Negative pressure aspirator

The technology of negative pressure suction device and negative pressure generator is applied in the direction of suction container, suction device, hypodermic injection device, etc. It can solve the problems of limited capacity of negative pressure suction device, pollution of operating table, liquid backflow and other problems, and achieve simple insertion The effect of connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

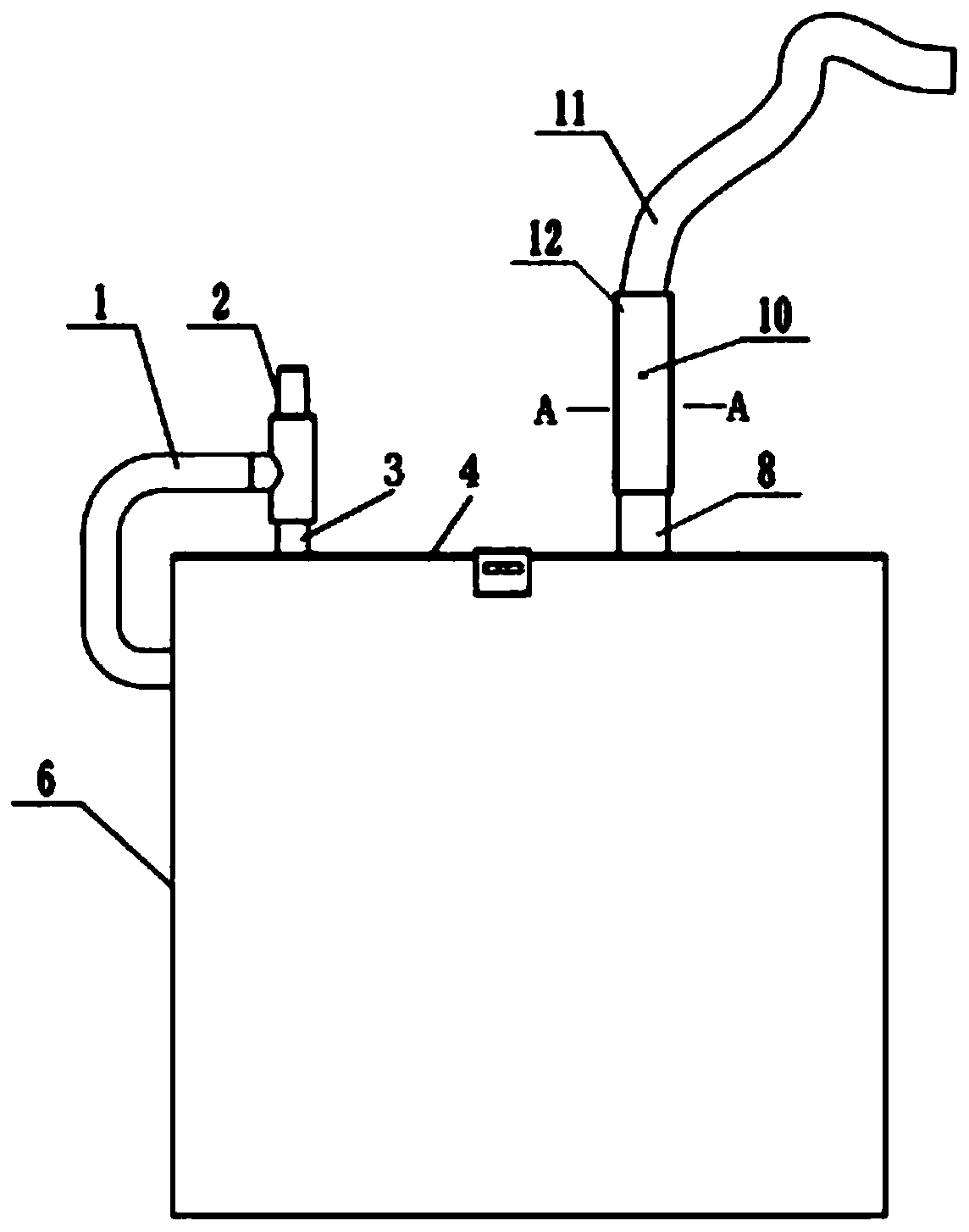

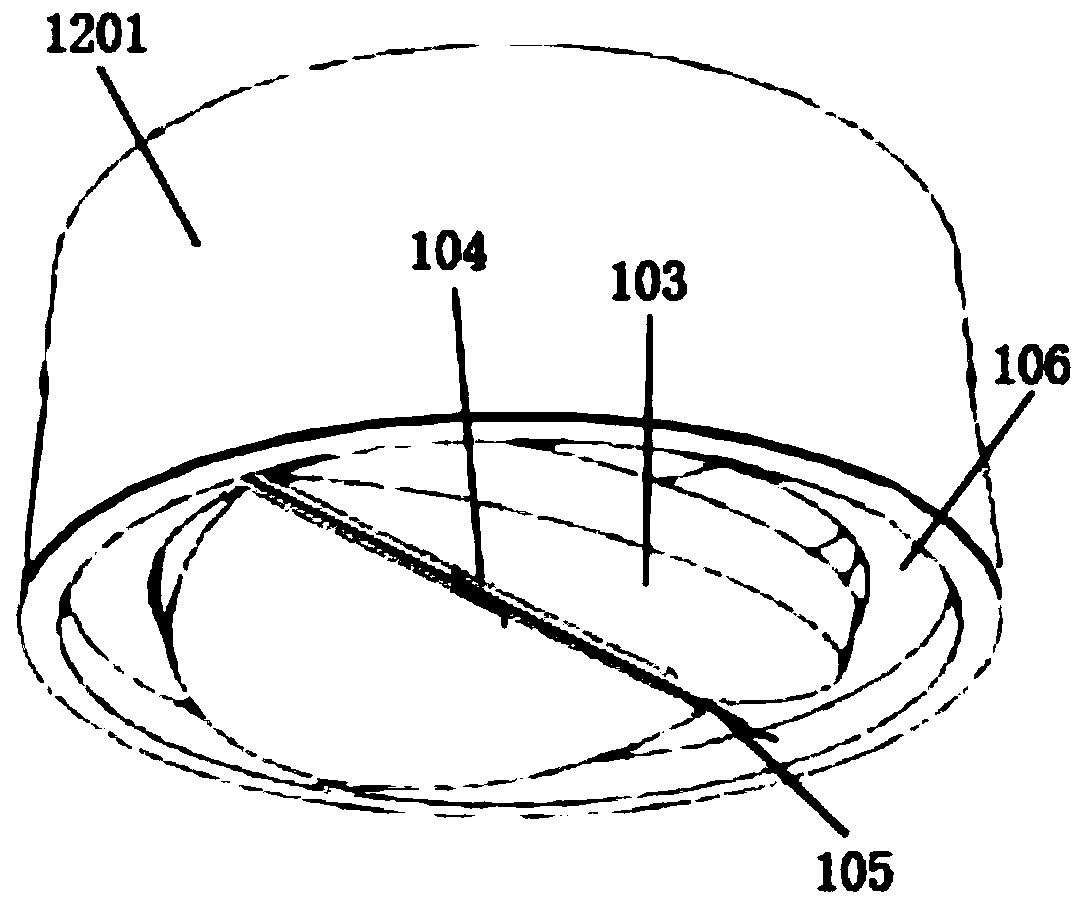

[0031] see Figure 1 to Figure 2 , a negative pressure suction device provided by the present invention includes an anti-reverse valve 12 and a liquid collection bottle 6 . The liquid collecting bottle 6 is made of transparent plastic material, the connecting pipe 1 and the liquid collecting bottle 6 are plugged in, the other end of the connecting pipe 1 is glued to the connecting pipe 2 of the negative pressure generator, and the lower end of the connecting pipe 2 of the negative pressure generator is The negative pressure tube 3 is sealed and connected, and the negative pressure tube 3 and the upper cover 4 of the liquid collection bottle are integrated. A connection buckle 8 is also glued on the liquid collection bottle 6 . The upper end of the anti-reverse valve 12 is provided with a suction pipe 11 , and the lower end of the anti-reverse valve 12 is connected with the liquid collection bottle 6 through the connection buckle 8 . A backstop 10 is provided inside the anti-...

