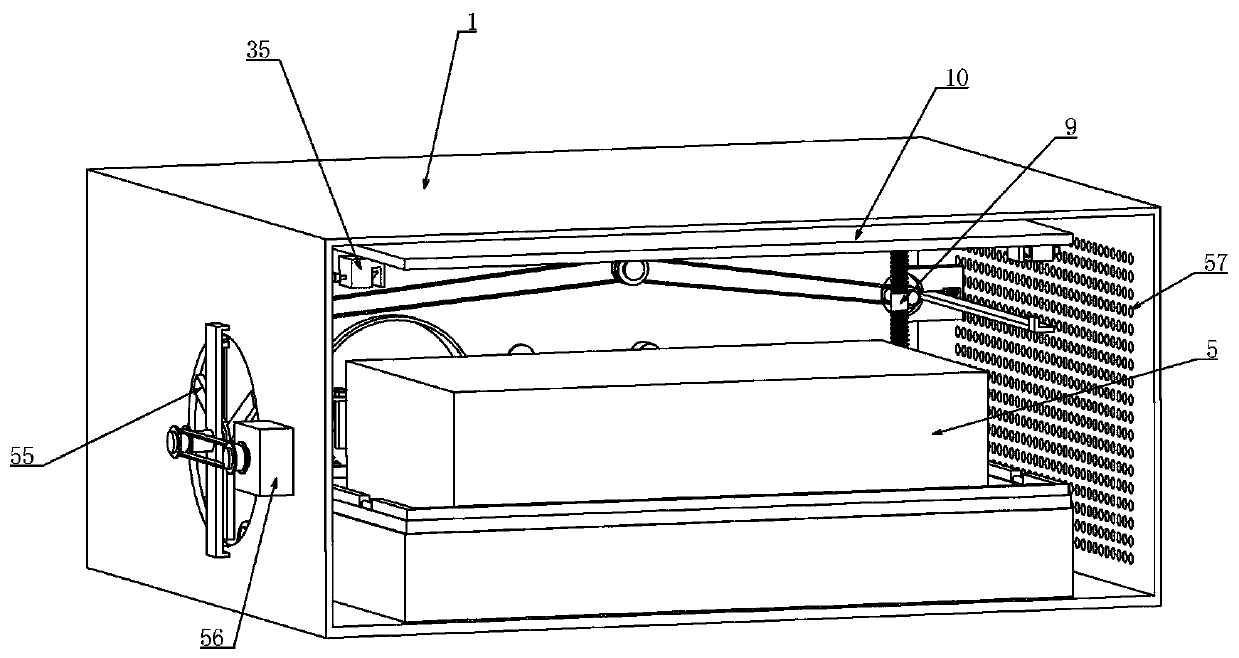

A big data computer network security protection device

InactiveCN109582099BEffective protectionPlay a protective effectDigital processing power distributionFire - disastersReliability engineering

The invention relates to a big data computer network security protection device. According to the invention, the sector gear is used for intermittently driving the seventh gear, A fourth gear, fifth gear and sixth gear, a sequential generator is formed; Therefore, the actions of wire drawing, wire withdrawing, back plate retraction and cover plate and rectangular block covering are successfully completed in case of a fire disaster; the big data computer is effectively protected; A clamping device is added, so the clamping between the cover plate and the rectangular block becomes very reliable;meanwhile, an unlocking device is added while a clamping device is added; The unlocking device is triggered by the sector gear as well, the structure is ingenious, operation is easy, the big data computer can be well protected when a fire disaster occurs or is about to happen, the fire disaster protection effect is good, and the loss of the big data computer caused by the fire disaster can be effectively reduced to the minimum.

Owner:ZHENGZHOU TECHN COLLEGE

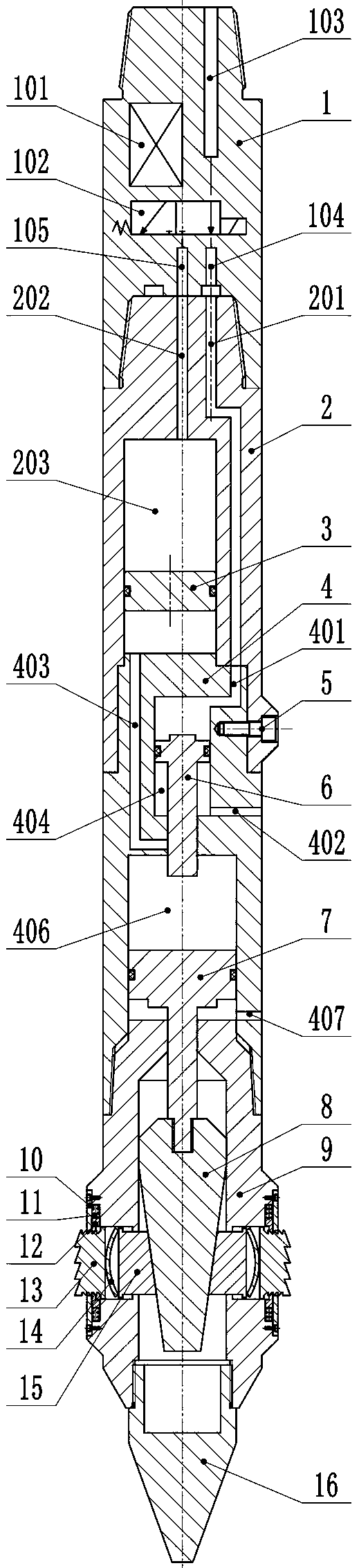

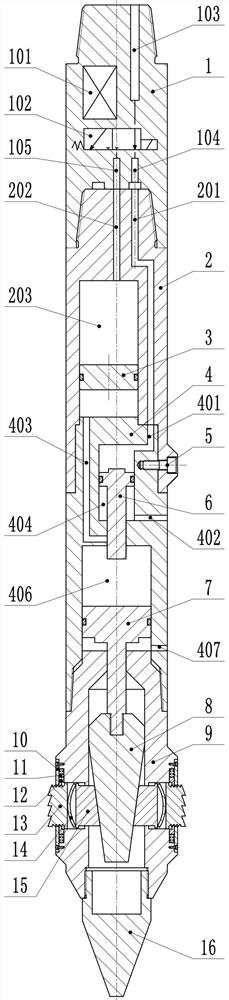

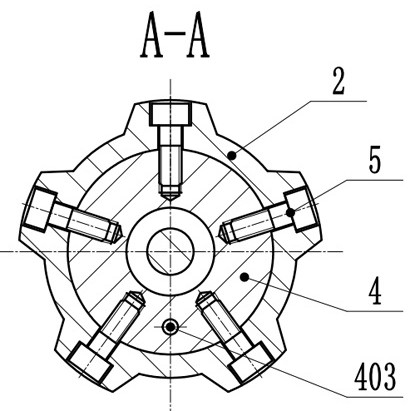

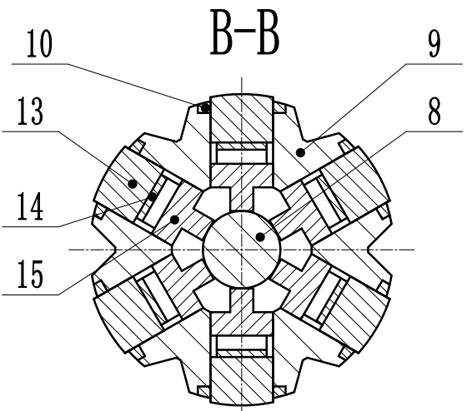

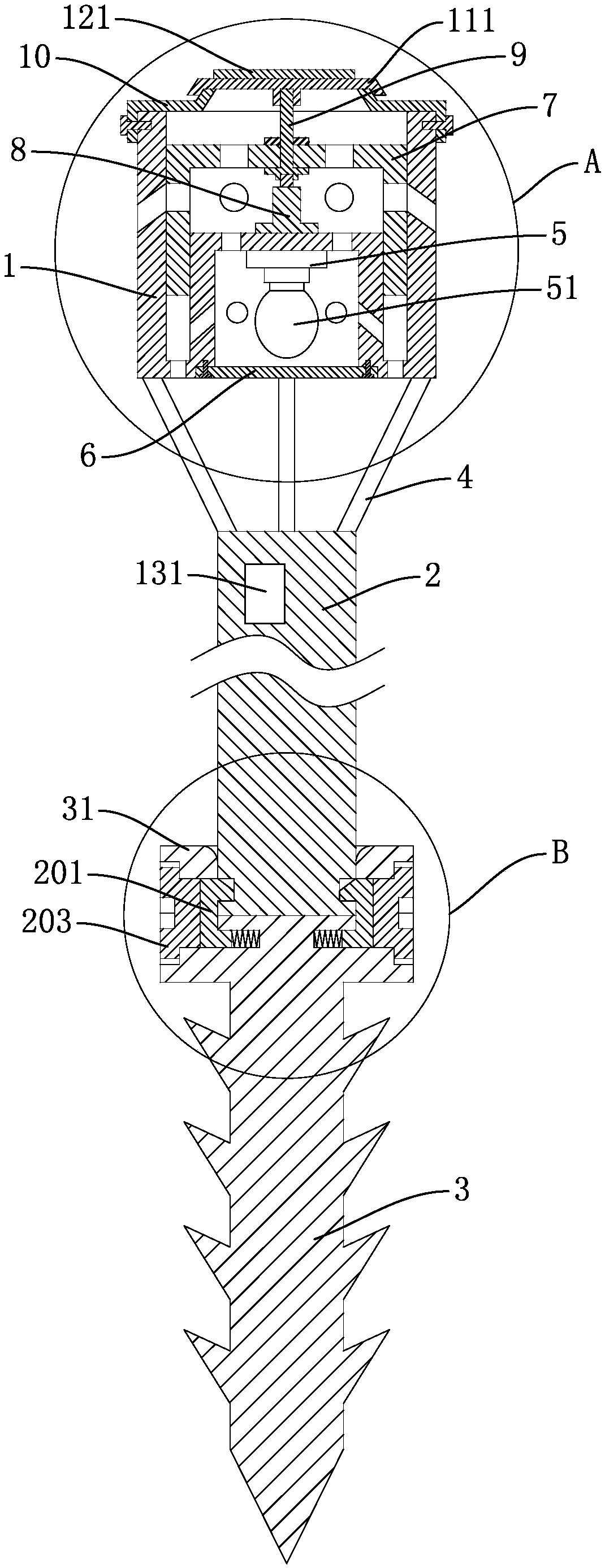

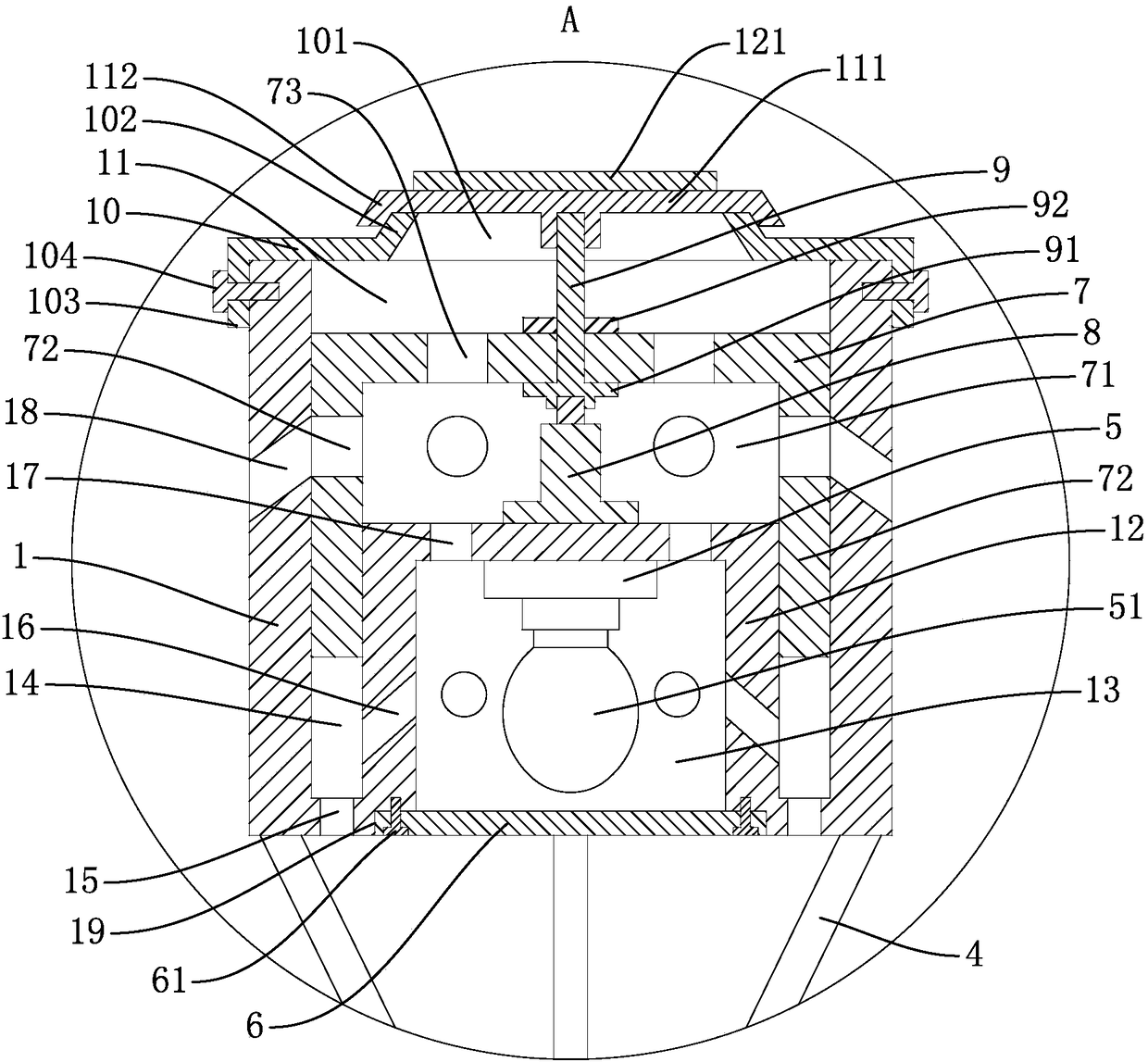

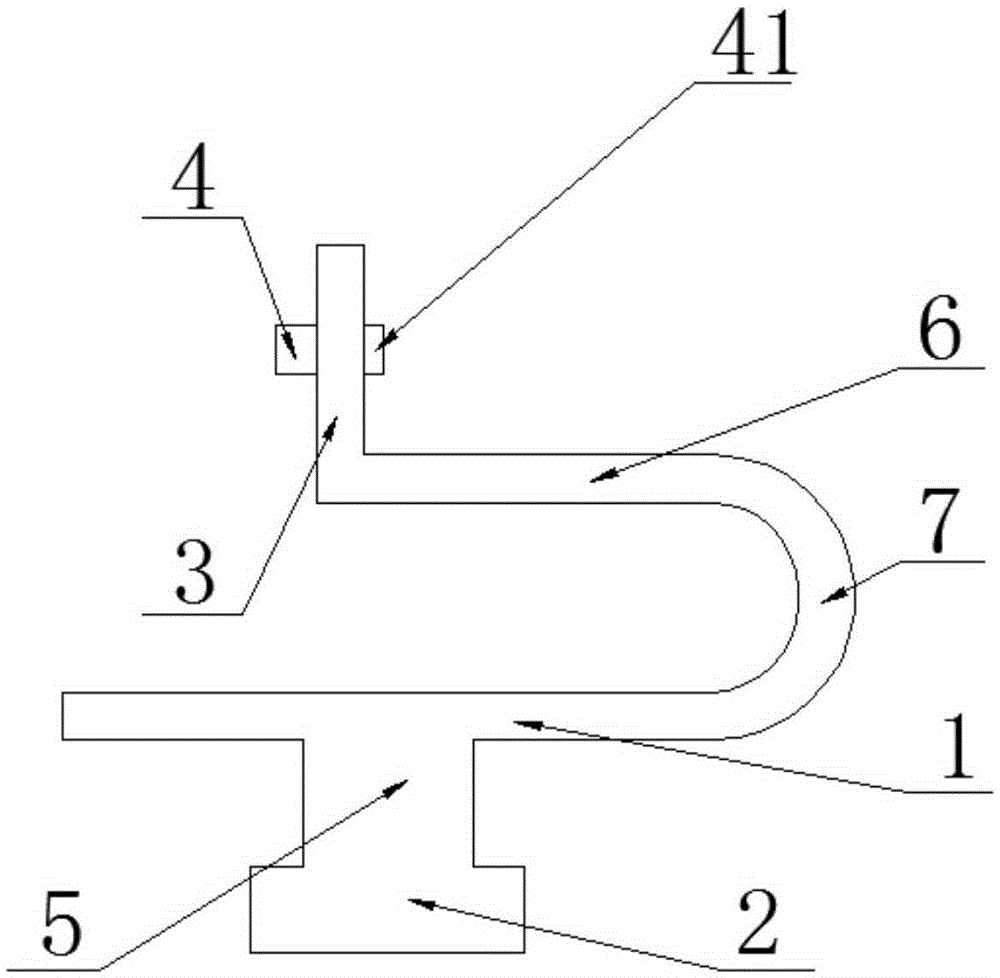

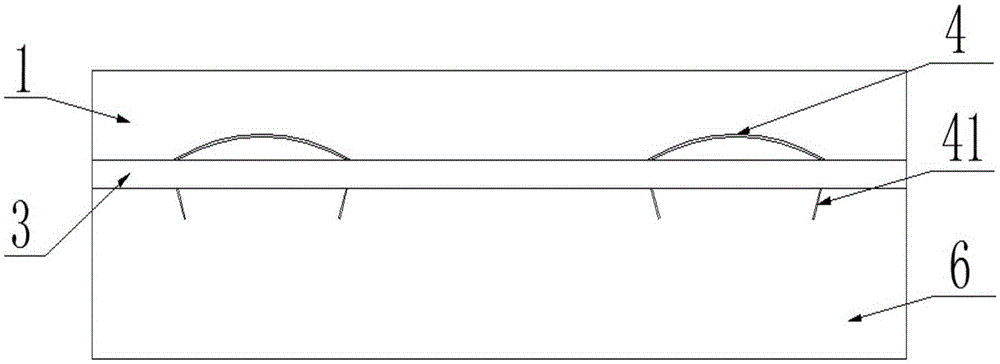

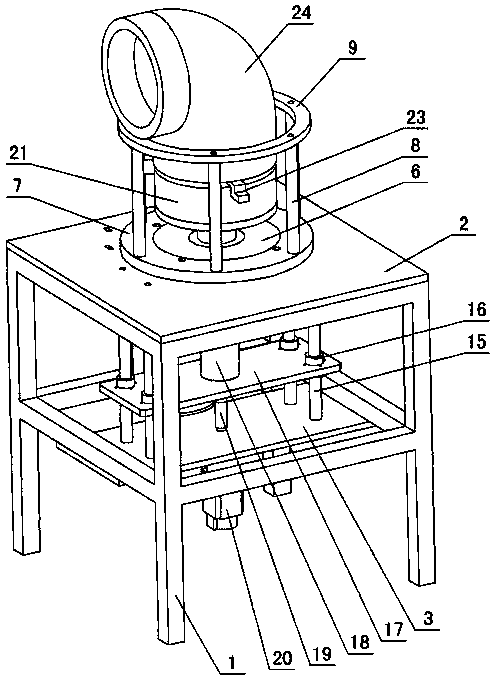

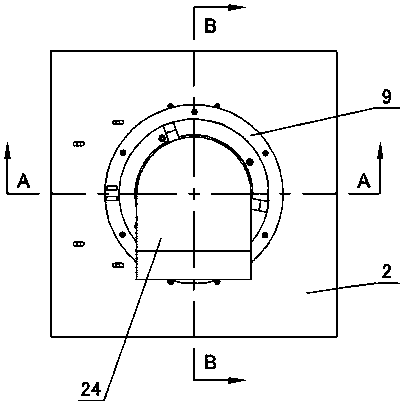

Open hole side tracking seat sealing machine for air drilling

ActiveCN110397419AReliable settingsClamping and reliableDirectional drillingSealing/packingGas industryEngineering

