Automatized shaft mouth operation clamp for petroleum well workover

A technology for workover and oil, applied in the field of automatic wellhead operation devices, can solve the problems of high labor intensity, low operation efficiency, environmental pollution, etc., and achieve the effects of compact structure, improved work efficiency, and improved reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing:

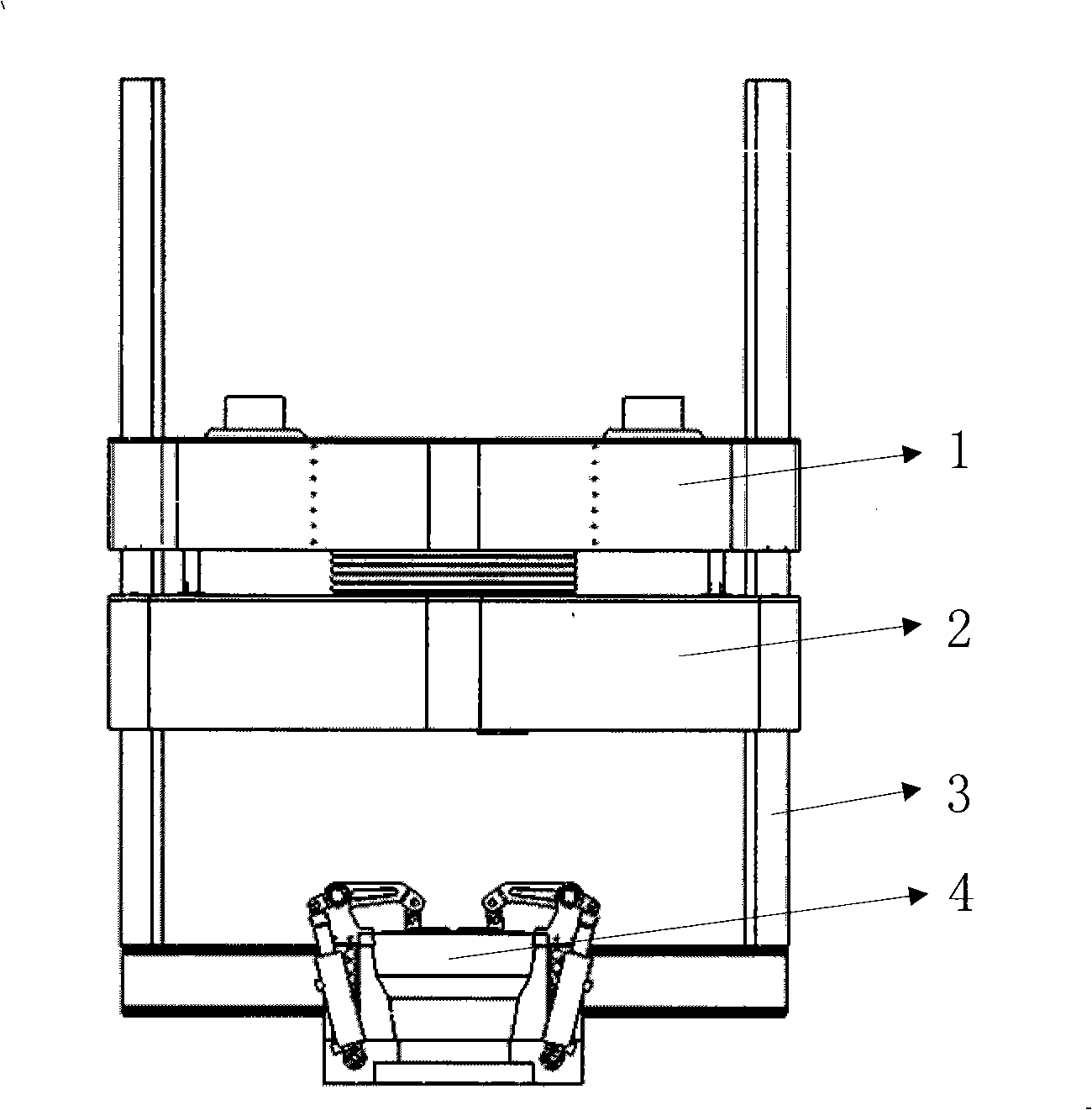

[0044] Such as figure 1 As shown, this kind of automatic wellhead tongs for oil well workover consists of main tongs 1, back tongs 2, a group of vertical guide rails 3 with embedded rack 56, and slips 4. These components and the connection relationship between these components are described in detail below:

