Composite molding process for electric vehicle chassis suspension assembly

A composite molding and electric vehicle technology, applied in vehicle components, transportation and packaging, etc., can solve problems affecting passenger comfort, suspension deformation, poor strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

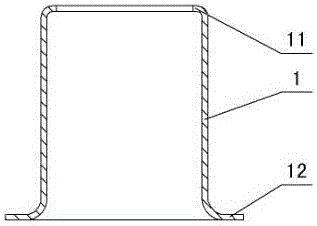

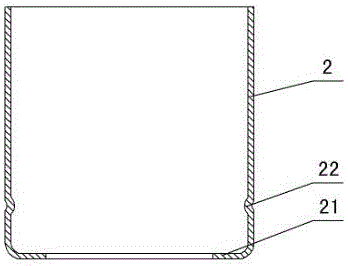

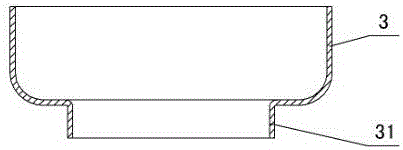

[0029] The invention relates to a composite molding process of an electric vehicle chassis suspension assembly, such as figure 1 — Figure 9 As shown, it is characterized in that: comprising the following steps:

[0030] ⑴ Stretch forming: using a stretching die, take the iron sheet, and pass the iron sheet through the stretching die to make the fixed ring 1, the upper sealing sleeve 2, the fixing box 3, the fixing seat 5, the lower sealing sleeve 6, and the upper sealing ring There are inner flanging 11 of the fixing ring and outer flanging 12 of the fixing ring, the inner flanging 21 of the upper sealing sleeve is formed on the upper sealing sleeve, the inner stretching 31 of the fixing box is formed on the fixing box, and the inner pulling of the fixing seat is formed on the fixing seat Stretching 51, vertical plane 52 and circular arc surface 53, the inner flange 61 of lower sealing sleeve is shaped on the lower sealing sleeve;

[0031] (2) Rolling the upper sealing slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com