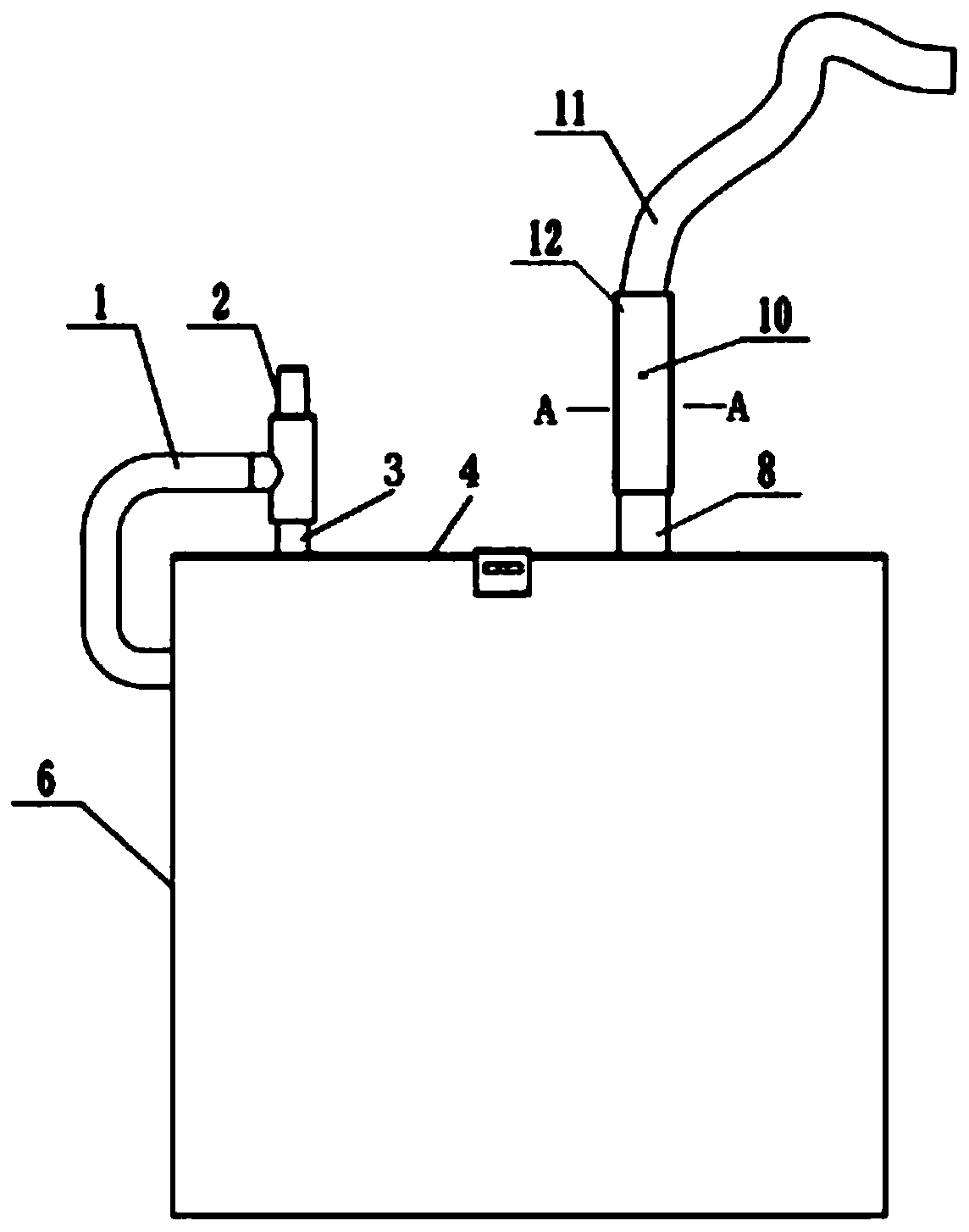

The invention relates to an open hole side tracking seat sealing machine used in air drilling field in petroleum and natural gas industry, and solves the problem that a whipstock in open hole drillingis hard to fix. The upper end of a control pup joint is in screwed connection to the lower end of the whipstock, the lower end of the control pup joint is in screwed connection to the upper end of anoil storage barrel, and a gas inlet channel is connected to a gas conveying runner in the whipstock; the lower end of the oil storage barrel and the upper end of a pressurizing barrel are fastened byplugging bolts, and an oil pressing piston is placed in an inner cavity of an oil storage chamber; the piston end of the pressurizing piston is placed in an exhaust chamber of the pressurizing barrel, a piston rod of the pressurizing piston is placed in an oil inlet throat of the pressurizing barrel, and the upper end of an actuating piston is placed in a pressure oil chamber of the pressurizingbarrel; the upper end of an anchoring barrel is in screwed connection to the lower end of the pressurizing barrel, and the lower end of the anchoring barrel is in screwed connection to the upper end of a guiding shoe; a cone body is placed in an inner cavity of the anchoring barrel, and the upper end of the cone body is in screwed connection to the lower end of the actuating piston. The open holeside tracking seat sealing machine converts compressed air which is relatively small in pressure into a pressure oil liquid which is large in pressure, so that the whipstock is seat-sealed reliably inan open hole well section.

Owner:XIHUA UNIV

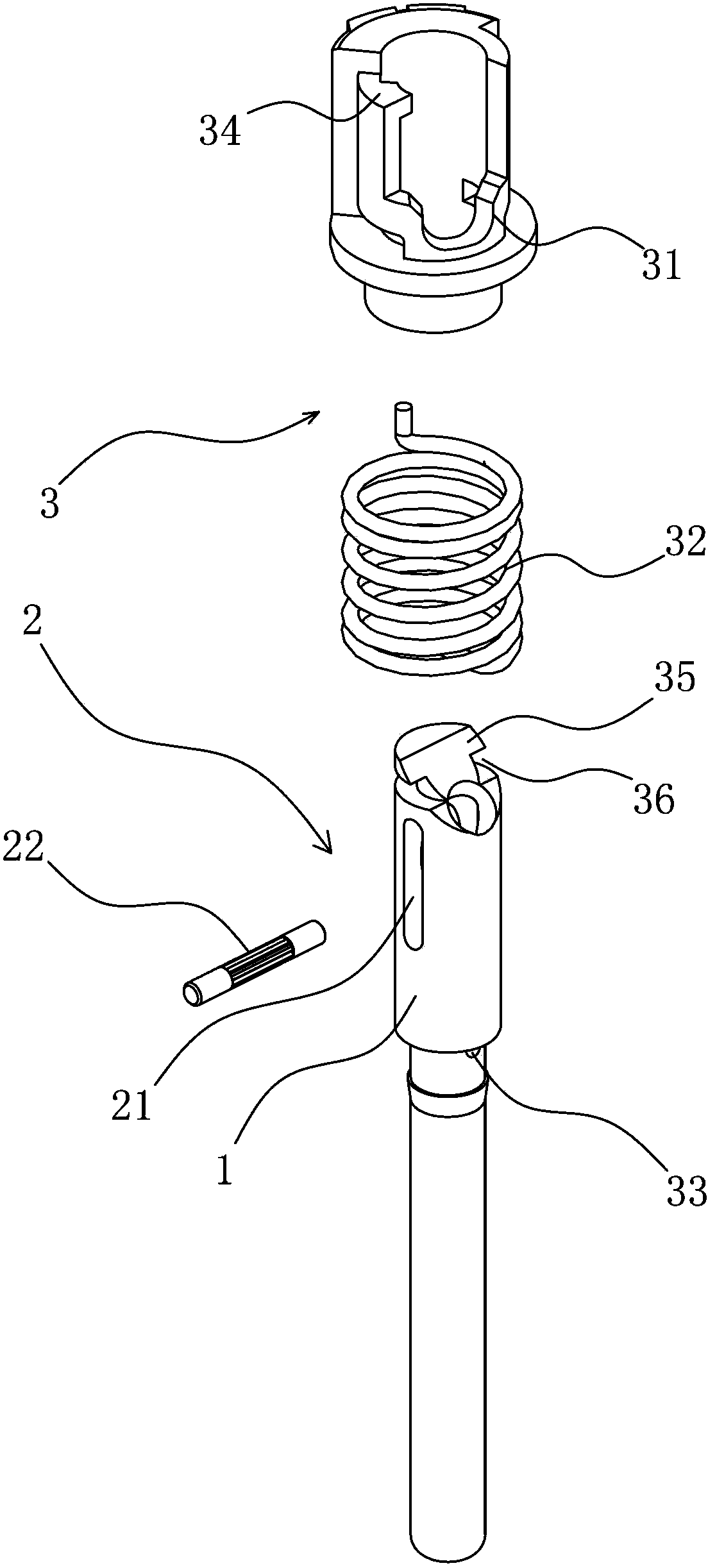

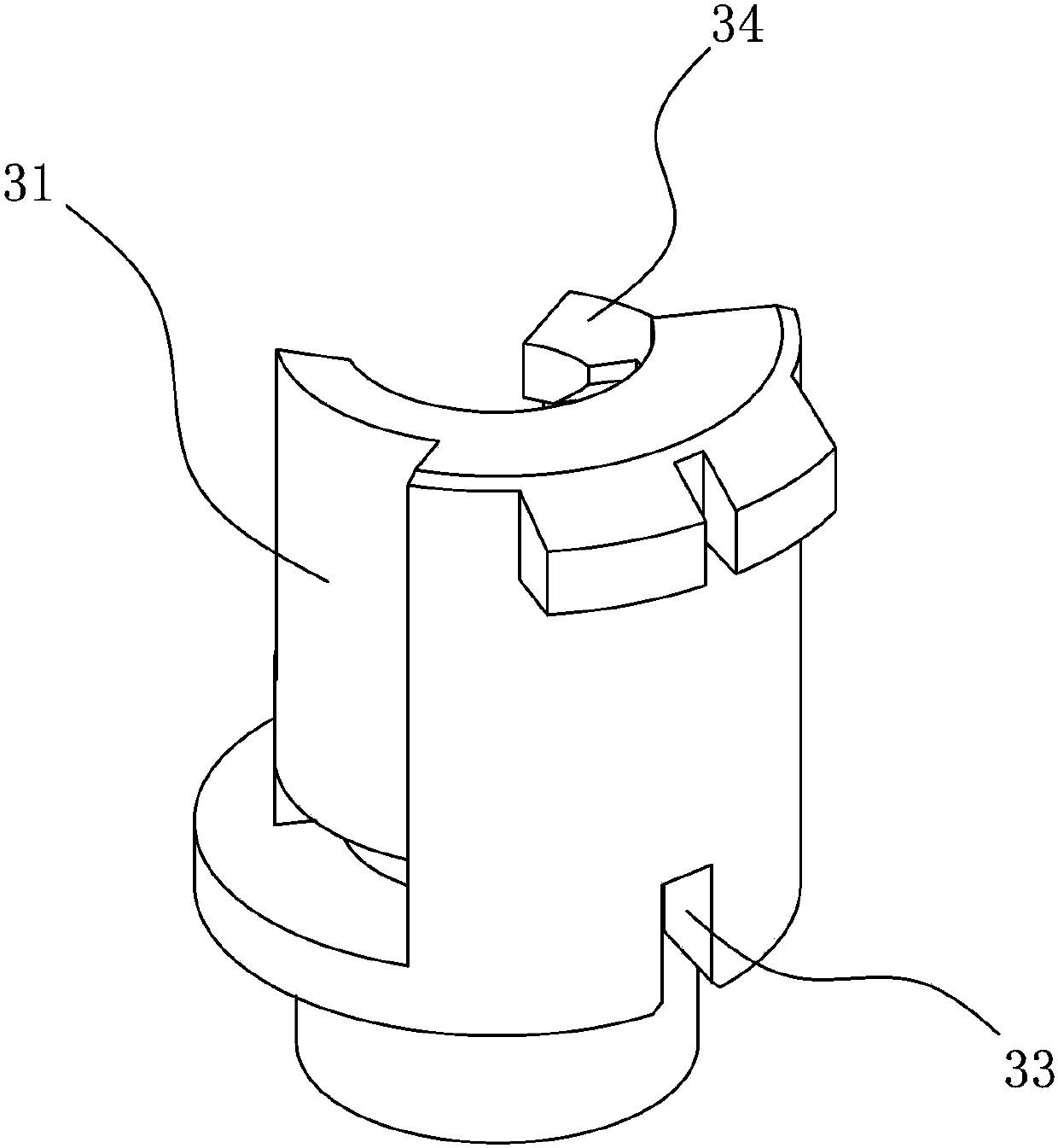

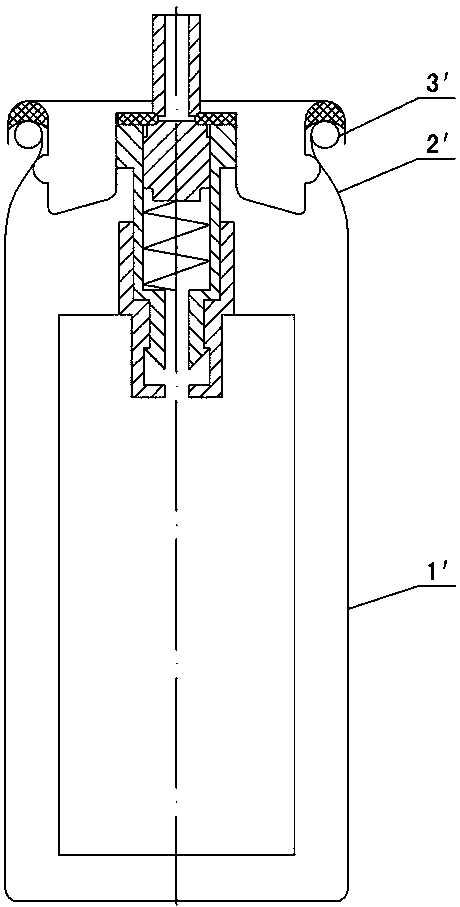

Negative pressure aspirator

ActiveCN111569165ASimple plug-in connectionRealize linkage controlIntravenous devicesSuction drainage systemsPistonEngineering

The invention discloses a negative pressure aspirator. The negative pressure aspirator comprises an anti-check valve and a liquid collecting bottle, wherein a suction tube is arranged at the upper endof the anti-check valve; check devices are arranged in the anti-check valve; each check device comprises a second piston and a screw rod, and the screw rod is arranged at the left end of the second piston; third pistons are arranged below the check devices; lockers are arranged below the third pistons; each locker comprises a first piston and a locking rod; and the anti-check valve is arranged between the suction tube and the liquid collecting bottle. The plurality of pistons, check devices and locking rods are arranged in the anti-check valve; linkage control is conducted on the check devices and the locking rods by means of a negative pressure environment in the liquid collecting bottle; in the negative pressure environment, the check devices can be opened, so that the suction tube cansuck liquid such as blood into the liquid collecting bottle; and when the negative pressure environment does not exist, the check devices can be closed immediately, so that the liquid in the suction tube cannot flow back to pollute an operating table to cause patient infection when a suction bag is replaced.