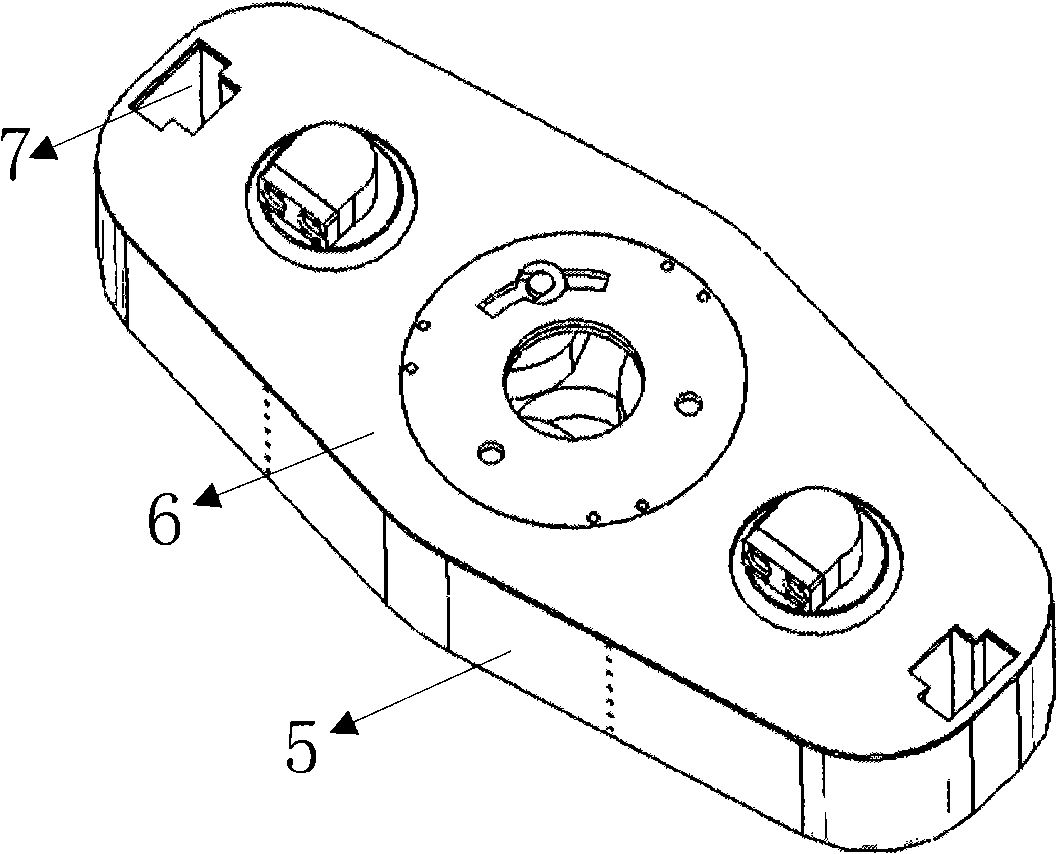

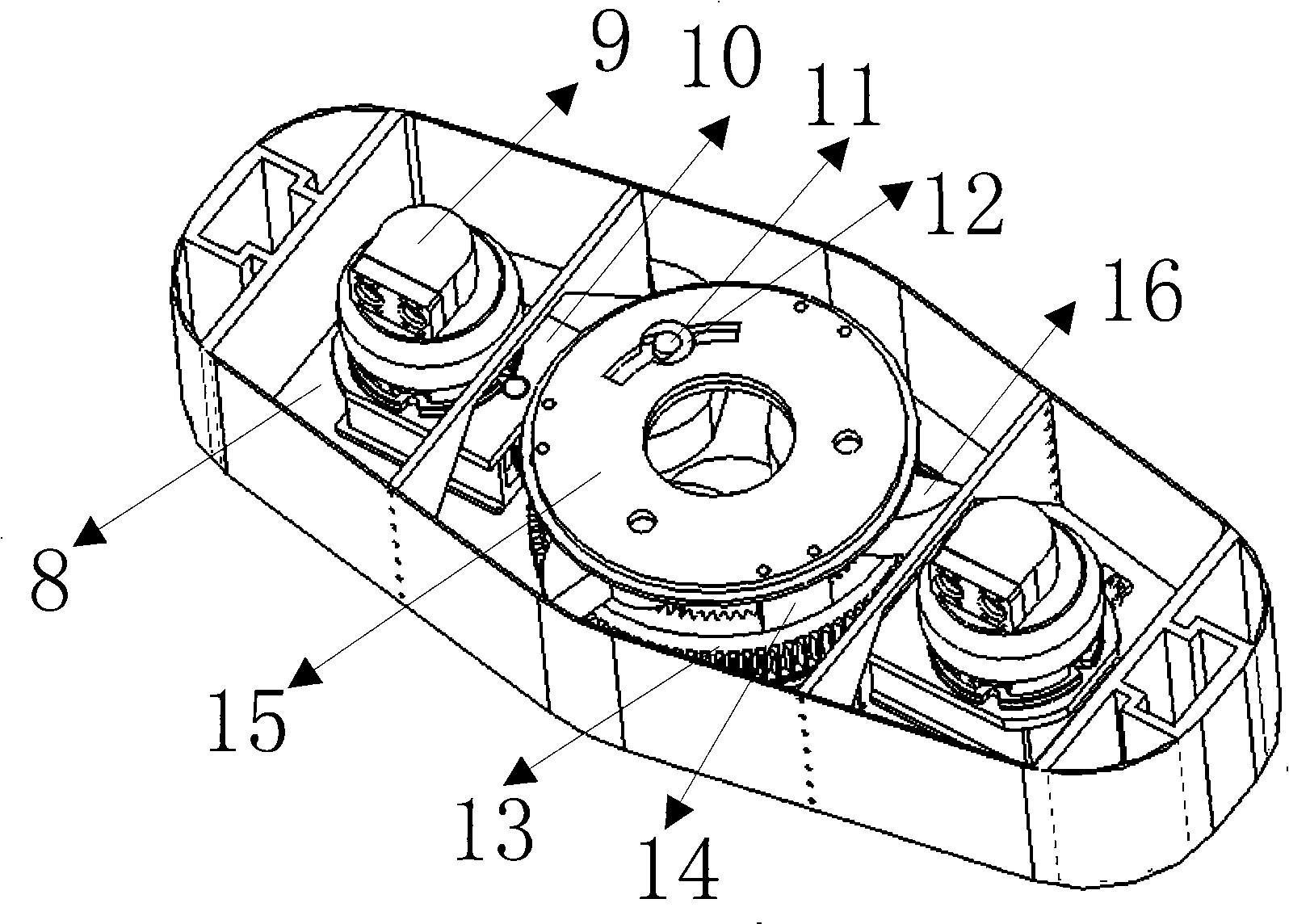

[0045] Such as figure 2 As shown, the exterior of the main tongs 1 is a shell structure, and the shell is composed of the main tongs upper cover plate 6, the main tongs side wall plate 5 and the main tongs bottom plate 8 after connection, and the realization of the connection can be completed by bolts. Wherein the center of the upper cover plate 6 of the main tongs and the bottom plate of the main tongs 8 is provided with jaws, and both sides are symmetrically provided with guide rail grooves 7 of the main tongs. Four basic structures that realize the function of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com