Wiring terminal convenient to disassemble and assemble

A technology that facilitates disassembly and assembly of terminal blocks. It is applied to the parts, connections, and contact parts of the connection device. It can solve the problems of reducing the stability of the terminal blocks and not fixing the clamping parts very firmly, so as to save assembly time and structure. Simple, secure and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

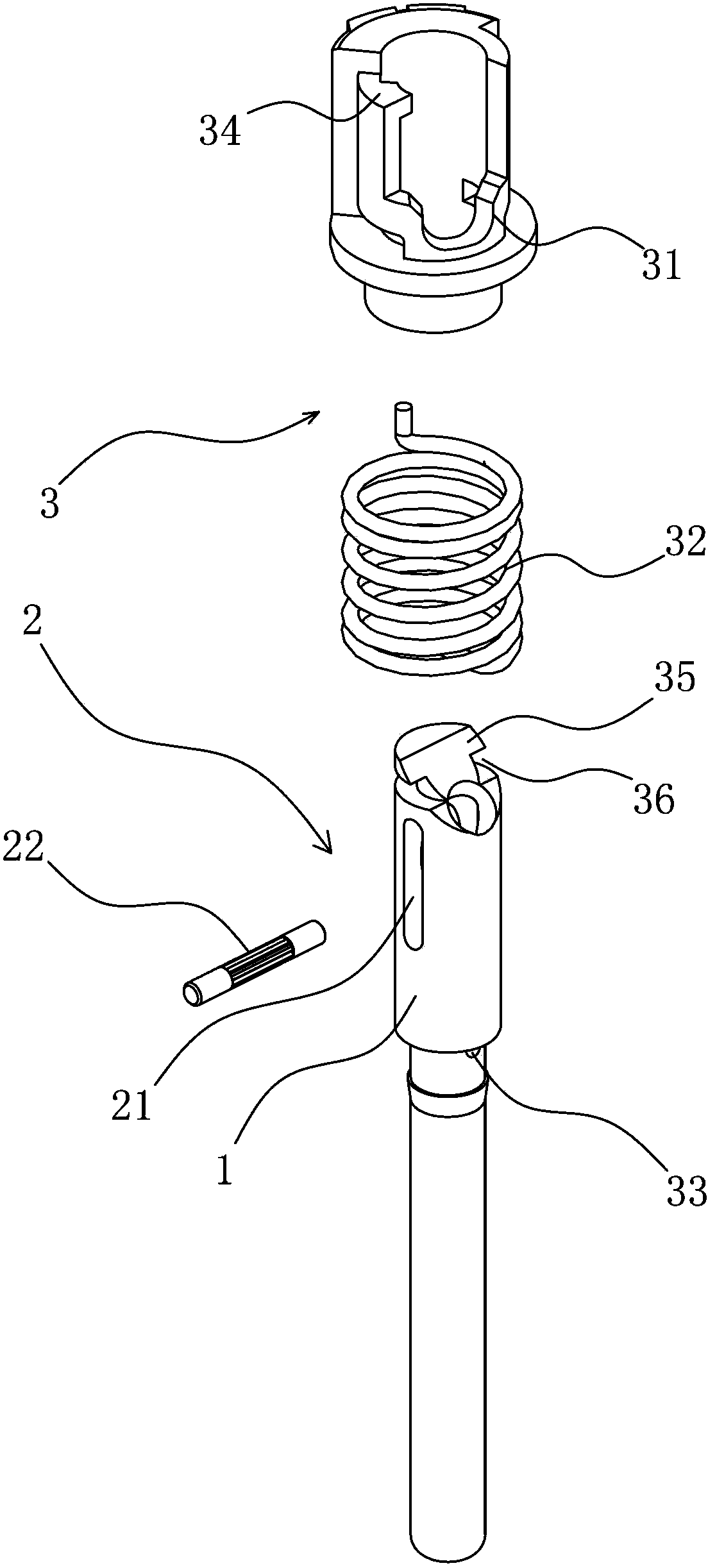

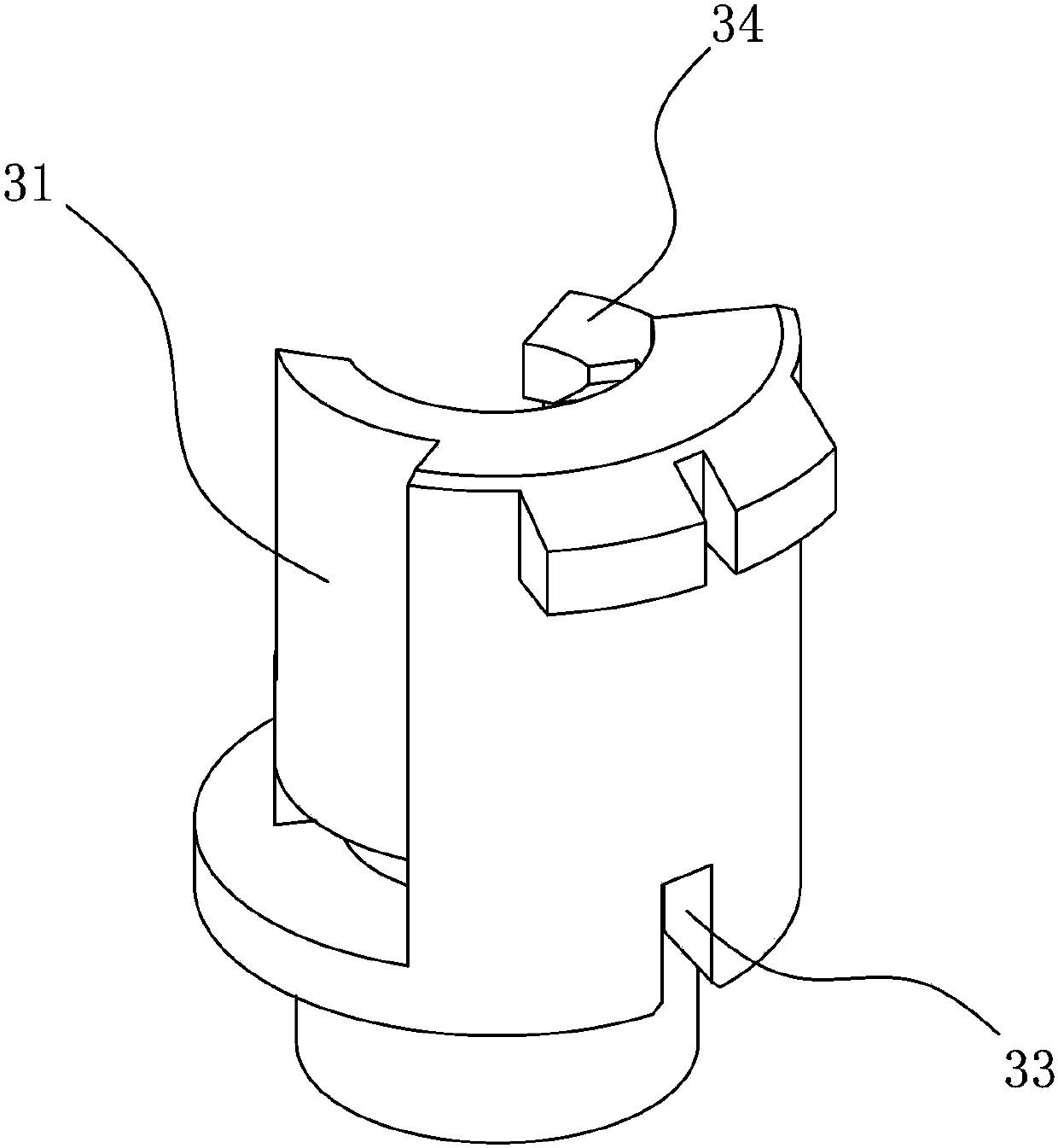

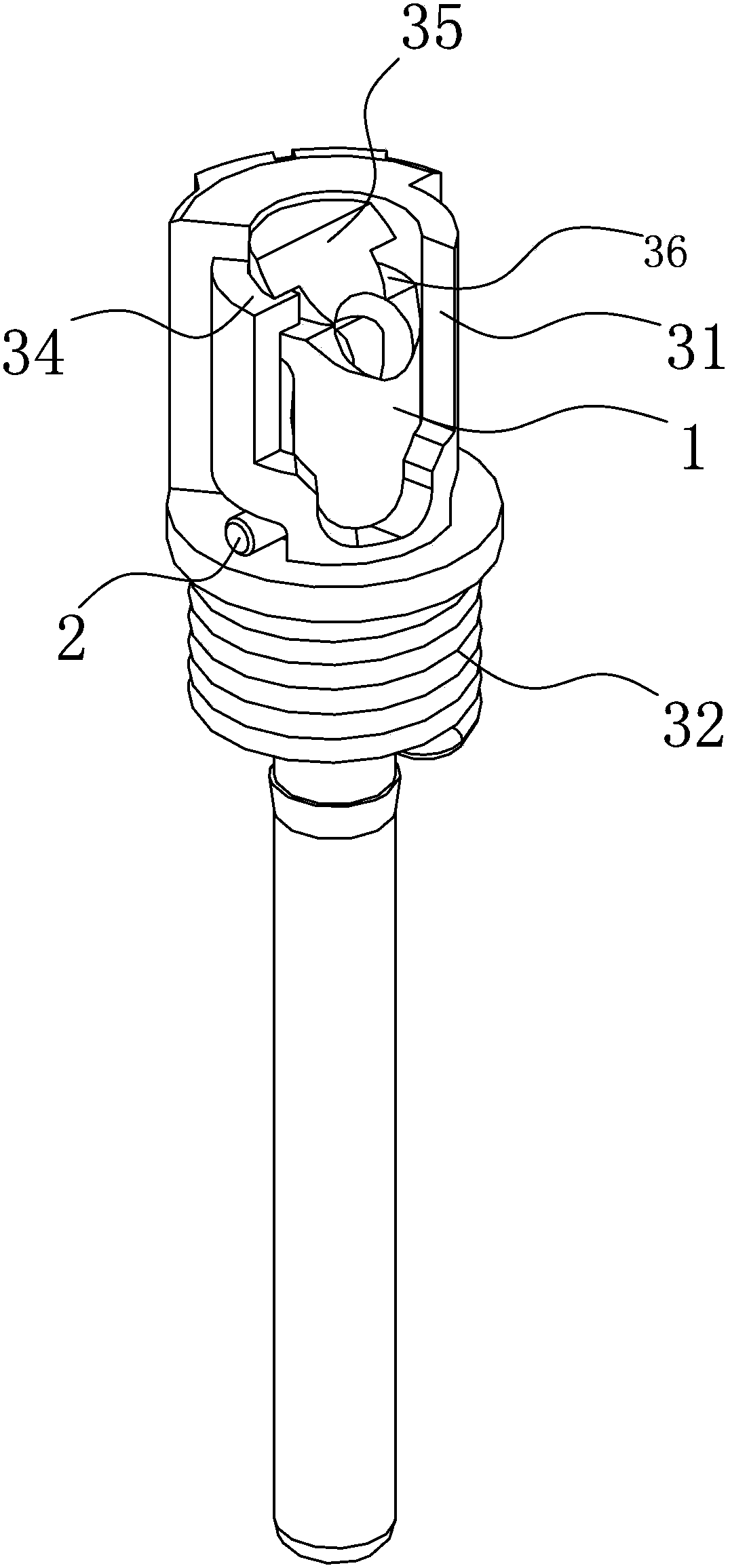

[0042] Such as Figure 1 to Figure 8 As shown, according to an embodiment of a convenient disassembly and assembly terminal provided by the present invention, it includes a terminal post 1, and a clamping assembly 2 for clamping a wire is installed on the terminal post 1, and the clamping assembly 2 includes a set The chute 21 on the terminal 1 and the crimping shaft 22 sliding in the chute 21, the chute 21 is arranged axially along the terminal 1, and also includes a locking assembly 2 The locking assembly 3 is used to control the crimping shaft 22 by rotating the locking assembly 3 to fix the wire in the terminal 1, and the