Owner:SHANGHAI CITY JIADING DISTRICT CENT HOSPITAL

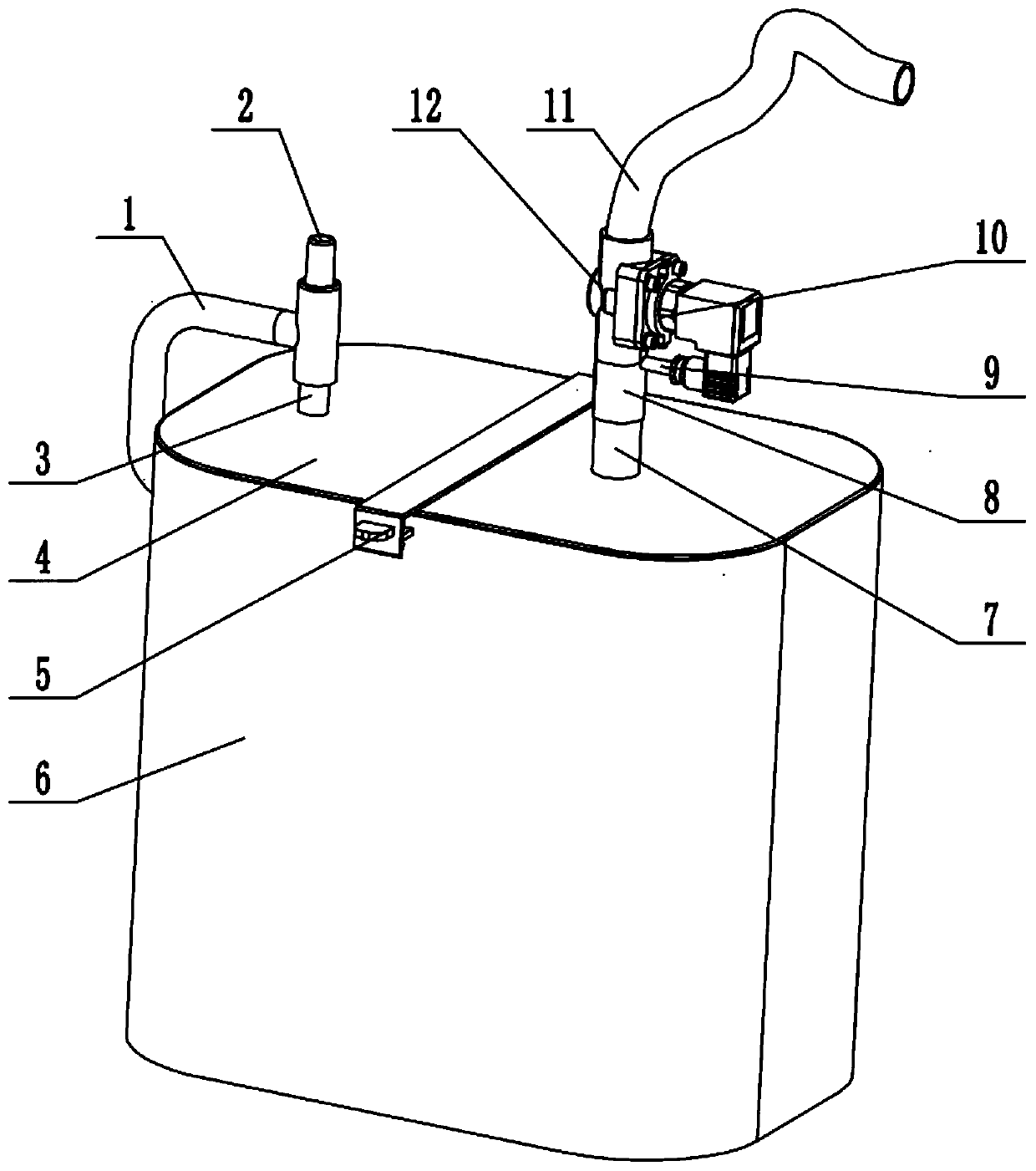

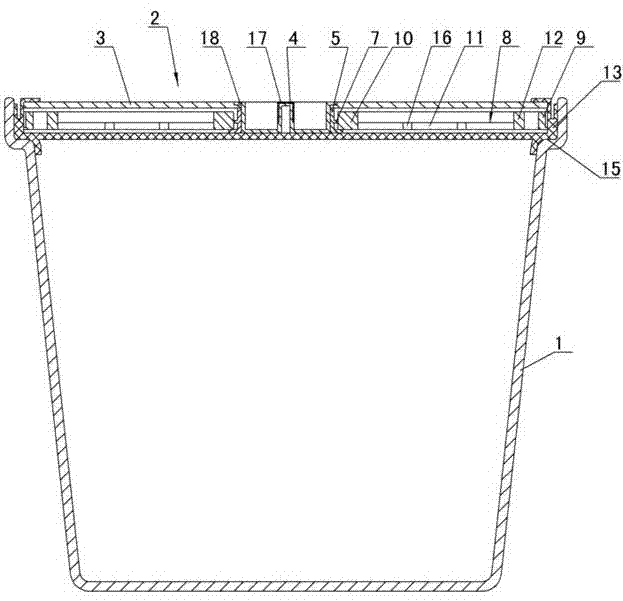

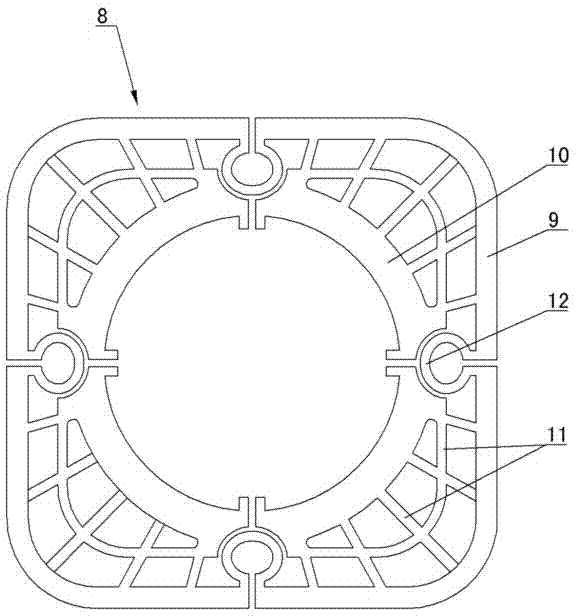

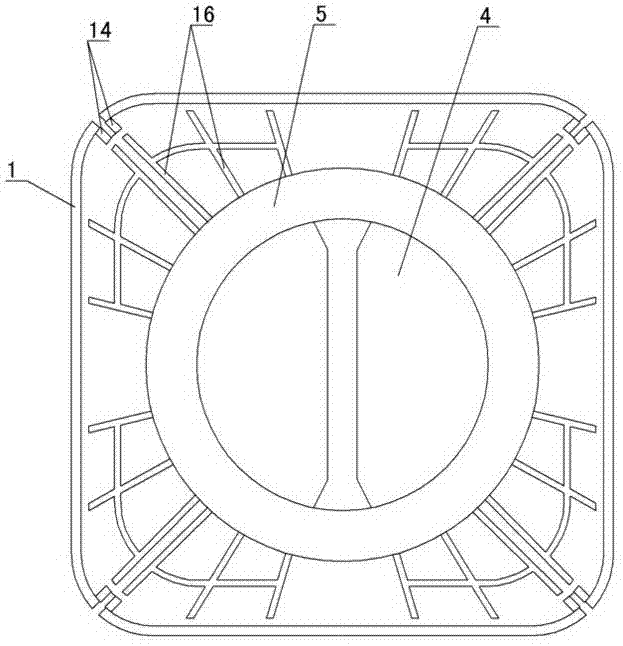

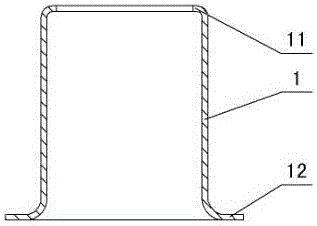

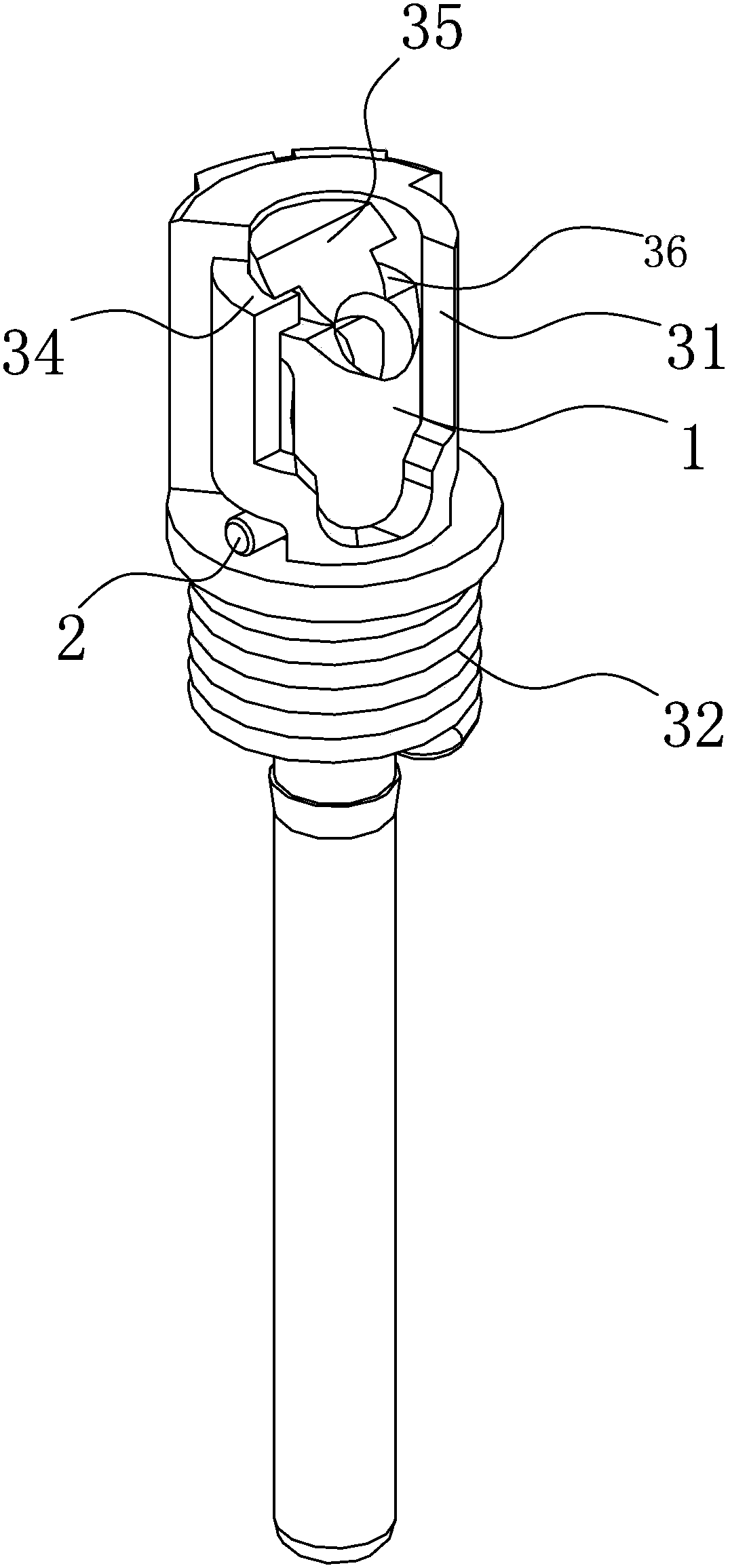

Rotary supporting clamping sealing tank and machining method

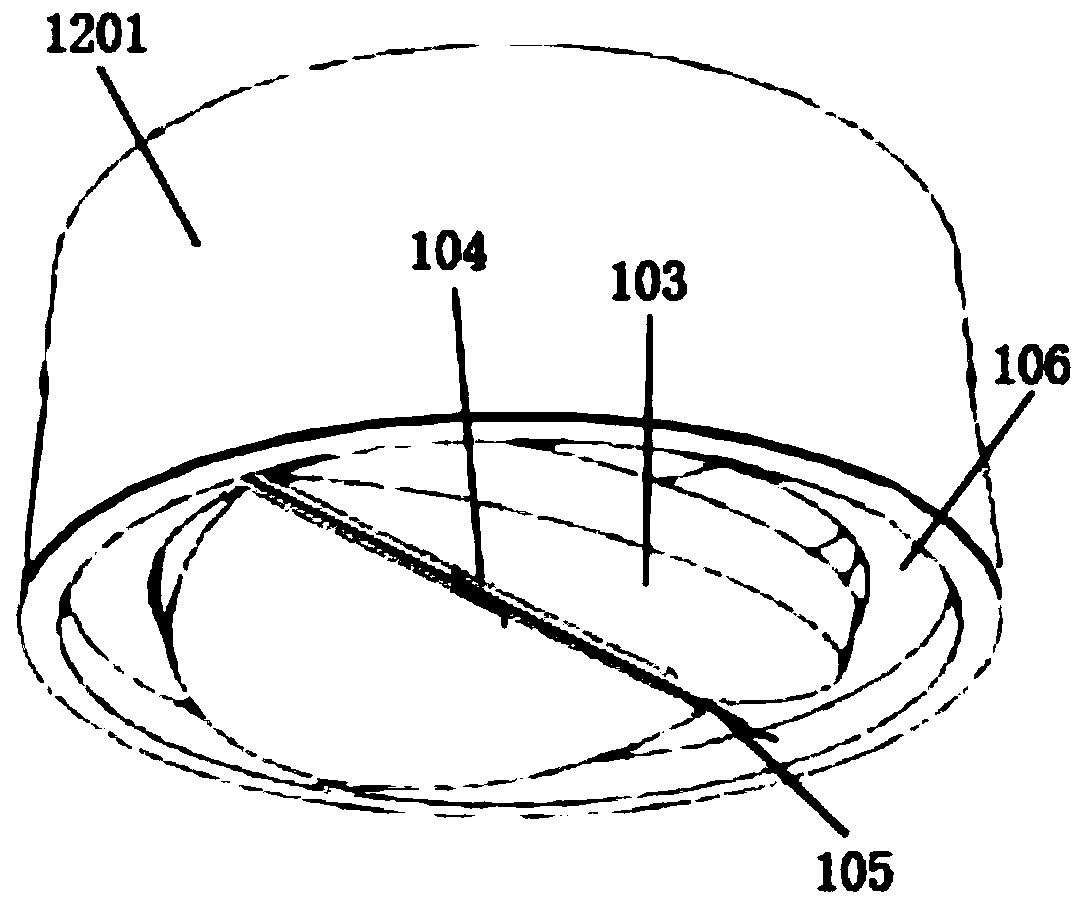

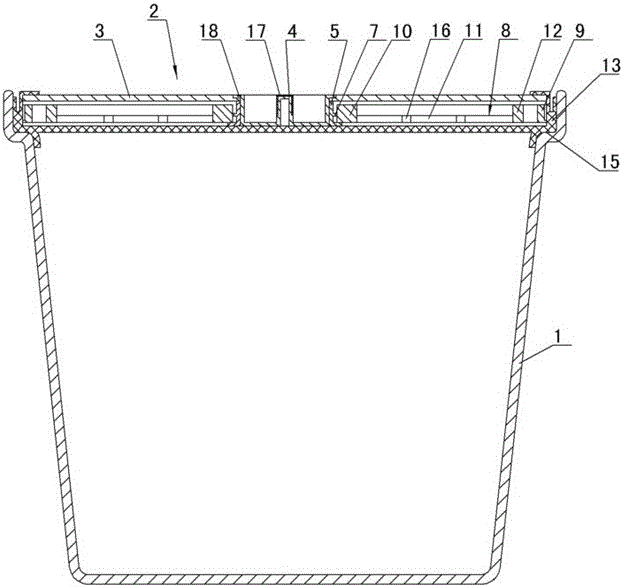

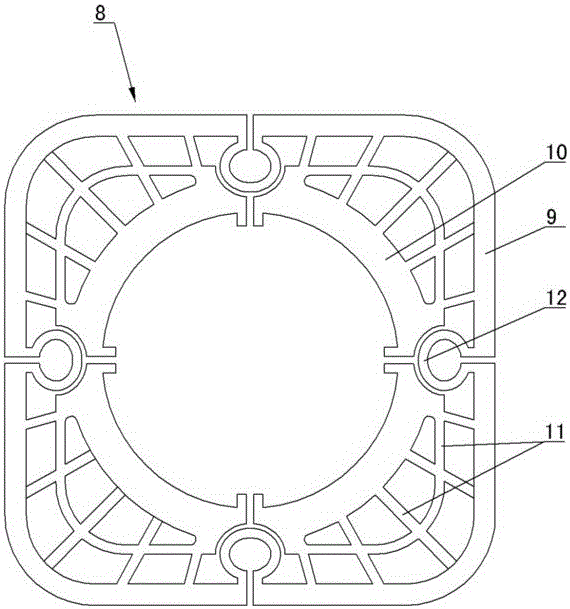

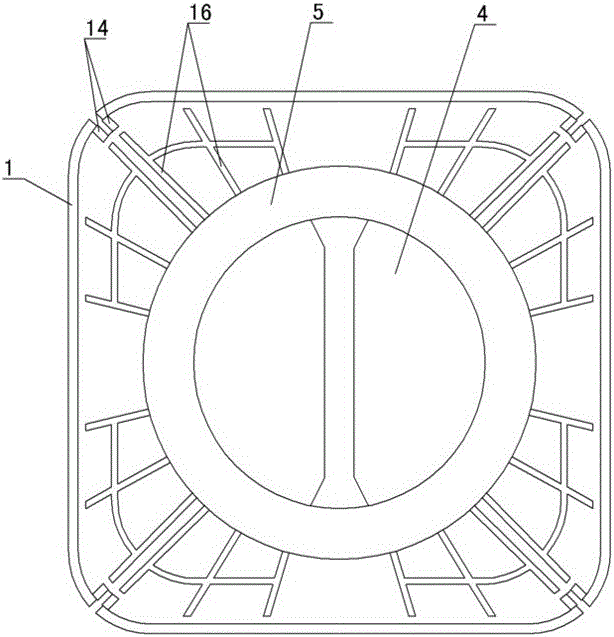

A rotary supporting clamping sealing tank comprises a tank body and a tank cover, the tank cover comprises a cover plate, a knob is arranged in the cover plate, a knob clamping ring is arranged on the lower portion of the knob, four evenly-distributed supporting clamping blocks with slopes are arranged on the outer wall of the knob clamping ring, a supporting frame is arranged on the bottom face of the cover plate, the supporting frame comprises four sides corresponding to the opening portion of the tank body and an inner ring corresponding to the knob clamping ring, the inner ring and the four sides are broken from the middles and are respectively divided into four equally-divided parts, the inner ring with the four equally-divided parts and the four sides are connected through a support, the four sides with the equally-divided parts are connected through opening elastic rings, the supporting clamping blocks with the slopes are in contact with the inner ring, the periphery of the supporting frame and the periphery of the cover plate are coated with sealing cushion covers, and the sealing cushion covers are matched with the opening of the tank body. The supporting and clamping modes are adopted by the tank, operation is easy, the cover can be conveniently opened or closed, and after the tank cover and the tank body are buckled, the sealing effect is good.

