Vertical high-precision post processor for plastic pipe

A plastic pipe, high-precision technology, applied in the direction of metal processing, etc., can solve the problems of affecting production efficiency, high manufacturing cost, large volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

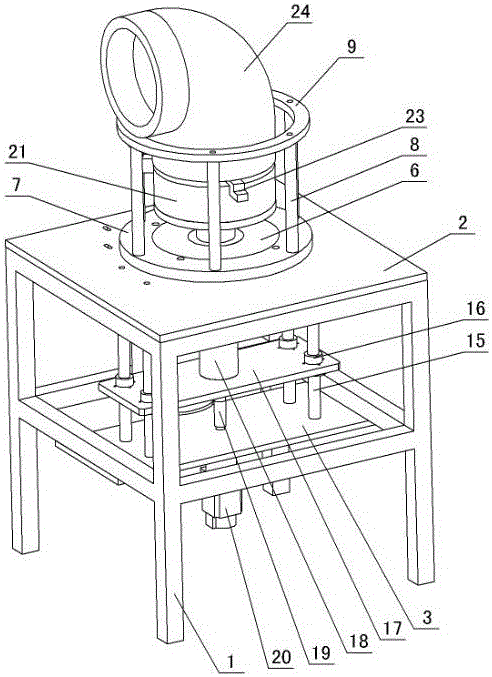

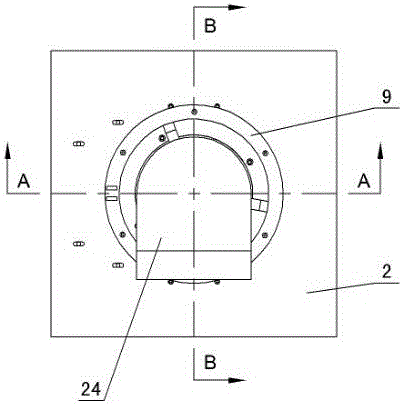

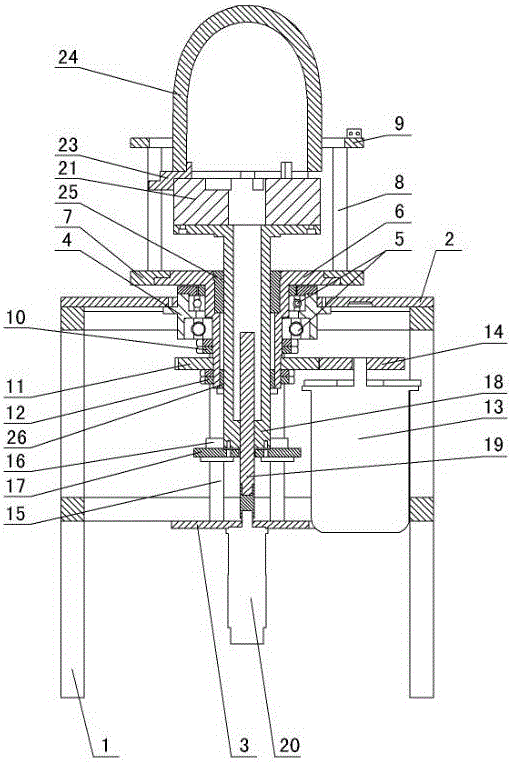

[0012] The invention relates to a vertical high-precision post-processing machine for plastic pipes, such as figure 1 — Figure 5 As shown, it is characterized in that it includes a frame 1, an upper fixing plate 2 and a lower fixing plate 3 are arranged on the frame, a bearing sleeve 4 is arranged in the upper fixing plate, a bearing 5 is arranged in the bearing sleeve, and the inner wall of the bearing is connected to a copper sleeve shaft 6 , the upper end of the copper sleeve shaft is provided with a knife rest support plate 7, a knife rest support rod 8 is arranged on the knife rest support plate, a knife rest ring 9 is arranged on the knife rest support rod, a blade is arranged on the knife rest ring, and a blade is set on the copper sleeve shaft 6 outer walls A bearing lock nut 10, a driven gear 11 and a gear lock nut 12 are arranged in sequence at the lower end of the bearing 5, and a large motor 13 is set in the frame 1, and the output shaft of the large motor is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com