terminal controls the sliding clamp of the crimping shaft 1 in the chute 21 by rotating the locking assembly 3 Locking component 3 while tightening or loosening the wire can realize the fixation of clamping component 2, making it more convenient, fast and efficient to install, saving assembly time; clamping the wire is more firm and reliable; without the ...

Embodiment 2

[0045] Such as Figure 9 to Figure 16 As shown, according to an embodiment of a convenient disassembly and assembly terminal provided by the present invention, it includes a terminal post 1, and a clamping assembly 2 for clamping a wire is installed on the terminal post 1, and the clamping assembly 2 includes a set The chute 21 on the terminal post 1 and the crimping shaft 22 sliding in the chute 21 also include a locking assembly 3 for locking the clamping assembly 2, and the locking assembly 3 is controlled by rotating the locking assembly 3. The crimping shaft 22 fixes the wire in the terminal 1, and the terminal controls the sliding of the crimping shaft 1 in the chute 21 to clamp or loosen the wire by rotating the locking assembly 3. At the same time, the locking assembly 3 can realize the clamping The fixing of the component 2 makes the installation more convenient, fast and efficient, and saves assembly time; the clamping of the wires is more firm and reliable; the wire...

Embodiment 3

[0048] Such as Figure 17 to Figure 24 As shown, according to an embodiment of a convenient disassembly and assembly terminal provided by the present invention, it includes a terminal post 1, and a clamping assembly 2 for clamping a wire is installed on the terminal post 1, and the clamping assembly 2 includes a set The chute 21 on the terminal 1 and the crimping shaft 22 sliding in the chute 21 also include a locking assembly 3 for locking the clamping assembly 2, and the crimping assembly is controlled by rotating the locking assembly. The wire spool 22 fixes the wire in the terminal 1, and the terminal controls the clamping assembly 2 by rotating the locking assembly 3 to slide and clamp or loosen the wire in the chute 21. Fixing makes installation more convenient, fast and efficient, saving assembly time; the clamping of wires is more firm and reliable; wires can be installed without tools.

[0049] see Figure 7 to Figure 24 According to the convenient disassembly termi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com