Owner:台州市富龙塑胶有限公司

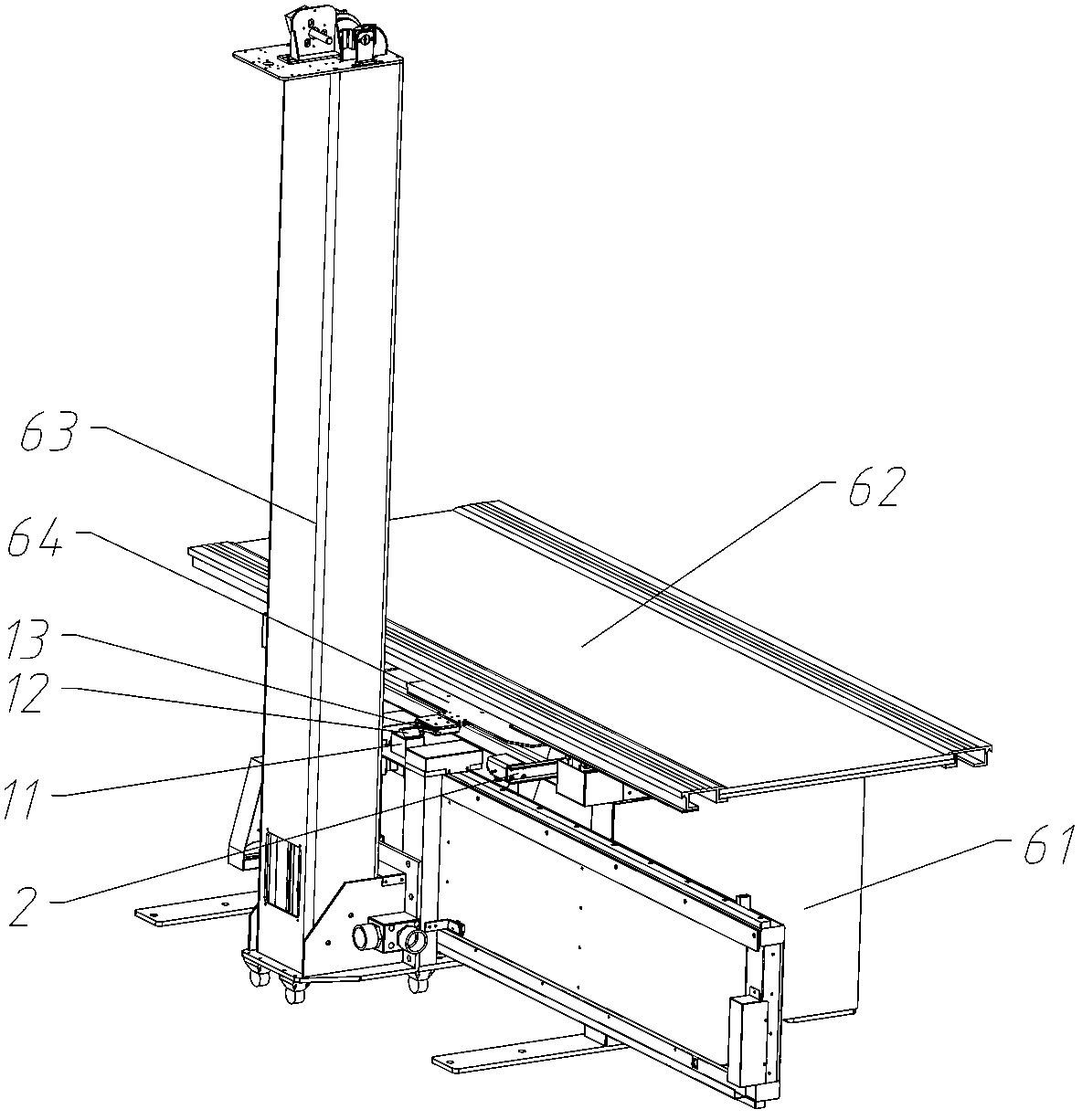

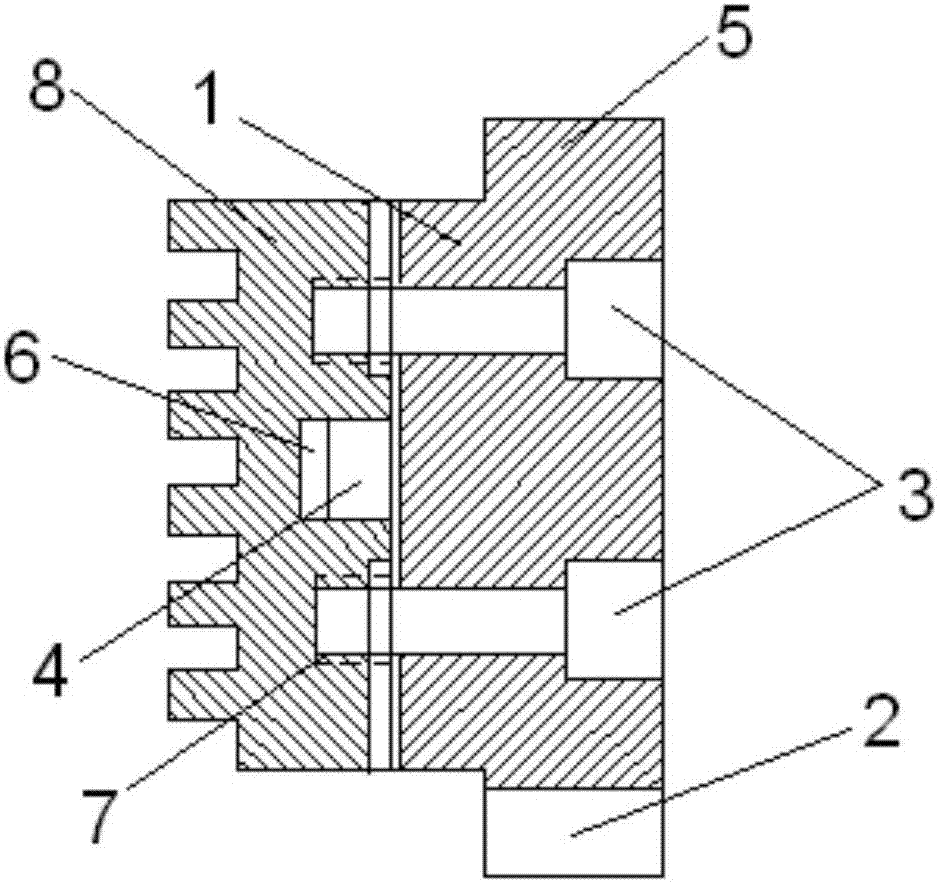

Vertical high-precision post processor for plastic pipe

ActiveCN106273204AClamping and reliableGuaranteed service lifeMetal working apparatusPost processorEngineering

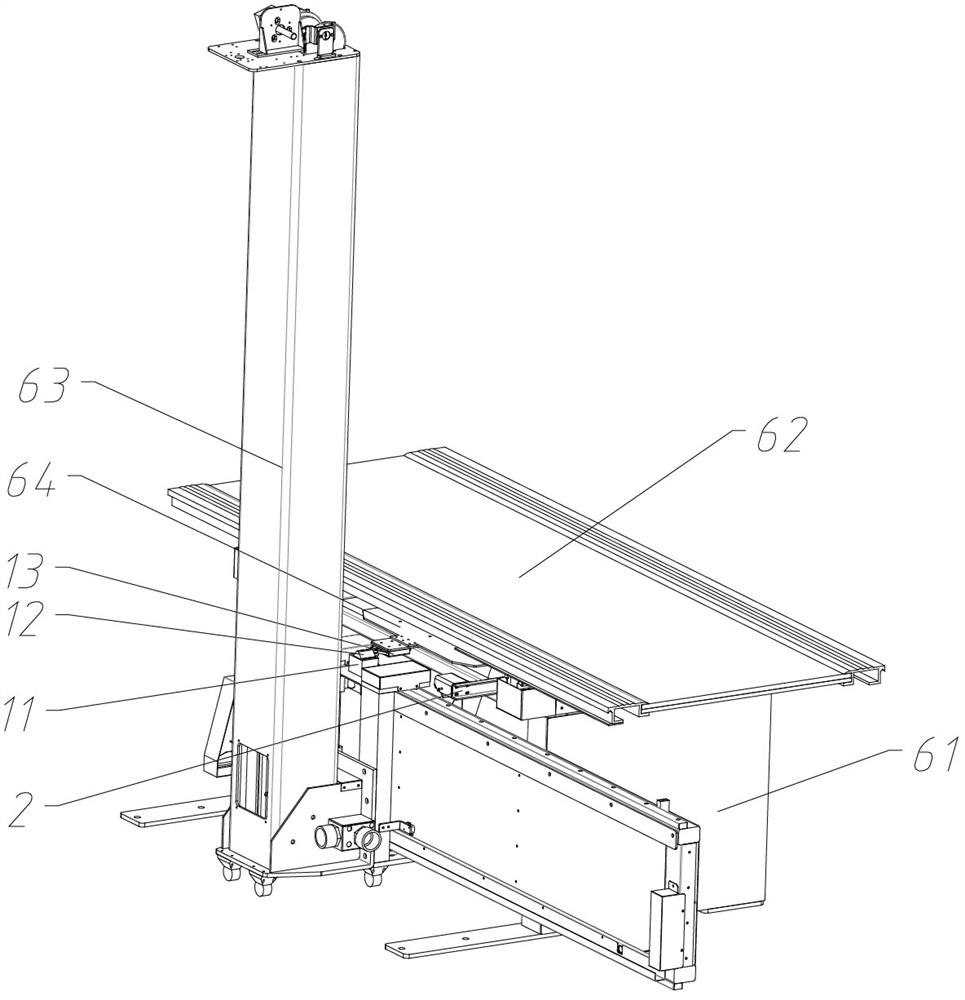

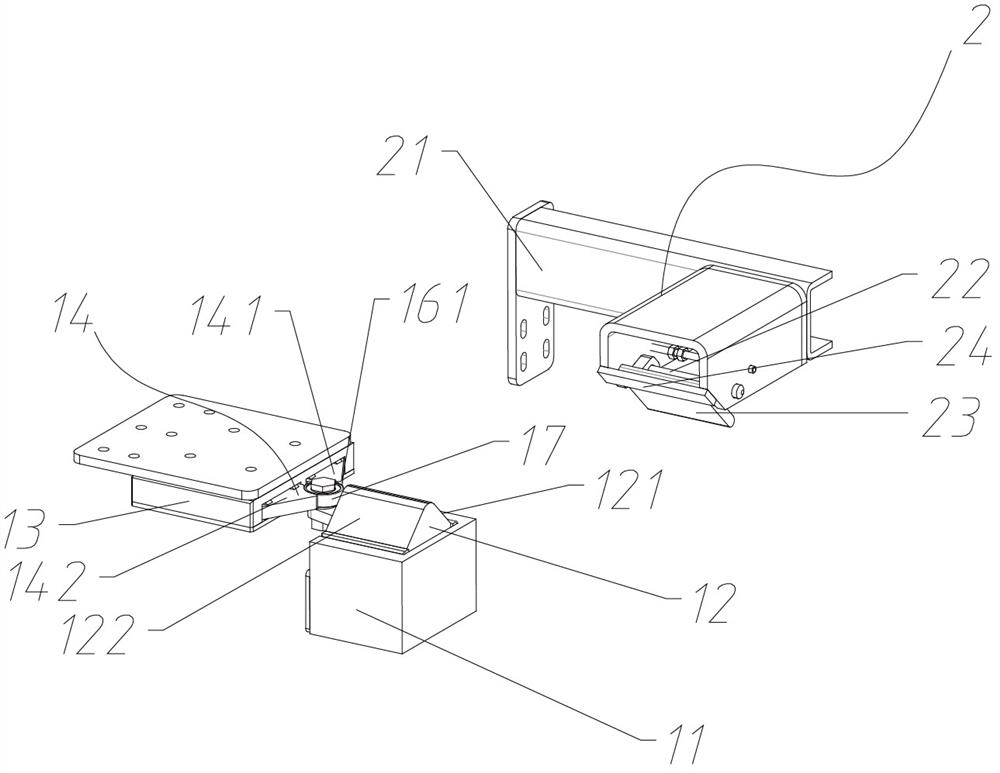

A vertical high-precision post processor for a plastic pipe is characterized by comprising a rack; an upper fixing plate and a lower fixing plate are arranged on the rack, a bearing bush is arranged in the upper fixing plate, bearings are arranged in the bearing bush, the inner walls of the bearings are connected with a copper bush shaft, a tool rest supporting plate is arranged outside the upper end of the copper bush shaft, tool rest supporting rods are arranged on the tool rest supporting plate, a tool rest ring is arranged on the tool rest supporting rods, and blades are arranged on the tool rest ring; bearing locking nuts, a driven gear and gear locking nuts are arranged on the part, located at the lower ends of the bearings, of the outer wall of the copper bush shaft in sequence; a large motor is arranged in the rack and connected with a driving gear, the driving gear is meshed with the driven gear, guide columns are arranged between the upper fixing plate and the lower fixing plate, guide sleeves are arranged on the guide columns, a sliding plate is arranged on the guide sleeves, a vertical adjusting block is arranged on the sliding plate, communicated screw holes are formed in the vertical adjusting block and the sliding plate, a screw is arranged in the screw holes, a small motor is arranged below the lower fixing plate, an output shaft of the small motor is connected with the screw, a chuck is arranged on the vertical adjusting block, clamping grooves are formed in the chuck, clamping bases are arranged in the clamping grooves, and the clamping bases are matched with the inner wall of the plastic pipe.

Owner:YONGGAO CO LTD

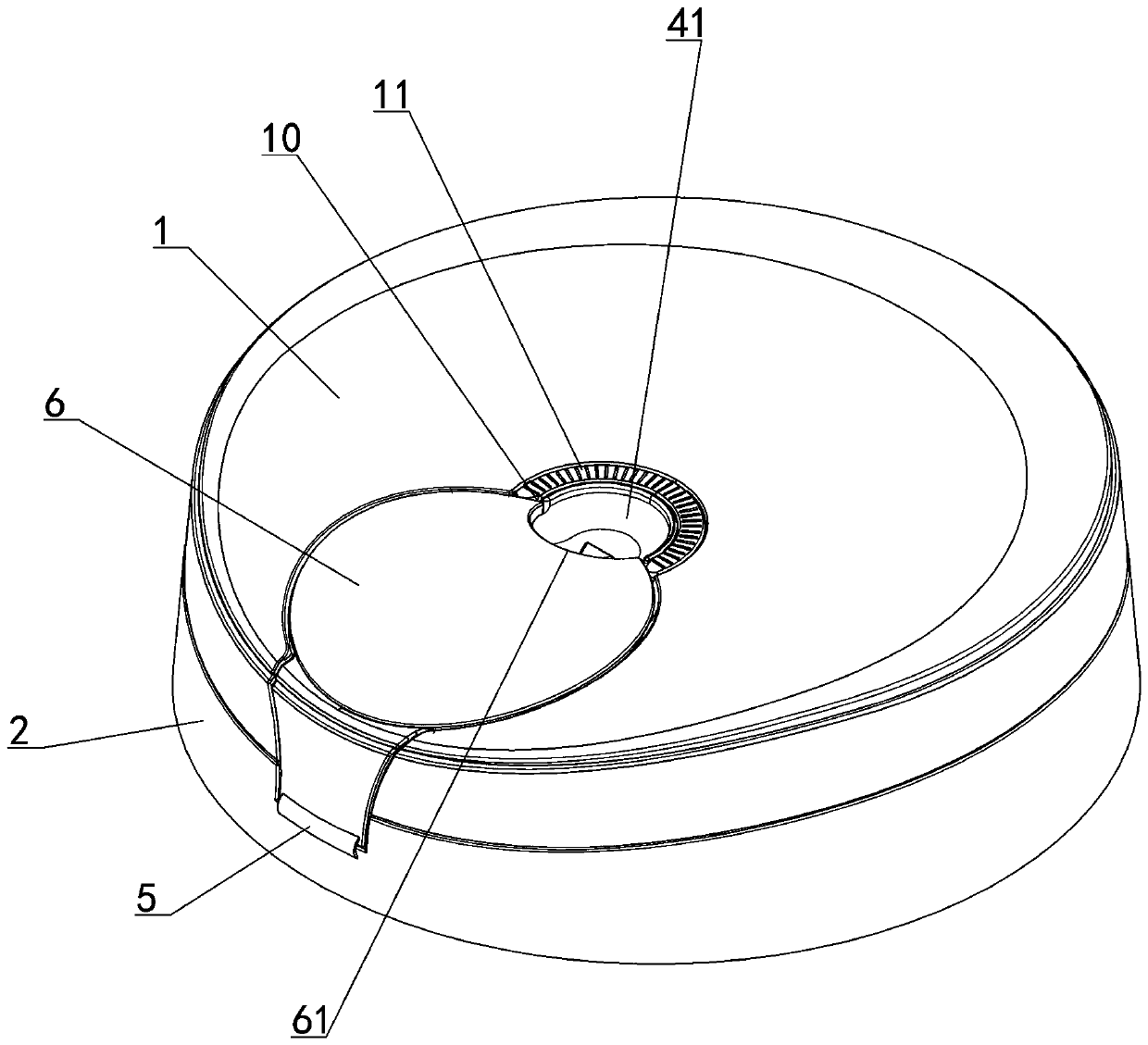

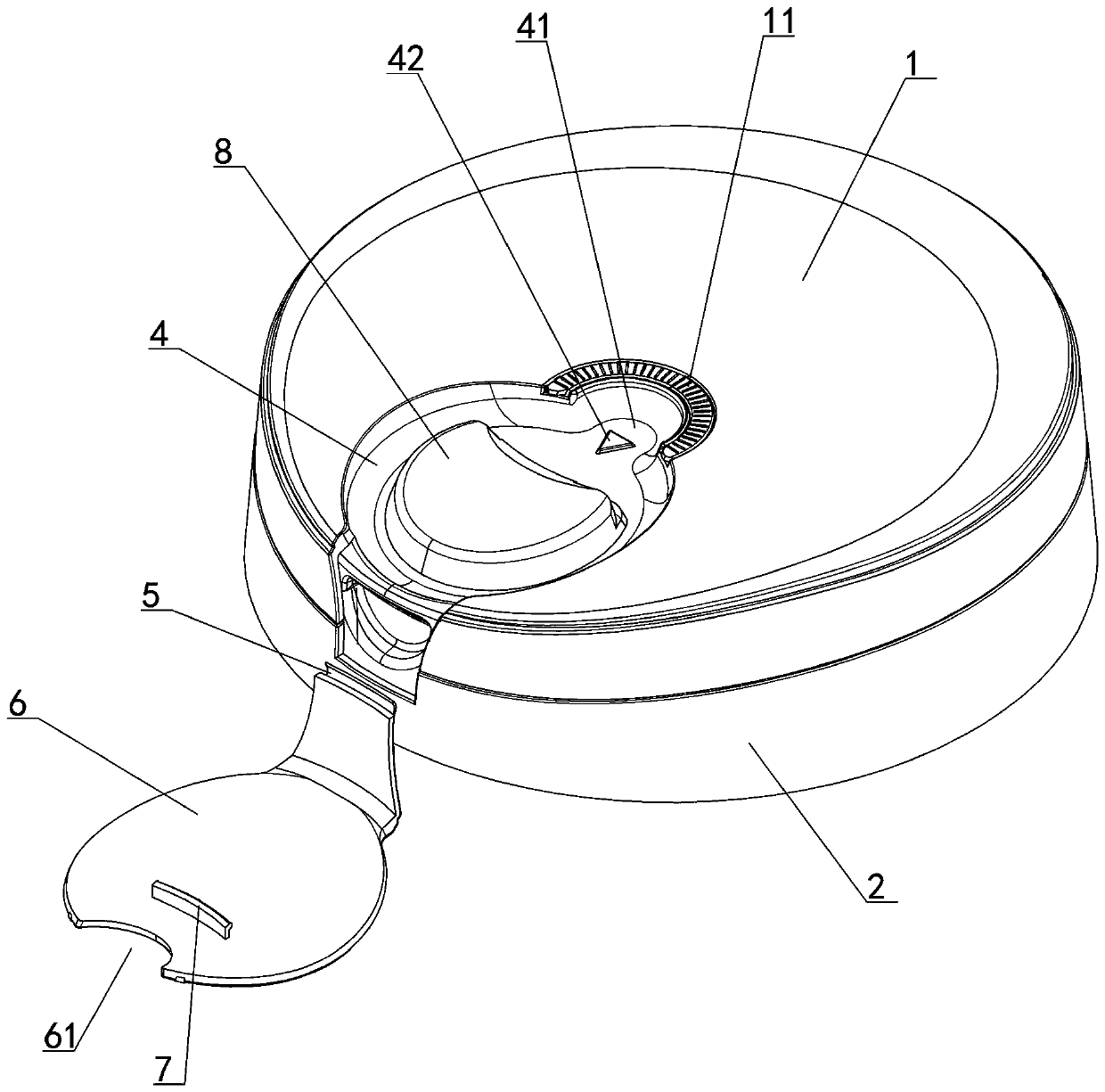

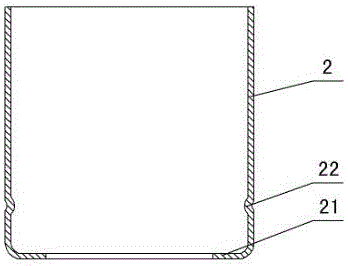

Pull buckle type anti-theft food packaging tin cover

The invention discloses a pull buckle type anti-theft food packaging tin cover. The pull buckle type anti-theft food packaging tin cover comprises a tin cover body arranged on a tin body, the tin cover body comprises an upper cover and a lower cover, one side of the upper cover is connected with one side of the lower cover through a connecting piece, the other side of the upper cover is connectedwith the other side of the lower cover through a pull buckle mechanism, the pull buckle mechanism comprises pull buckle which is arranged on lower cover and integrally connected with lower cover through pull folding piece, wherein a buckle is arranged on the pull buckle, a groove corresponding to the pull buckle in appearance is formed in the upper cover, a finger groove is formed in the front endof the groove, a boss is arranged in the groove, a clamping groove is formed in the boss, during buckling, the pull buckle is buckled on the boss and clamped in the clamping groove through the buckle, and an integrally-connected anti-theft mechanism is arranged at the front end of the pull buckle. According to the scheme, losses caused by collision and friction in the transportation process are avoided, the top face of the cover is integrally buckled with the pull buckle in an anti-theft mode, the pull buckle is reliable in clamping and safe in sealing, the hidden danger that young children can easily open the cover is effectively prevented, the periphery and the surface of the cover are integrally opened and used smoothly, and other potential safety hazards do not exist.