Embodiment 2

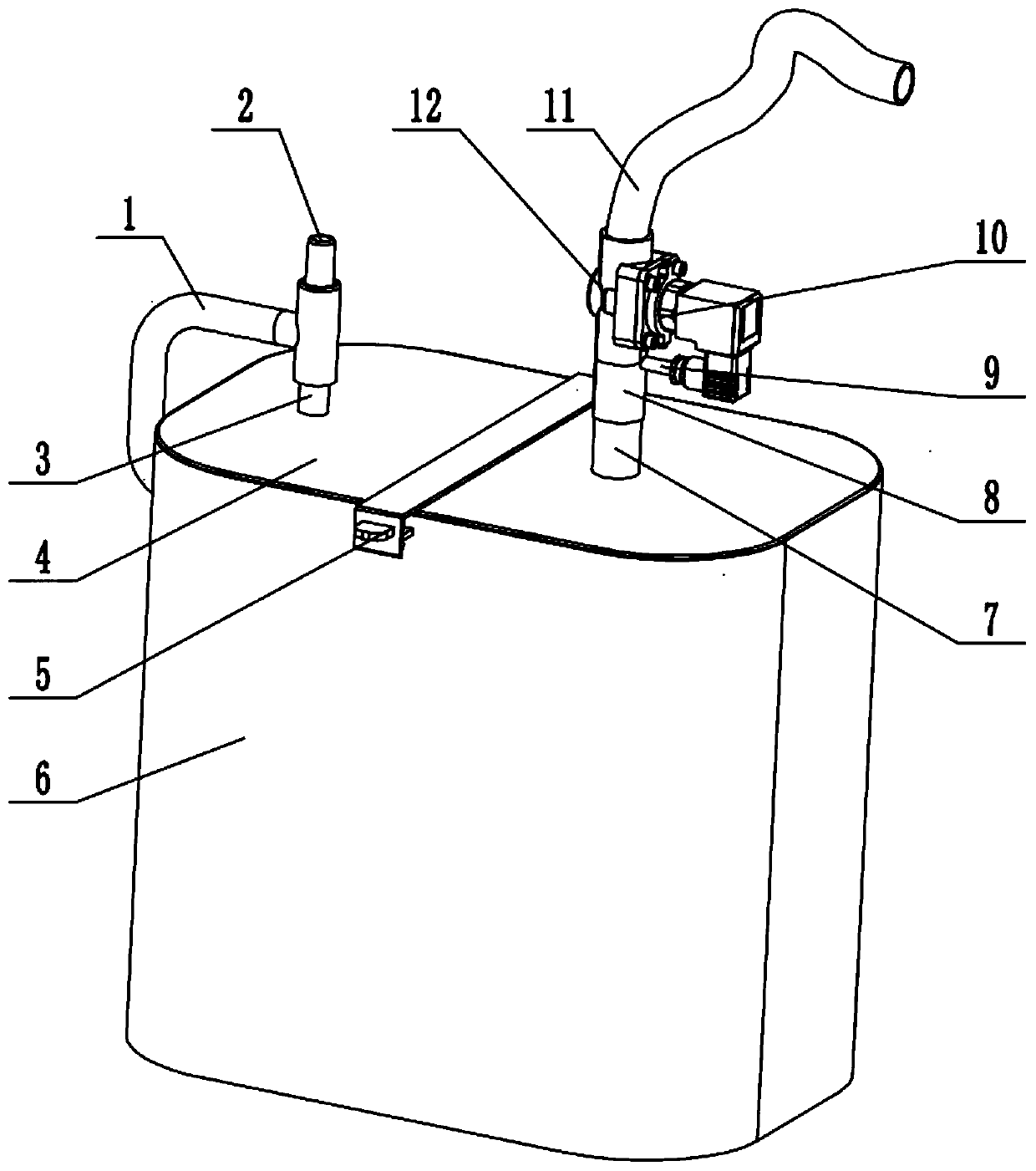

[0034] see Figure 3-Figure 12, is a kind of negative pressure suction device that the present invention adds several components on the basis of embodiment 1, comprises anti-return valve 12 and liquid collection bottle 6, and the upper end of anti-return valve 12 is provided with suction tube 11 , the inside of the anti-reverse valve 12 is provided with a checker 10, the bottom of the checker 10 is provided with a third piston 13, the left side of the third piston 13 is provided with a spring, and the left side of the spring is provided with an air pressure valve 14, the second The bottom of the three pistons 13 is provided with a locking device 9, the locking device 9 includes a first piston 91 and a locking rod 92, the left side of the first piston 91 is provided with a locking rod 92; the bottom of the locking rod 92 is provided with a connecting card Buckle 8, the left side of the connection buckle 8 is provided with a liquid inlet pipe 7, and the bottom of the liquid inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com