Underwater chain stopper

A technology for chain stoppers and anchor chains, which is applied to ships and other directions, and can solve the problems of not being able to meet the needs of semi-submersible ships, and not being able to adapt to ships' water and underwater chain stops at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

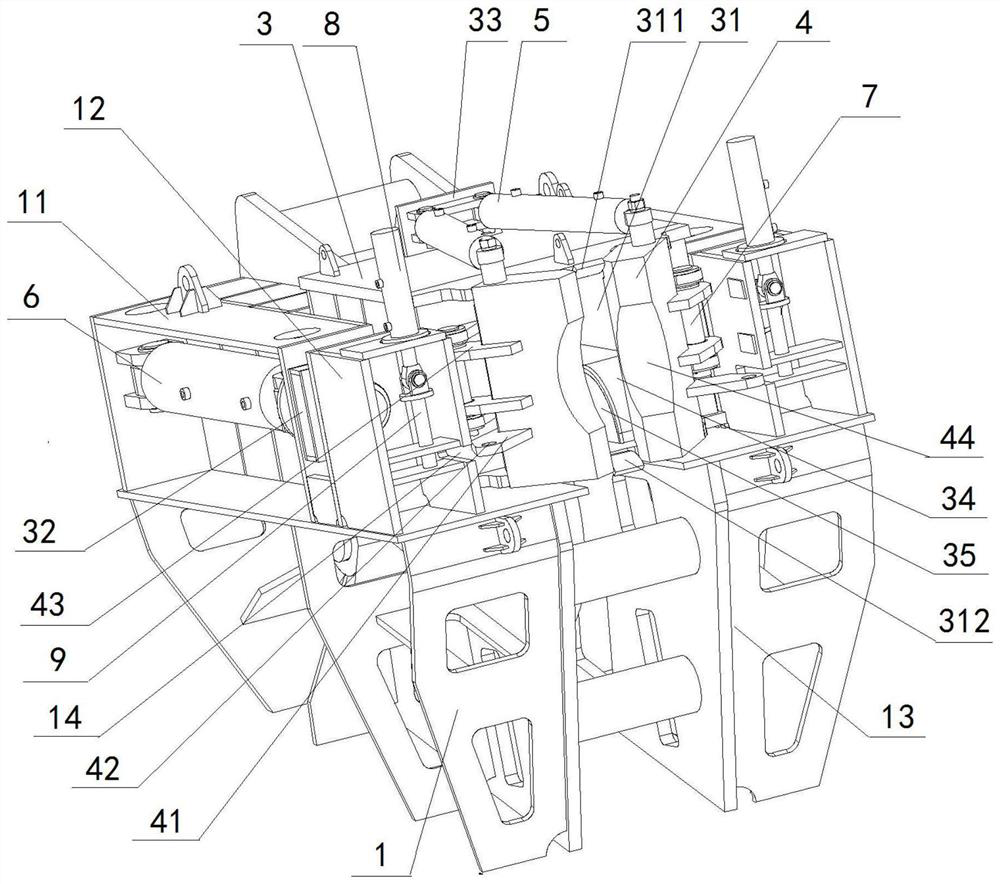

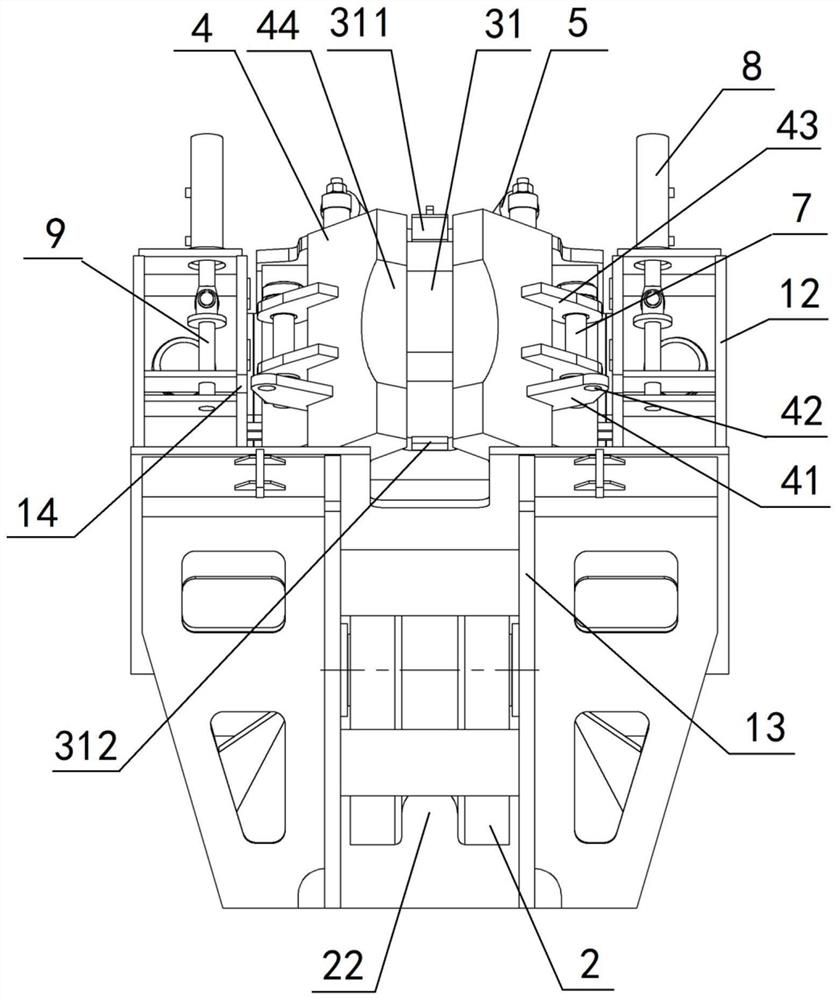

[0092] The underwater chain stopper includes a chain stopper bracket 1, a roller 2 and a brake knife holder 3, the roller 2 and the brake knife holder 3 are all arranged in the middle of the chain stopper bracket 1, and the roller 2 is located on the brake knife holder 3, the front side of the switch blade frame 3 is provided with two opposite switch blades 4, the switch blades 4 rotate with the switch blade frame 3 through the rotating pin 7, and the roller 2 connects with the chain stop bracket through the roller shaft 21 1 rotating fit; the middle part of the knife holder 3 is provided with an anchor chain channel 31; the left and right sides of the knife holder 3 are symmetrically provided with two tensioning oil cylinders 6, and the cylinder body of the tensioning oil cylinder 6 and The chain puller support 1 is fixedly connected, and the piston rod of the tensioning cylinder 6 is in transmission cooperation with the knife holder 3 through the knife holder connecting block...