Owner:TAIZHOU HUANGYAN SHUNAN PLASTIC

Sealing device of food filling machine and using method of sealing device

The invention provides a sealing device of a food filling machine and a using method of the sealing device. The sealing device of the food filling machine comprises a handle I, a handle II and a foodfilling machine nozzle, a clamp head II is arranged at the top of the handle I, the food filling machine nozzle is arranged on one side of the clamp head II, a clamp head I is arranged at the top of the handle II, the food filling machine nozzle is arranged on one side of the clamp head I, a sealing sleeve is arranged at the bottom of the food filling machine nozzle, a supporting lug I is arrangedon one side of the sealing sleeve, one side, far away from the supporting lug I, of the sealing sleeve is provided with a supporting lug II, a spring III is arranged at the bottom of the supporting lug I, and a spring I is arranged at the bottom of the supporting lug II. According to the sealing device, a caliper structure design is adopted, the use is more flexible, the sealing sleeve can be reliably attached to the food filling machine nozzle, the mounting and dismounting operation processes are simple, and the damage to the internal structure of the food filling machine nozzle can be completely avoided.

Owner:陈策

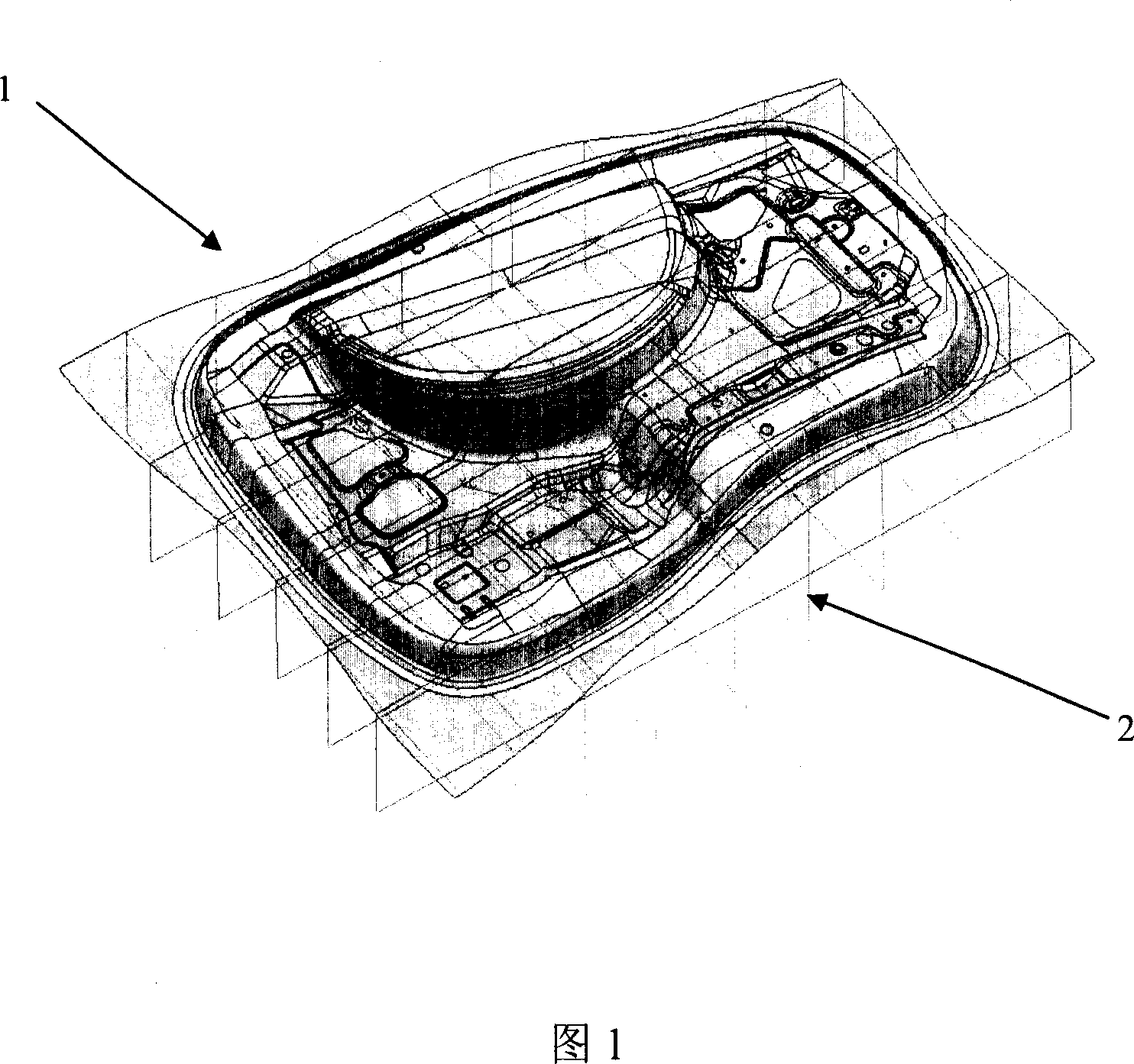

Composite molding process for electric vehicle chassis suspension assembly

The invention discloses a composite molding process for an electric vehicle chassis suspension assembly. The composite molding process for the electric vehicle chassis suspension assembly is characterized by comprising the following steps of 1, drawing molding; 2, upper sealing sleeve rolling; 3, injection molding; 4, fixing base fixing; 5, lower sealing sleeve jacking; 6, fixing box jacking; 7, composite flanging and molding; 8, primary composite molding part plastic spraying; 9, primary composite molding part fixing; 10, shock-proof buffering ring jacking; 11, upper sealing sleeve jacking; 12, fixing ring jacking; and 13, fixing box rolling. After all parts are drawn and molded through a drawing mold, a fixing base serves as a main assembly part; all the parts are sequentially clamped into the fixing base through a hydraulic cylinder, and then flanging is conducted through the hydraulic cylinder, so that all the parts are tightly clamped; and compared with existing welding connecting, the drawing cost is low, assembly is reliable, the fastness is good, the overall strength is high, the service life is long, welded joints are avoided, the appearance is attractive, the machining period is short, and the production efficiency is high.

Owner:李志联

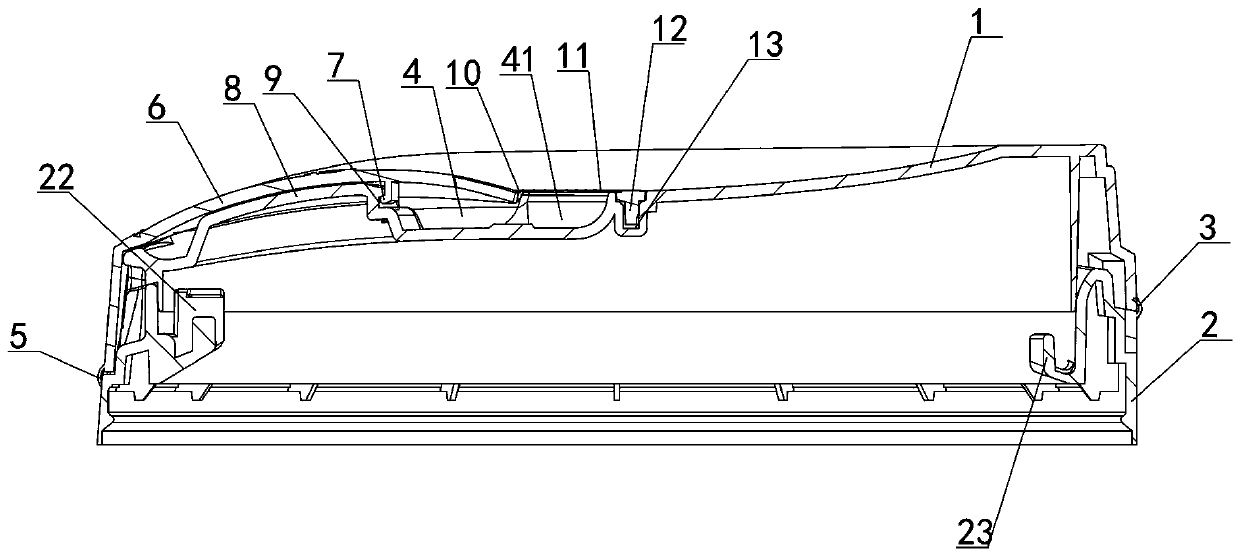

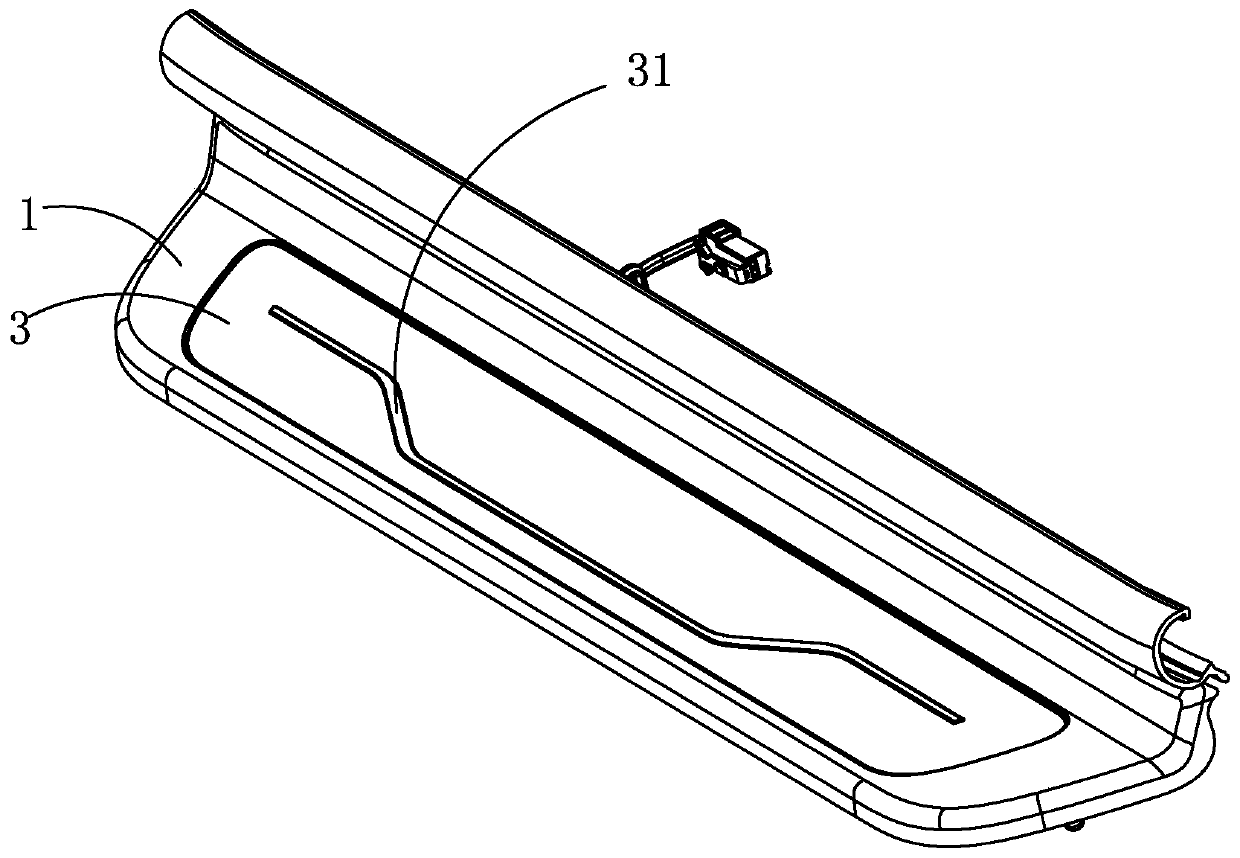

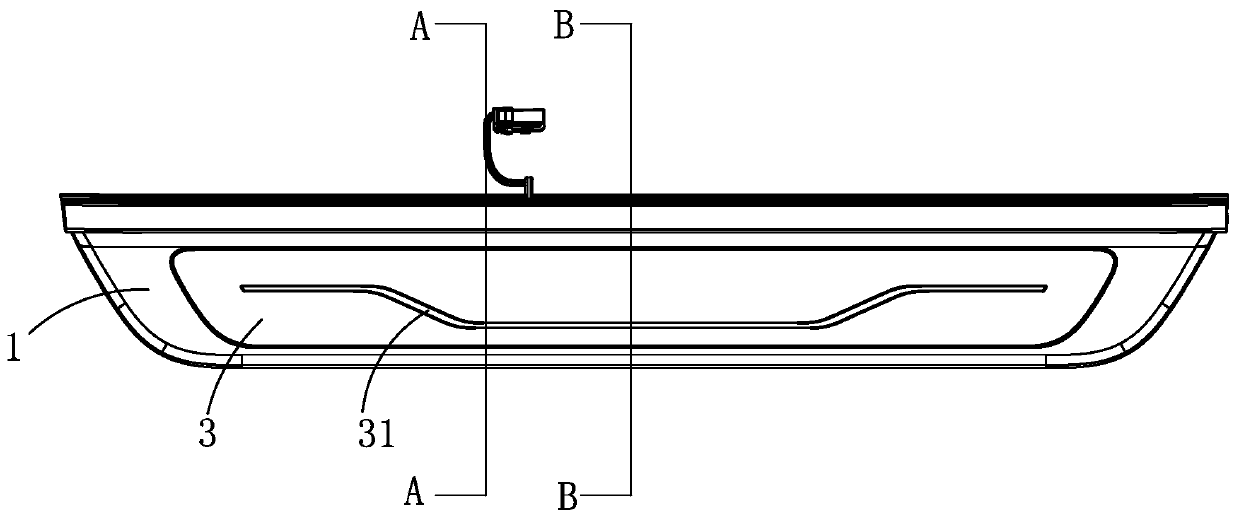

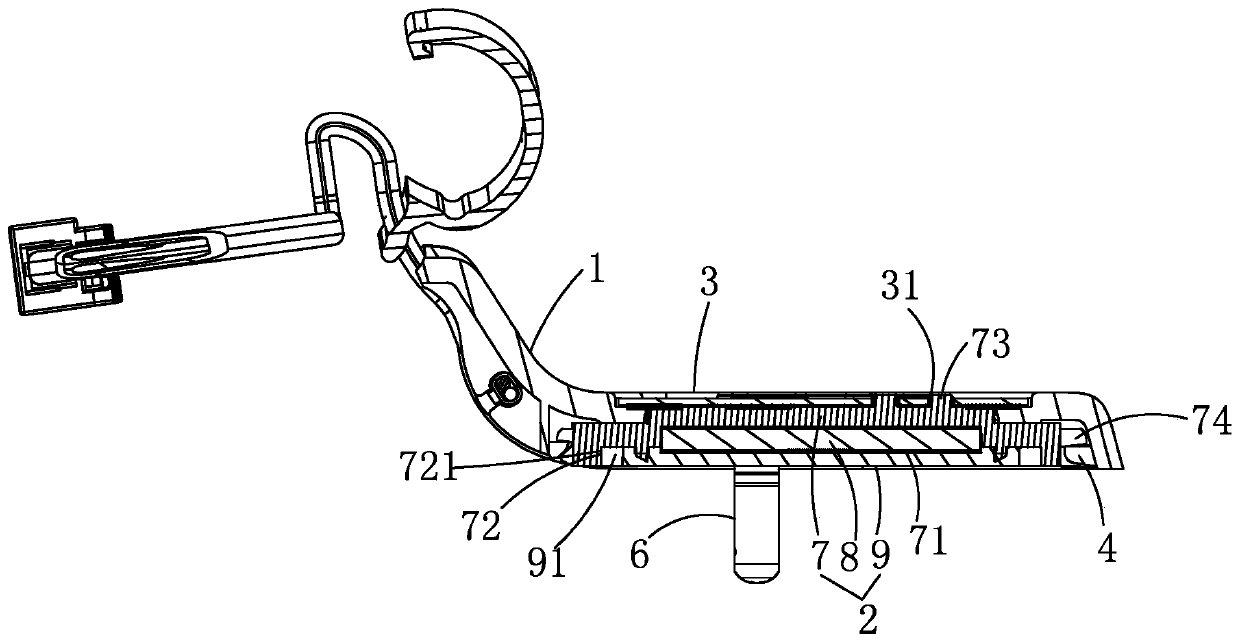

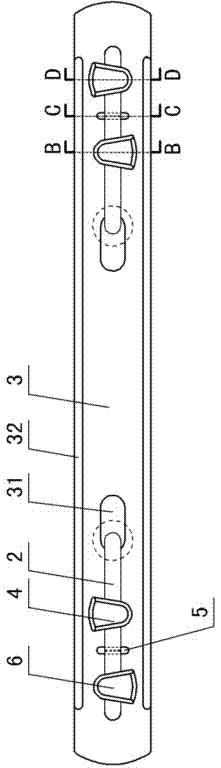

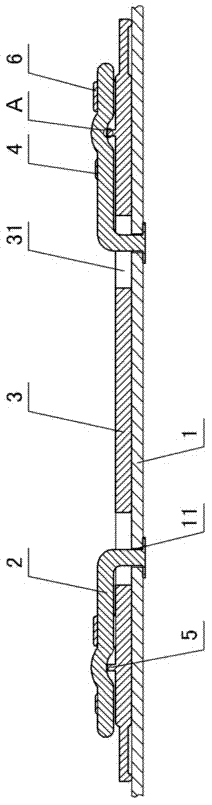

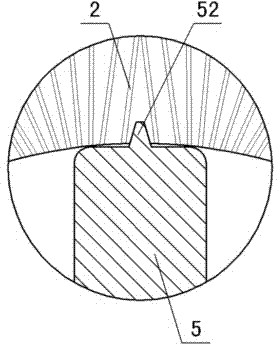

Light-emitting automobile door pedal

InactiveCN109760584AImprove the sealing effectImprove waterproof effectLighting circuitsDoor lightingElectrical and Electronics engineeringLight emitting device

The invention relates to a light-emitting automobile door pedal which comprises a pedal body and a light-emitting device, wherein the pedal body is provided with a light-emitting device mounting cavity; the light-emitting device is clamped in the light-emitting device mounting cavity; the light-emitting device comprises a light-transmitting plate, a light-emitting circuit board and a bottom plate;the light-transmitting plate is provided with a light-emitting circuit board mounting cavity; the light-emitting circuit board is arranged in the light-emitting circuit board mounting cavity; and thebottom plate is connected with the light-transmitting plate and seals the light-emitting circuit board mounting cavity. The light-transmitting plate is provided with the light-emitting circuit boardmounting cavity, the light-emitting circuit board is arranged in the light-emitting circuit board mounting cavity, and the bottom plate is connected with the light-emitting circuit board and seals thelight-emitting circuit board mounting cavity, so that a sealing effect of the light-emitting device is improved, to prevent water from entering the light-emitting circuit board mounting cavity through a gap to wet the light-emitting circuit board and then causing failure or electricity leakage of the light-emitting device; a waterproof effect of the light-emitting automobile door pedal is improved, therefore, the safety of the light-emitting automobile door pedal is improved.

