Clamping antiskid type transparent tear ejector tank

A sprayer and transparent technology, which is applied in the direction of liquid spray guns, weapon types, weapons without explosives, etc., can solve the problems of unreliable clamping, lower production efficiency, and many processing steps, so as to reduce manufacturing costs and improve production efficiency , the effect of fewer processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

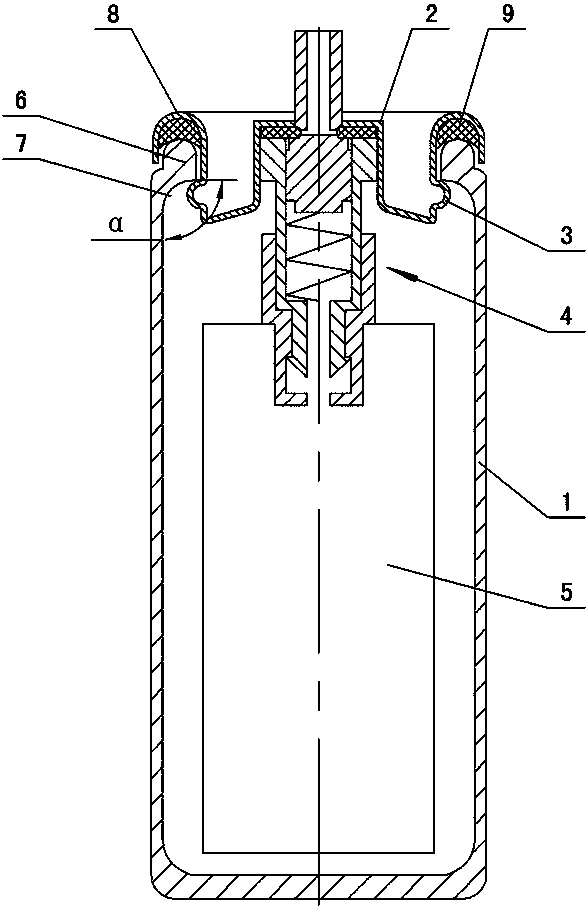

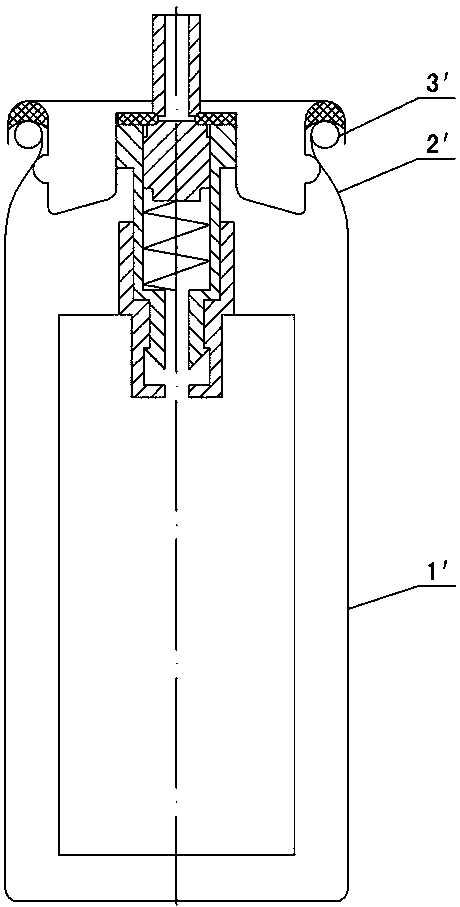

[0009] The invention relates to a clamping non-slip transparent tear gas injector tank, such as figure 1 As shown, the tank body 1 including the tear gas injector is equipped with compressed air, and a tank cover 2 is arranged on the upper mouth of the tank body. The bottom is connected to the bag body 5, and the tear gas liquid is housed in the bag body. It is characterized in that: the upper part of the transparent tank made of PC plastic has an upper neck 6, and a tank cover 2 is installed in the upper neck, and the inner wall of the upper neck and the tank body 1 The inner walls are transitioned through an arc-shaped groove 7, and the arc-shaped groove matches the undercut 3 of the tank cover. The angle α between the vertical inner wall of the tank body 1 and the lower part of the upper neck 6 is 70°-90°. Use transparent PC plastic (polycarbonate) to inject into a tube blank in an injection molding machine, and then put the tube blank in a blow molding machine and blow mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com