Embodiment 2

[0094] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

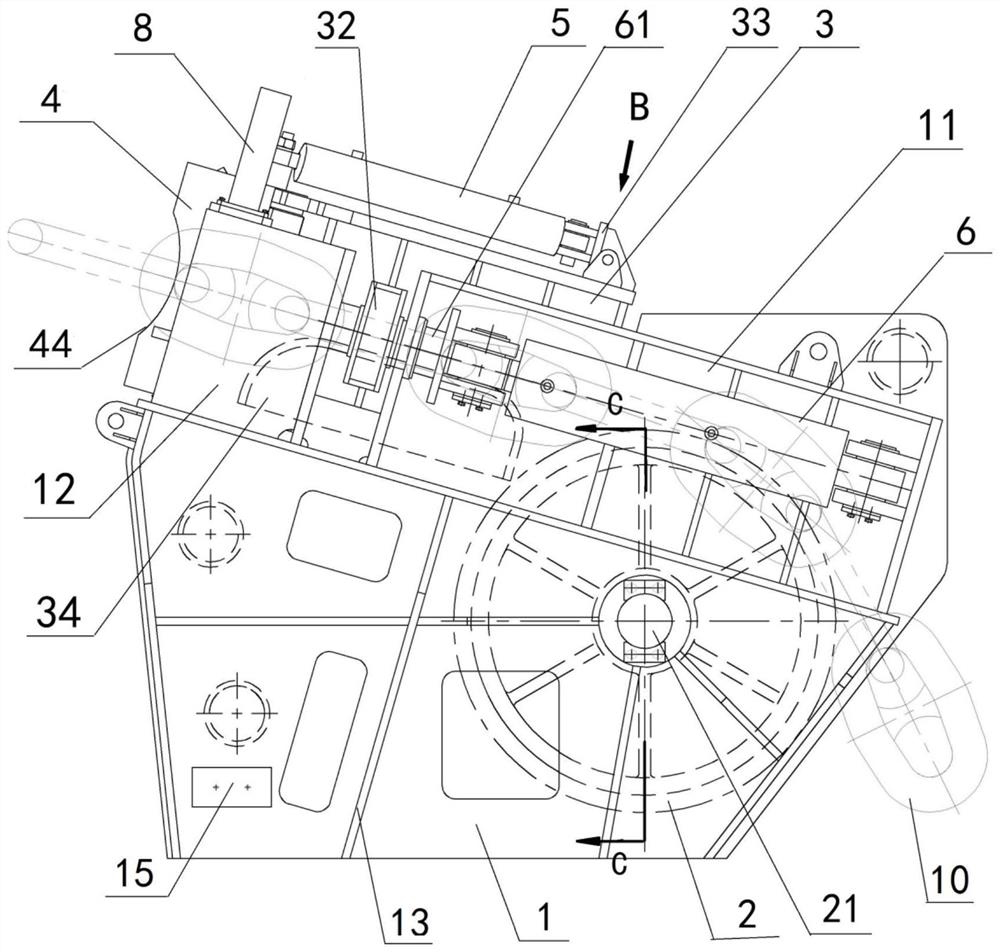

[0095] The chain stop bracket 1 includes a bottom bracket 13, two tension cylinder brackets 11 and two latch mechanisms 12, and the two tension cylinder brackets 11 are symmetrically fixed on the left and right sides of the top of the bottom bracket 13, The two latch mechanisms 12 are symmetrically fixed on the left and right sides of the top of the bottom bracket 13; the latch mechanism 12 is located on the front side of the blade holder connecting block 32, and the tension cylinder bracket 11 is located on the blade holder connecting block. 32, the tension cylinder bracket 11 is fixedly provided with a tension cylinder 6, the piston rod of the tension cylinder 6 is fixedly connected with one end of the push pin 61, and the other end of the push pin 61 is sequentially connected with The outer wall of the oil cylinder bracket 11 and the outer wall of the latch mechanism 12 are slidably matched,...

Embodiment 3

[0097] Embodiment 3 is basically the same as Embodiment 2, and its difference is:

[0098] The push pin 61 includes a first cylinder 611 and a second cylinder 612 integrally arranged, the first cylinder 611 and the second cylinder 612 are arranged coaxially, and the diameter of the first cylinder 611 is larger than that of the second cylinder The diameter of the body 612; one end of the first cylinder 611 is fixedly connected with the tensioning oil cylinder 6, the other end of the first cylinder 611 is fixedly connected with one end of the second cylinder 612, and the other end of the second cylinder 612 One end passes through the knife holder connecting block 32 and the spacer 613 in turn and is fixedly connected with the shaft end retaining ring 614; 32 through the spacer 613 and the shaft end retaining ring 614 limit fit; the first column 611 slides with the outer wall of the tension cylinder bracket 11 through the second water lubricated bearing 62, and the spacer 613 pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com