Owner:广东维杰汽车部件制造有限公司

An open hole sidetracking setter for air drilling

ActiveCN110397419BReliable settingsClamping and reliableDirectional drillingSealing/packingEngineeringOil and natural gas

The invention relates to an open hole sidetracking setting device used in the field of air drilling in the oil and gas industry. It solves the problem of difficult fixation of the skewer in open-hole drilling. The upper end of the control short-circuit is connected with the screw thread at the lower end of the tilter, the lower end of the control short-circuit is connected with the upper end of the oil storage cylinder with a screw thread, and the air intake channel is connected with the internal delivery flow channel of the tilter; the lower end of the oil storage cylinder is connected with the booster cylinder The upper end of the body is fastened with a plug screw, and the oil pressure piston is placed into the cavity of the oil storage chamber; the piston end of the booster piston is placed into the exhaust chamber of the booster cylinder, and the piston rod of the booster piston is placed into the inlet of the booster cylinder. In the oil throat, the upper end of the actuating piston is placed in the pressure oil chamber of the pressurized cylinder; the upper end of the anchoring cylinder is connected with the lower end of the pressurized cylinder with threads, and the lower end of the anchoring cylinder is connected with the upper end of the guide shoe; the cone is placed into the inner cavity of the anchoring cylinder, and the upper end of the cone is connected with the lower end of the actuating piston with a screw. The invention converts the compressed air with low pressure into the pressure oil with high pressure, so as to ensure the reliable setting of the skewer in the open hole section.

Owner:XIHUA UNIV

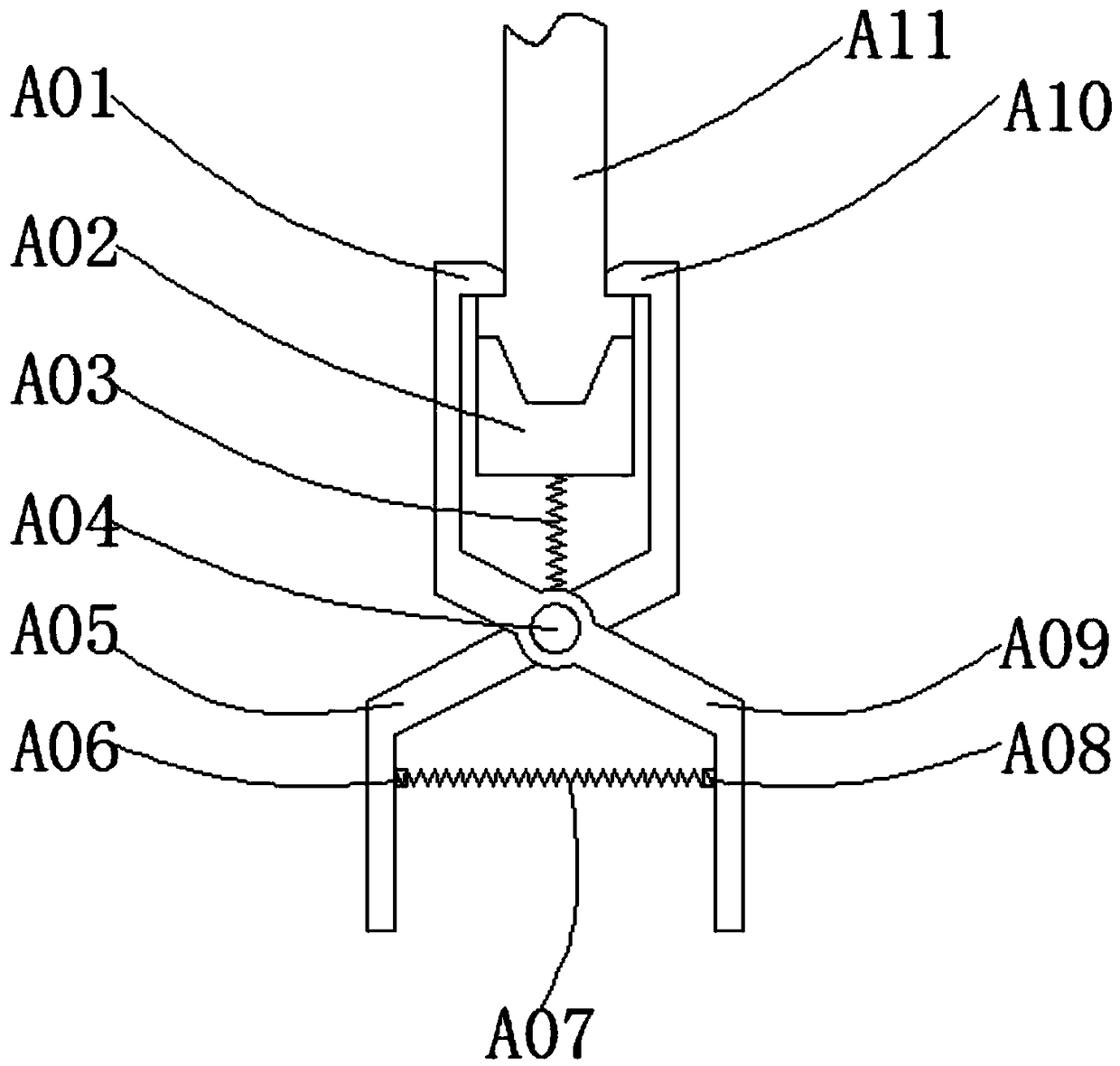

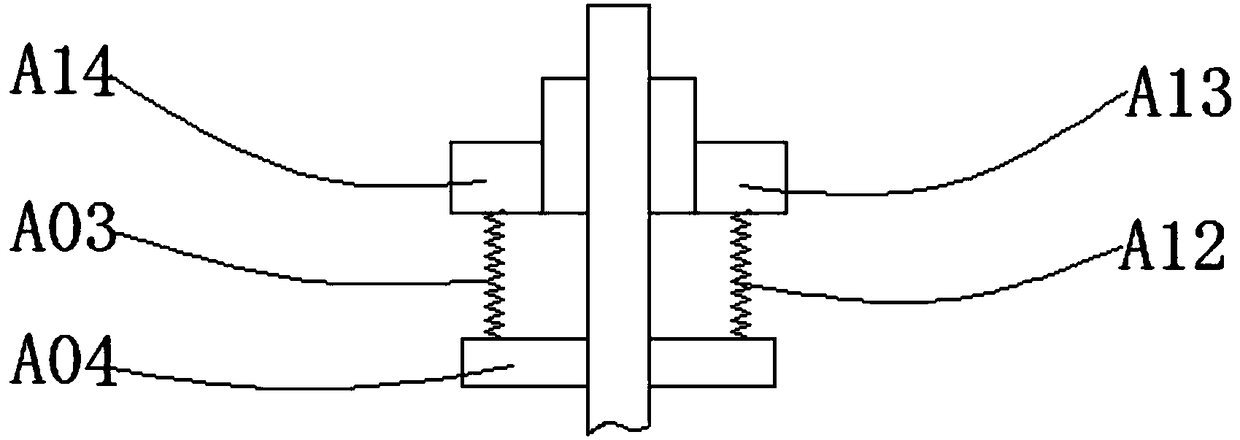

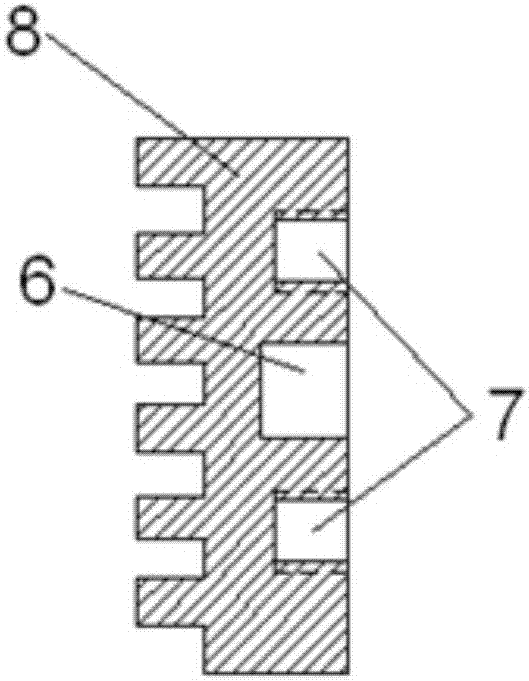

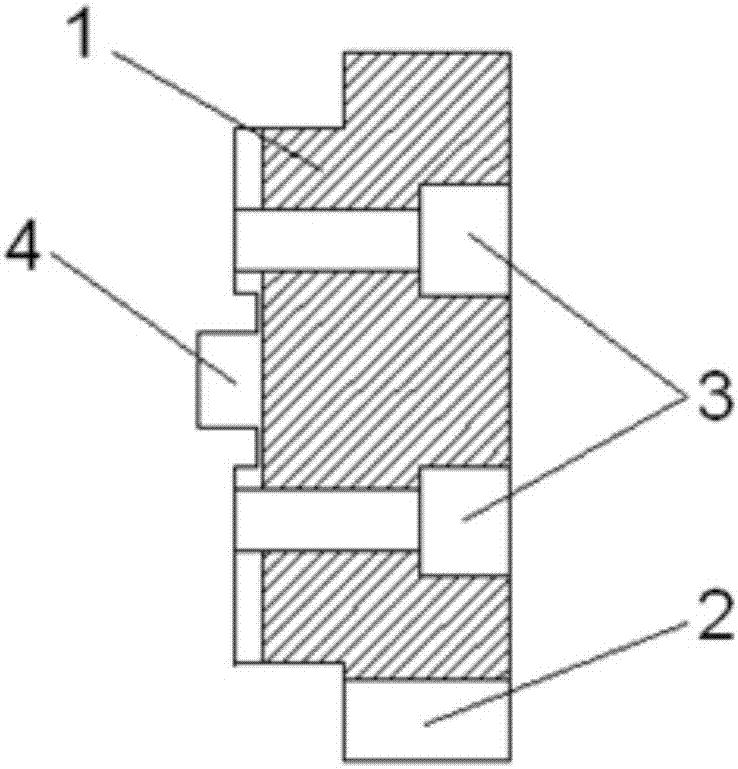

Wiring terminal convenient to disassemble and assemble

ActiveCN102760991BClamping and reliableQuick clampingCoupling contact membersClamped/spring connectionsEngineeringMechanical engineering

The invention relates to a wiring terminal convenient to disassemble and assemble. The wiring terminal comprises a wiring post, wherein a clamping assembly used for clamping a conducting wire is installed on the wiring post, and the clamping assembly comprises a slide groove arranged on the wiring post and a wire-pressing shaft sliding in the slide groove; the wiring terminal further comprises a locking assembly used for locking the clamping assembly, and the wire-pressing shaft is controlled by rotating the locking assembly, so as to fix the conducting wire in the wiring post. By the wiring terminal convenient to disassemble and assemble provided by the invention, a rotating block connected with a pressure spring can be automatically locked while the wire-pressing shaft is controlled by the rotating block to clamp or release the conducting wire, so that the clamping and the releasing for the conducting wire are faster in speed and higher in efficiency, assembly time is saved, and the clamping for the conducting wire is firmer and more reliable; the conducting wire can be installed without the aid of a tool; simultaneously, the wiring terminal is simple in structure and convenient to operate.

Owner:KEDU ELECTRIC CO LTD

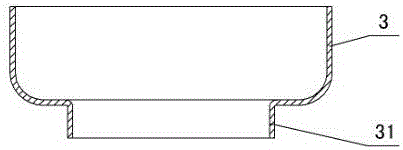

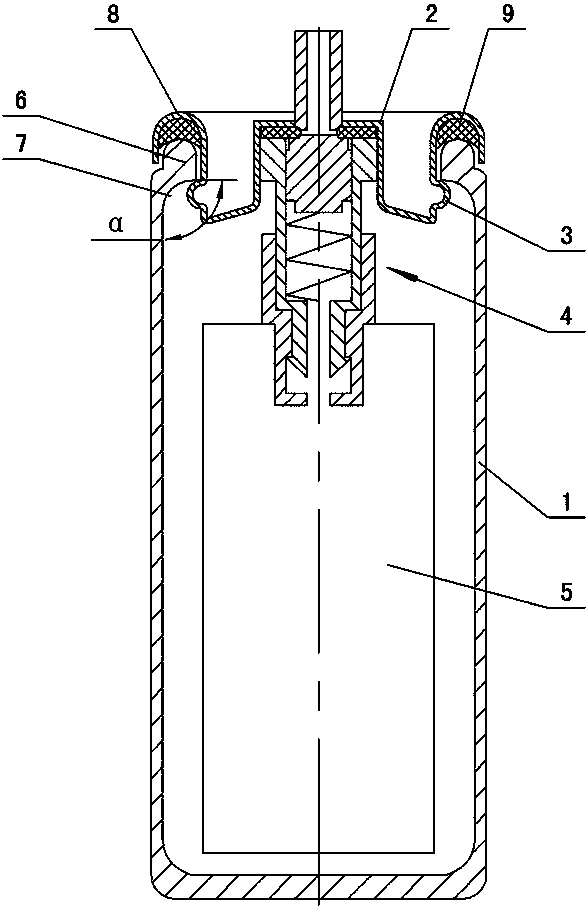

Clamping antiskid type transparent tear ejector tank

ActiveCN104236386AClamping and reliableEasy clampingLiquid ejecting gunsManufacturing cost reductionBiochemical engineering

A clamping antiskid type transparent tear ejector tank comprises a tank body for a tear ejector; the tank body is loaded with compressed air; an upper opening of the tank body is provided with a tank cover; the external wall of the tank cover is provided with a reversed button; a valve component is arranged in the tank cover; a bag body is connected below the valve component; the bag body is internally loaded with tear liquid. The clamping antiskid type transparent tear ejector tank is characterized in that the upper portion of the transparent tank body which is made of PC (Poly Carbonate) plastics is provided with an upper necking opening; the tank cover is installed inside the upper necking opening; transition between the internal wall of the upper necking opening and the internal wall of the tank body is achieved through an arc-shaped groove; the arc-shaped groove is matched with the reversed button of the tank cover; an included angle alpha between the vertical internal wall of the tank body and the lower portion of the upper necking opening is from 70 to 90 degrees. According to the clamping antiskid type transparent tear ejector tank, by the arc-shaped groove, clamping of the reversed button is facilitated, the reversed button is prevented from upwards separating from the tank body, and reliable clamping between the tank cover and the tank body is guaranteed; the transparent tank body which is made of the PC plastics is fewer in machining steps and convenient to manufacture, improves the production efficiency, reduces the manufacturing cost and is convenient for a user to observe the remaining tear liquid loaded inside the bag body in the tank body; the tear liquid can be timely replaced when being used up, and the condition that the tear liquid is used up under emergency conditions is avoided.

Owner:ZHEJIANG NANTAI TECH

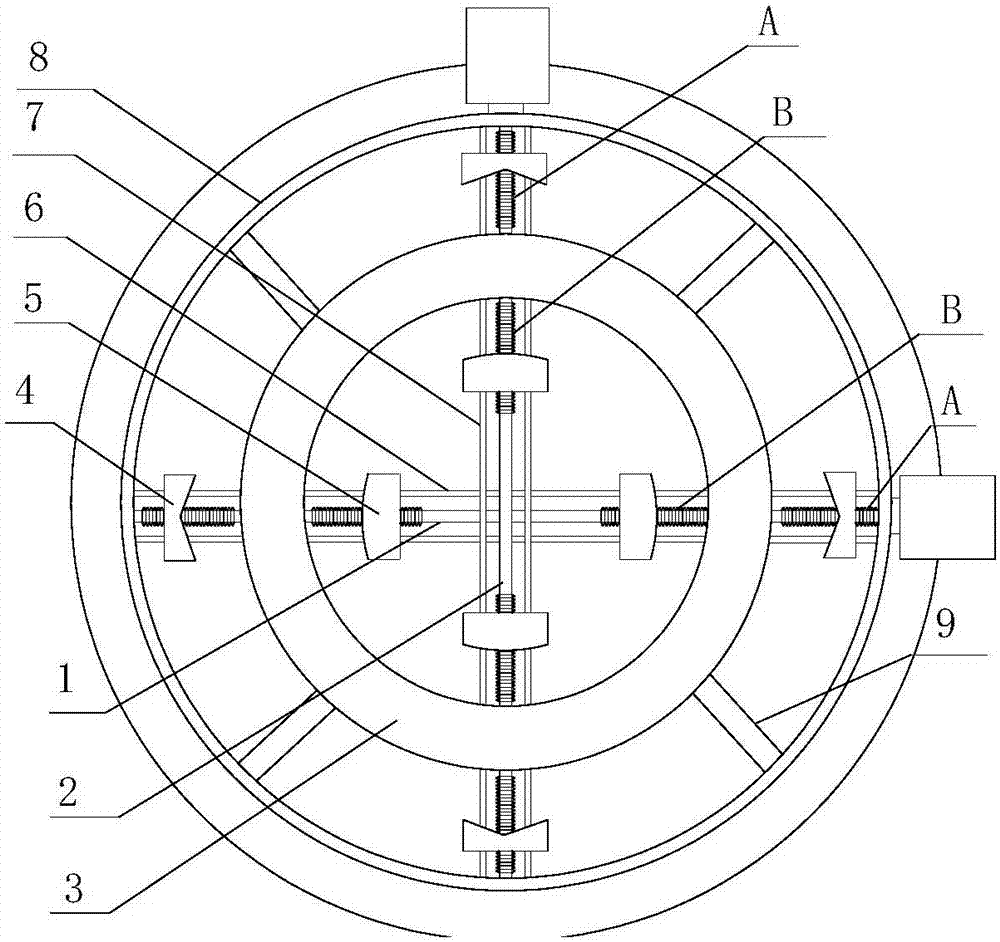

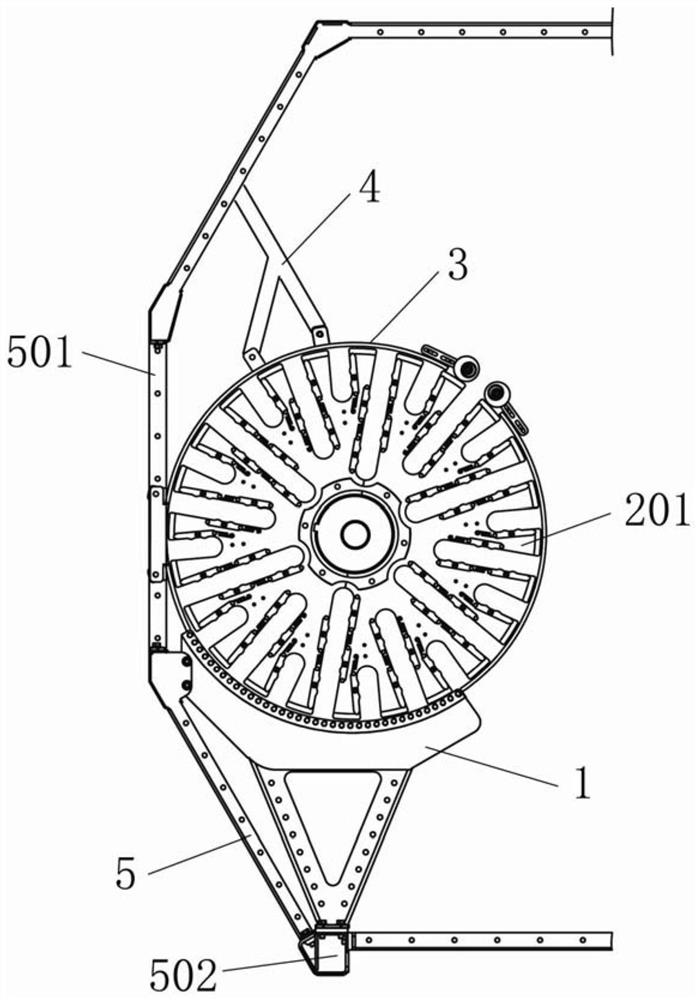

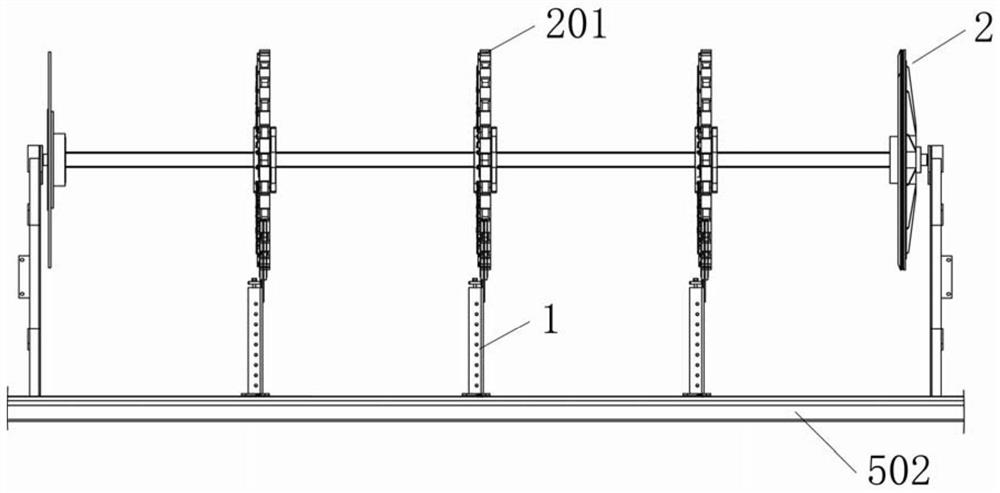

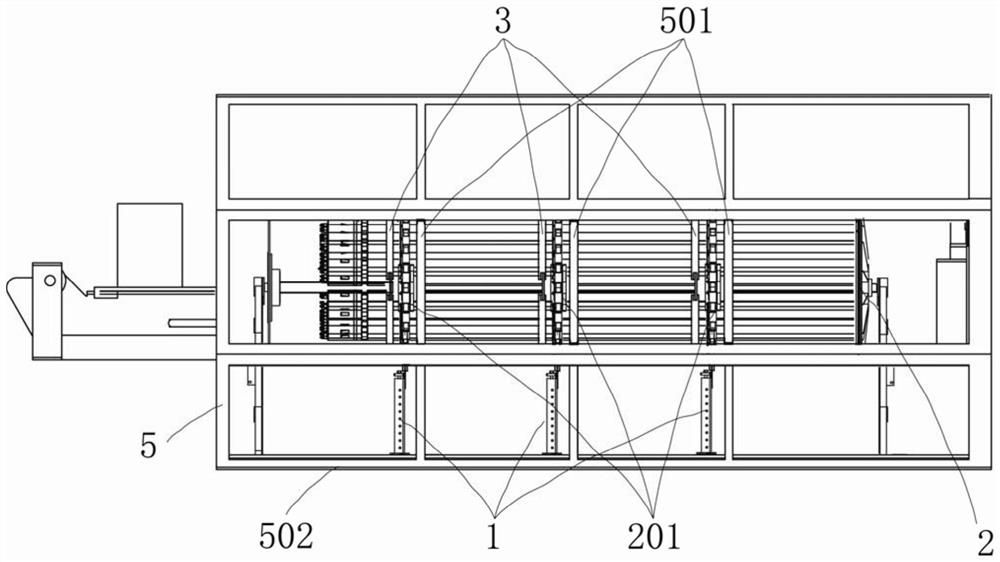

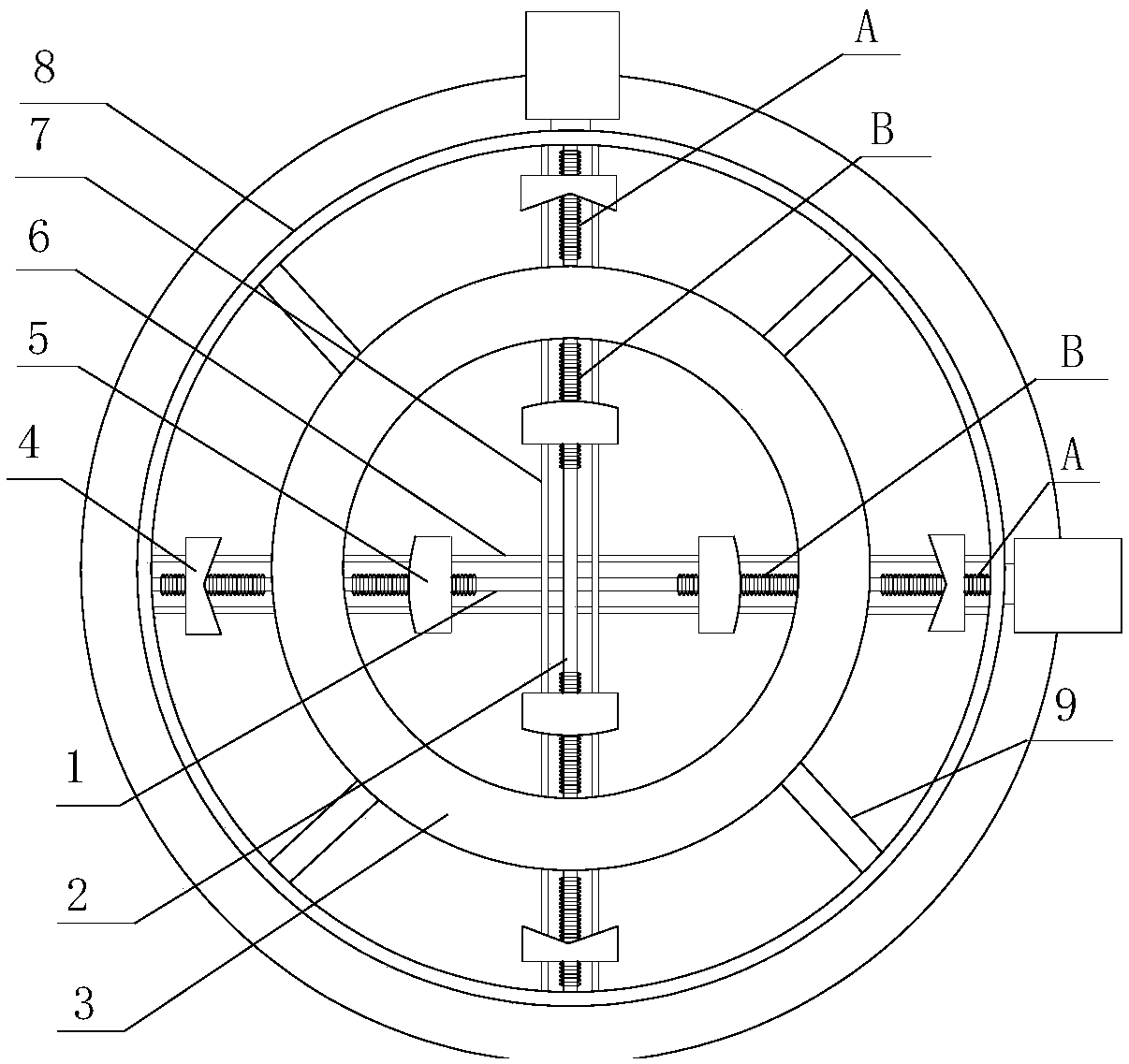

The arc-shaped rotating support mechanism of the drill pipe magazine of the subsea drilling rig stored in a horizontal manner

ActiveCN110306941BSolve bending deformationImprove protectionDrilling rodsDrilling casingsSubmarineSupport surface

The invention discloses an arc-shaped rotating and supporting mechanism of a drill pipe library of a seabed drilling rig stored in a horizontal lying mode. The arc-shaped rotating and supporting mechanism comprises a frame, n circular separating discs with pipe storage grooves and n arc-shaped supporting frames, wherein n is an integer larger than or equal to 2, and the n arc-shaped supporting frames are fixedly mounted on a back sliding rail of the frame and are arranged parallelly and coaxially; the n separating discs are supported on the n arc-shaped support frames correspondingly, and thearc-shaped support surfaces of the arc-shaped support frames are in contact with the arc surfaces of the edges of the corresponding separating discs; and the separating discs are used for forming a rotatable auxiliary support for the whole drill pipe library and drill pipes stored thereon. According to the arc-shaped rotating and supporting mechanism, the arc-shaped support frames are used for rotating and supporting the circular separating discs with the pipe storage grooves in the drill pipe library, so that the problems that the rotation cannot be realized due to the bending deformation easily caused by the fact that the drill pipe library is large in weight and long in length, and a main shaft and bearings at two ends of the main shaft of the drill pipe library are small are solved; and the arc-shaped rotating and supporting mechanism has the advantages of being simple and compact in structure, convenient to control, low in cost and the like.

Owner:HUNAN SEA BULL GEOLOGICAL EXPLORATION CO LTD

Gardening landscape lamp

ActiveCN108105671AEasy to insertEasy to snapMechanical apparatusElectric circuit arrangementsEngineering

Owner:瑞安市森威家用电器有限公司

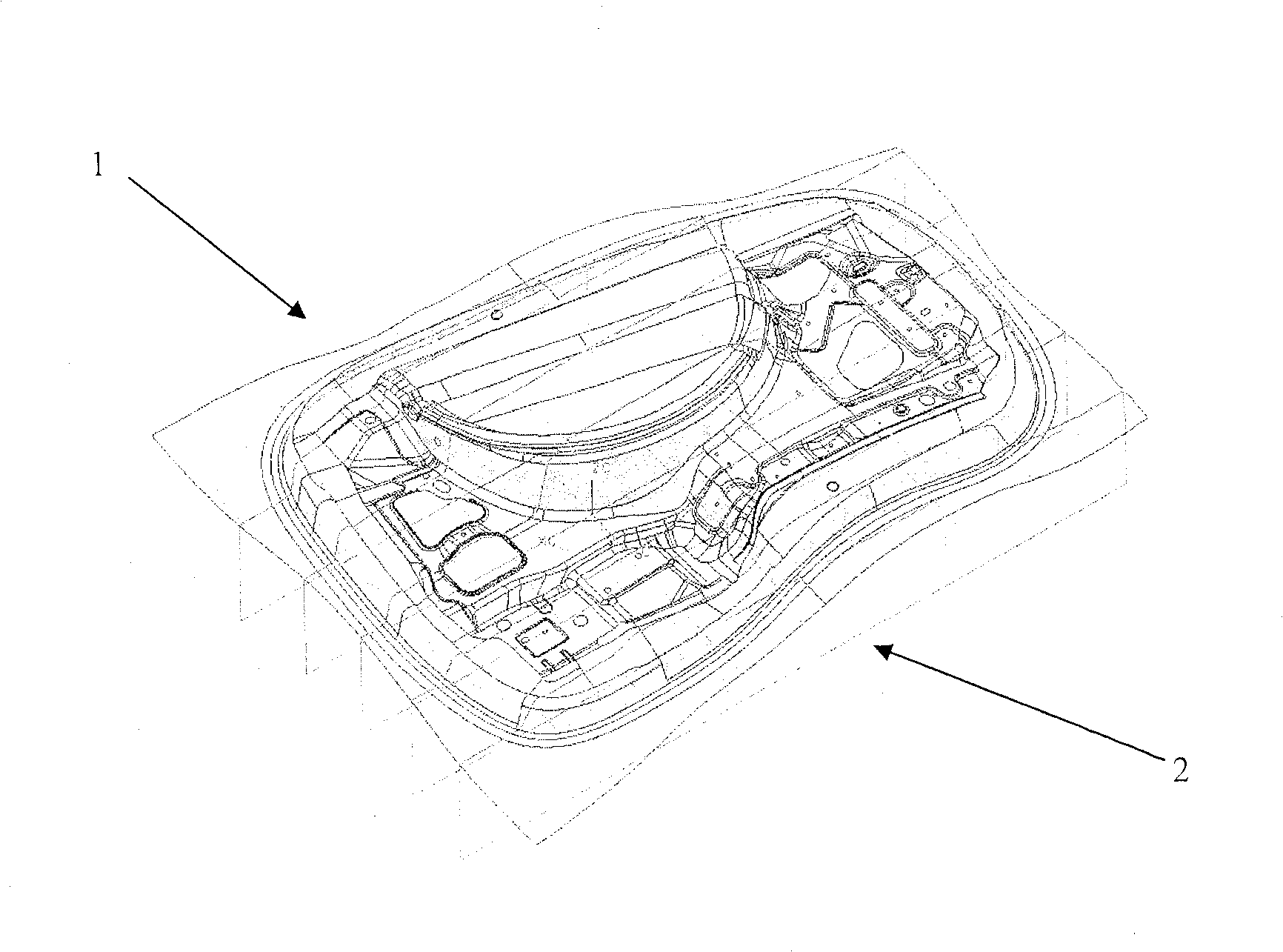

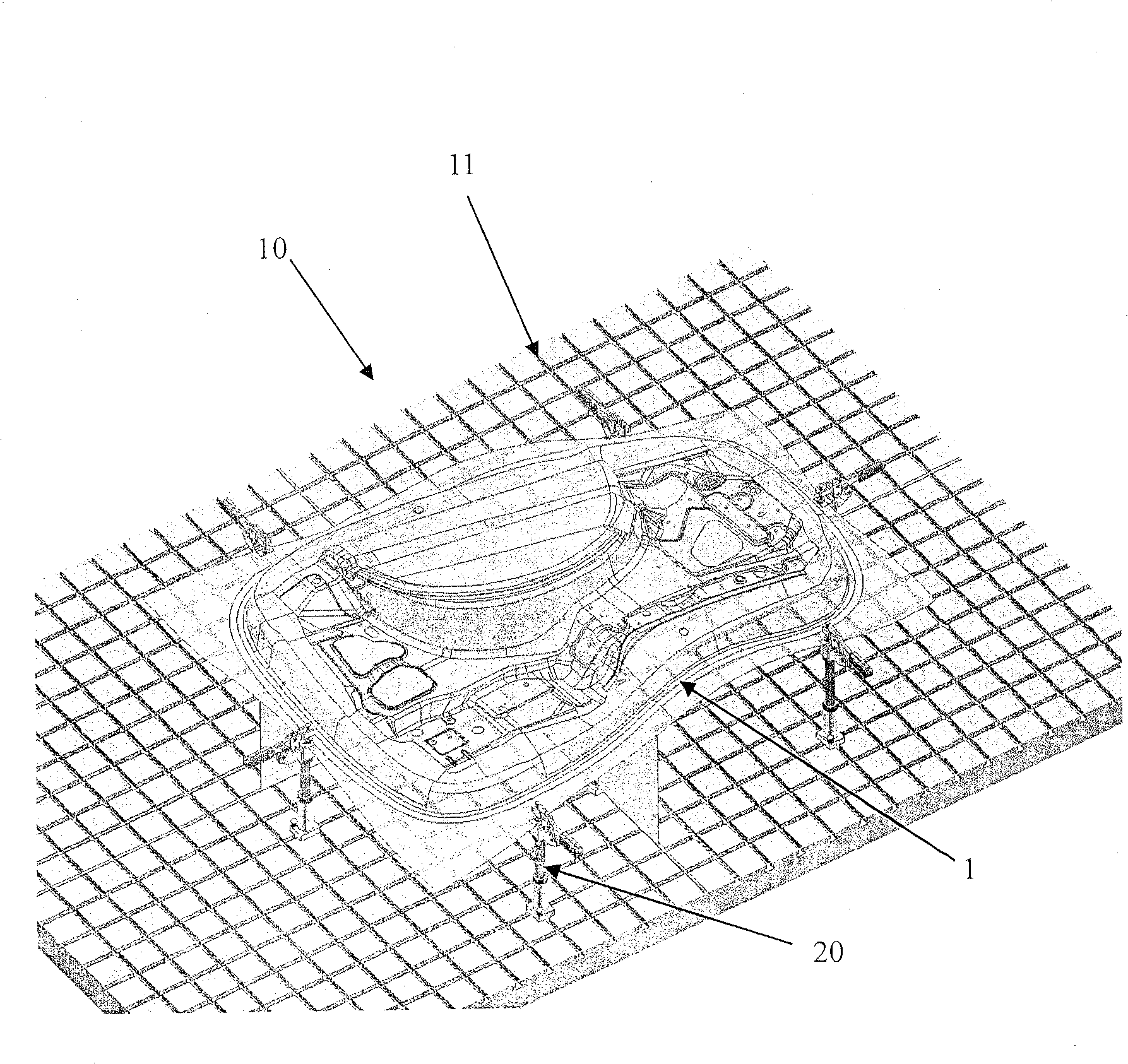

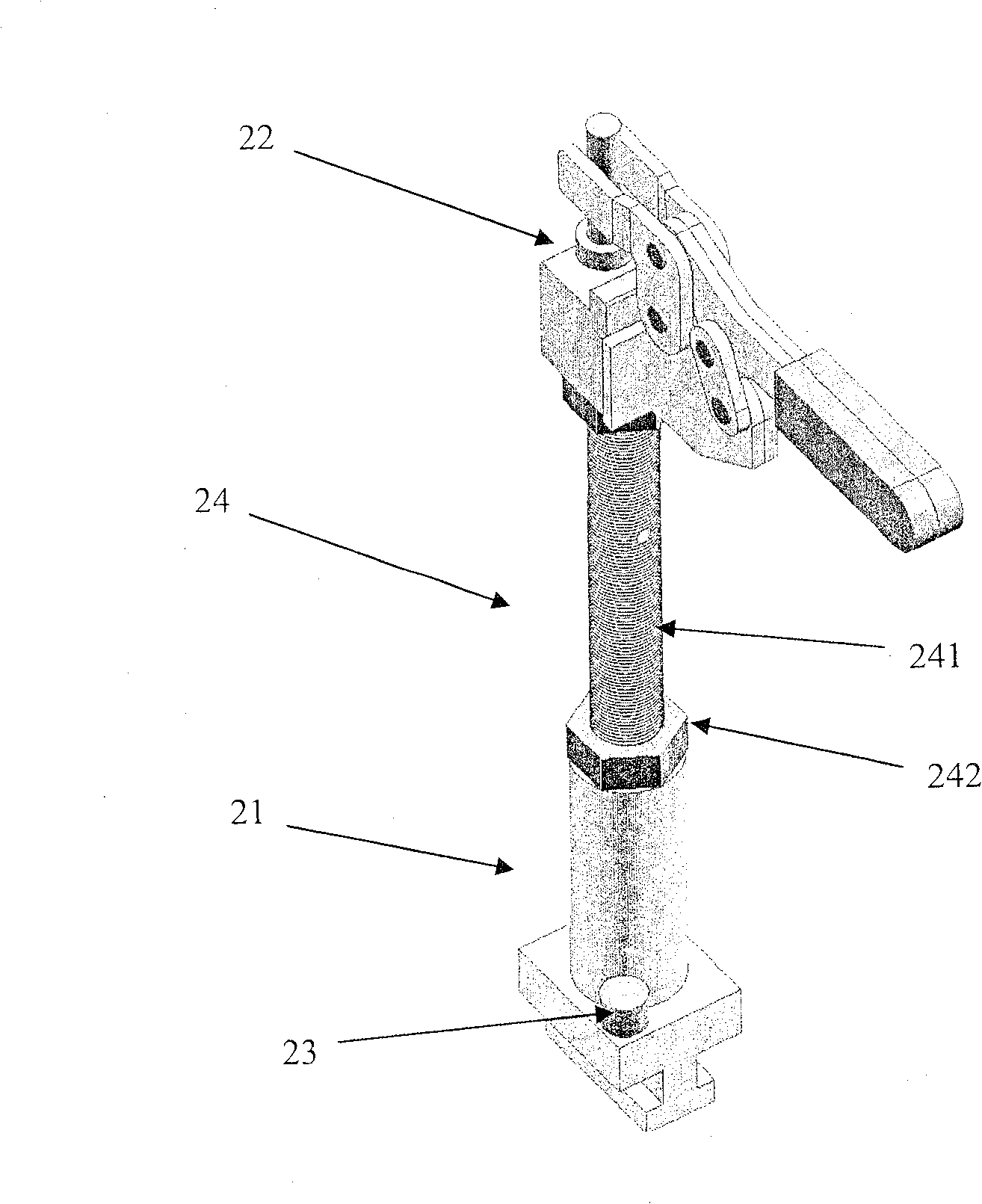

Laser cutting positioner of drawn component

InactiveCN100478113CSimple structureLow costWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLaser cutting

Owner:BYD CO LTD

Fixing device of spring hinge folder

A fixing device of a spring hinge folder comprises a folder body. An upper mounting hole and a lower mounting hole are formed in the folder body. Springs are arranged in the mounting holes respectively. The upper end of each spring is matched with a fixing hole of a fixing plate. The fixing device of the spring hinge folder is characterized in that two symmetrical clamping mechanisms used for fixing the springs are arranged on the fixing plate, each clamping mechanism comprises a first clamping hook, a clamping sheet and a second clamping hook, and the springs are wound around the first clamping hooks, the clamping sheets and the second clamping hooks in sequence. At the time of assembly, the upper ends of the upper group of springs and the lower group of springs penetrate through the fixing holes respectively; all the springs are wound around the first clamping hooks, the first clamping hooks clamp the springs, and then first frictional force is applied to the springs; the springs are wound around the clamping sheets, and then second frictional force is applied to the springs; finally, the springs are wound around the second clamping hooks, and then third frictional force is applied to the springs. The first clamping hooks, the clamping sheets and the second clamping hooks respectively clamp the springs, so that clamping and limiting are reliable, retraction of the springs is avoided, and it is guaranteed that all files are tightly overlapped.

Owner:李盛

Laser cutting positioner of drawn component

InactiveCN1958211ASimple structureLow costWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLaser cutting

Owner:BYD CO LTD

A linkage self-locking automobile wheel hub fixing device

ActiveCN107214537BNo looseningCompact structurePositioning apparatusMetal-working holdersSelf lockingScrew thread

Owner:ANHUI JIANGHUAI WHEEL CO LTD

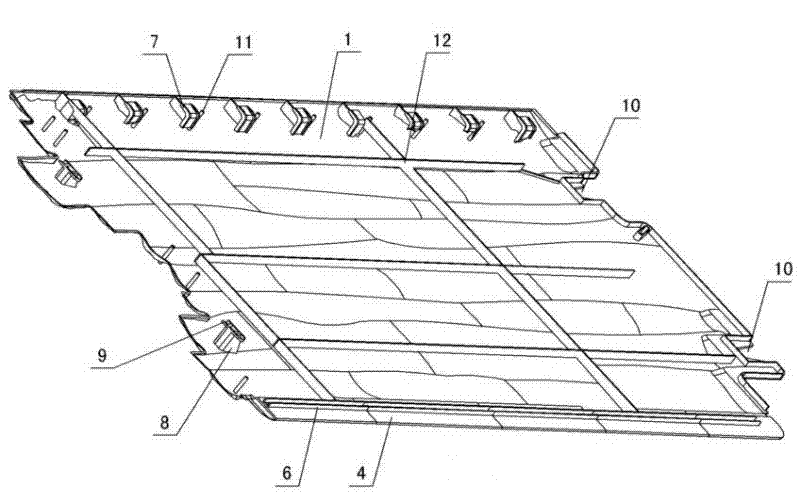

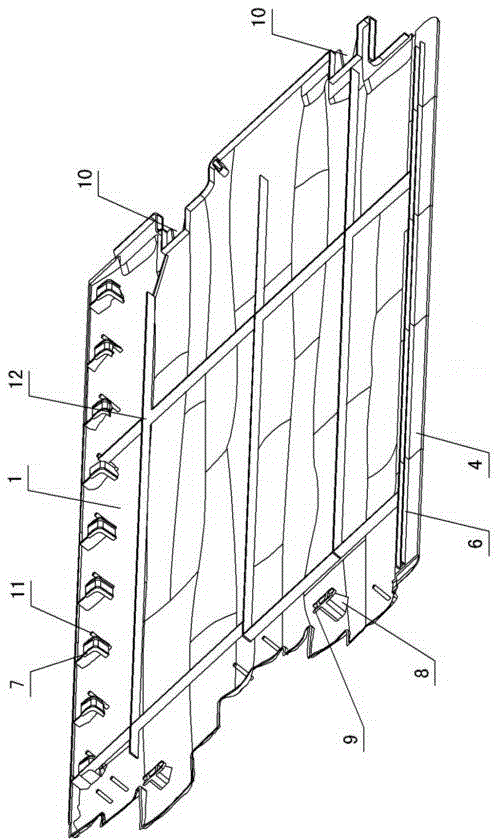

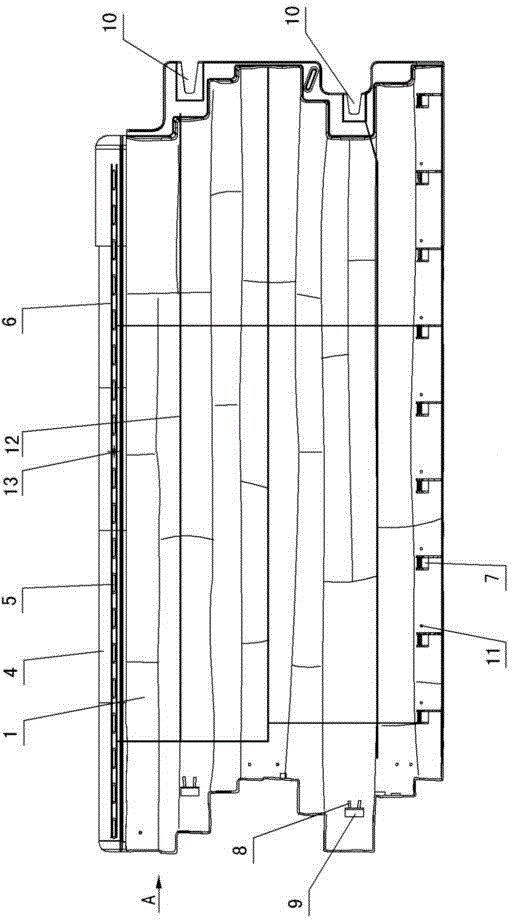

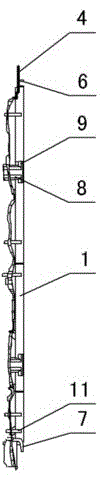

Clamping type quick connection device of reinforced plastic wallboard

The invention discloses a clamping type quick connection device of a reinforced plastic wallboard. The device comprises an injection molding wallboard; the outer surface of the wallboard is uniformly provided with brick-shaped or imitation marble bumps and grooves; a hanging piece is arranged on the edge of the wallboard; a support strip is arranged on the back of the hanging piece and is in contact with the wall; a fixed elongated slot is arranged in the hanging piece, and the hanging piece is fixed on the wall through a fastening piece; insertion hooks are arranged on the back of the lower edge of the wallboard; the insertion hook of the previous wallboard is matched with the hanging piece of the next wallboard; the device is characterized in that: a clamp seat is arranged on the back of the edge at one end of the wallboard; a clamp plate is arranged on the clamp seat; a bayonet is arranged on the edge at the other end of the wallboard; and the clamp plate of one wallboard is in inserting and clamping connection with the bayonet of another wallboard. In the scheme, since the clamp plate and the bayonet are in inserting and clamping connection, the mounting is convenient and reliable, the assembly speed is high, the working time is saved, and the labor cost is lowered.

Owner:和田通全球生态科技工程有限公司

Fastening type lamp mounting plate

InactiveCN105402693AEasy to disassembleEasy to fixLighting support devicesLight fasteningsKeelSurface plate

The invention discloses a fastening type lamp mounting plate. The fastening type lamp mounting plate comprises a lower clamping plate and an upper clamping plate, the two of which are arranged horizontally; a curved plate is connected between an inner edge of the lower clamping plate and an inner edge of the upper clamping plate; an opening of the curved plate is inward; a baffle plate is arranged at an outer edge of the upper clamping plate in a length direction; a lower edge of the baffle plate is fixedly connected with the outer edge of the upper clamping plate; a mounting strip is arranged on a lower surface of the lower clamping plate in the length direction; a clamping strip is arranged on a lower surface of the mounting strip in the length direction; the clamping strip is wider than the mounting strip; at least one elastic piece is arranged on an outer side surface of the baffle plate. According to the fastening type lamp mounting plate, the mounting plate is inserted into a lamp mounting frame by use of the mounting strip and the clamping strip and then fastened to a keel in a lamp mounting reserved hole; as the elastic piece is arranged on the panel lamp mounting plate, the elastic piece is deformed during clamping, such that a lamp can be clamped in the lamp reserved hole.

Owner:CHONGQING BEACON OPTOELECTRONICS TECH

Clamping type quick connection device of reinforced plastic wallboard

The invention discloses a clamping type quick connection device of a reinforced plastic wallboard. The device comprises an injection molding wallboard; the outer surface of the wallboard is uniformly provided with brick-shaped or imitation marble bumps and grooves; a hanging piece is arranged on the edge of the wallboard; a support strip is arranged on the back of the hanging piece and is in contact with the wall; a fixed elongated slot is arranged in the hanging piece, and the hanging piece is fixed on the wall through a fastening piece; insertion hooks are arranged on the back of the lower edge of the wallboard; the insertion hook of the previous wallboard is matched with the hanging piece of the next wallboard; the device is characterized in that: a clamp seat is arranged on the back of the edge at one end of the wallboard; a clamp plate is arranged on the clamp seat; a bayonet is arranged on the edge at the other end of the wallboard; and the clamp plate of one wallboard is in inserting and clamping connection with the bayonet of another wallboard. In the scheme, since the clamp plate and the bayonet are in inserting and clamping connection, the mounting is convenient and reliable, the assembly speed is high, the working time is saved, and the labor cost is lowered.

Owner:HETIANTONG GLOBAL ECOLOGICAL TECH ENG CO LTD

Underwater chain stopper

An underwater chain stopper comprises a chain stopper support, a roller and a switch blade frame, the switch blade frame is arranged in the middle of the chain stopper support, the roller is arranged on the rear side of the switch blade frame, and two switch blades are arranged on the front side of the switch blade frame. The roller is positioned in the middle of the chain stopper bracket, and is rotationally matched with the chain stopper bracket through a roller shaft; an anchor chain channel is arranged in the middle of the knife switch frame. The left side and the right side of the knife switch frame are each provided with a tensioning oil cylinder, cylinder bodies of the tensioning oil cylinders are fixedly connected with the chain stopper support, and piston rods of the tensioning oil cylinders are in transmission fit with the knife switch frame through knife switch frame connecting blocks. Two knife switch overturning oil cylinders are symmetrically arranged at the top of the knife switch frame, cylinder bodies of the knife switch overturning oil cylinders are fixedly connected with the knife switch frame, and piston rods of the knife switch overturning oil cylinders are in transmission fit with the knife switches on the corresponding sides of the knife switch overturning oil cylinders. According to the underwater chain stopper, the turnover oil cylinder automatically controls the switch blade to be opened and closed, operation is safer and more convenient, and underwater work can be well adapted.

Owner:WUHAN MARINE MACHINERY PLANT +1

Linkage device and DR shooting machine

ActiveCN109730705AEasy to disengageAdd depthPatient positioning for diagnosticsAgricultural engineeringEngineering

The invention belongs to the technical field of linkage equipment, and provides a linkage device and a DR shooting machine. The linkage device comprises a guide base, a mounting block, a linkage block, a linkage positioning block and a first elastic component; the linkage block is slidably arranged on the guide base in the vertical direction; the linkage positioning block is slidably arranged on the mounting block in the longitudinal direction and provided with a groove, and buffering slopes are arranged at the two sides of the groove; the first elastic component is arranged on the mounting block and used for providing longitudinal elastic force for the linkage positioning lock, the guide base is used for being connected with a first linkage part, and the mounting block is used for being connected with a second linkage part. According to the linkage device and the DR shooting machine, the problem in the prior art that a linkage mechanism cannot be connected or is not easily separated due to excessive fastness is solved.

Owner:河北天地智慧医疗设备股份有限公司

Vertical high-precision post-processing machine for plastic pipes

ActiveCN106273204BClamping and reliableGuaranteed service lifeMetal working apparatusSlide plateEngineering

A vertical high-precision post processor for a plastic pipe is characterized by comprising a rack; an upper fixing plate and a lower fixing plate are arranged on the rack, a bearing bush is arranged in the upper fixing plate, bearings are arranged in the bearing bush, the inner walls of the bearings are connected with a copper bush shaft, a tool rest supporting plate is arranged outside the upper end of the copper bush shaft, tool rest supporting rods are arranged on the tool rest supporting plate, a tool rest ring is arranged on the tool rest supporting rods, and blades are arranged on the tool rest ring; bearing locking nuts, a driven gear and gear locking nuts are arranged on the part, located at the lower ends of the bearings, of the outer wall of the copper bush shaft in sequence; a large motor is arranged in the rack and connected with a driving gear, the driving gear is meshed with the driven gear, guide columns are arranged between the upper fixing plate and the lower fixing plate, guide sleeves are arranged on the guide columns, a sliding plate is arranged on the guide sleeves, a vertical adjusting block is arranged on the sliding plate, communicated screw holes are formed in the vertical adjusting block and the sliding plate, a screw is arranged in the screw holes, a small motor is arranged below the lower fixing plate, an output shaft of the small motor is connected with the screw, a chuck is arranged on the vertical adjusting block, clamping grooves are formed in the chuck, clamping bases are arranged in the clamping grooves, and the clamping bases are matched with the inner wall of the plastic pipe.

Owner:YONGGAO CO LTD

A linkage device and dr film machine

ActiveCN109730705BEasy to disengageAdd depthPatient positioning for diagnosticsEngineeringMechanical engineering

The invention belongs to the technical field of linkage equipment, and proposes a linkage device and a DR film machine, comprising a guide seat and a mounting block; a linkage block, the linkage block is slidably arranged on the guide seat along a vertical direction; The longitudinal sliding is arranged on the mounting block, the linkage positioning block is provided with a groove, and the two sides of the groove are provided with buffer inclined surfaces; elastic element one, the elastic element one is arranged on the mounting block, and the elastic element one is used to provide the linkage positioning block. The elastic force along the longitudinal direction, the guide seat is used to connect with the first linkage, and the installation block is used to connect with the second linkage. The above technical solution solves the problem that the linkage mechanism in the prior art cannot be connected or is too firm and difficult to separate.

Owner:河北天地智慧医疗设备股份有限公司

Rotary support clamping sealing tank and processing method

A rotary supporting clamping sealing tank comprises a tank body and a tank cover, the tank cover comprises a cover plate, a knob is arranged in the cover plate, a knob clamping ring is arranged on the lower portion of the knob, four evenly-distributed supporting clamping blocks with slopes are arranged on the outer wall of the knob clamping ring, a supporting frame is arranged on the bottom face of the cover plate, the supporting frame comprises four sides corresponding to the opening portion of the tank body and an inner ring corresponding to the knob clamping ring, the inner ring and the four sides are broken from the middles and are respectively divided into four equally-divided parts, the inner ring with the four equally-divided parts and the four sides are connected through a support, the four sides with the equally-divided parts are connected through opening elastic rings, the supporting clamping blocks with the slopes are in contact with the inner ring, the periphery of the supporting frame and the periphery of the cover plate are coated with sealing cushion covers, and the sealing cushion covers are matched with the opening of the tank body. The supporting and clamping modes are adopted by the tank, operation is easy, the cover can be conveniently opened or closed, and after the tank cover and the tank body are buckled, the sealing effect is good.

Owner:台州市富龙塑胶有限公司

Novel chuck jaw for disc-type workpiece

The invention relates to a new type of chuck claw for a roulette workpiece, which is composed of a claw and a tooth block of the claw. The claw is provided with a claw positioning groove, a V-shaped groove, an inner hole supporting claw and a bolt through hole. The claw tooth block is provided with a claw positioning block and a threaded hole, and the claw and the claw tooth block are positioned by the claw positioning block and the claw positioning groove, and are connected together with bolts. The invention has the advantages of high strength, reliable clamping, low manufacturing cost and long service life, and has good clamping effect on processing roulette workpieces on the lathe.

Owner:天津凯泰利科技有限公司

Multi-rod piping clip

InactiveCN101845803BReduce riskAddress or mitigate the hazardMarine site engineeringWater leakageLocking mechanism

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com